Gypsum proportioning equipment

A kind of equipment and gypsum technology, which is applied in the field of gypsum proportioning equipment, can solve the problems of low production efficiency, time-consuming and labor-intensive proportioning, and inaccurate proportioning, and achieve the effect of solving time-consuming and laborious, increasing the stirring range and increasing the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Other objects and advantages of the present invention will become apparent by explaining the following preferred embodiments of the present invention.

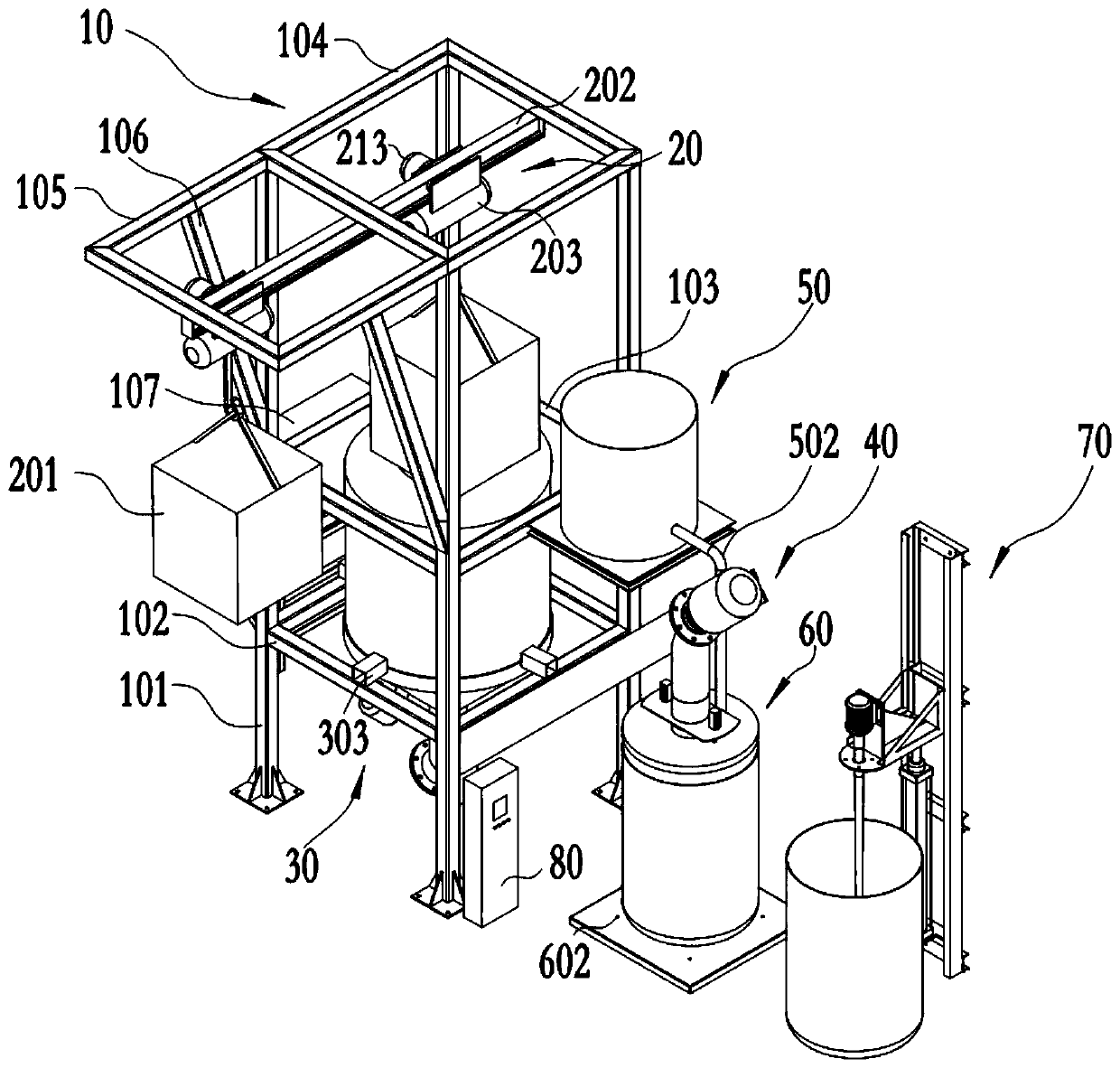

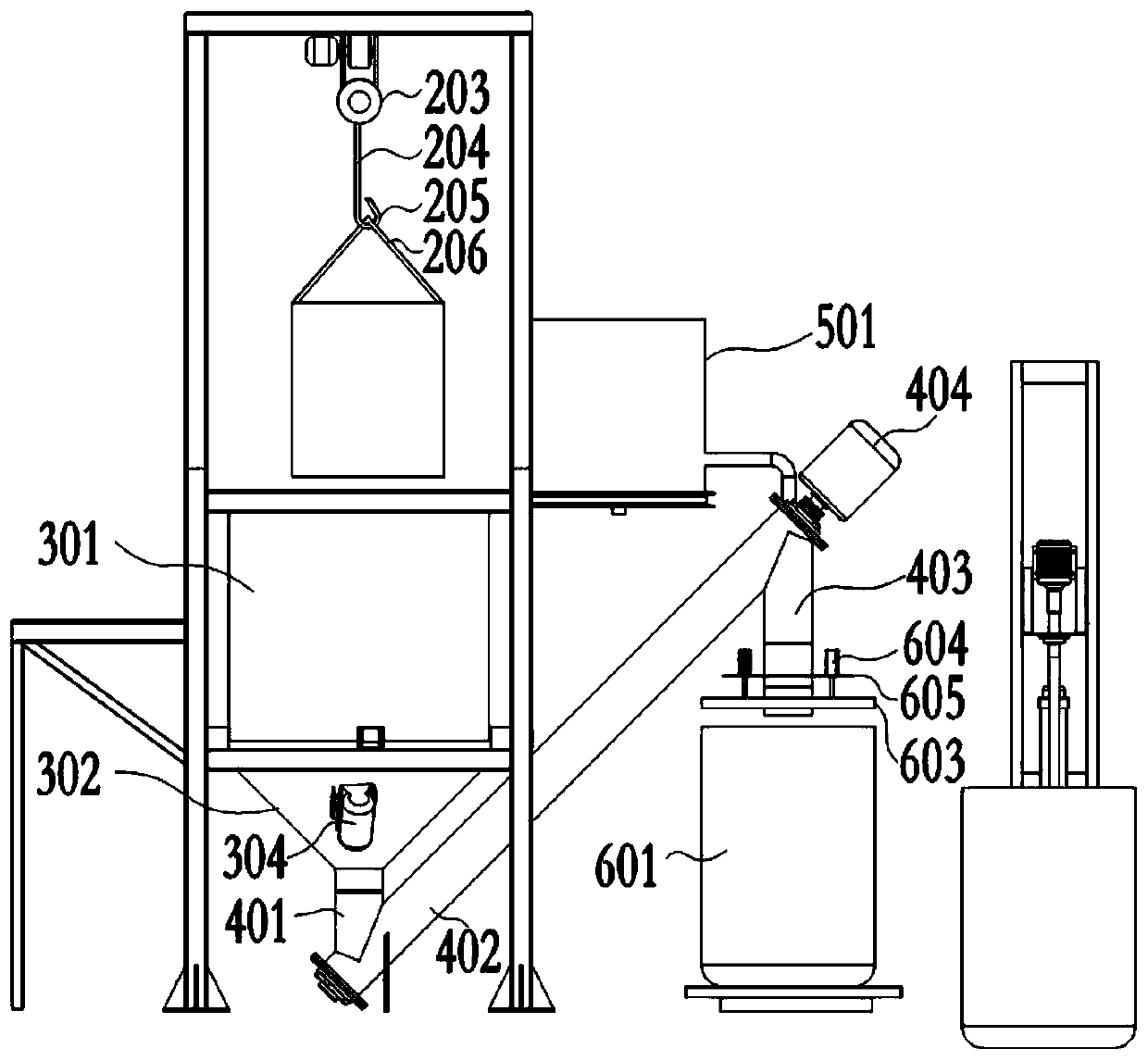

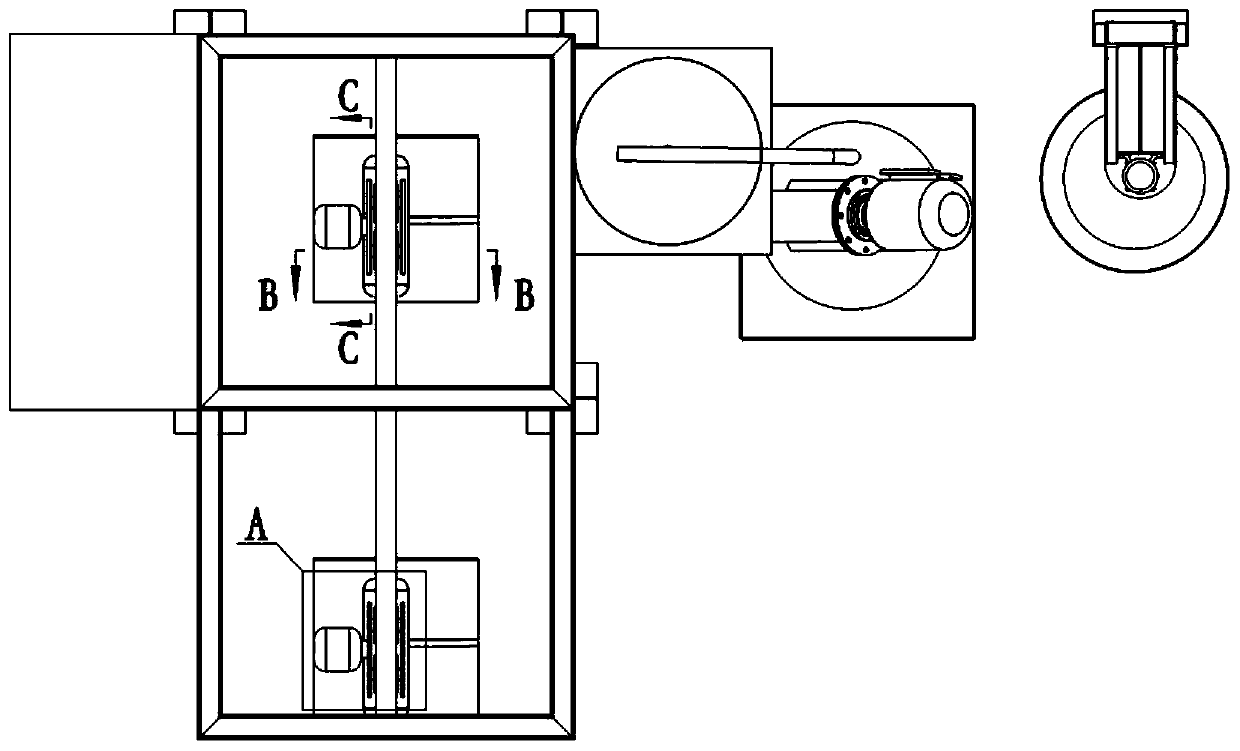

[0039] Figure 1-Figure 10 A schematic structural diagram of a gypsum proportioning equipment proposed by the present invention is shown. For the convenience of description, the "up", "down", "left" and "right" referred to below are consistent with the up, down, left and right directions of the drawings themselves, but do not limit the structure of the present invention.

[0040] figure 1 The schematic diagram of the three-dimensional structure of a gypsum proportioning equipment in the embodiment of the present invention is exemplarily shown.

[0041] like figure 1 As shown, a gypsum proportioning equipment includes a support frame 10 , a discharging mechanism 30 , a ton bag 201 , a powder feeding mechanism 40 , a water feeding mechanism 50 and a mixing mechanism 60 . The support frame 10 includes a tripod 101, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com