Clad copper foil printed circuit board laminating plate of radiator

A technology for printed circuit boards and heat sinks, applied to printed circuit parts, circuits, electrical components, etc., can solve problems such as poor heat dissipation, low heat transfer efficiency, and large thermal resistance of the insulating layer, achieving poor heat dissipation, Large thermal resistance and low heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through the description of specific embodiments with reference to the accompanying drawings.

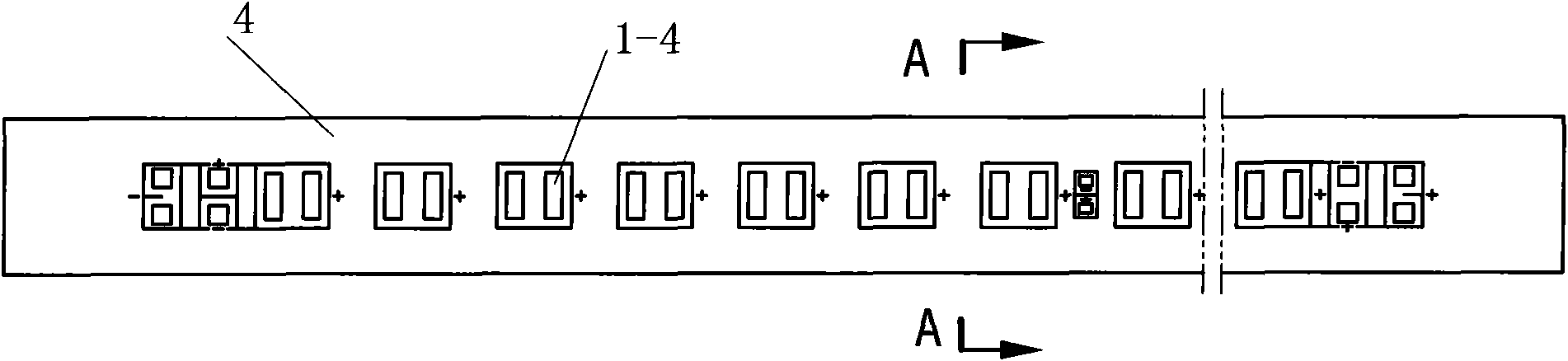

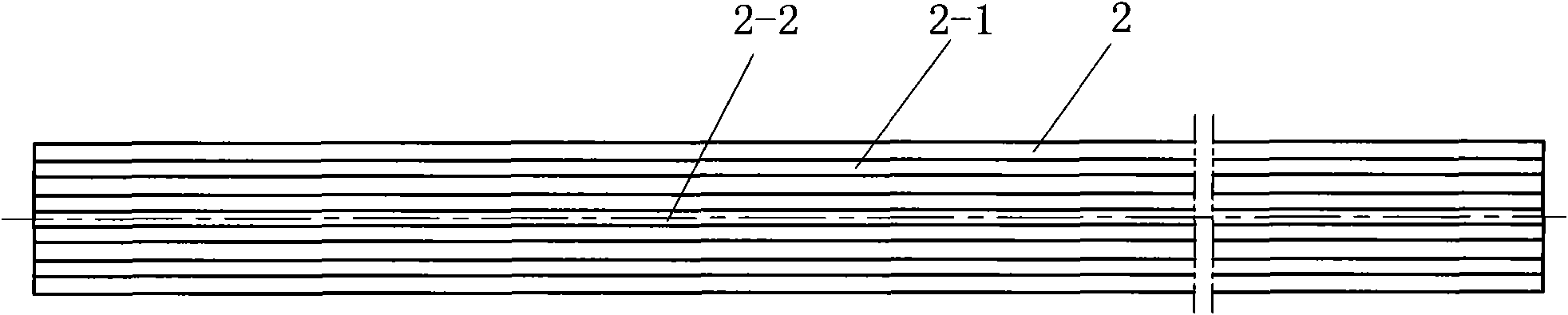

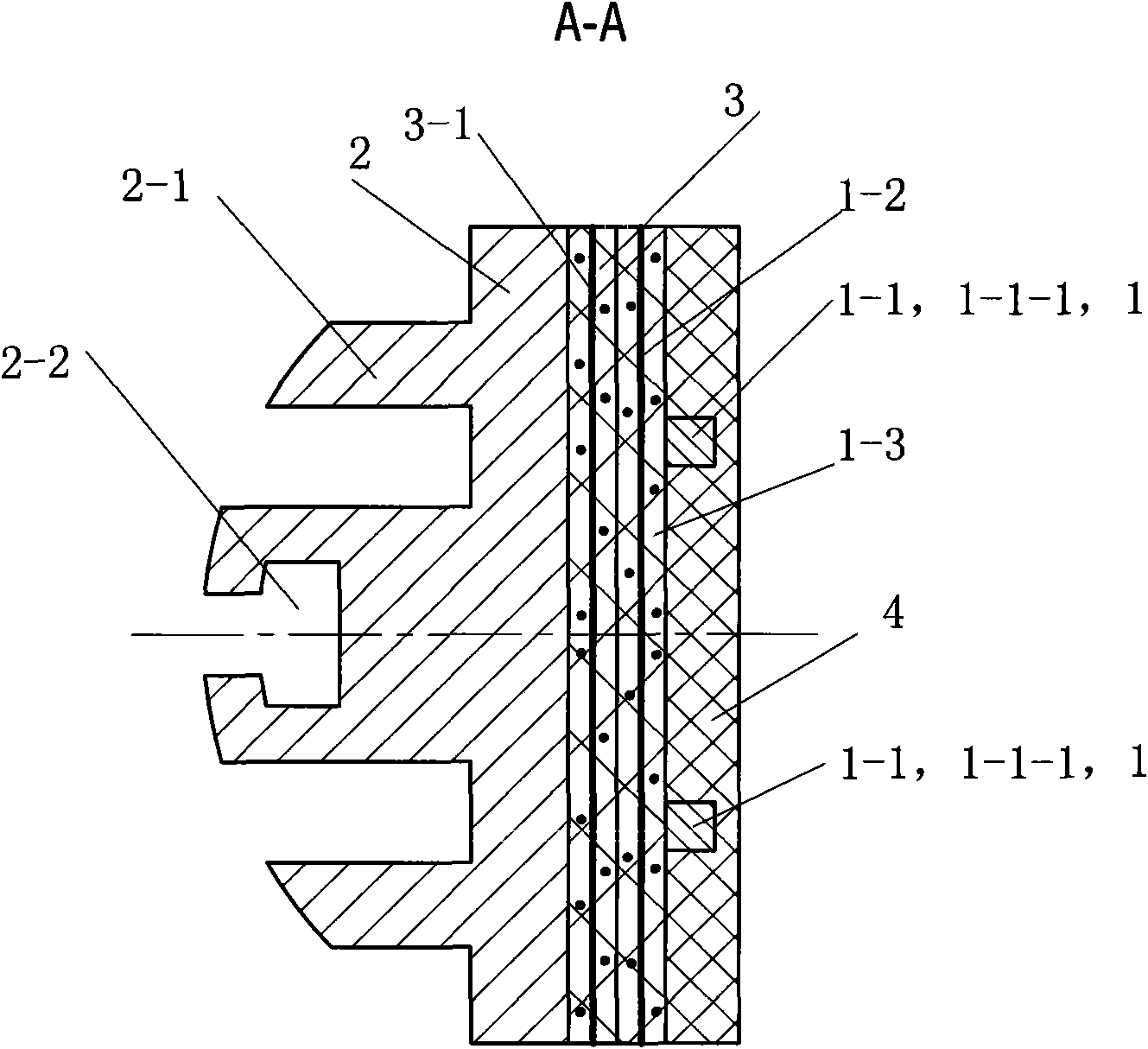

[0025] One of the specific implementation modes, as attached Figure 1-8 shown.

[0026] A radiator-based copper-clad printed circuit board laminate, comprising a plurality of copper-foil printed circuit boards 1 and a radiator 2 provided with several welding pads 1-4 for LED light-emitting diodes, and the radiator 2 It is a substrate; the heat sink 2 is laminated and bonded with the copper foil printed circuit board 1 through the insulating and heat-conducting layer 3; the entire copper foil printed circuit board 1 located outside the pads 1-4 The surface is provided with an insulating solder resist material layer 4 . The copper foil printed circuit board 1 is composed of a copper foil layer 1-1 and a glass fiber cloth 1-2, which are laminated and hot-pressed by a second insulating and heat-conducting layer 1-3; the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com