Antibacterial spraying-free plastic, production device and processing method

A production device and spray-free technology, applied in the field of production device and processing, antibacterial and spray-free plastics, can solve the problem of insufficient mixing, and achieve the effect of improving the mixing effect, improving the fluency, and avoiding stuttering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

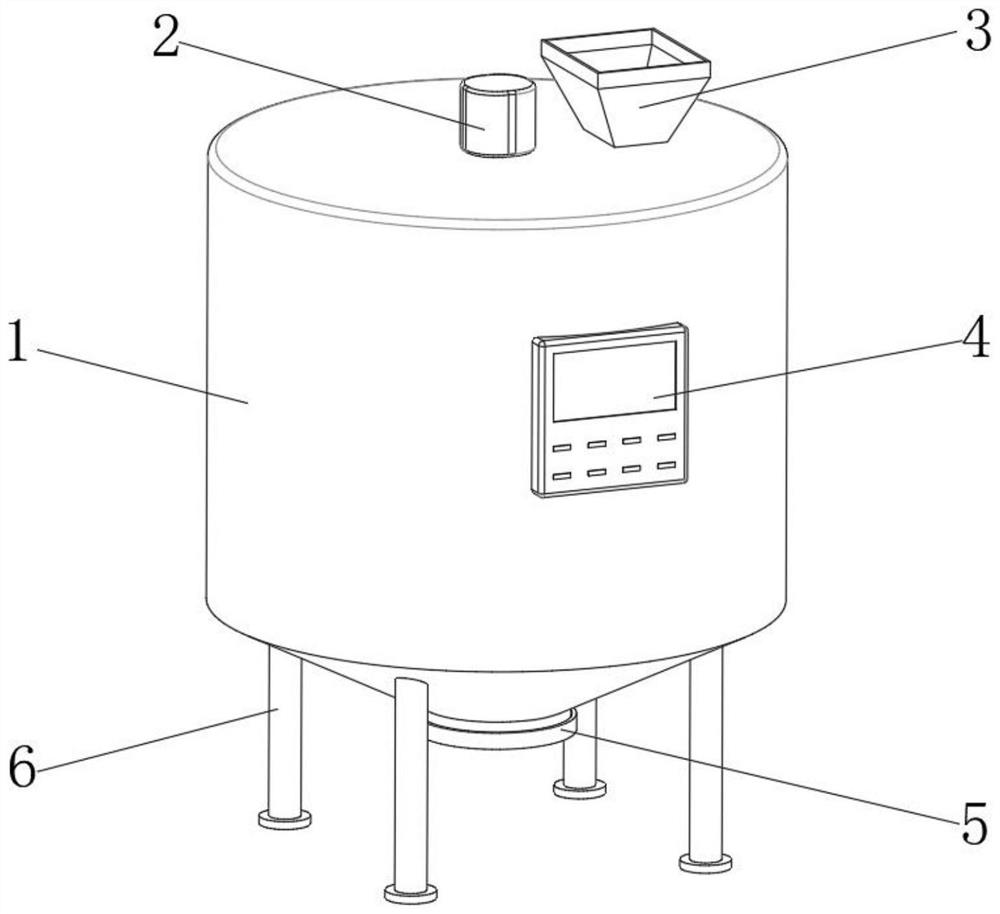

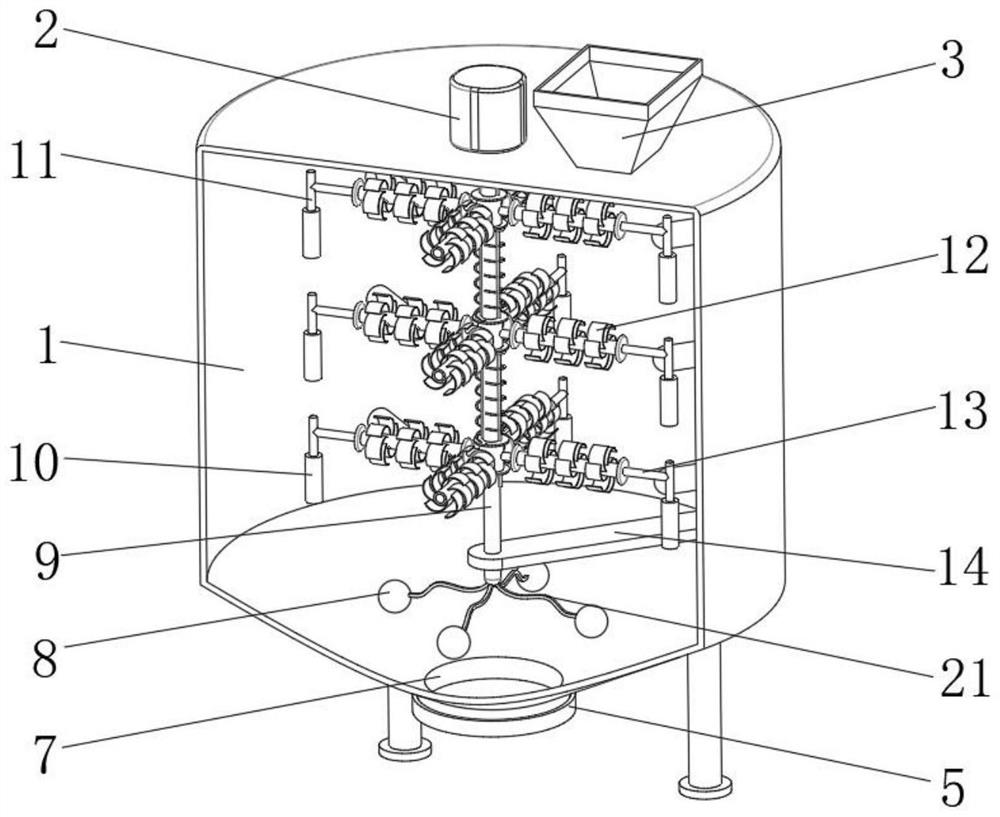

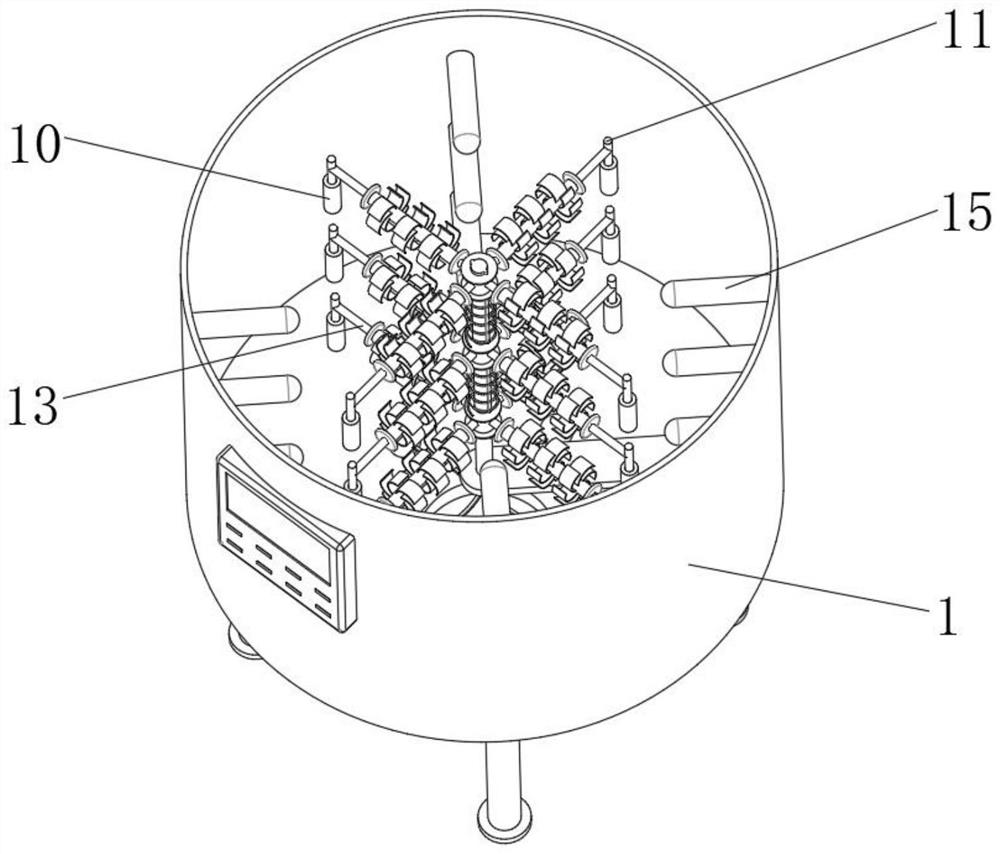

[0038] A production device for antibacterial spray-free plastics, such as Figure 1-4As shown, it includes a mixing tank main body 1, a mixing motor 2 is fixed on the top outer wall of the mixing tank main body 1 by screws, the output end of the mixing motor 2 is rotatably connected to a rotating main shaft 9, and the outer wall of the rotating main shaft 9 is slidingly connected to two or more The sliding seat 19 of the sliding seat 19, the outer walls on both sides of the rotating main shaft 9 are integrally provided with guiding ribs 18, the sliding seat 19 is slidably connected to the outer walls of the guiding ribs 18, and the top outer wall and the bottom outer wall of the sliding seat 19 are integrally provided with installation Plate 17, the same spring 16 is welded between adjacent mounting plates 17 on different sliding seats 19; the outer wall of the sliding seat 19 is welded with evenly distributed horizontal mixing rods 13, and one end of the horizontal mixing rods...

Embodiment 2

[0043] A production device for antibacterial spray-free plastics, such as figure 1 As shown, in order to further improve the mixing effect; this embodiment makes the following improvements on the basis of Embodiment 1: the inner wall of the main body of the mixing tank 1 is welded with a support frame 14, and the outer wall of the rotating main shaft 9 is rotatably connected to the inner wall of the support frame 14, And one end of the rotating main shaft 9 runs through the support frame 14 and the stirring ball 8 is installed through the elastic cord 21. By arranging the elastic cord 21 and the stirring ball 8, the stirring ball 8 can be used to pair the bottom of the mixing tank main body 1 during the rotation of the rotating main shaft 9. The materials are stirred and mixed, which further improves the mixing effect.

Embodiment 3

[0045] An antibacterial spray-free plastic, the composition of which includes, by weight, 55-95 parts of ABS resin, 1-2 parts of compatibilizer, 1-2 parts of lubricant, 0.5-0.7 part of antioxidant, and 1.5 parts of toughening agent -2.5 parts, 0.8-2.7 parts of dispersant, 2-4 parts of pigment masterbatch.

[0046] The antibacterial agent is one or more of hydroxyapatite-loaded zinc antibacterial agent, zeolite-loaded silver antibacterial agent, diatomaceous earth-loaded zinc antibacterial agent, and chlorine-based antibacterial agent; the color masterbatch is carbon black, titanium One or more of white powder, zinc yellow, phthalocyanine red.

[0047] The composition of the antibacterial spray-free plastic is further limited to: 70-80 parts of ABS resin, 1.5-1.7 parts of compatibilizer, 1.3-1.5 parts of lubricant, 0.6-0.7 parts of antioxidant, and 1.7-2.2 parts of toughening agent , 1-2 parts of dispersant, 2.5-3.5 parts of pigment masterbatch.

[0048] The antibacterial age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com