Die for achieving multidirectional forging of titanium alloy and machining method of die

A multi-directional forging and titanium alloy technology, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of low material utilization rate, irregular change of blank shape, large machining allowance, etc., and achieve Avoid the effects of grain growth, structure defects, and large amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments:

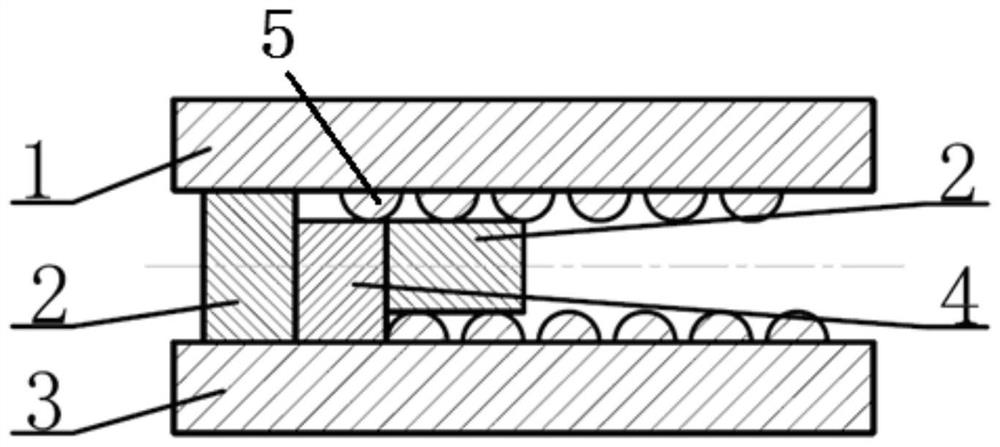

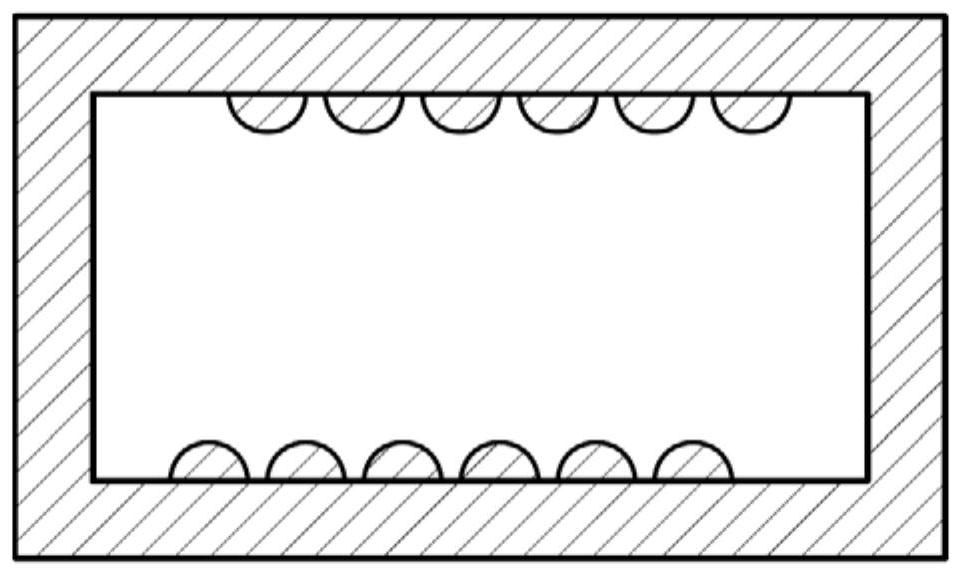

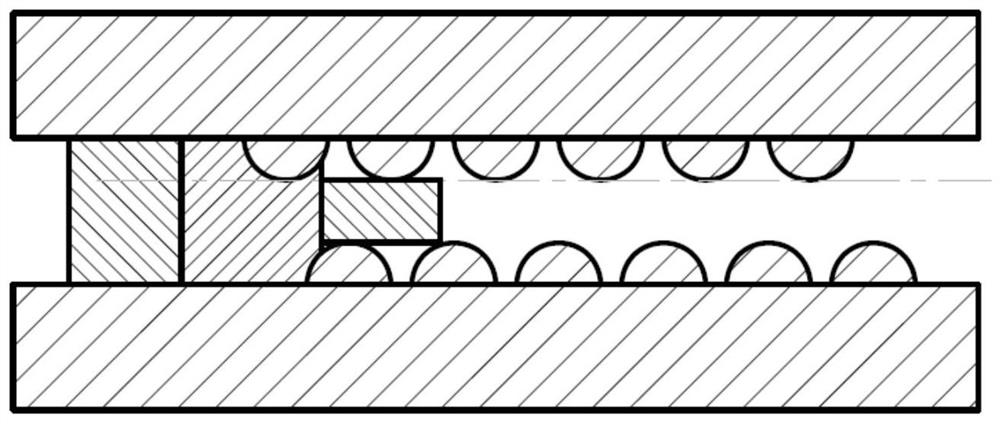

[0031] see attached figure 1 As shown, this kind of die for multi-directional forging of titanium alloy includes an upper die 1 and a lower die 3, and the titanium alloy blank 4 is forged between the upper die 1 and the lower die 3, and the lower surface of the upper die 1 and the lower die 3 are forged. The bulge-shaped protrusions 5 are evenly distributed on the upper surface of the upper mold, the bulge-shaped protrusions 5 are semicircles with the same diameter and are arranged in an arrangement, and the bulge-shaped protrusions 5 of the upper mold 1 and the lower mold 3 are mutually The upper and lower staggered distribution, the interval between the adjacent bulge-shaped protrusions 5 on the upper die 1 and the lower die 3 is 1 / 10 of the length of the side of the titanium alloy blank 4 along the horizontal travel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com