Wastewater ozone oxidation advanced treatment device

A technology of advanced treatment and ozone oxidation, applied in the direction of oxidized water/sewage treatment, chemical/physical process, mixer with rotating stirring device, etc., can solve the problems of low ozone utilization rate and ozone waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

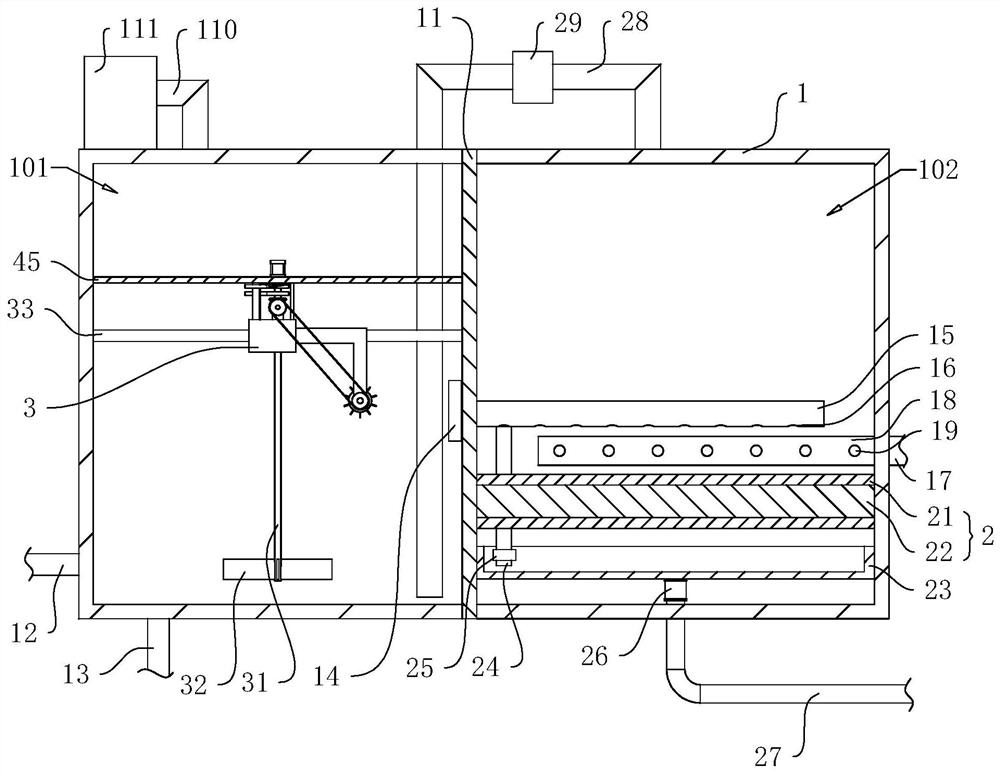

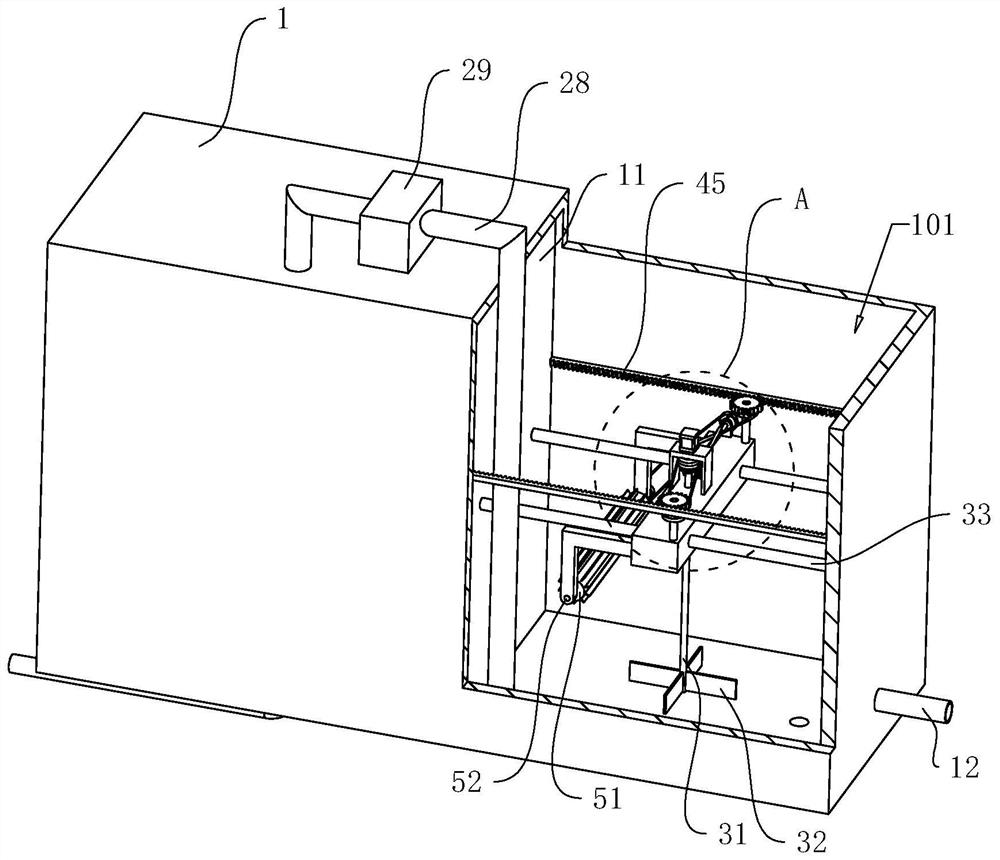

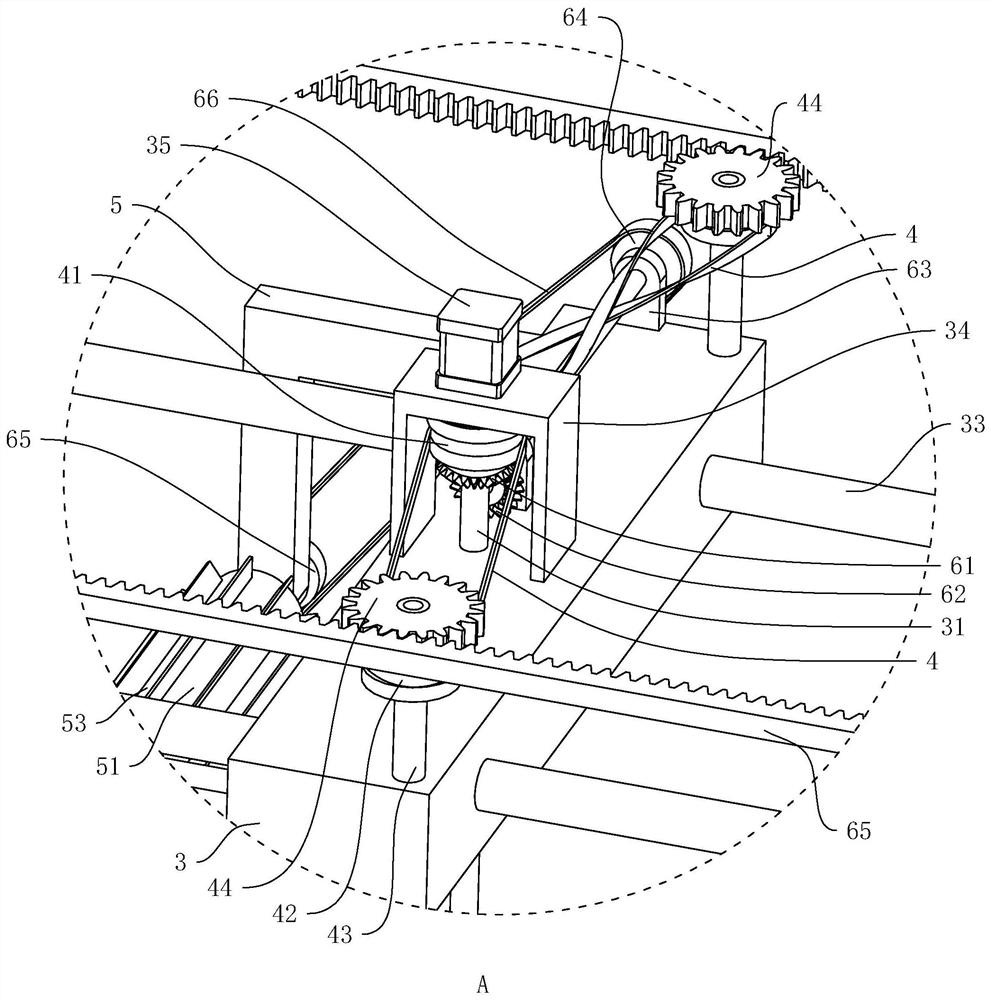

[0034] The following is attached Figure 1-3 The application is described in further detail.

[0035] The embodiment of the present application discloses a wastewater ozone oxidation advanced treatment device. Such as figure 1 As shown, a wastewater ozone oxidation advanced treatment device includes a device body 1, a partition 11 is vertically fixed between the top wall and the bottom wall of the device body 1, and the partition 11 separates the device body 1 into a settling chamber 101 and an ozone treatment chamber 102, the wastewater is settled in the settling chamber 101 and then enters the ozone treatment chamber 102 for advanced treatment.

[0036] The side wall of the settling chamber 101 is connected with a water inlet pipe 12, and the water inlet pipe 12 is equipped with a valve. The waste water enters the settling chamber 101 through the water inlet pipe 12, and the insoluble impurities in the waste water settle; the bottom wall of the settling chamber 101 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com