Patents

Literature

48results about How to "Increase absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

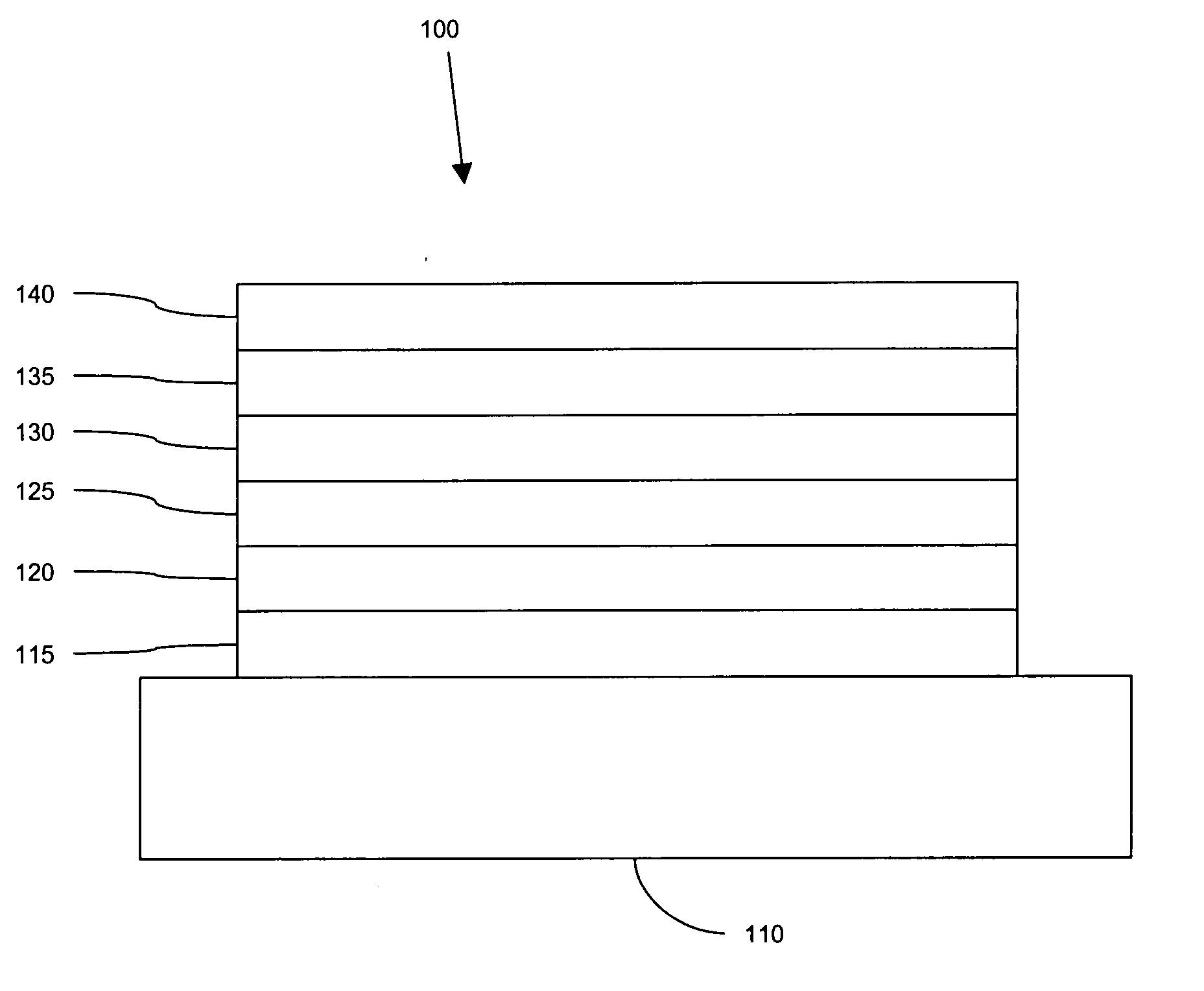

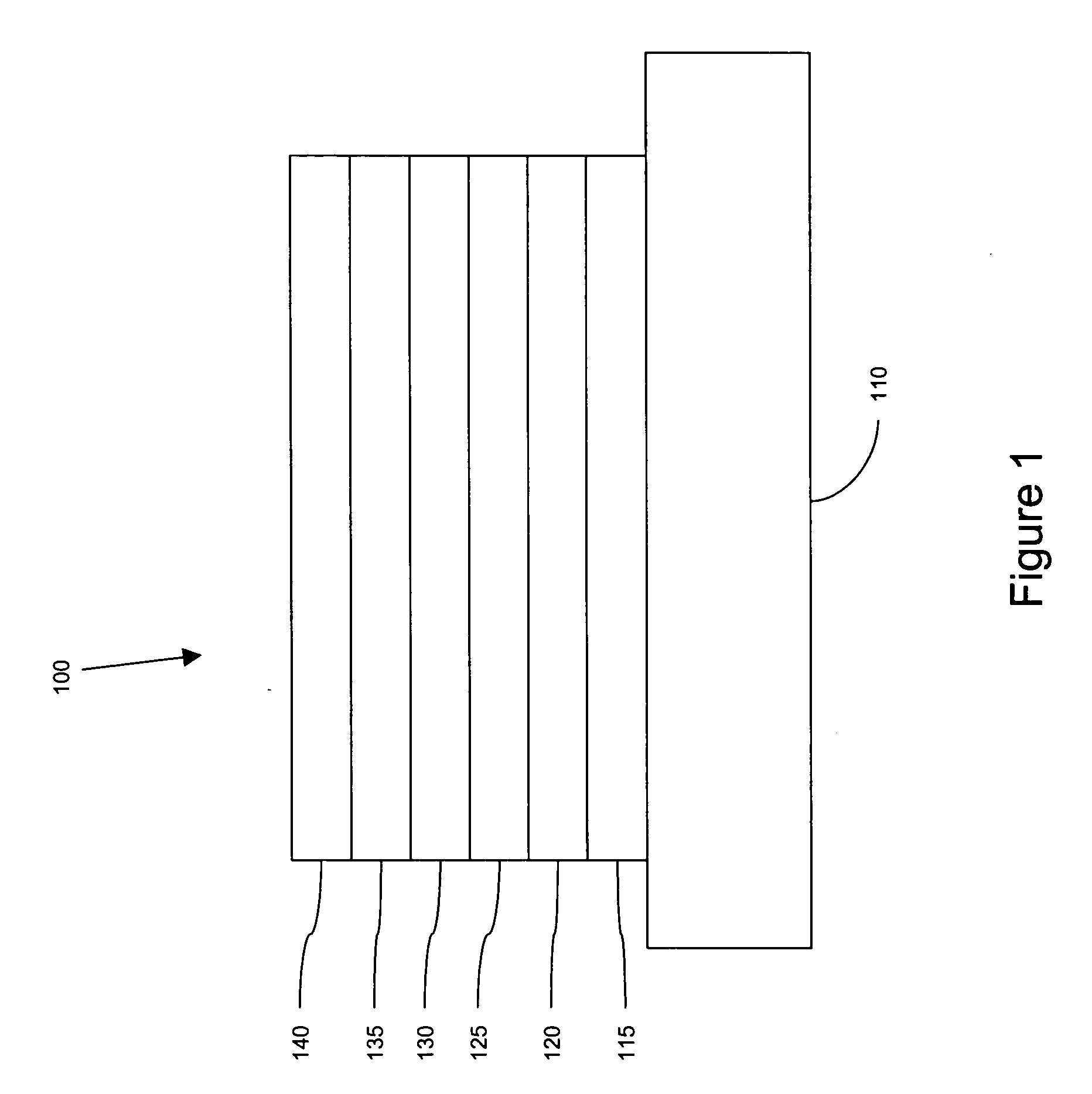

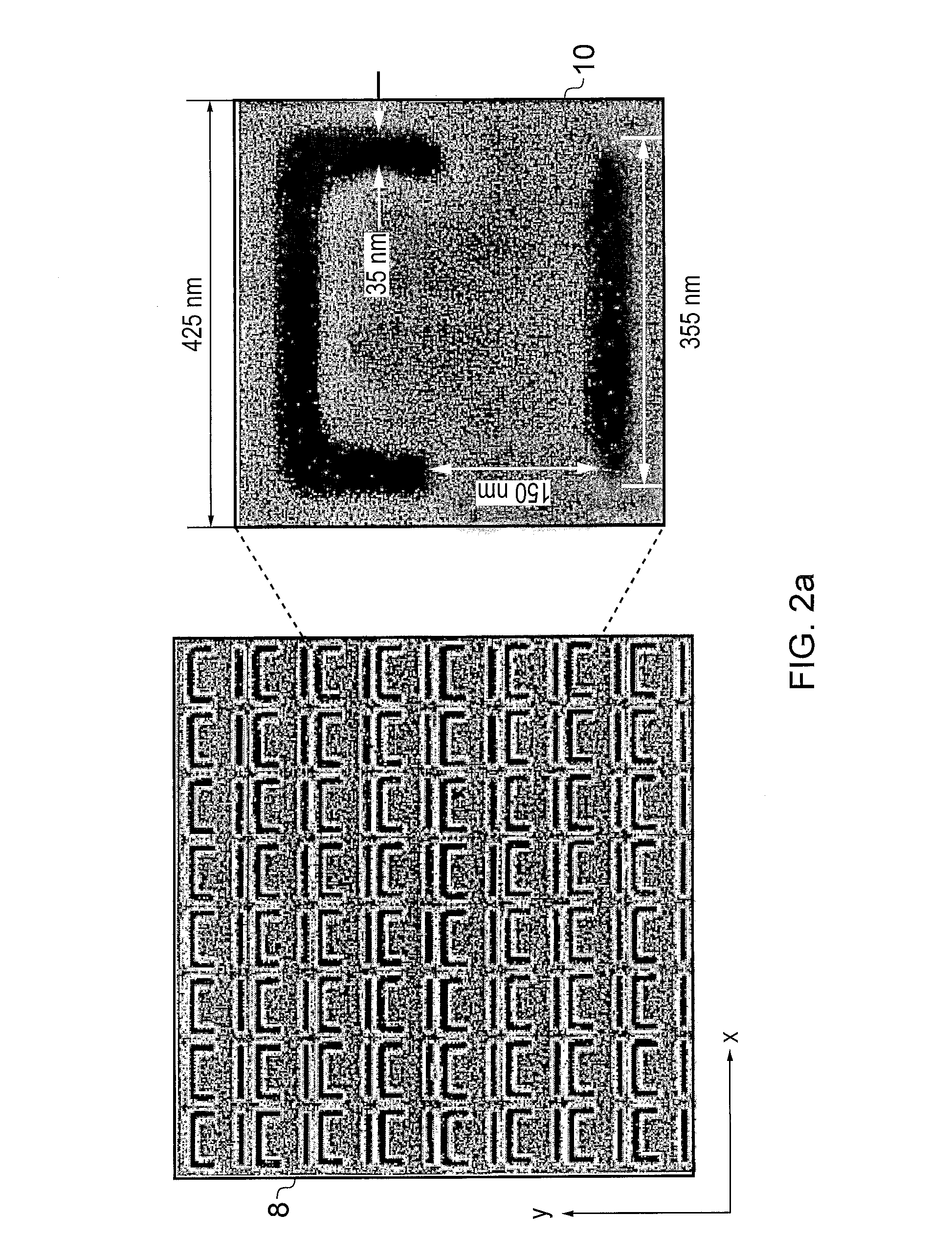

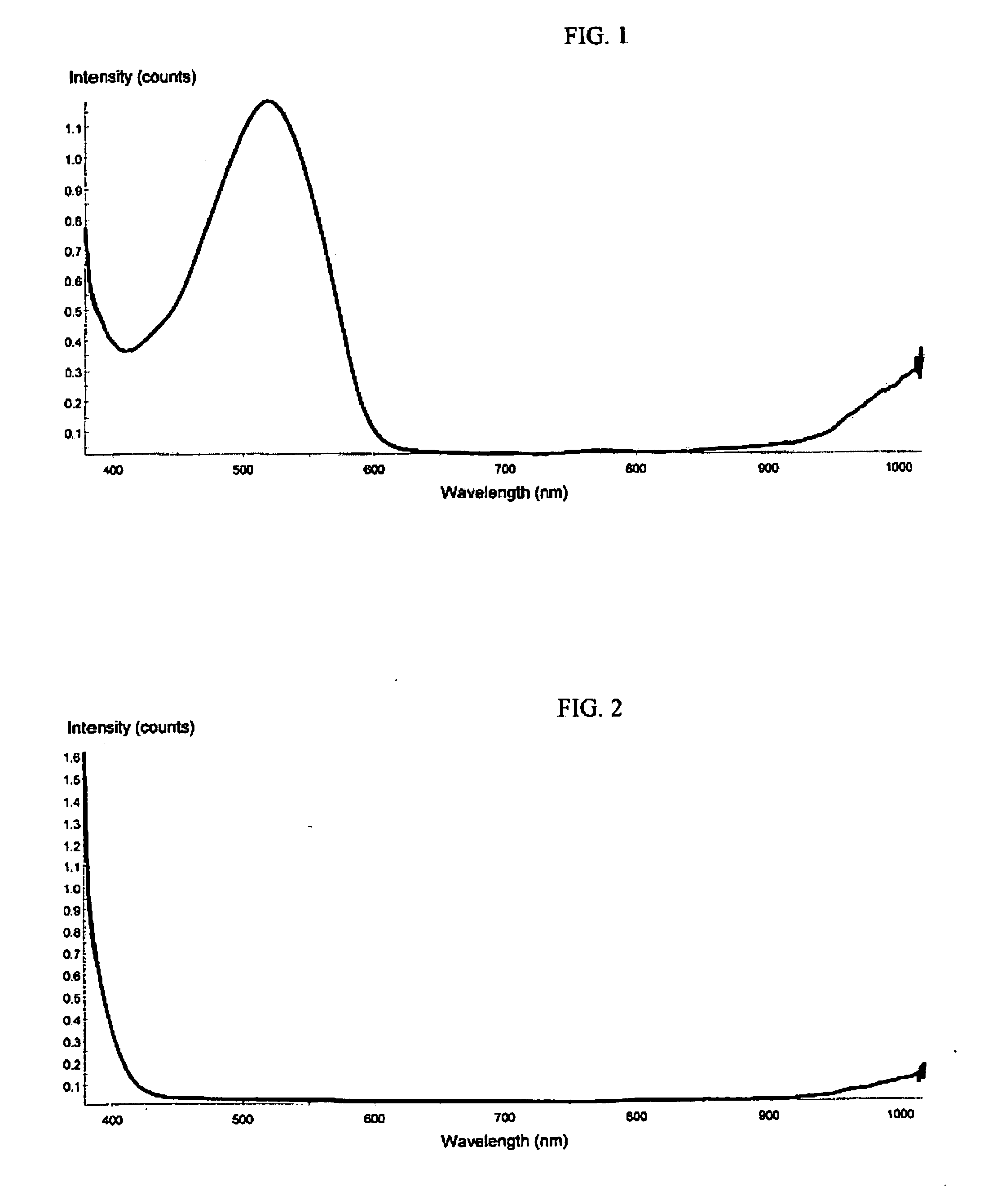

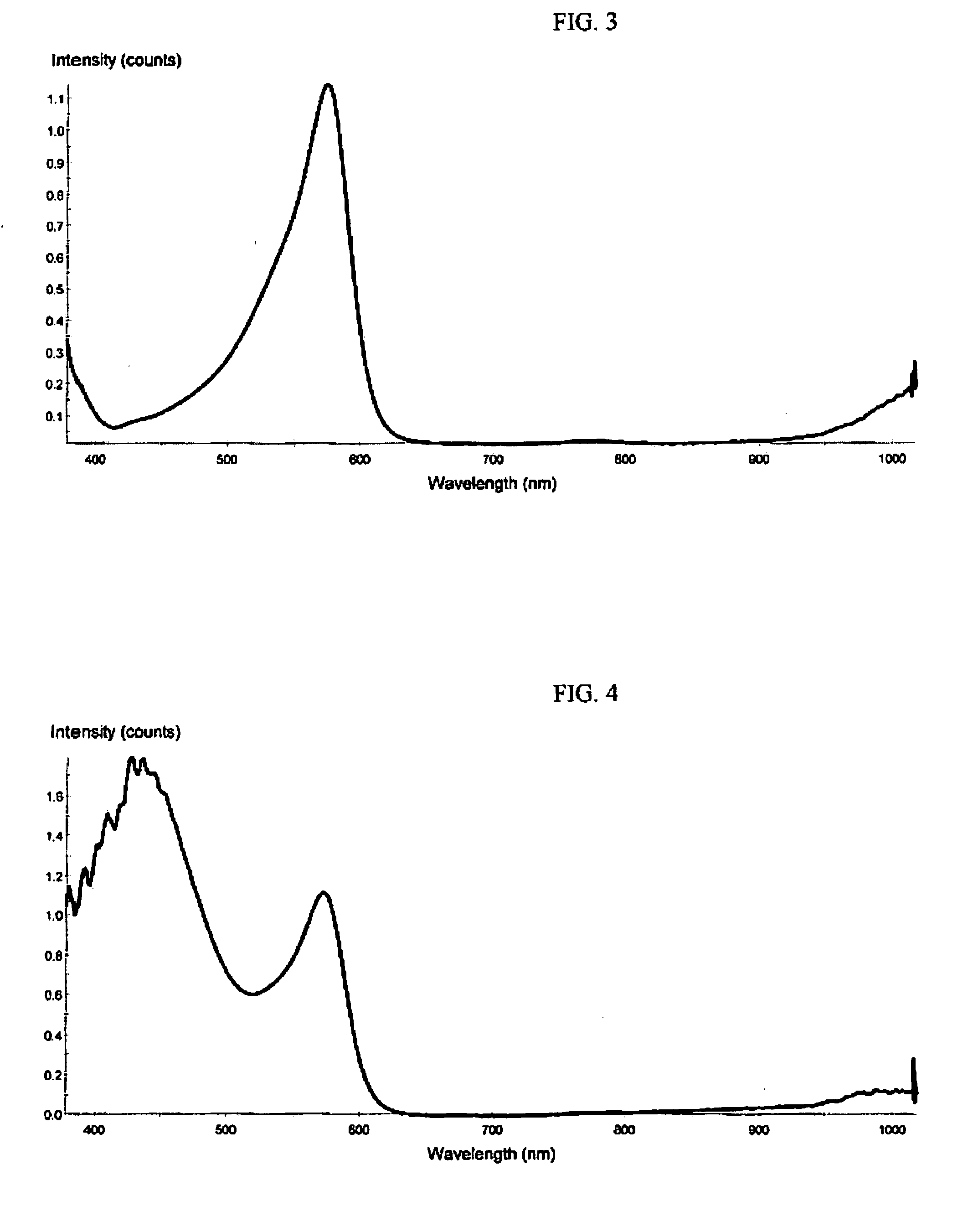

Organic photosensitive devices

ActiveUS20060032529A1Increase absorptionEfficient deviceSolid-state devicesSemiconductor/solid-state device manufacturingSurface plasmon polaritonNanometre

Owner:THE TRUSTEES FOR PRINCETON UNIV

Vitamin formulation for enhancing bone strength

InactiveUS6881419B2Increase absorptionDecrease excretionBiocideInorganic boron active ingredientsDietary vitaminCalcium EDTA

The present invention provides a method and composition for dietary vitamin supplementation utilizing a form and dosage of vitamins and minerals for enhanced calcium absorption. The method includes the steps of providing a pharmaceutically acceptable composition including calcium citrate, and supplementing the daily dietary regimen of a subject with calcium citrate within the range of approximately 100 mg calcium to approximately 2000 mg calcium, and preferably 1000 mg calcium. The chewable form of the supplement provided herein facilitates absorption of calcium in the teeth and bones of a subject, for enhanced physiological and psychological benefits. The supplement is especially beneficial for subjects experiencing osteoporosis, arthritis, demineralization of teeth and bones, bodily pain and lack of energy, as well as for the prevention of these ailments.

Owner:LOVETT WILLIAM E

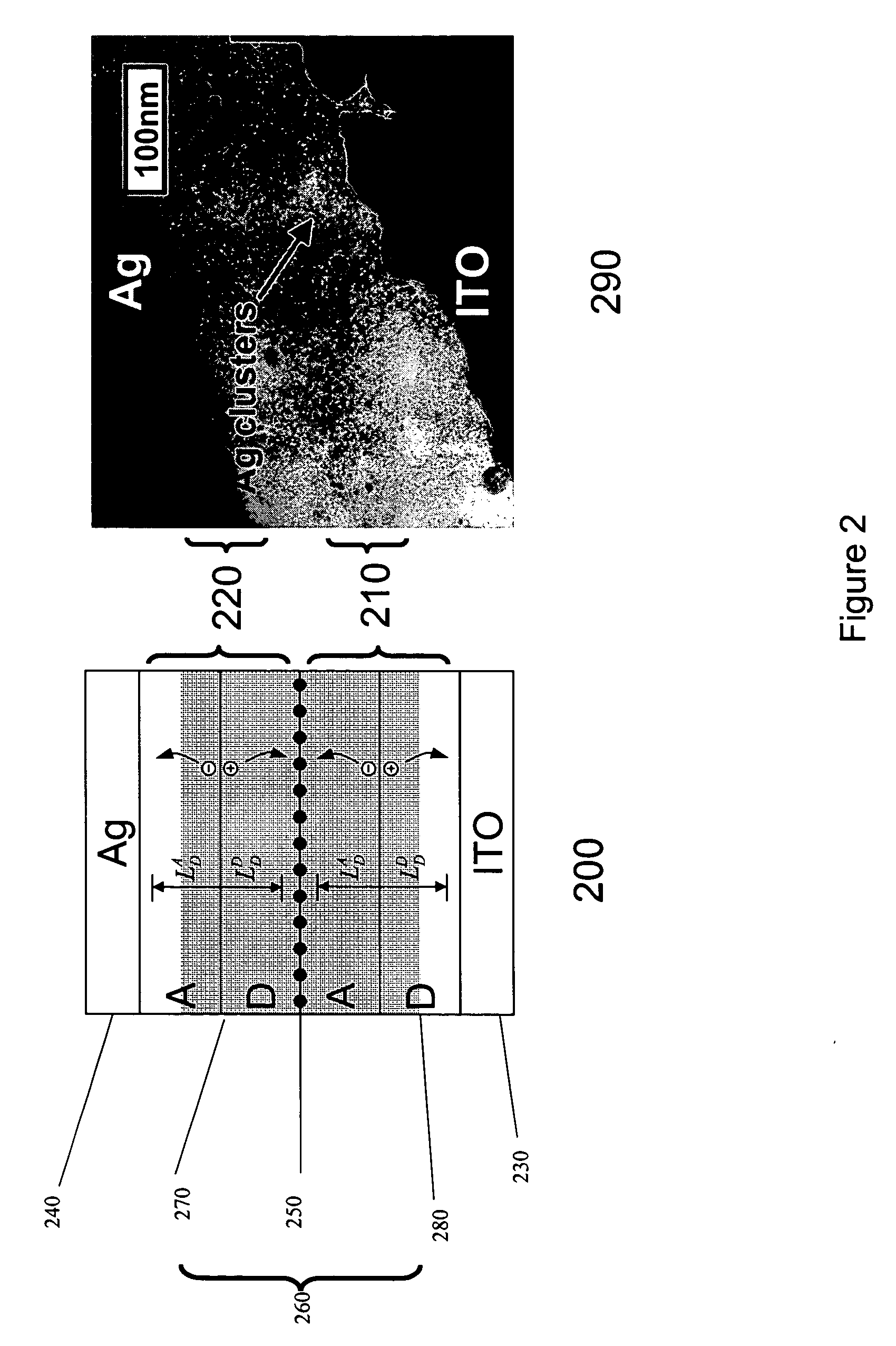

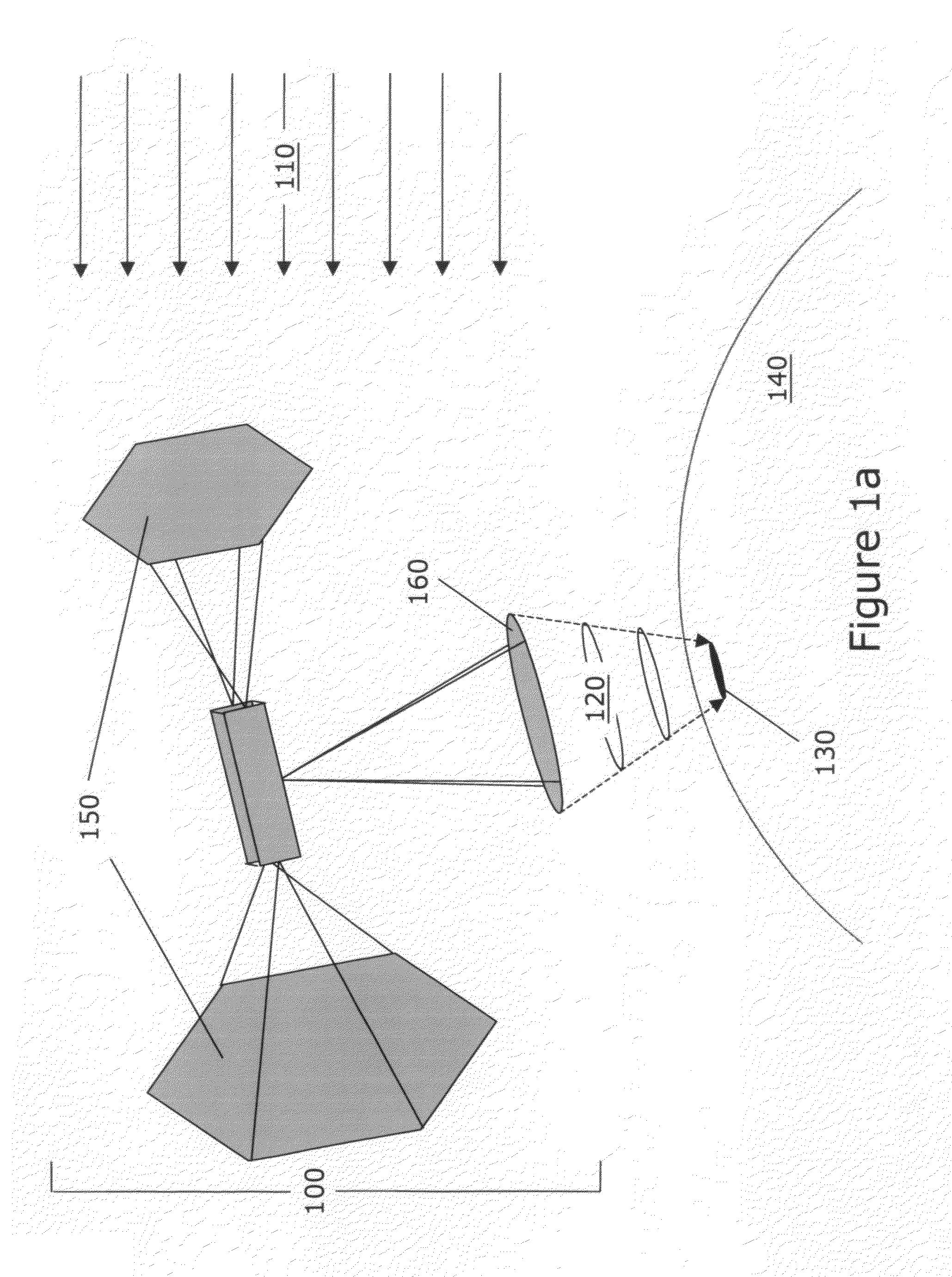

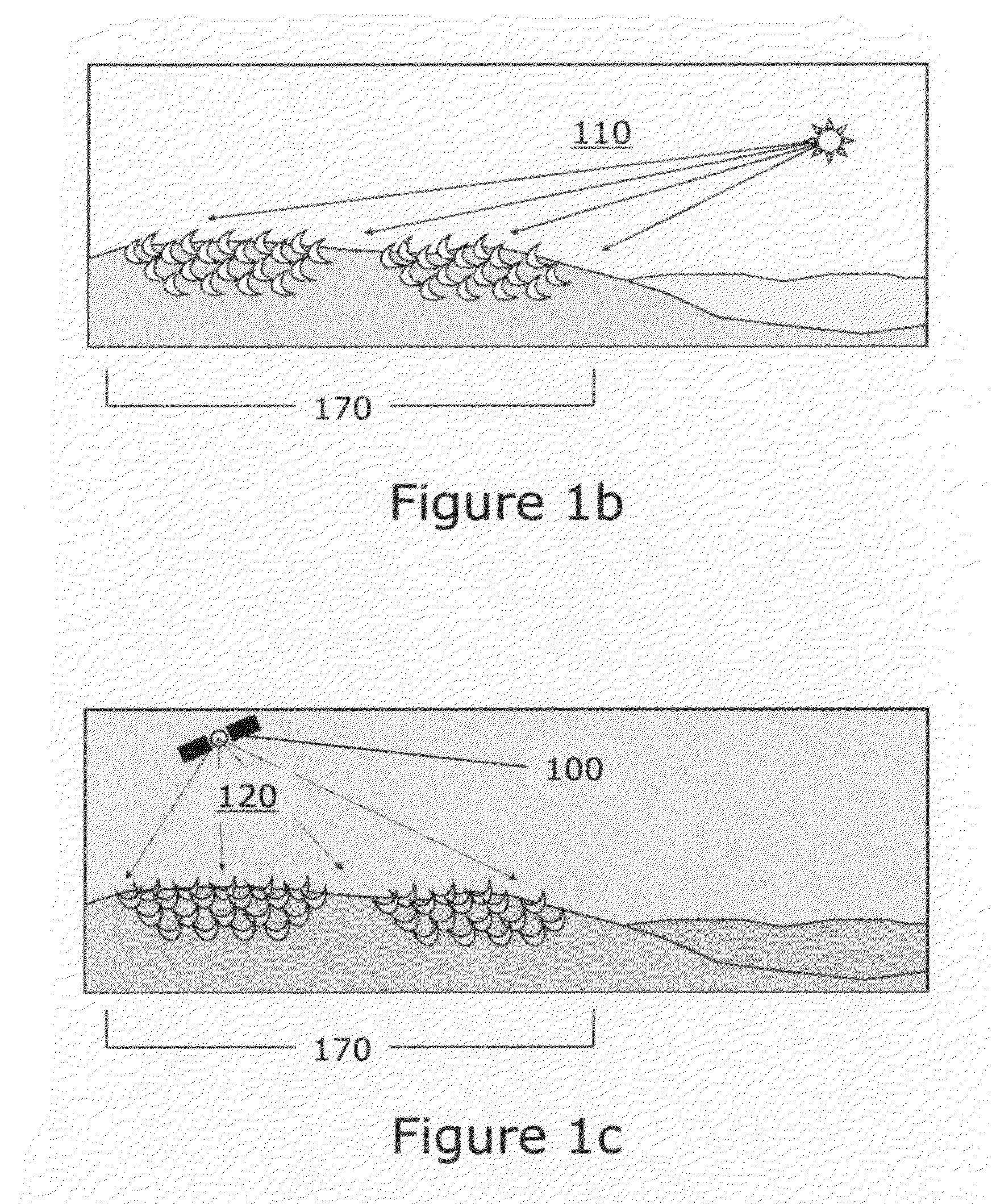

Process and method of making fuels and other chemicals from radiant energy

InactiveUS20080175766A1Increase absorptionIncrease abilitySolar heating energySolar heat devicesChemical energyCompound (substance)

Processes and methods of producing fuels and other chemicals whereby a substantial portion of the chemical energy of the product is provided by solar energy (110) or a powerbeam (120) consisting of microwave, laser or other radiant energy, and performing thermochemical processes. Systems and applications include using radiant energy to drive moderate- to high-temperature endothermic reactions, followed by downstream chemical reactions and separations to create the desired chemical product.

Owner:MANKINS JOHN CARLTON +1

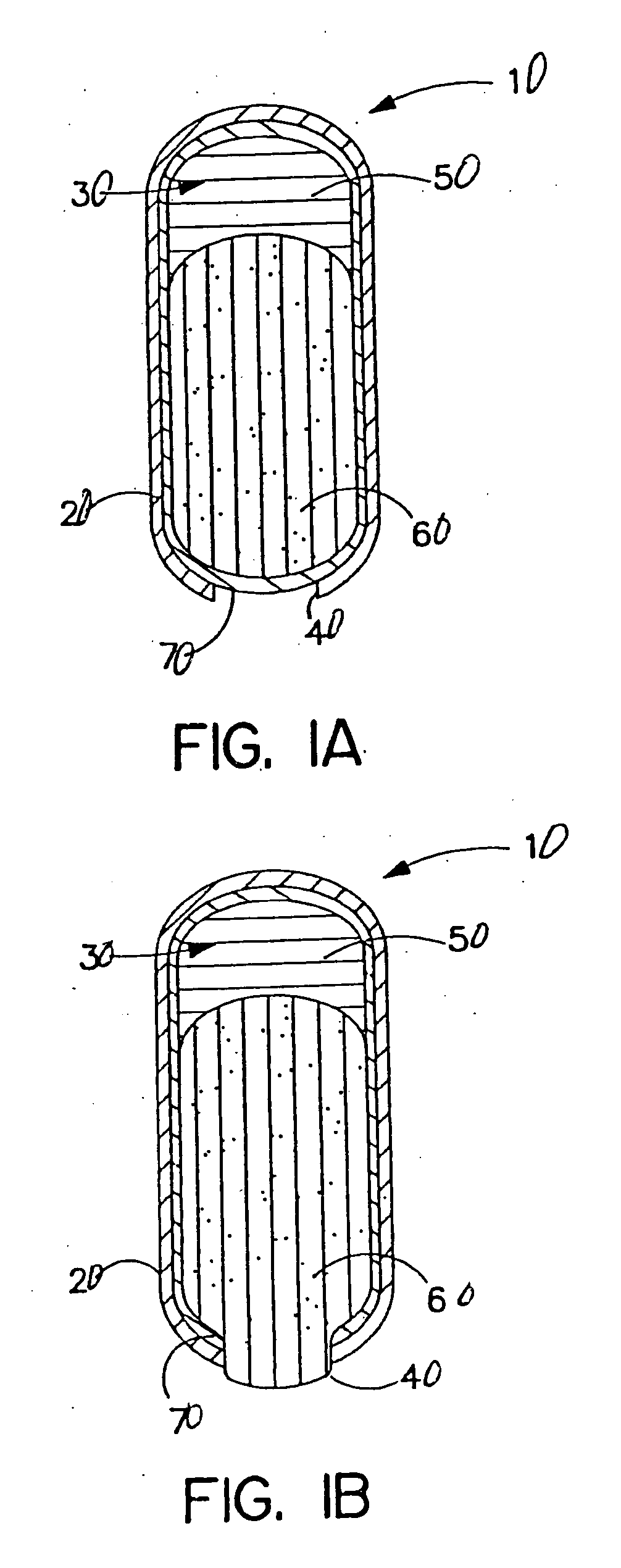

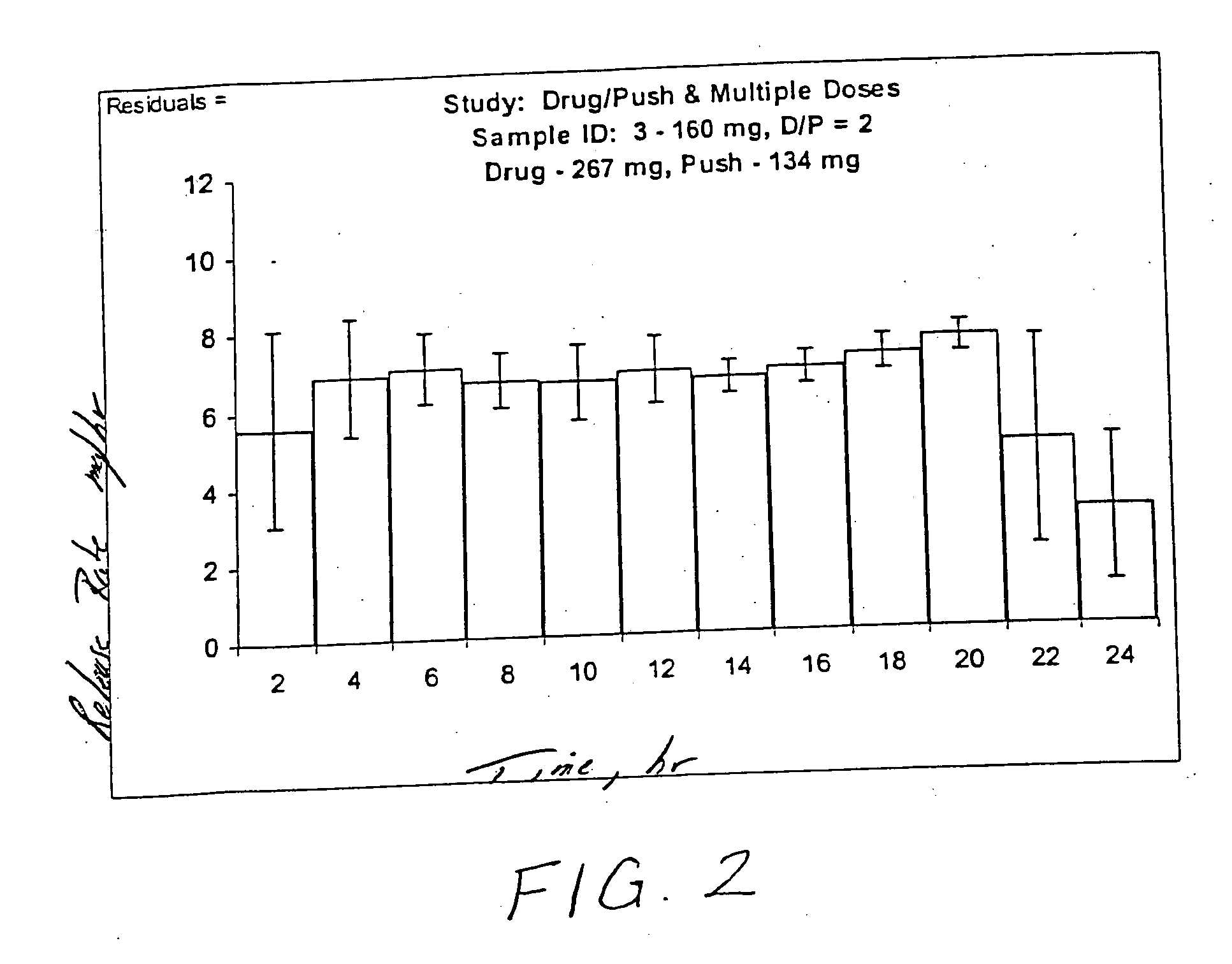

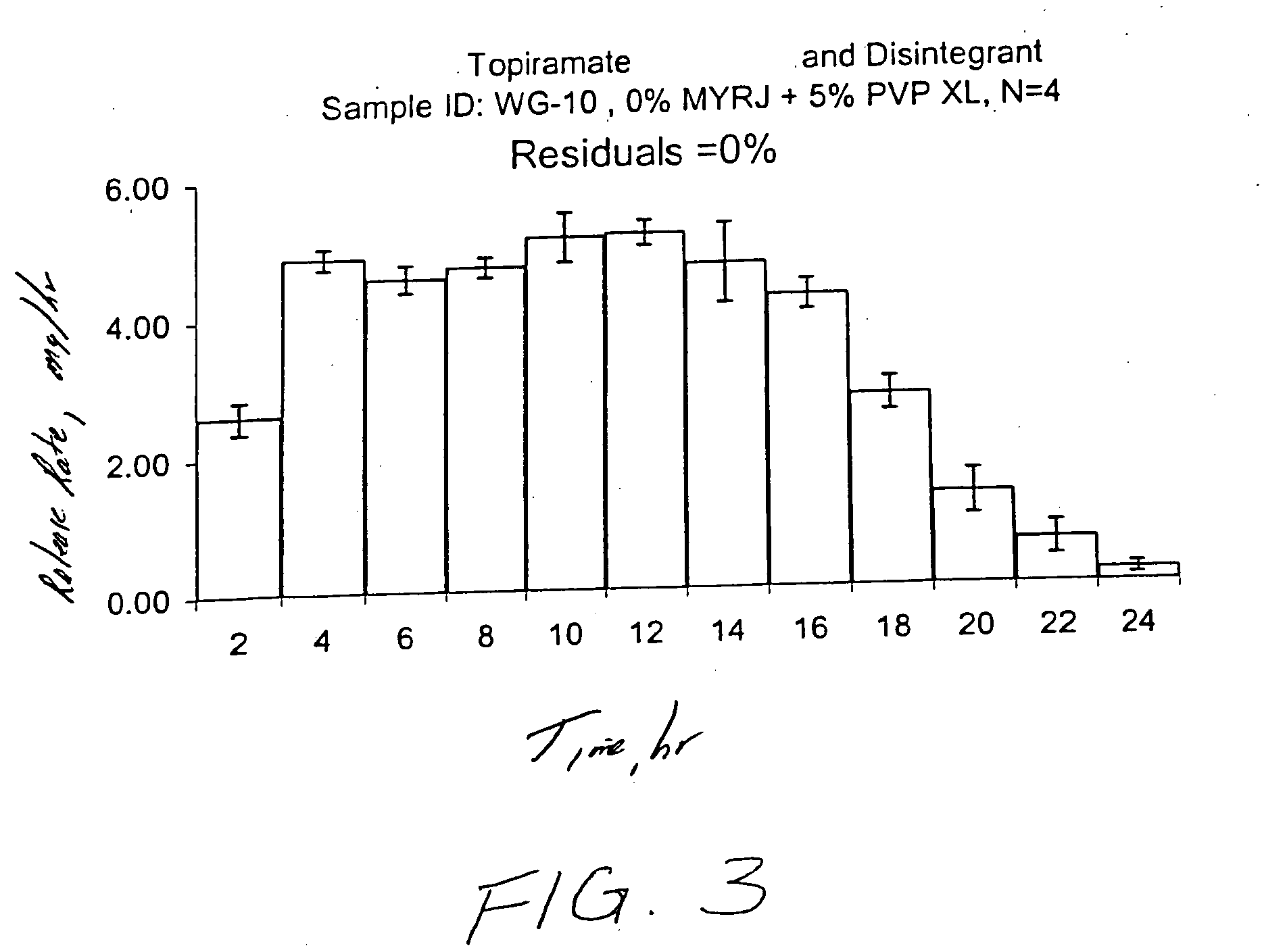

Uniform delivery of topiramate over prolonged period of time with enhanced dispersion formulation

InactiveUS20050058707A1Enhance bioavailabilityIncrease absorptionNervous disorderCapsule deliveryTopiramateControlled Release Dosage Form

Compositions and dosage forms for enhanced dispersion of topiramate in a controlled release dosage form delivered as a dry or substantially dry erodible solid at a uniform rate over a prolonged period of time are described.

Owner:ALZA CORP

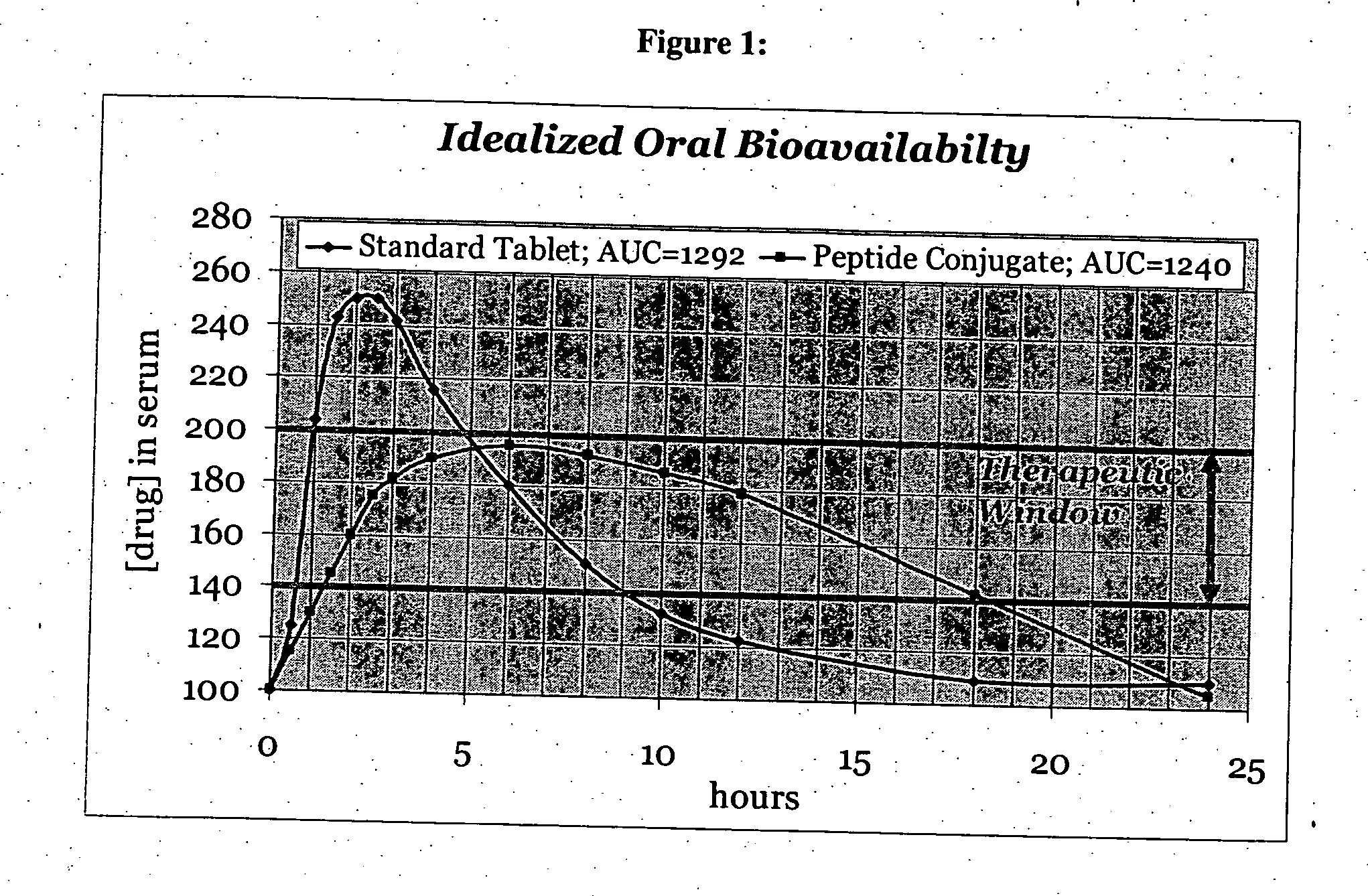

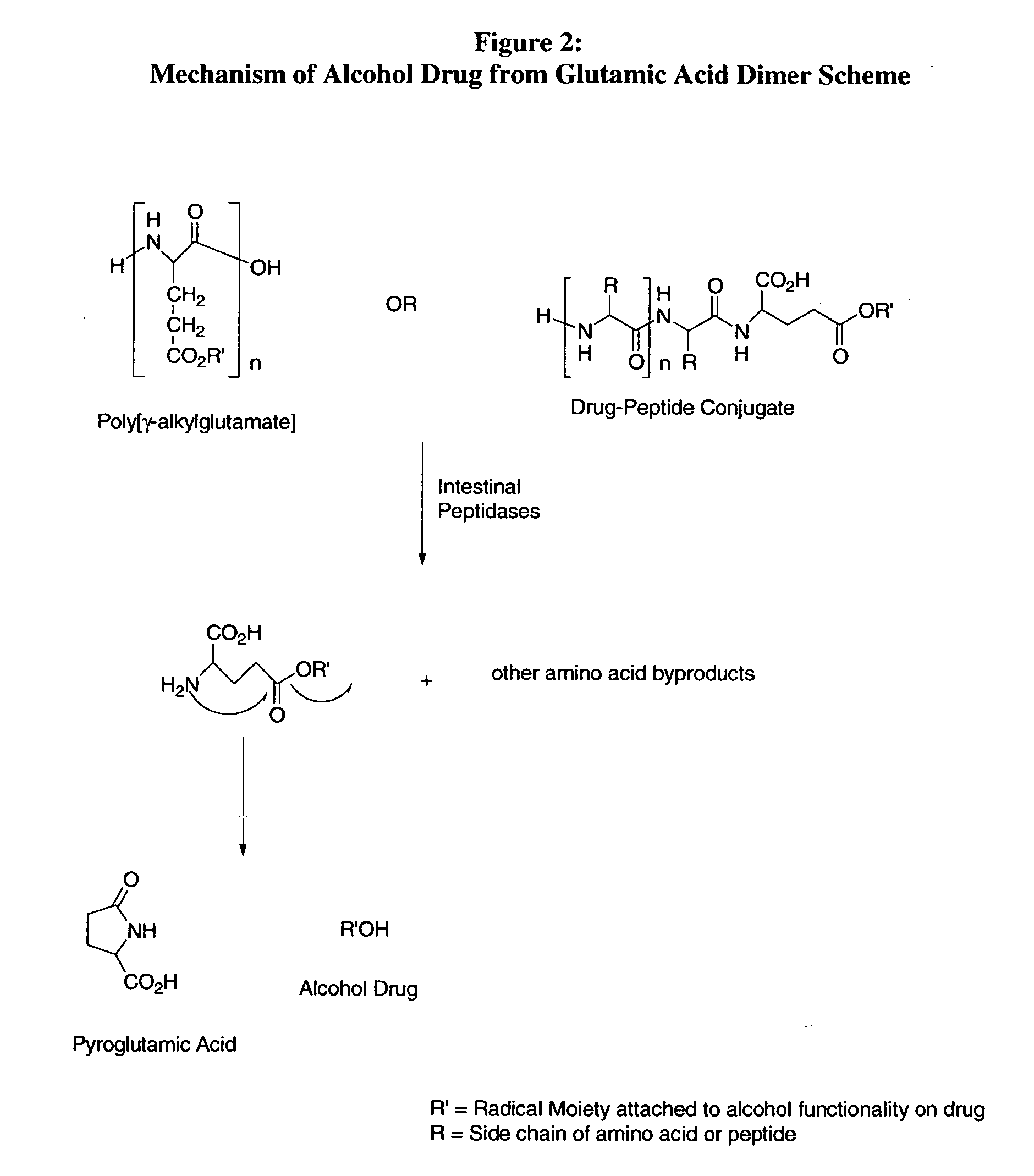

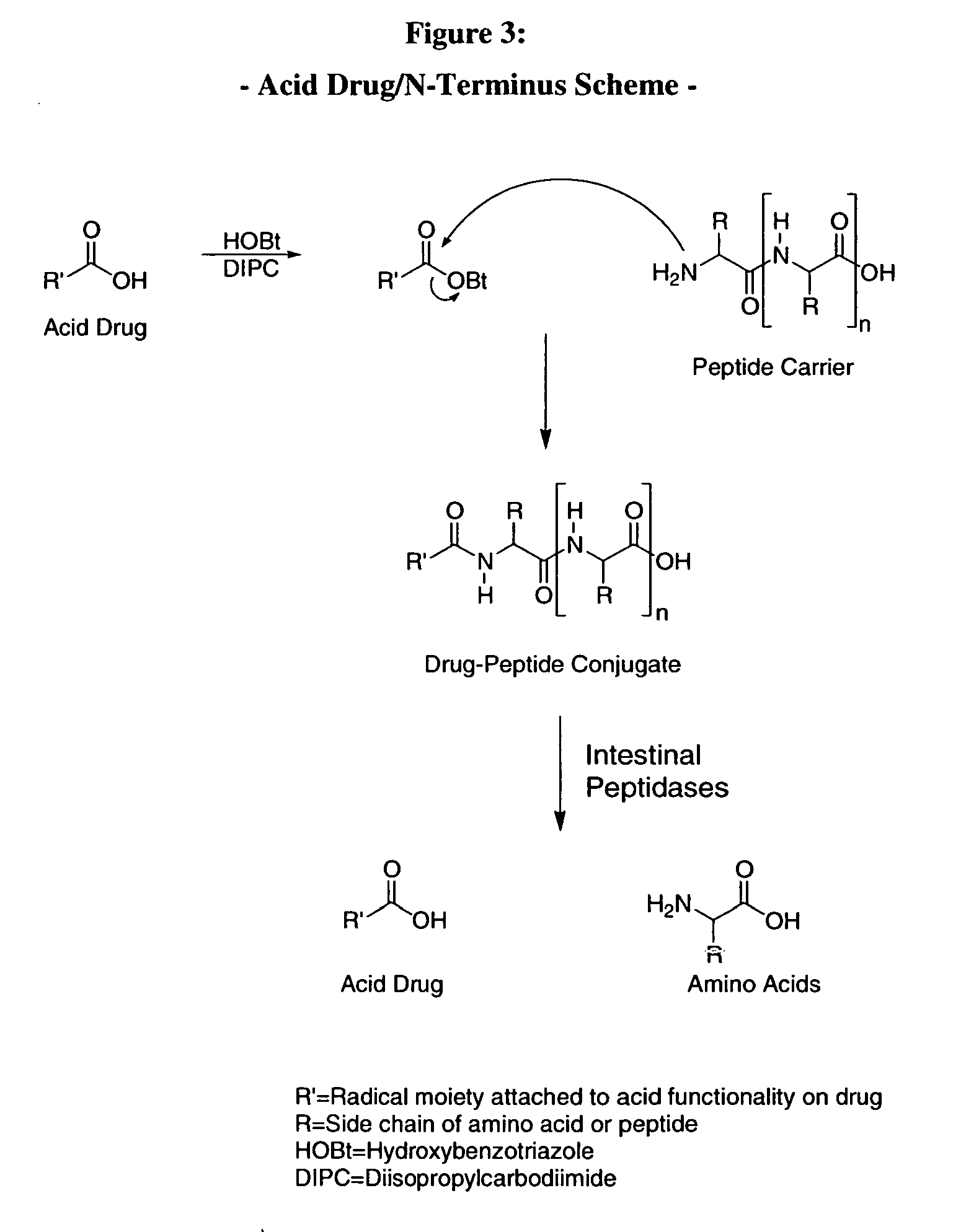

Active agent delivery systems and methods for protecting and administering active agents

The present invention relates to active agent delivery systems and more specifically to compositions that comprise amino acids, as single amino acids or peptides, covalently attached to active agents and methods for administering conjugated active agent compositions.

Owner:TAKEDA PHARMACEUTICA CO LTD

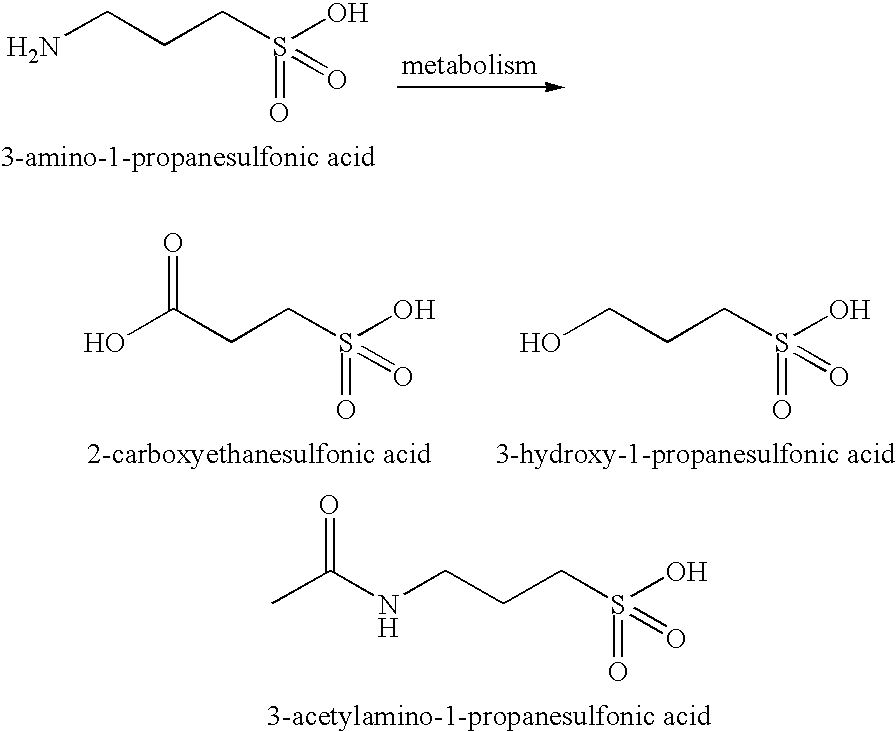

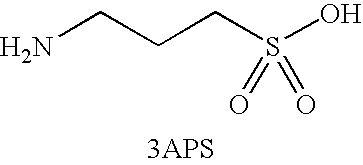

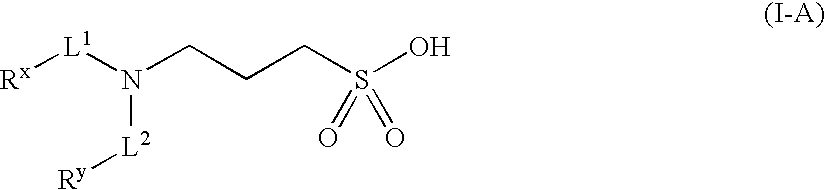

Methods, compounds, compositions and vehicles for delivering 3-amino-1-propanesulfonic acid

ActiveUS20080146642A1Increase bioavailabilityIncrease absorptionBiocideNervous disorderAmino acidDisease

The invention relates to methods, compounds, compositions and vehicles for delivering 3-amino-1-propanesulfonic acid (3APS) in a subject, preferably a human subject. The invention encompasses compounds that will yield or generate 3APS, either in vitro or in vivo. Preferred compounds include amino acid prodrugs of 3APS for use, including but not limited to, the prevention and treatment of Alzheimer's disease.

Owner:BHI

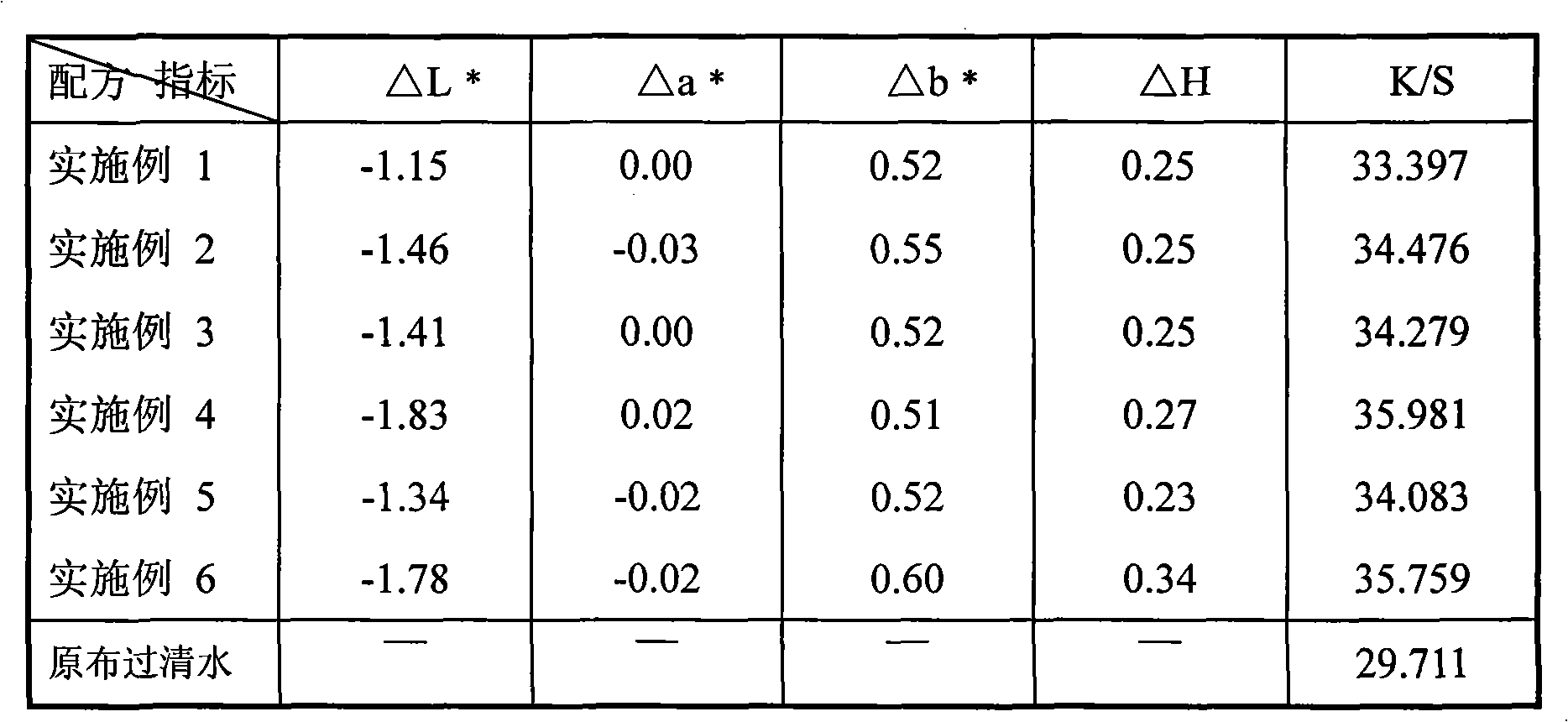

Fibre deep-dyeing agent emulsions and manufacture method thereof

InactiveCN101255657AIncrease the amount of light absorbedIncrease absorptionFibre typesIonFunctional monomer

The invention discloses a fiber deeper emulsion, which includes (according to weight): 20-40% vinyl monomer, 0.2-4% hydroxyl silicone oil, 0.001-2% reactive functional monomer, 0.5-5% emulsifier, 0.05-1% initiator, 50-80% de-ionized water and is prepared by a semi-continuous seeding emulsion polymerization technology. The invention is characterized in that the particle size of the fiber deeper emulsion is small, the amount of the emulsifier used is small, and the reaction process is easy to control and not to pollute the environment. The fiber fabric processed by the deeper emulsion has the advantages of deep color, wash durability, bearing dry cleaning, inhibiting whitening and smooth feeling, etc.

Owner:ZHEJIANG UNIV

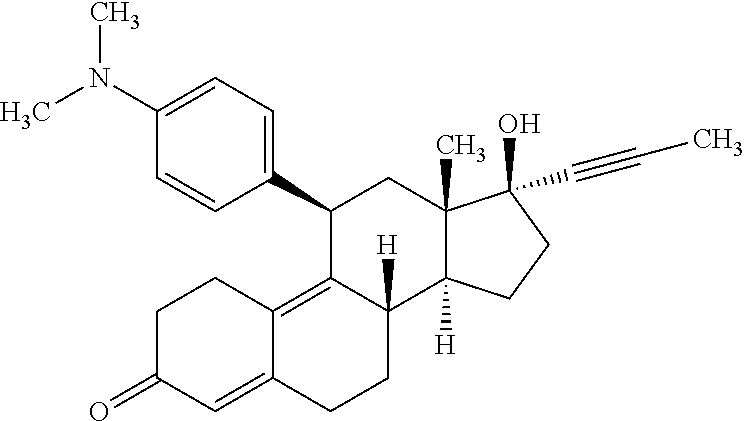

Optimizing mifepristone absorption

ActiveUS20130131030A1Increase absorptionImprove absorptionOrganic active ingredientsIntrathecalDisease

The present invention provides a method for altering the pharmacokinetics of mifepristone upon oral administration. Mifepristone absorption into the blood is increased upon administration with meals. The method of the invention can benefit patients suffering from conditions including psychiatric illnesses and hormonal disorders.

Owner:CORCEPT THERAPEUTICS INC

Method for preparing vitamin D calcium soft capsules

InactiveCN102125581APromotes calcium absorptionIncrease absorptionOrganic active ingredientsMetabolism disorderGramMineral oil

The invention discloses a method for preparing vitamin D calcium soft capsules. For effectively absorbing calcium, the human body needs to have sufficient vitamin D. Usually, people thick the vitamin D can thick the vitamin D can be completely acquired from sunlight, but the it is not the case in face. Suppose sunscreen cream applied can greatly reduce the generation of vitamin D, vitamin D is basically not generated in parts covered by clothes. Thus, vitamin D shortage is inevitable particularly when females who love beauty are so reluctant to act in sunlight for fear of being black in sunlight. Meanwhile, mineral oil and smoke are also enemies of vitamin D. The formula of the vitamin D calcium soft capsules comprises the following components: 500 grams of calcium carbonate powder, 0.05 gram of vitamin D3, 460 grams of soybean salad oil, 20 grams of soyabean lecithin and 20 grams of beewax. The vitamin D calcium soft capsules are used for supply calcium to human bodies.

Owner:哈尔滨顺亿堂医药生物科技开发有限公司

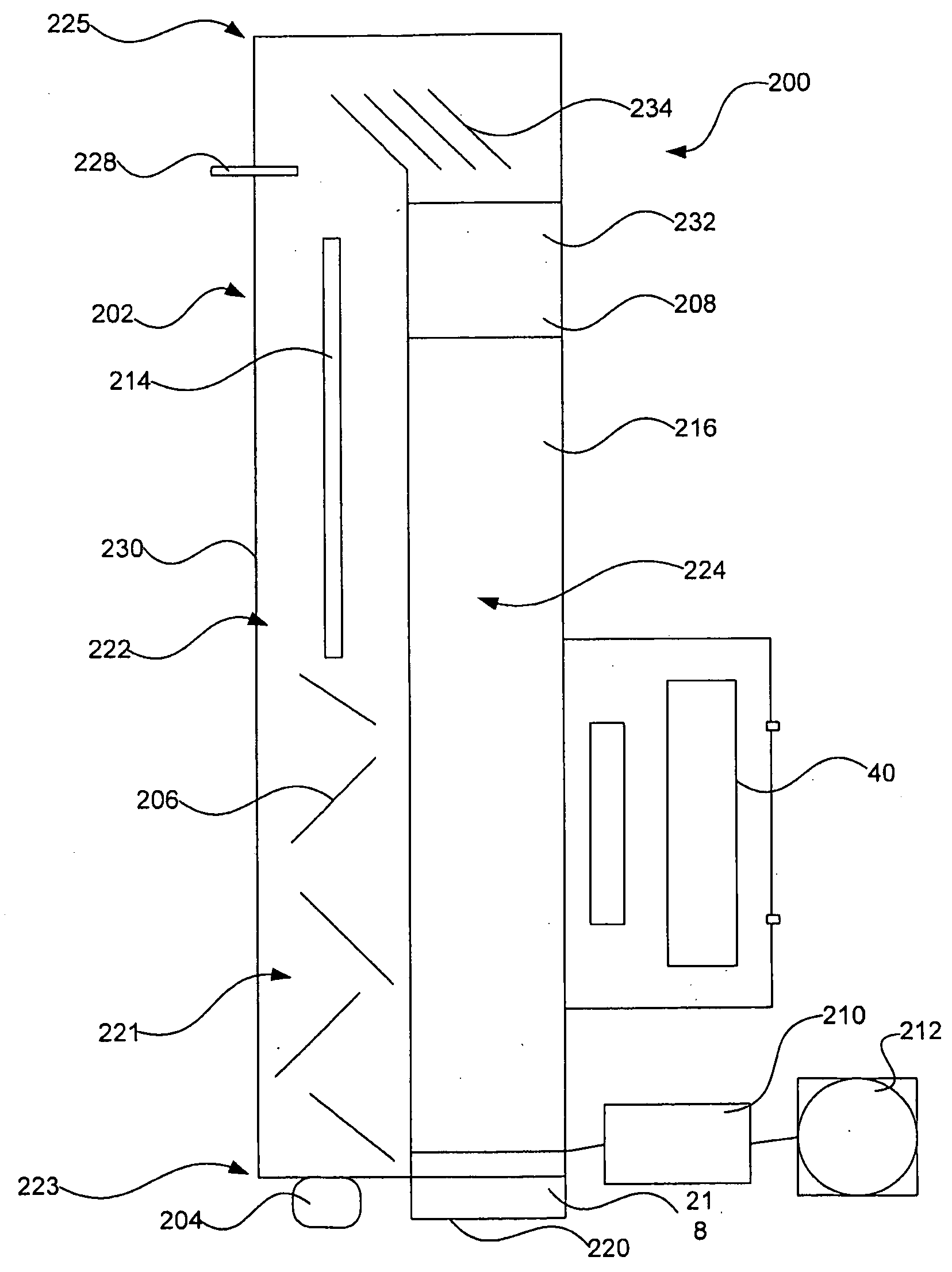

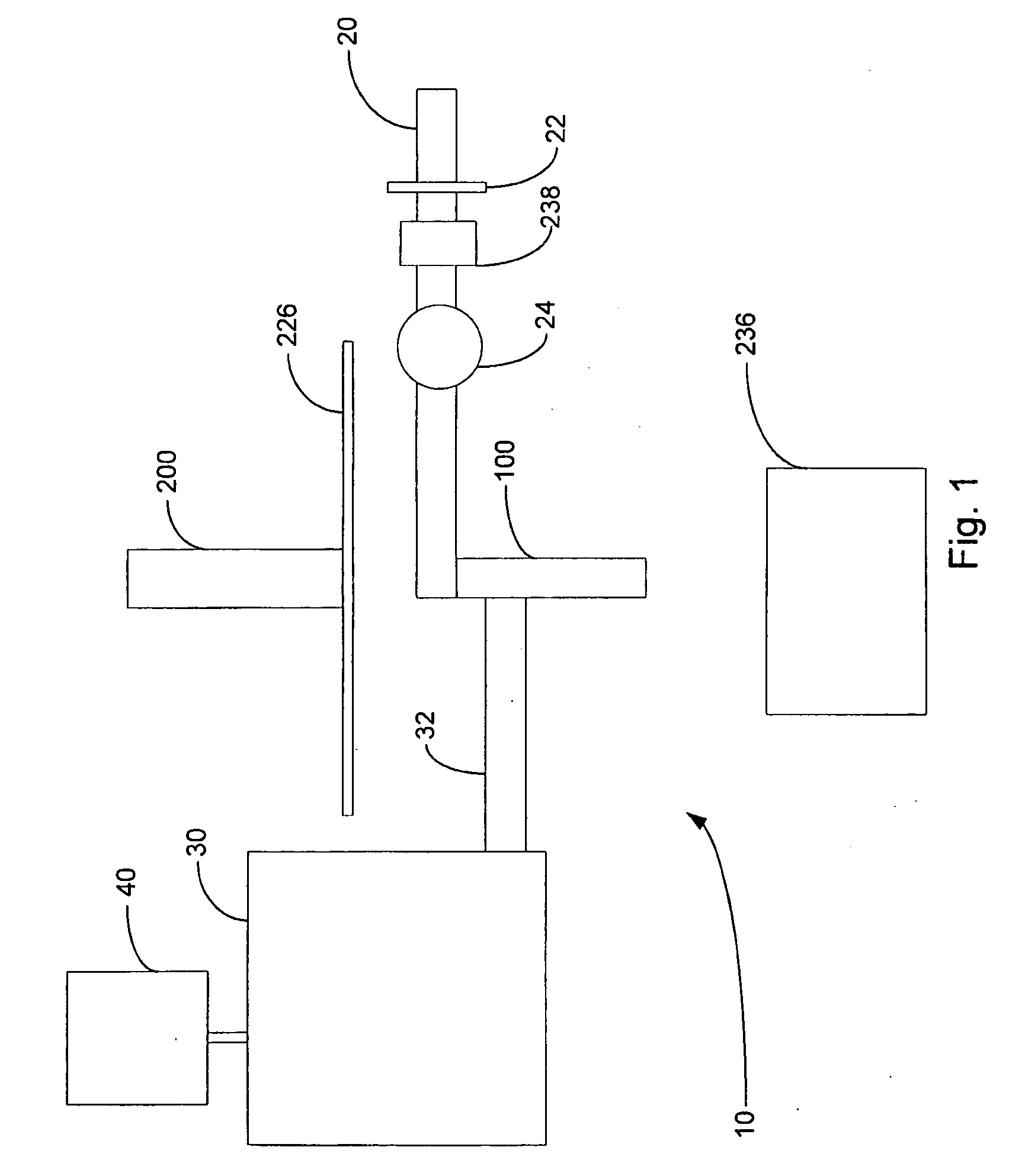

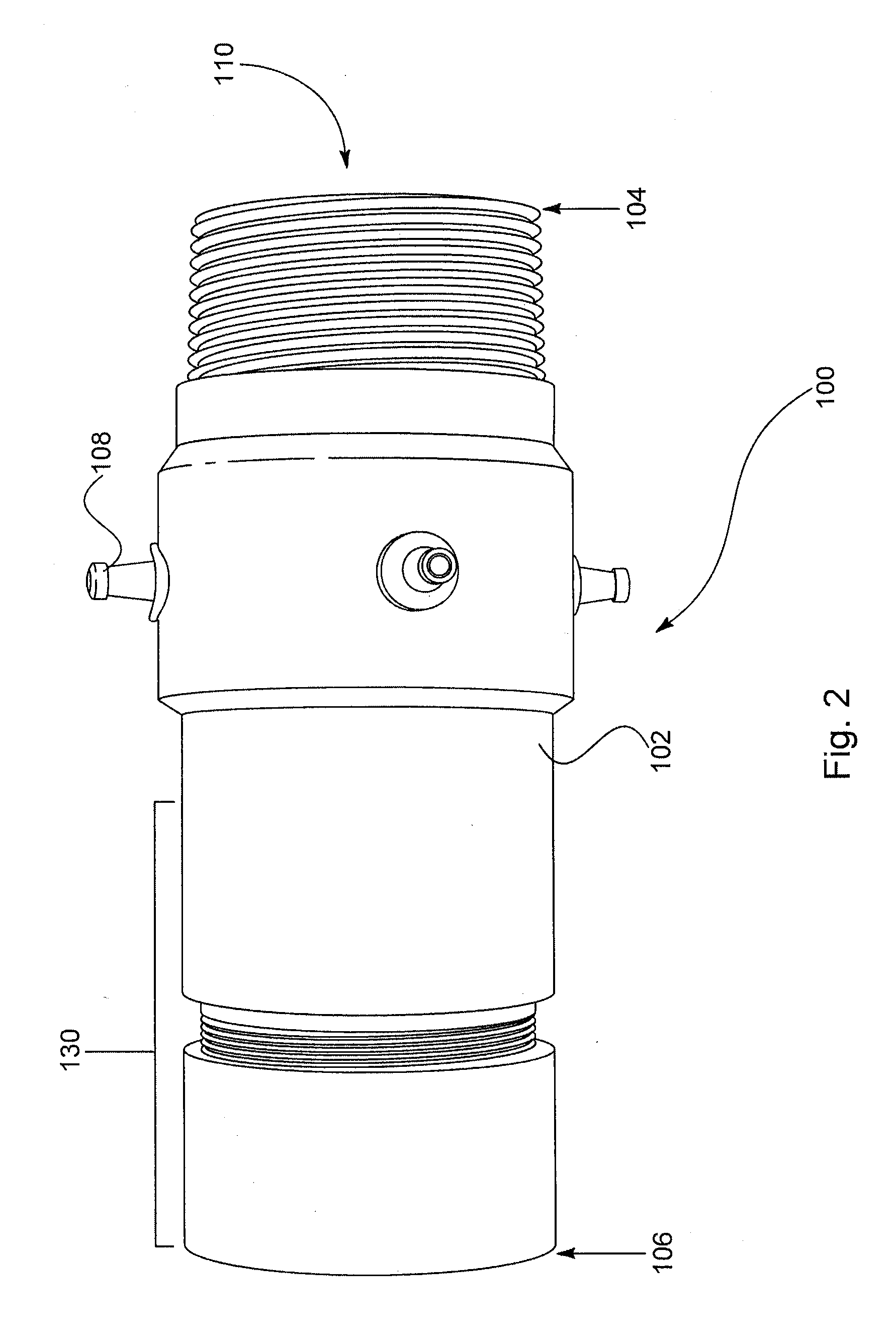

Systems and methods for producing ozonated water on demand

ActiveUS20090072052A1Increase mixingIncrease absorptionBurnersFlow mixersAqueous solutionSingle pass

Systems and methods for producing ozonated water on demand. In particular, these systems comprise a water source, an ozone source, and a nozzle that mixes ozone and water to form a highly concentrated, ozonated water solution. Instead of requiring the ozonated water to be re-circulated to achieve a desired ozone concentration, the nozzle is configured to form the ozonated water solution in a single pass through the nozzle. Additionally, instead of requiring the ozonated water to be discharged into a pressurized tank to increase ozone absorption, the nozzle allows the ozonated water to be openly discharged. In some cases, the nozzle comprises a venturi with multiple ozone inlets to increase mixing. Additionally, in some cases the nozzle comprises a single pass mixing mechanism that mixes the water and ozone to form the high concentrate, ozonated water solution in a single pass through the nozzle.

Owner:GILLETTE THOMAS D

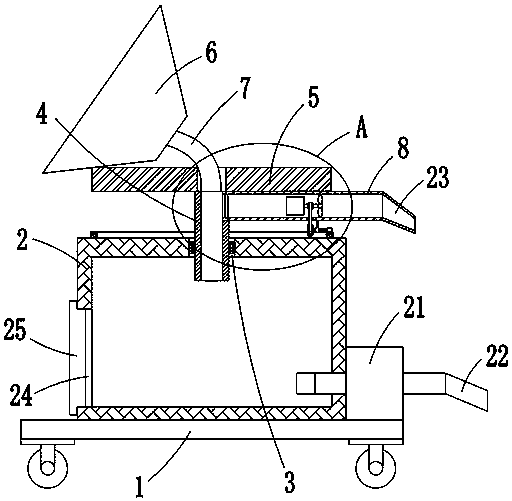

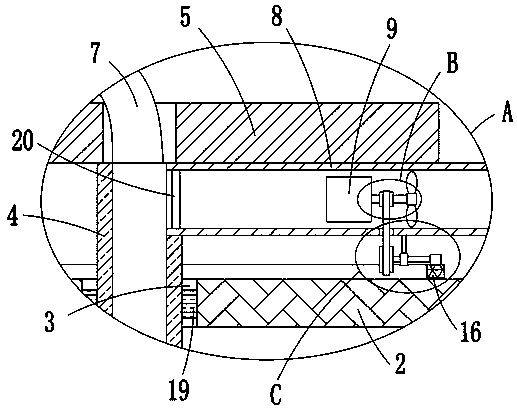

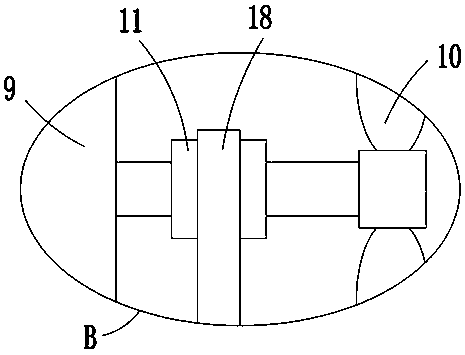

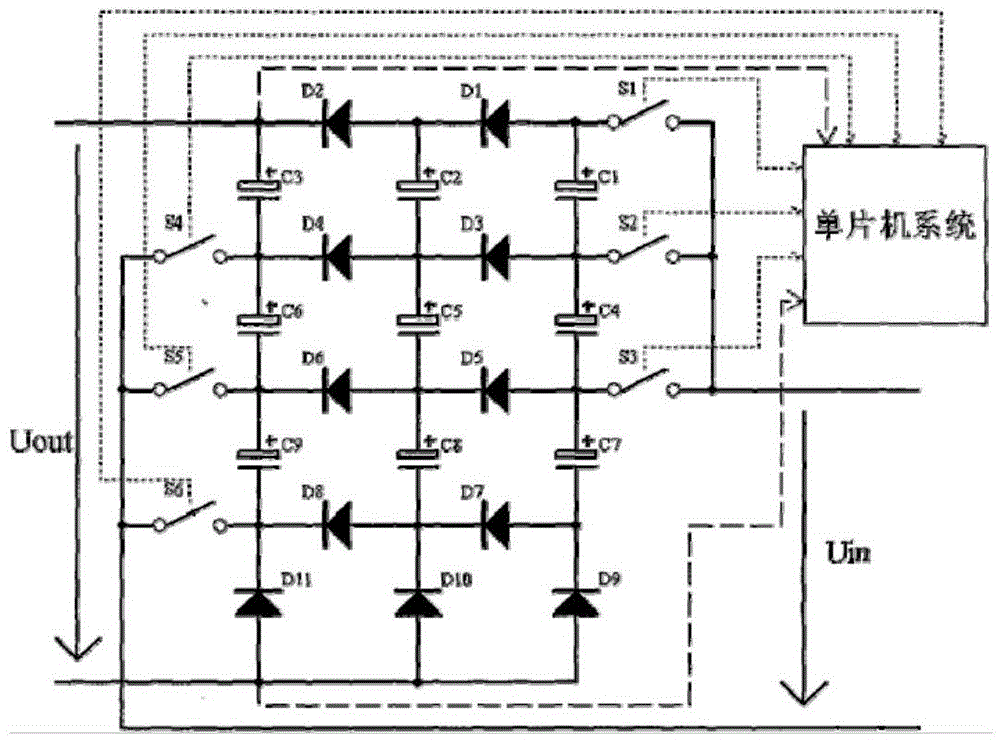

Electrical automatic dust removal equipment

ActiveCN109530333AIncrease absorptionAvoid enteringDispersed particle filtrationDirt cleaningSteel tubeTurning frames

The invention discloses electrical automatic dust removal equipment comprising a frame. The top of the frame is fixedly connected with a dust collecting box, and the inner wall of the top side of thedust collecting box is provided with a rotating hole which is internally provided with a steel pipe rotatably; the top end of the steel pipe extends to the position above the dust collecting box, andwelded with a rotating rod, and one side of the top of the rotating rod is fixedly provided with a dust hood located on one side of the steel pipe; one side of the bottom of the rotating rod is weldedwith a first pipe located on the other side of the steel pipe, and the first pipe communicates with the steel pipe; and the dust hood is fixedly connected with one end of a corrugated pipe. The electrical automatic dust removal equipment has the advantages of rational design, high practicability and convenient control, and facilitates driving the dust hood and a first nozzle to rotate, thereby raising dust on the ground; and the dust can be sucked into the dust hood through an air pump and fan blades greatly, and the electrical automatic dust removal equipment benefits dust removal for spacewith lots of dust.

Owner:JIANGSU SECURITY TECH CARRER ACADEMY

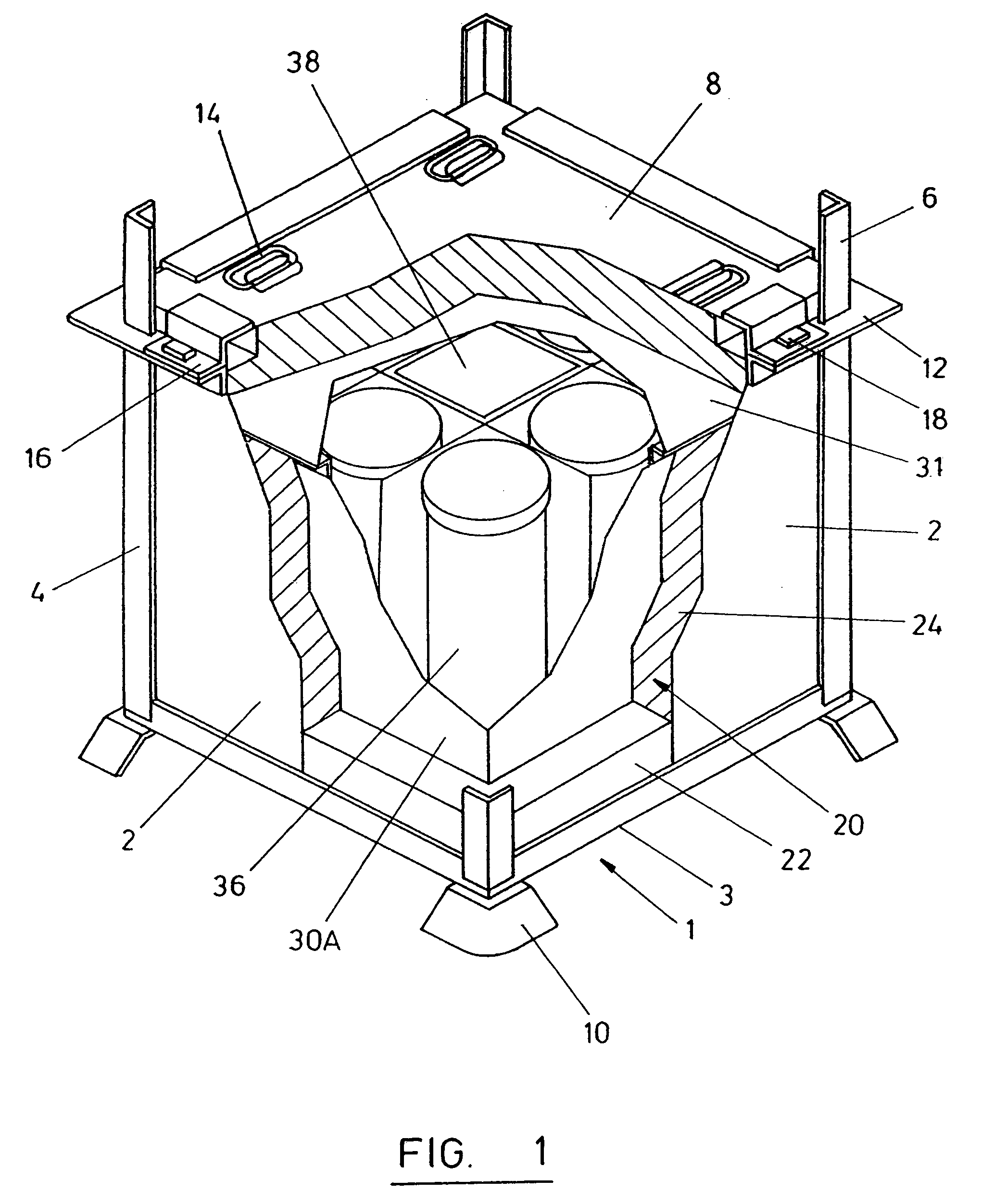

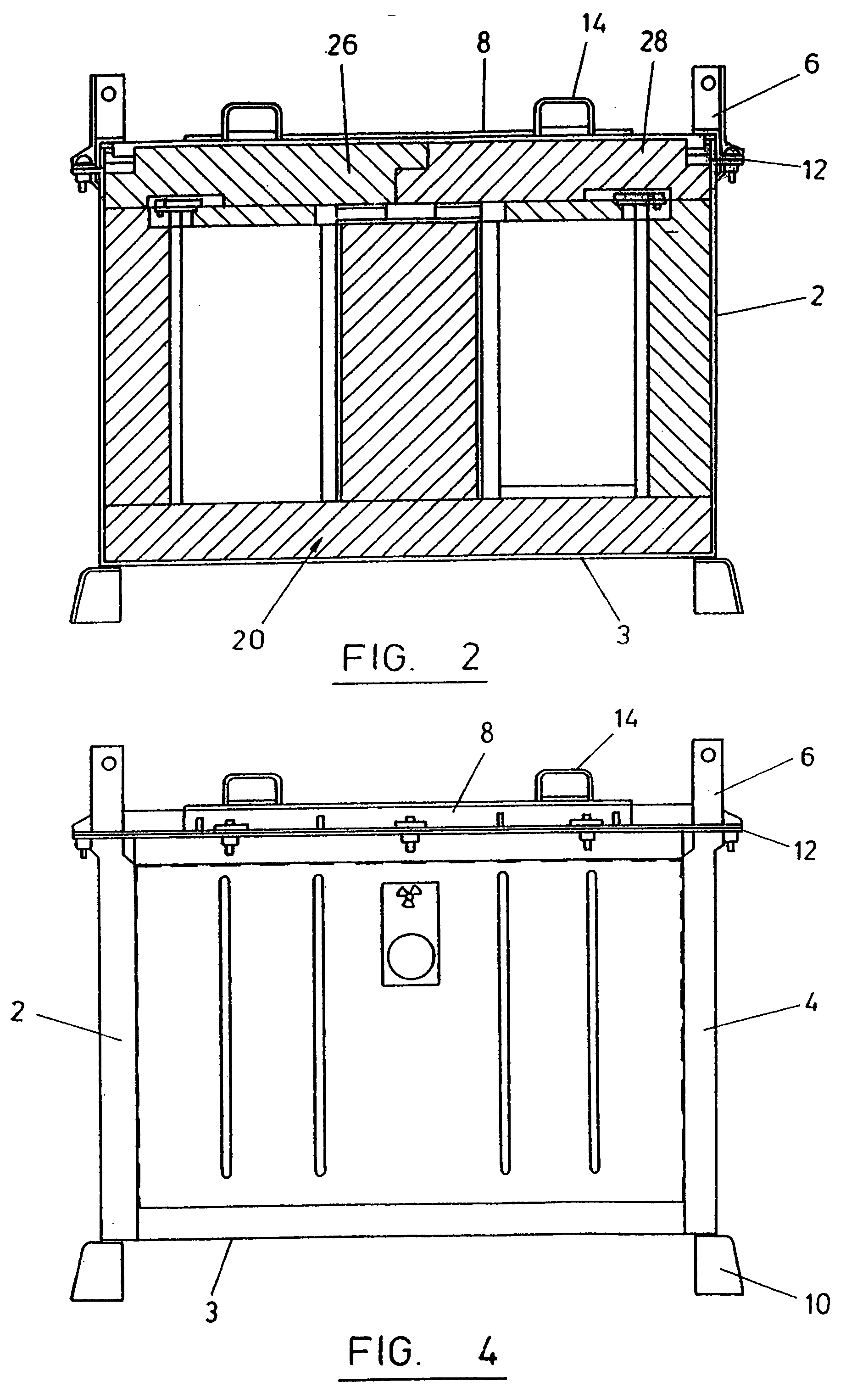

Container for nuclear fuel transportation

InactiveUS20060043320A1Increase absorptionLow costNuclear energy generationNuclear engineering problemsInternal cavityShipping container

A transport container for nuclear fuel is provided with an outer container having internal insulation, the insulation defining an internal cavity. The cavity receives a plurality of fuel containers wherein the internal volume of the fuel containers is at least 5% of the external volume of the outer container. The container allows substantially higher volume proportions of enriched fuel to be safely transported than is possible with prior containers.

Owner:URANIUM ASSET MANAGEMENT

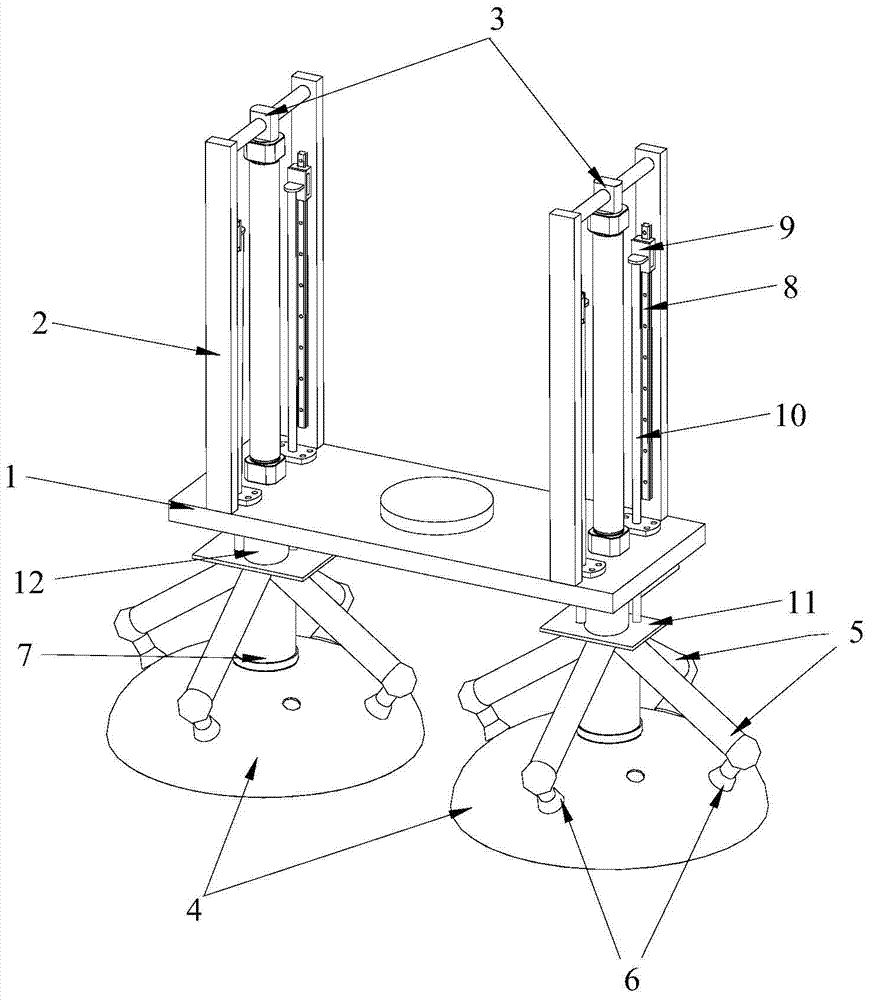

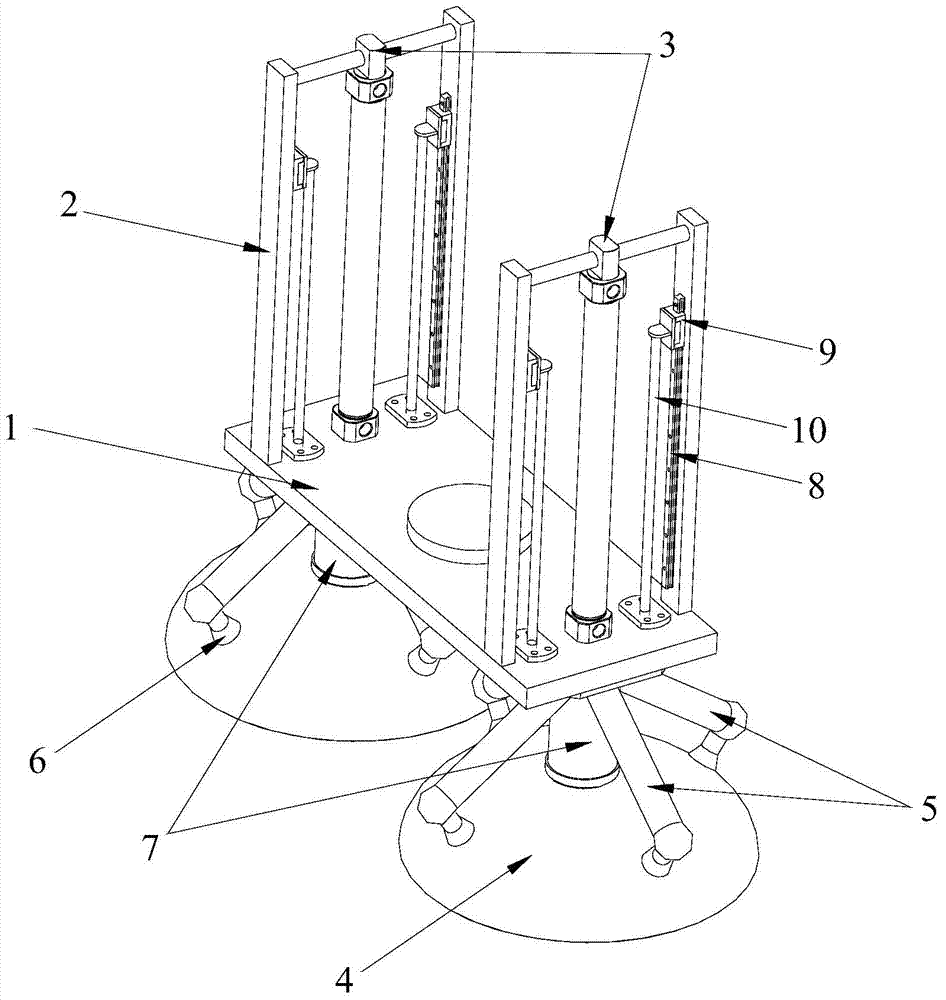

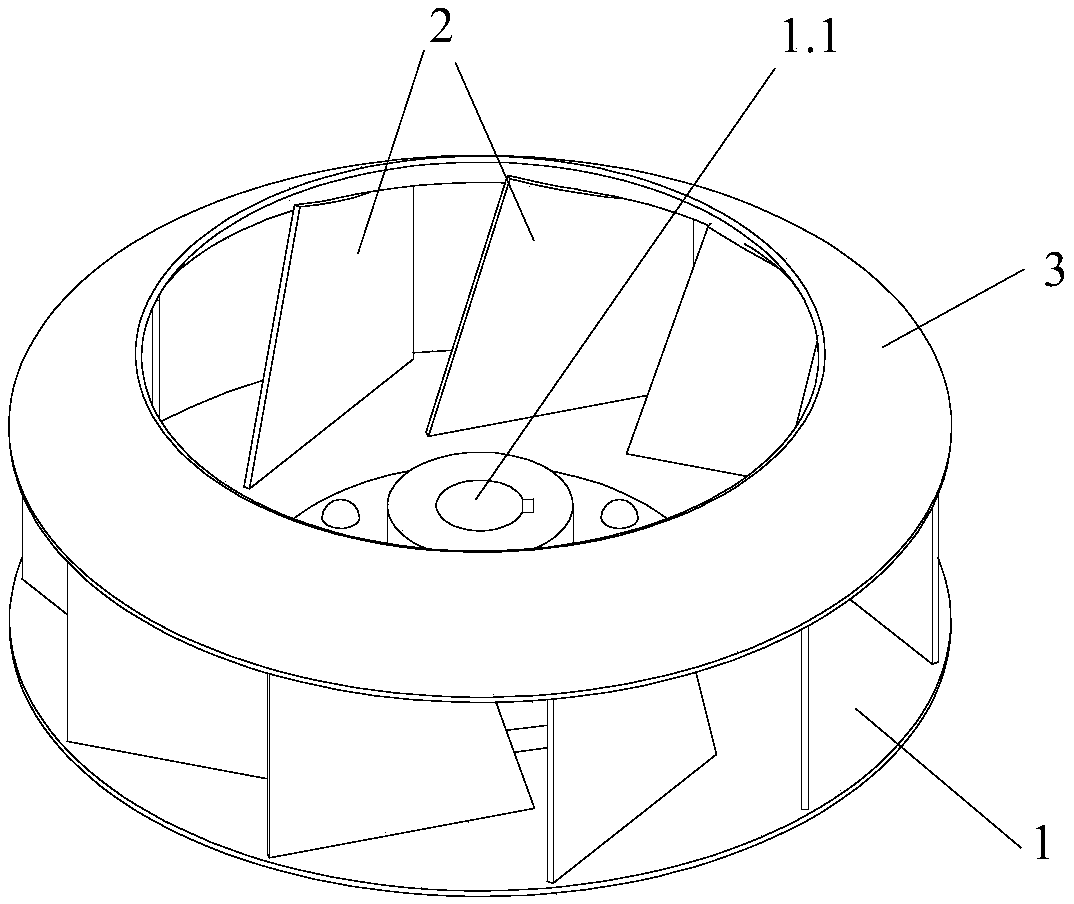

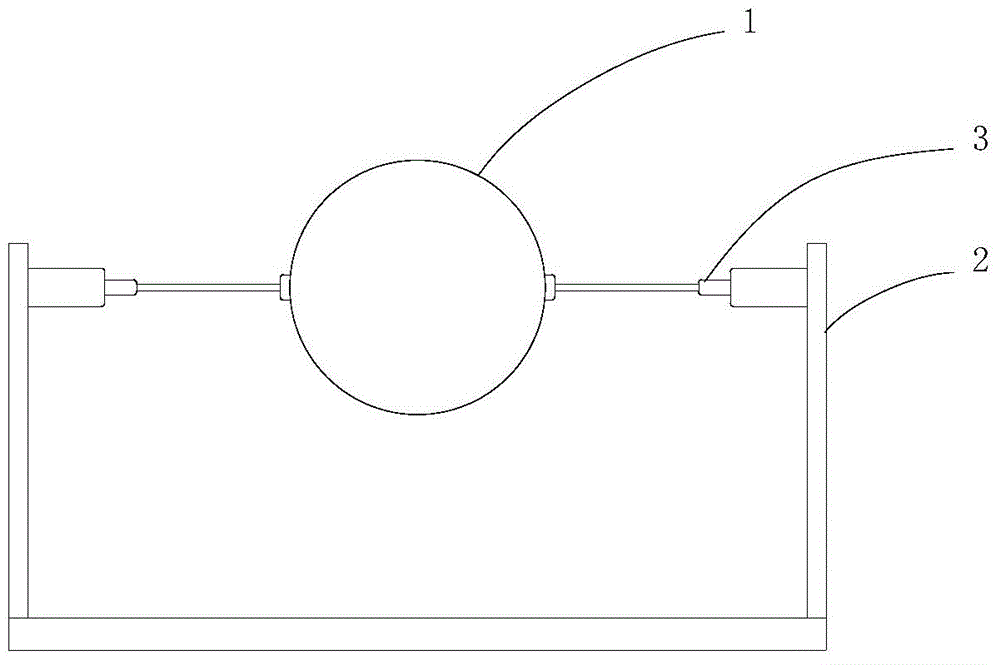

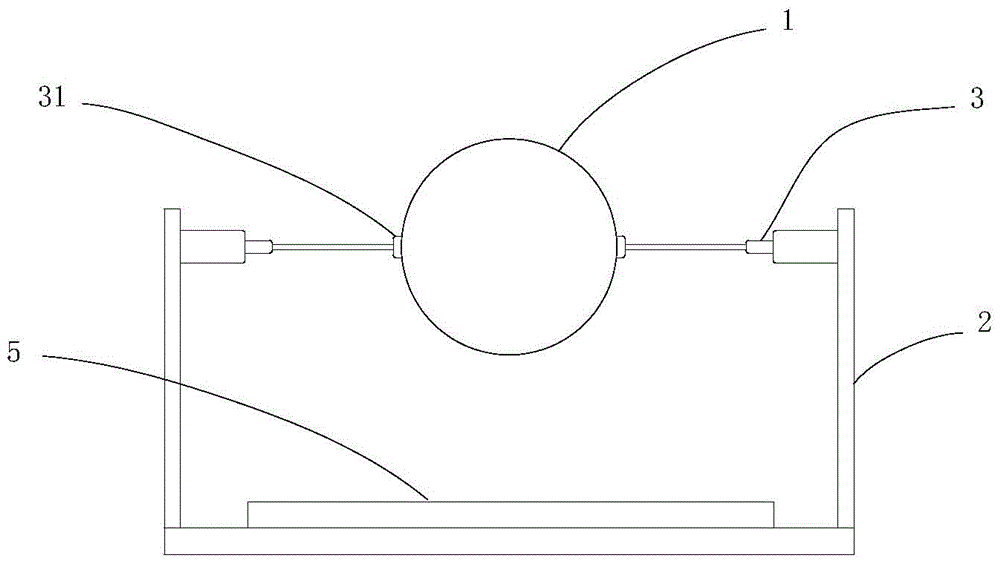

Suction type robot hand grab applied to circular arc surface workpieces

ActiveCN104772763AImprove gripIncrease absorptionGripping headsStacking articlesRobot handEngineering

The invention provides a suction type robot hand grab applied to circular arc surface workpieces. The suction type robot hand grab is arranged at the movable end of a robot, and is used for grabbing the circular arc surface workpieces. The hand grab comprises a connecting plate connected with the movable end of the robot and more than one bracket arranged on the connecting plate, wherein each bracket is provided with a driving device and a suction unit connected with the driving device; the driving devices are arranged on the brackets, and pushing parts of the driving devices are connected with the suction units; the suction units are arranged at the bottom of the connecting plate; suction points of the suction units and the workpieces are circumferentially distributed in a manner that the centers of the workpieces are centers of circles. The suction type robot hand grab applied to the circular arc surface workpieces is simple and compact in structure, high in universality and applicable to circular arc surface workpieces in different specifications; the workpieces can be stably grabbed in a rapid movement process of the robot, so that the problem about match between the hand grab and the workpieces is effectively solved, the grabbing balance and stability of the hand grab are improved, and production efficiency is improved.

Owner:广东泰格威机器人科技有限公司

Optical devices, systems and methods

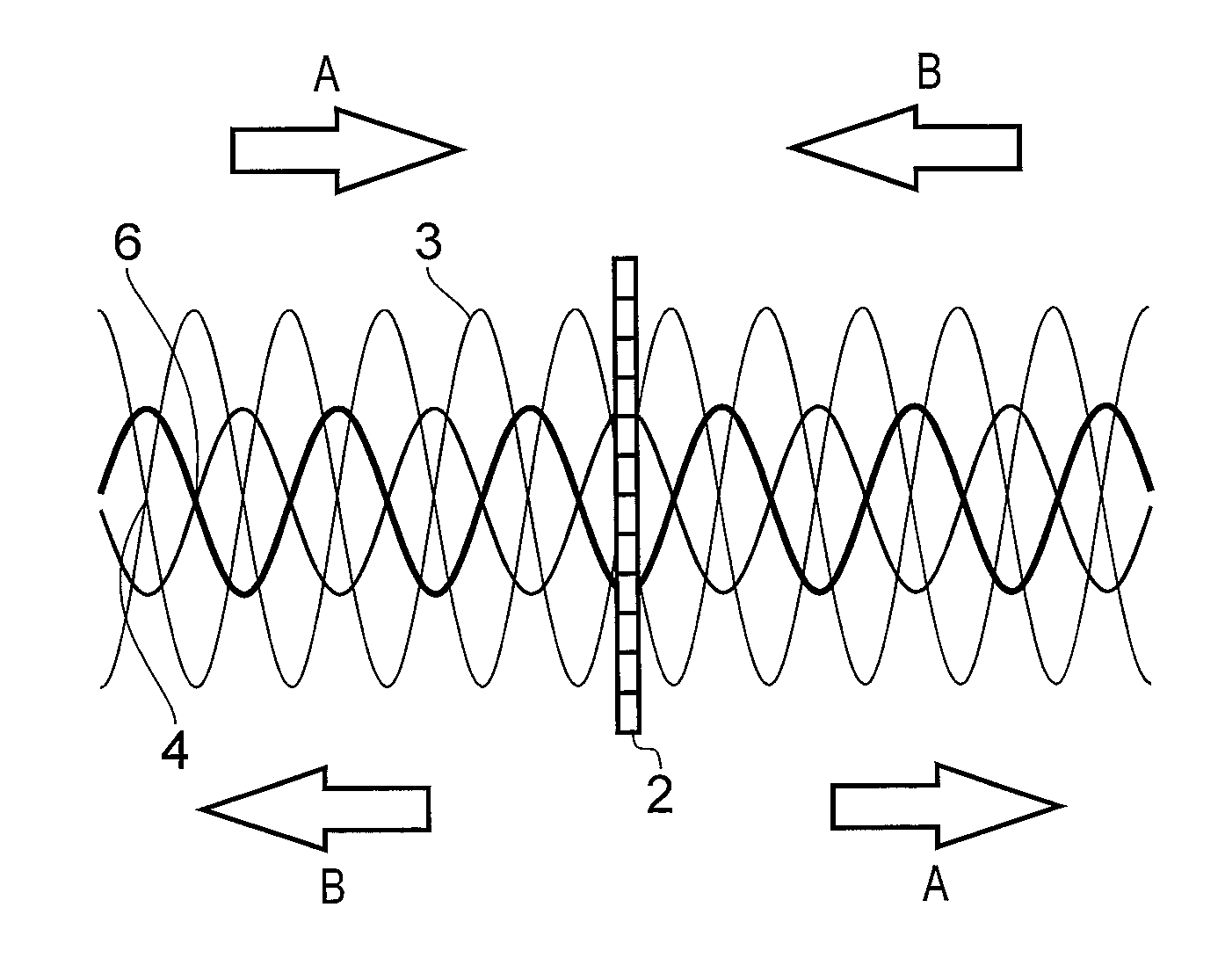

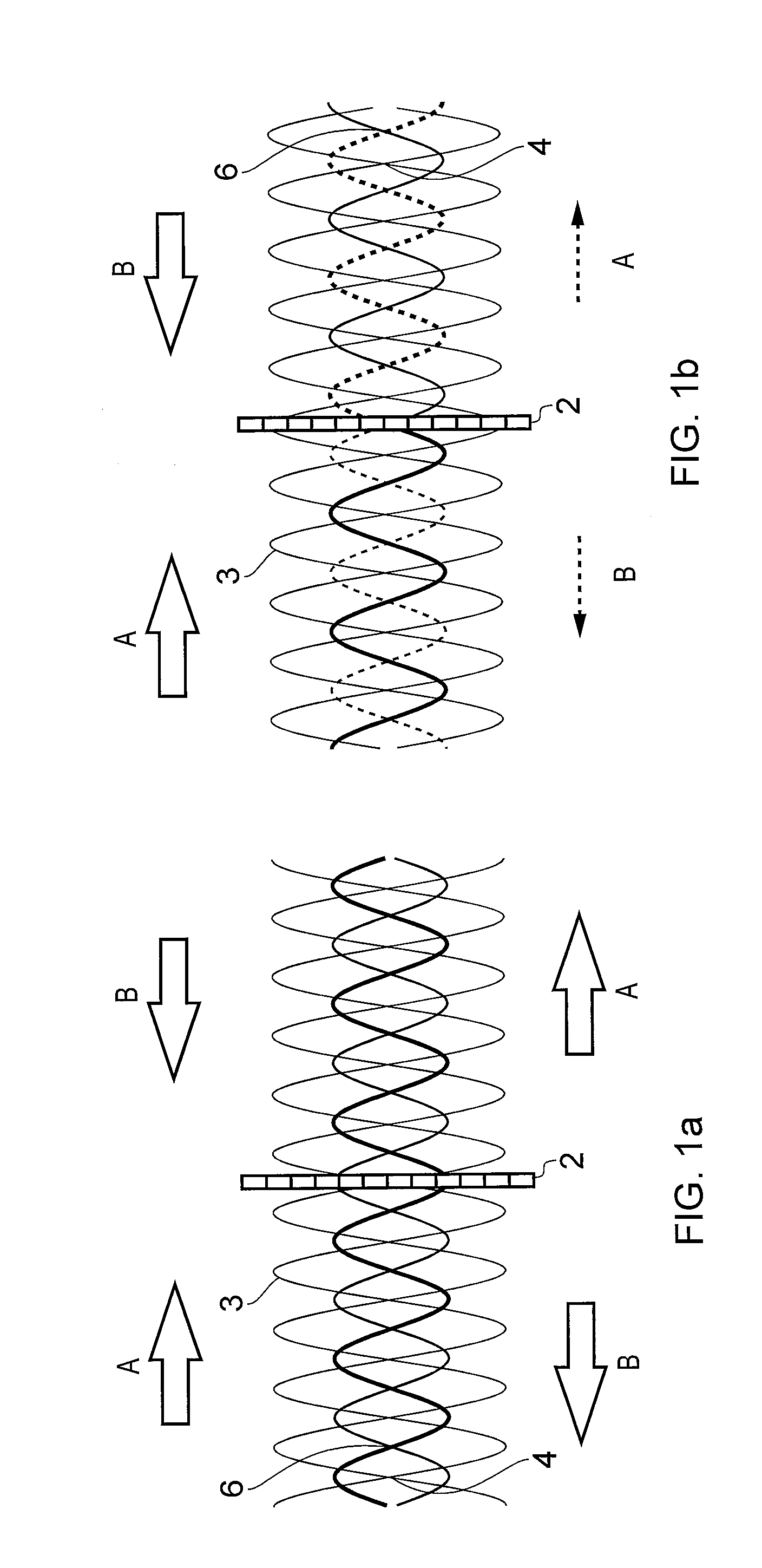

InactiveUS20150049377A1Increase absorptionTransmission controlNon-linear opticsOptical elementsPhasonLight beam

First and second coherent light beams of the same wavelength are propagated in opposite directions to interact on a sub-wavelength thickness metallic metamaterial layer which is structured with a periodicity such that there is a resonance matched to the wavelength of the coherent beams. The first beam is then able to modulate the intensity of the second beam by modulating the phase and / or intensity of the first beam. The interference of the counter- propagating beams can eliminate or substantially reduce Joule loss of light energy in the metamaterial layer or, on the contrary, can lead to a near total absorption of light, depending on the mutual phase and / or intensity of the interacting beams. A modulation is thus provided without using a non-linear effect.

Owner:UNIV OF SOUTHAMPTON

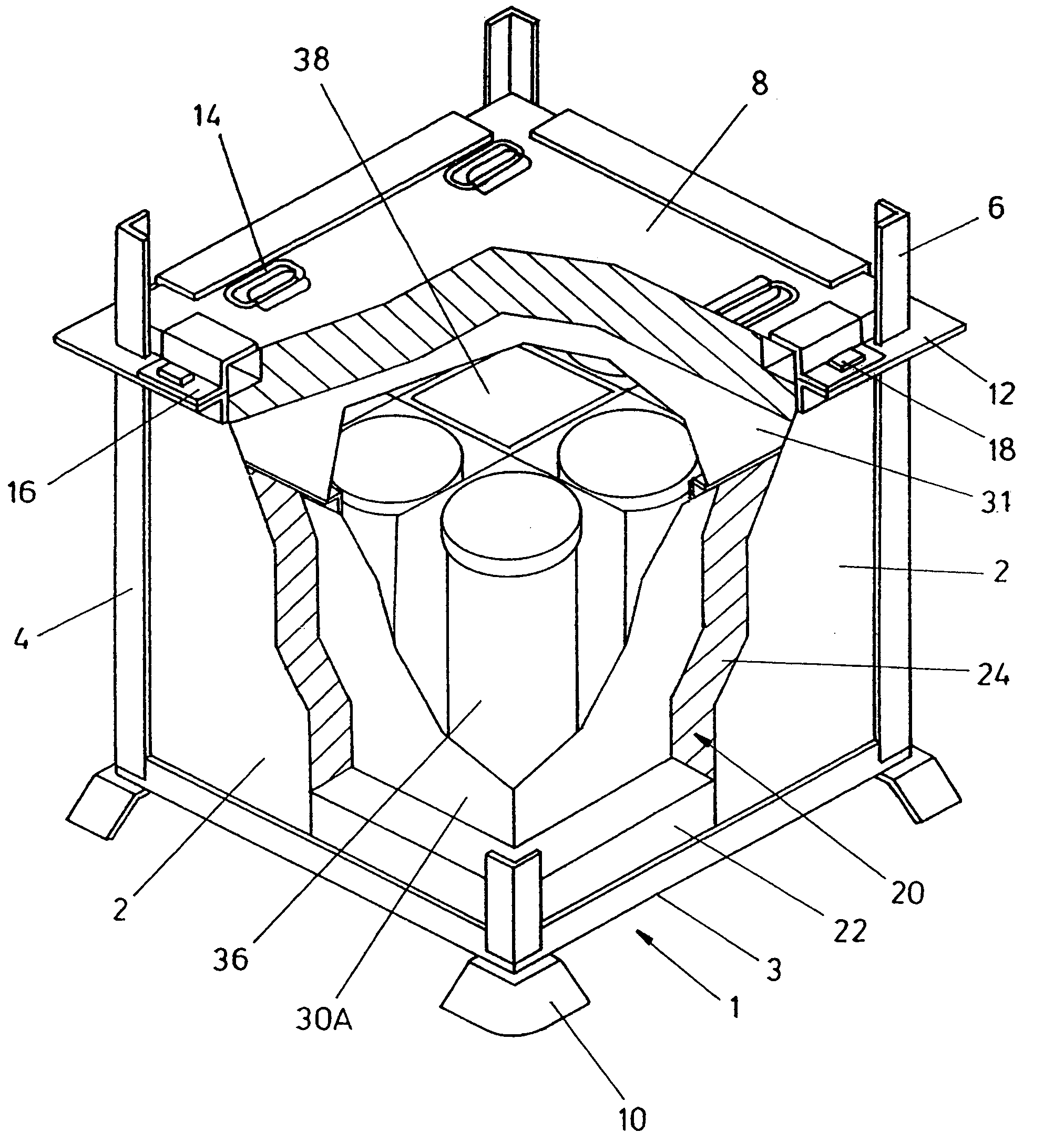

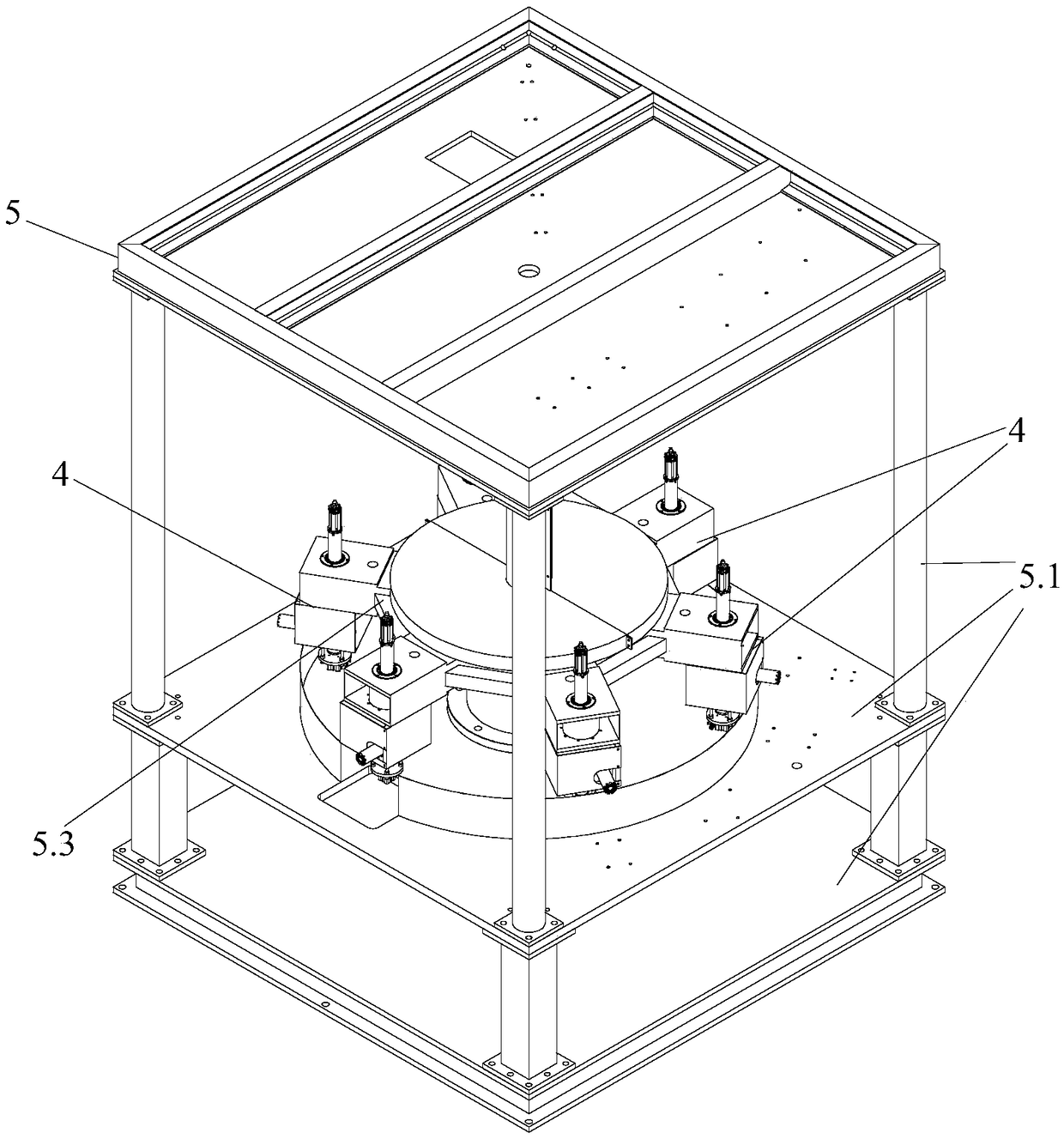

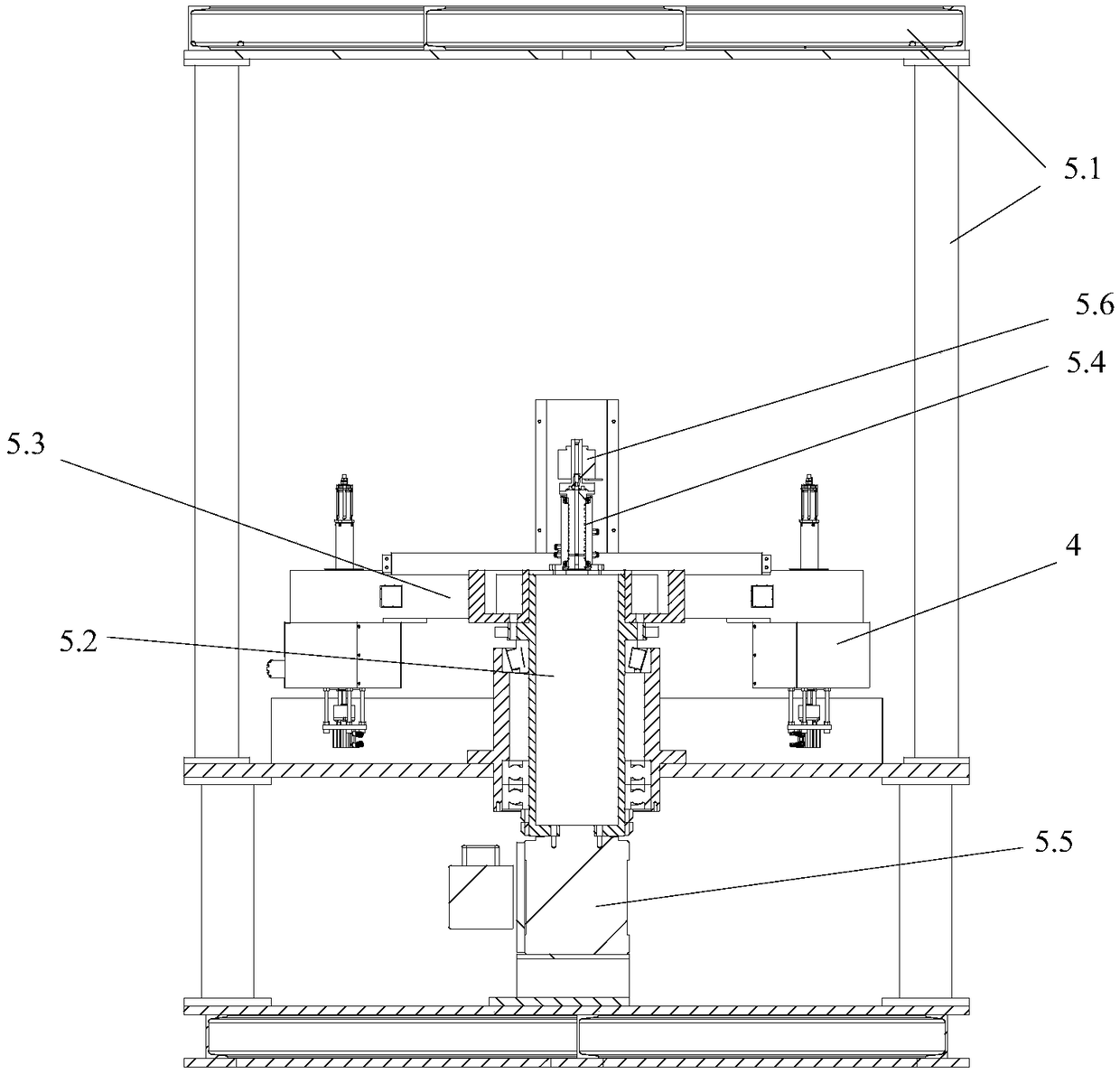

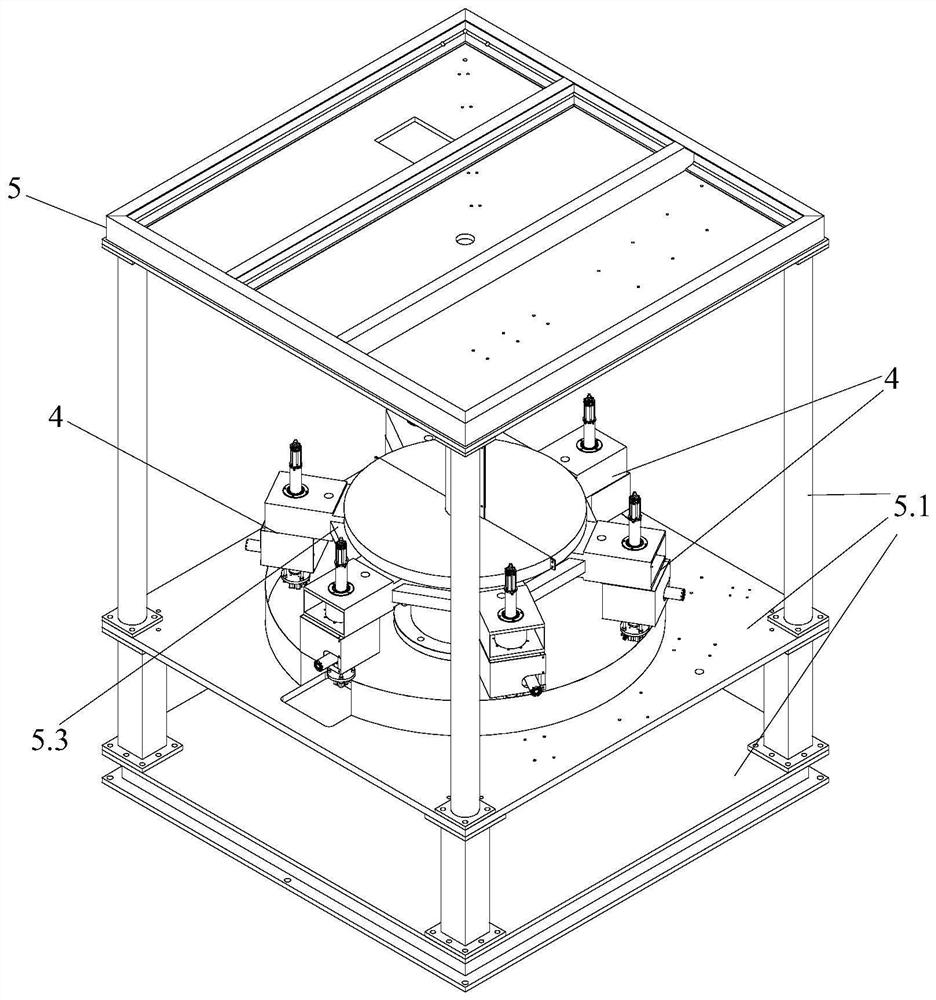

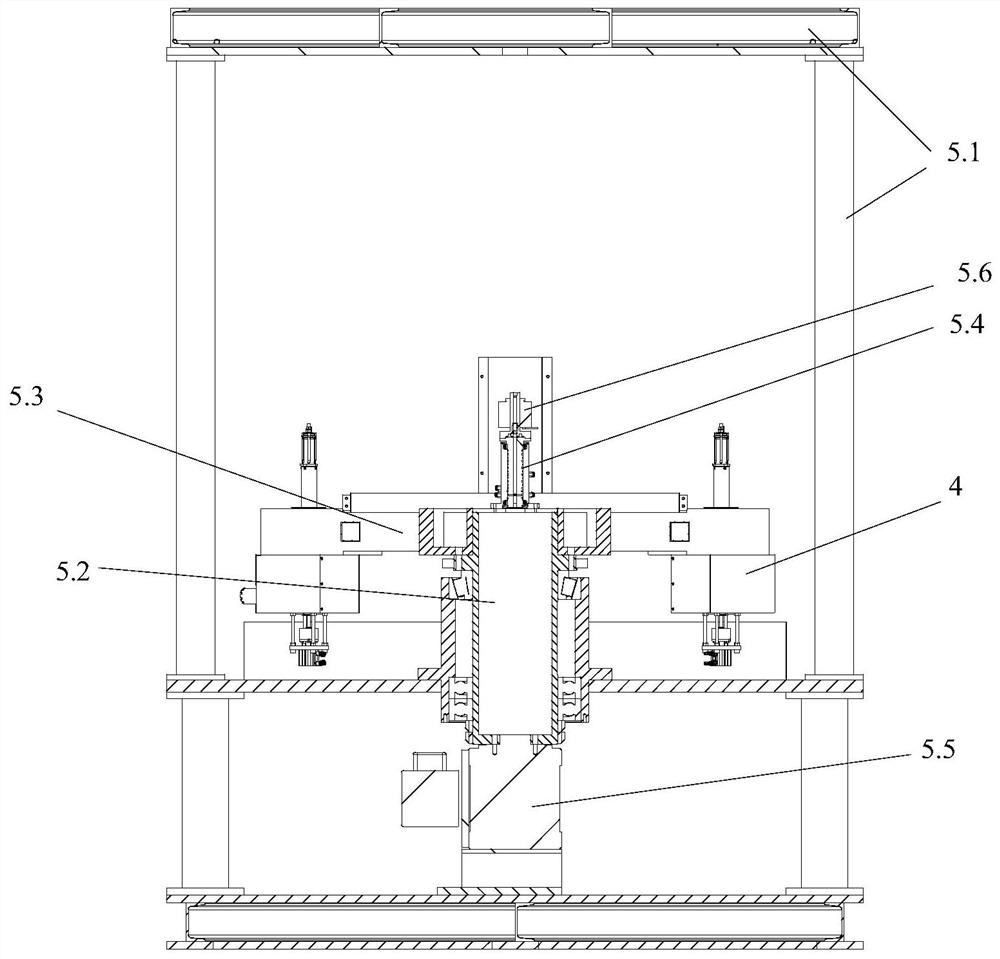

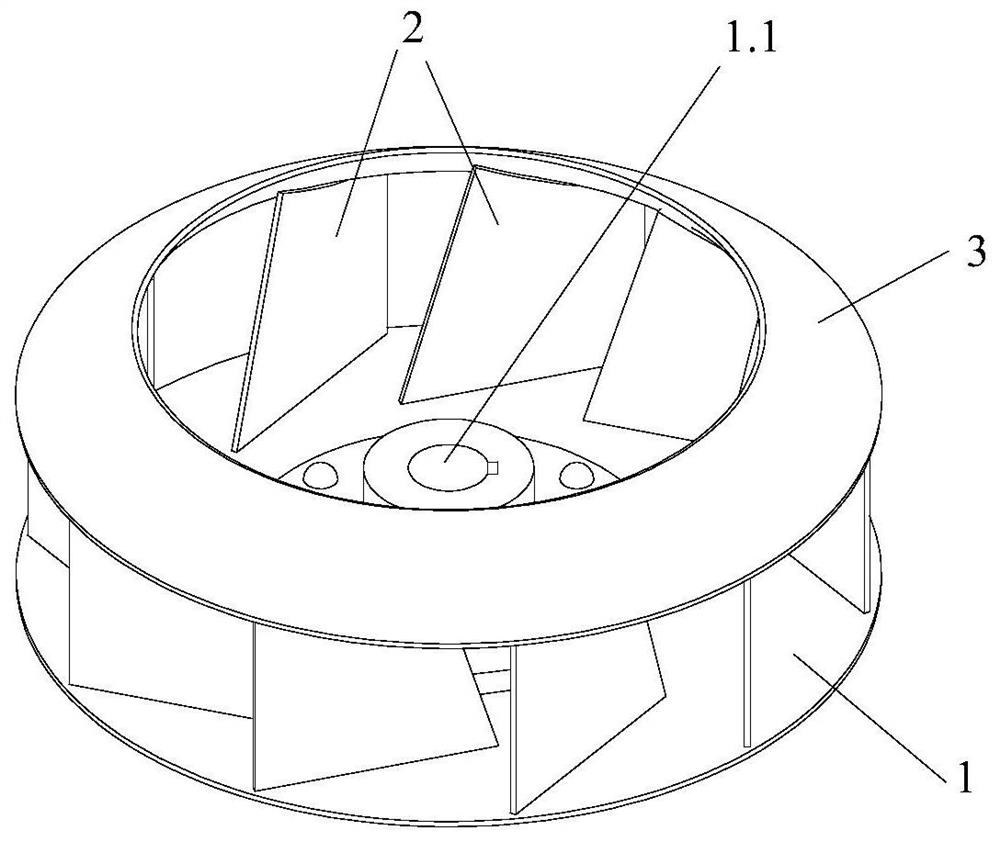

Multi-station full-automatic welding equipment for fan impeller machining

PendingCN109262189ASolve efficiency problemsImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesImpellerWork in process

The invention provides multi-station full-automatic welding equipment for fan impeller machining. The multi-station full-automatic welding equipment comprises chassis positioning mechanisms, a main frame mechanism, a blade and chassis assembling positioning mechanism located at a second machining station, a first welding mechanism used for welding blades and a chassis at a second machining station, a top cover feeding mechanism located at a third machining station, a second welding mechanism used for conducting spot welding on top covers and the blades on the third machining station, a turningmechanism located on a fifth machining station, a third welding mechanism used for conducting all welding on the turned top cover welding semi-finished products and turned blade welding semi-finishedproducts on the fifth machining station, so that a fan impeller finished product is obtained and a discharging mechanism. The chassis positioning mechanisms are separately connected with the main frame mechanism. According to production demands, full-automatic welding can be conducted on the fan impeller to replace a traditional manual welding technology, and therefore welding efficiency, weldingquality and welding precision are improved.

Owner:FOSHAN GOOGOL AUTOMATION TECH

Powdery phosphorus fertilizer as well as preparation method and using method thereof

InactiveCN104163711AIncrease absorptionImprove efficiencyFertilizer mixturesMagnesium ammonium phosphateChemistry

The invention discloses a powdery phosphorus fertilizer as well as a preparation method and a using method thereof. The preparation method is characterized by comprising the following steps: uniformly mixing magnesium ammonium phosphate, an easily-soluble phosphorus fertilizer and an acidifier; and grinding and screening the mixture, so that the granularity of the screened materials is smaller than 150 meshes. The screened powdery fertilizer coats seeds or other granulated fertilizers. Compared with the prior art, the powdery phosphorus fertilizer has the advantages that the applied range of magnesium ammonium phosphate is expanded, and the fertilizer applying efficiency of the magnesium ammonium phosphate is improved.

Owner:HUBEI FORBON TECH

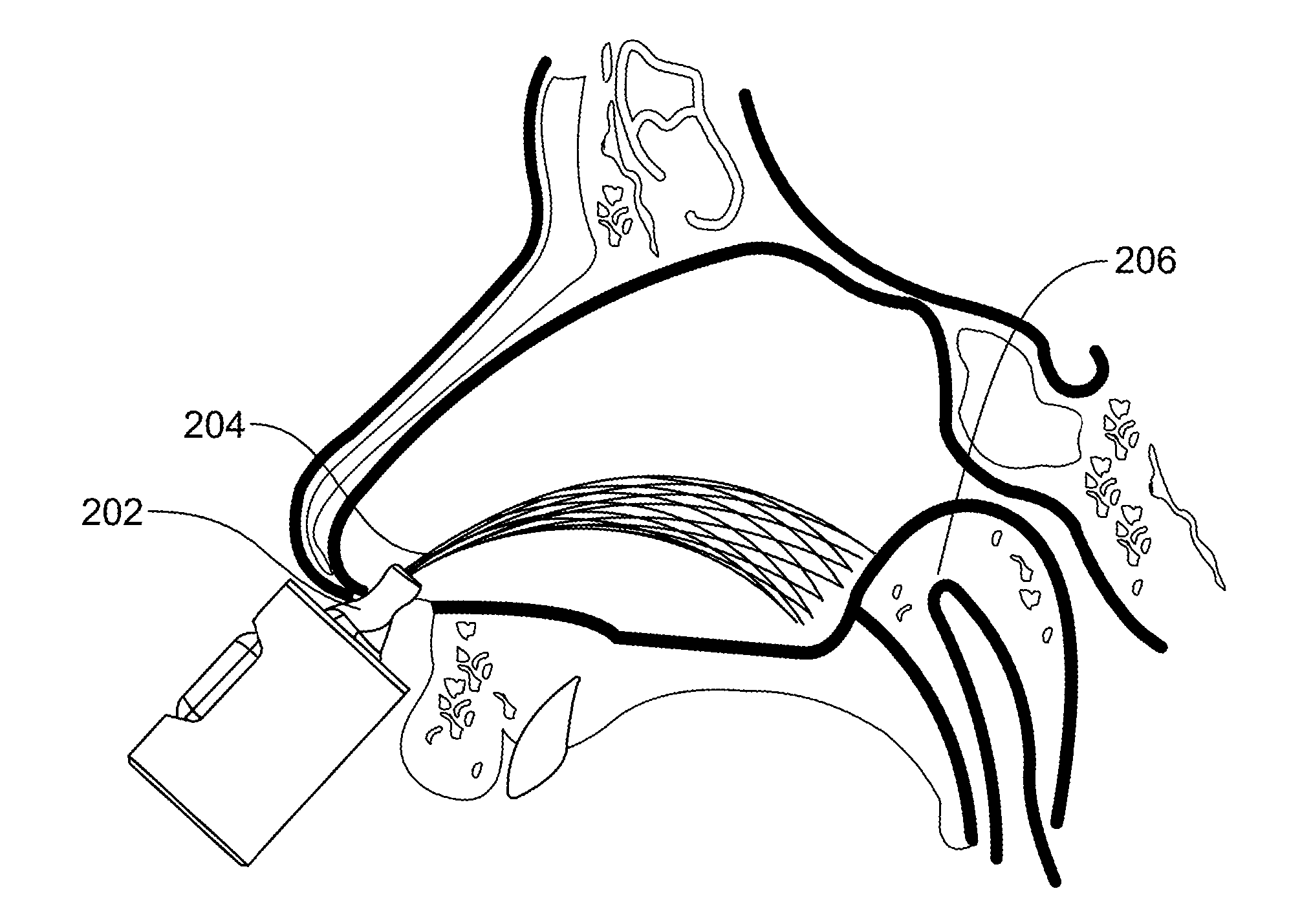

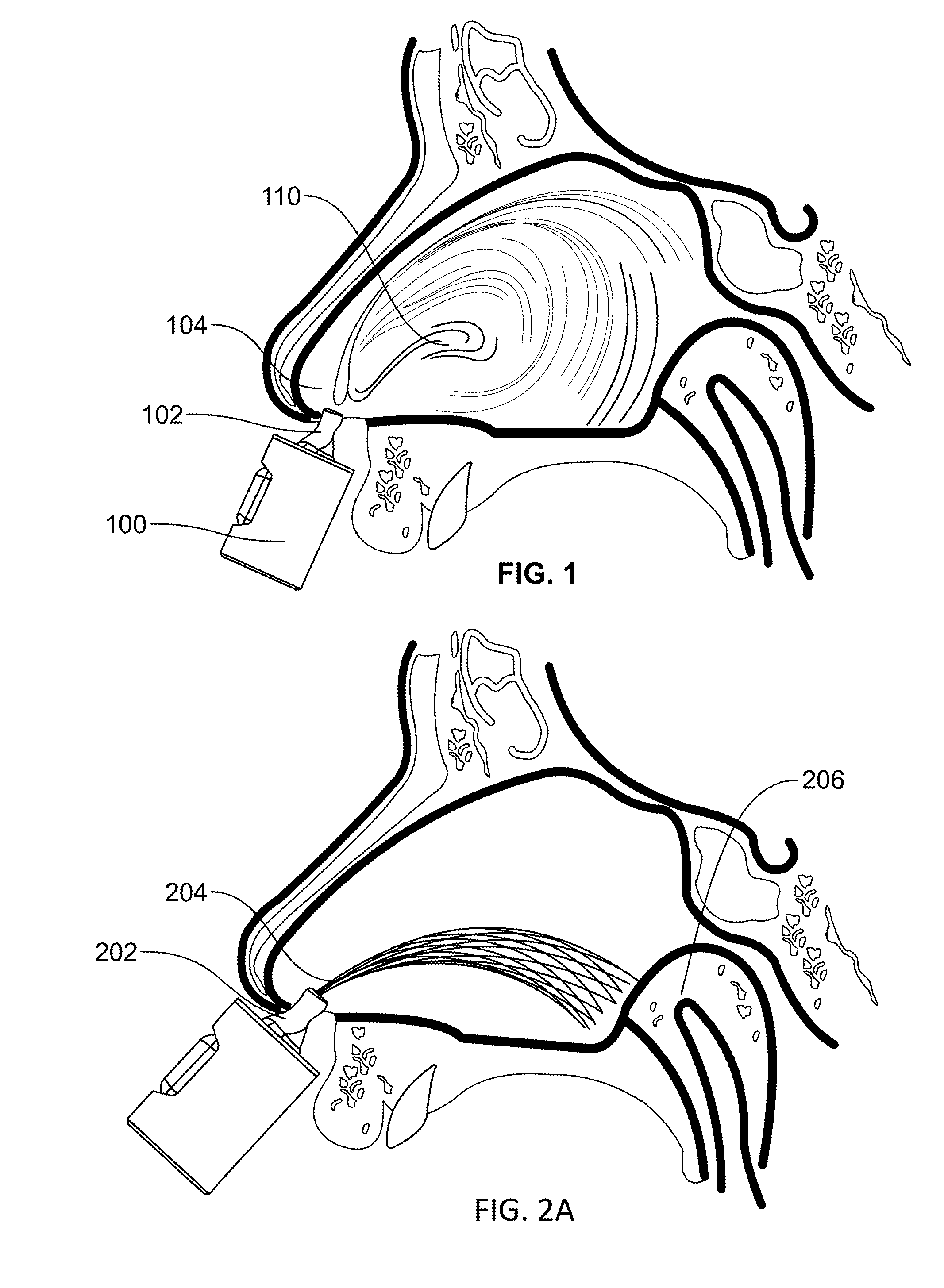

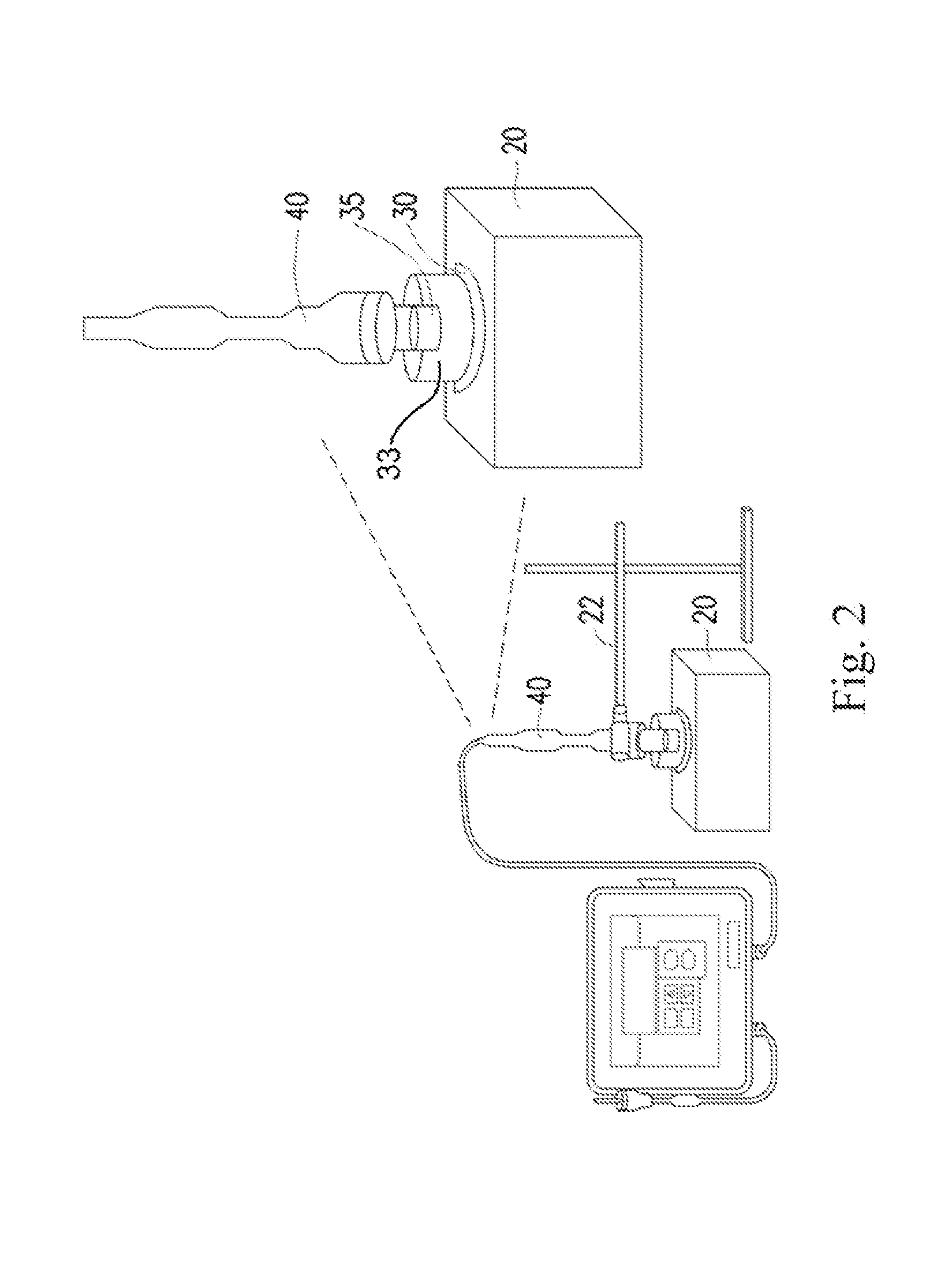

Nasal Delivery Device and Methods of Use

The present invention relates to a medical device for intranasal delivery of a medicament. The medicament may be any type of medicament suitable for nasal administration and delivery in the form of a spray. The present invention ensures that a complete dosage of the medicament is delivered, especially to specific areas in the nasal cavity, such as the rear of the nasal cavity where the SPG is located.

Owner:LEVIN BRUCE H

Method of Marking Biological Tissues for Enhanced Destruction by Applied Radiant Energy

InactiveUS20100145191A1Destruction be accelerateIncrease absorptionSurgical instrument detailsDiagnostic recording/measuringBiological tissueTherapeutic Area

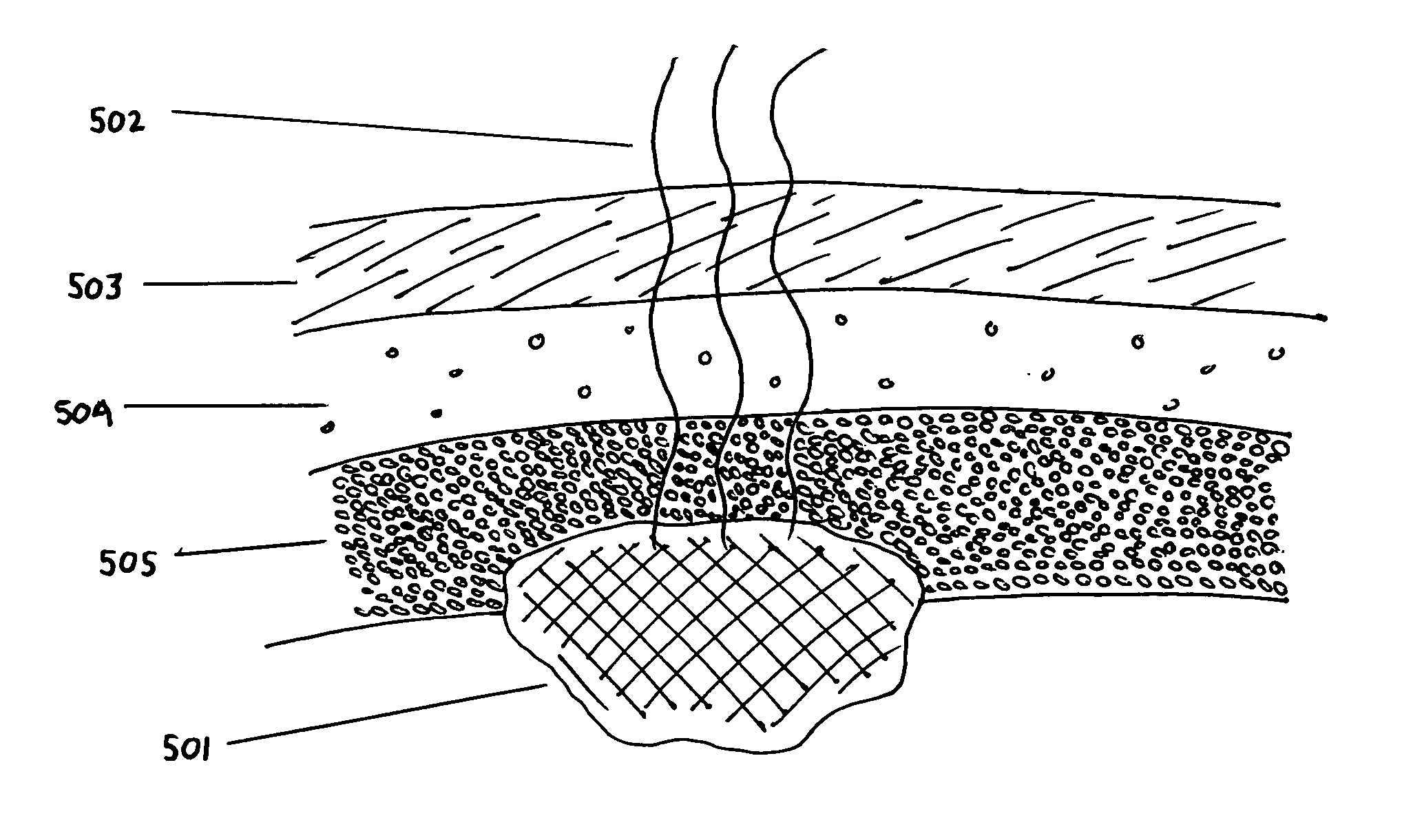

Methods for staining a selected tissue with a dye, stain or pigment that is attuned to absorb the energy from a radiant energy source are disclosed. The stain enhances absorption of incoming radiant energy, which results in increased destruction of stained tissues and decreased destruction of underlying tissues. This method provides clinicians with the ability to selectively mark a tissue for destruction, while leaving wanted tissues generally intact. Optionally, a radiant energy opaque substance that can be applied adjacent the stained treatment area to protect against incidental exposure to untargeted tissue. Also optionally, an oxidizing substance may be applied with the stain to further enhance the effect of this method. Wavelengths of radiant energy to which tissue is normally transparent may be utilized by applying appropriate stains to targeted tissue, thereby allowing targeted tissue to even be destroyed when it lies beneath untargeted tissue.

Owner:CAO GROUP

Improved pesticide composition

InactiveCN1449663AIncrease absorptionEnsure preventionBiocideSpecific information broadcast systemsRice plantMacrolide resistance

The invention provides an improved agrochemical composition having an increased absorbability of a macrolide compound as its active ingredient into rice plants. The improved agrochemical composition having an increased absorbability of a macrolide compound into rice plants contains the macrolide compound as its active ingredient and an alkaline earth metal carbonate. The invention also relates to the use therof.

Owner:BAYER CROPSCIENCE KK

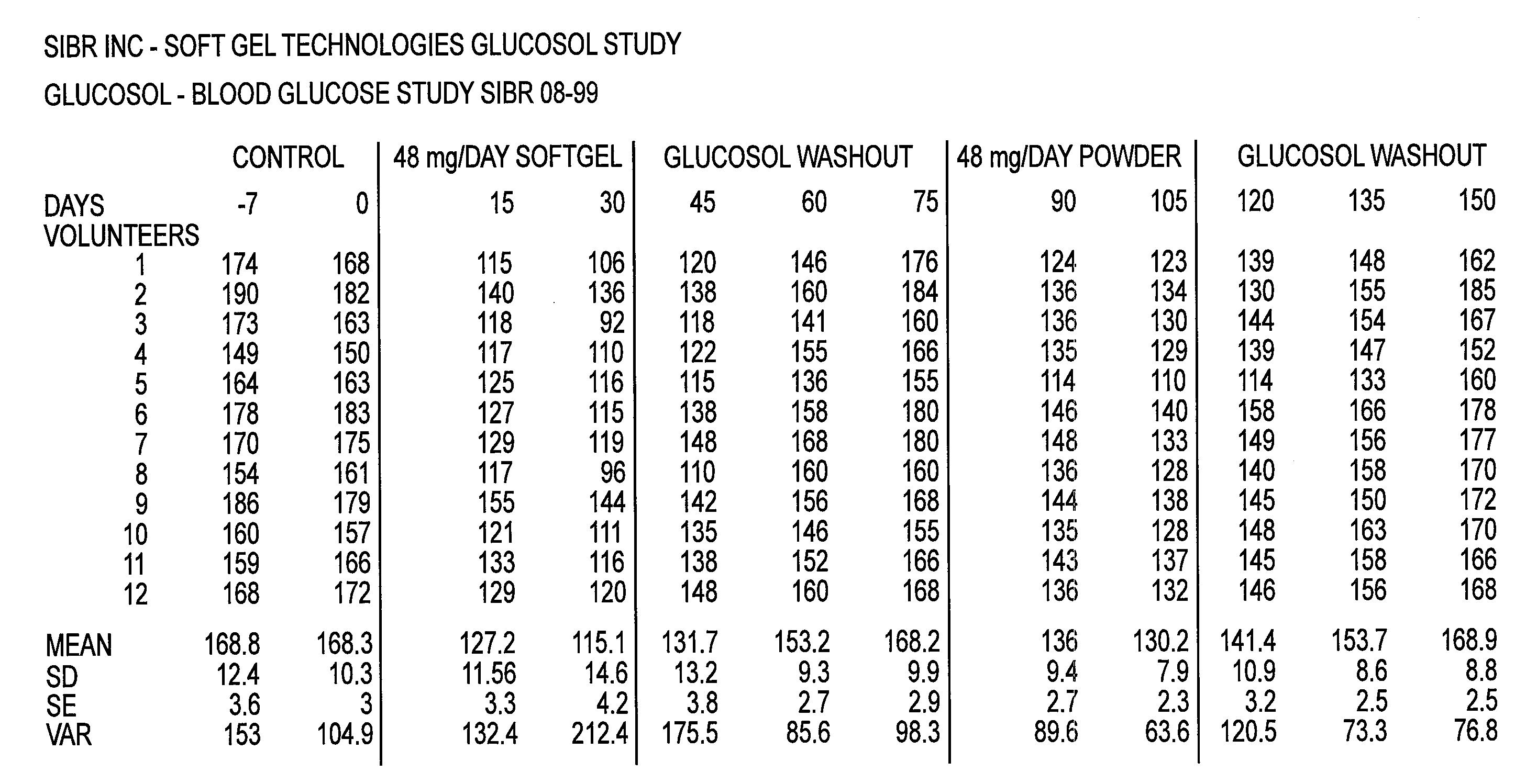

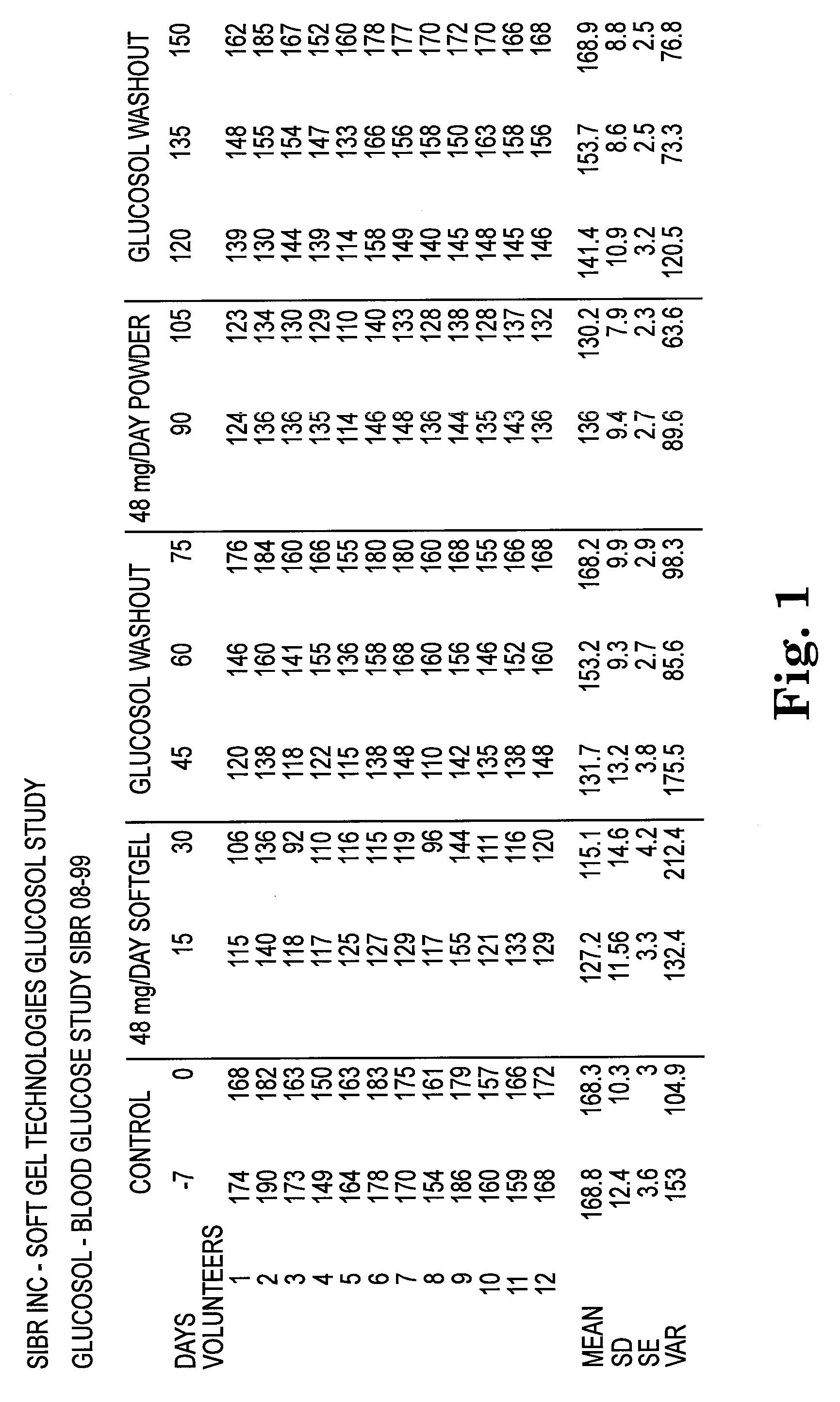

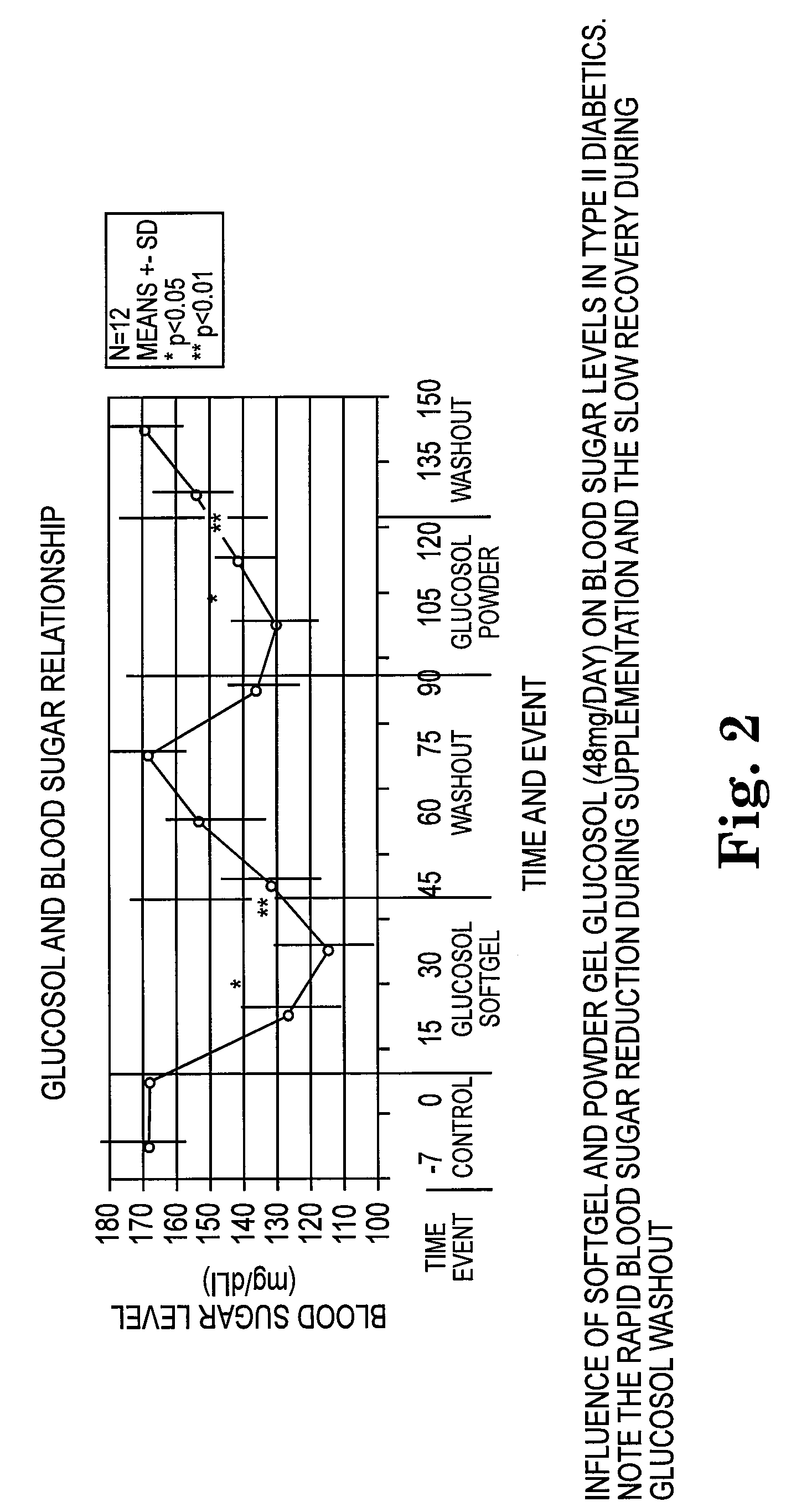

Corosolic Acid Formulation and Its Application for Weight-Loss Management and Blood Sugar Balance

InactiveUS20080152705A1Increase absorptionPromote absorptionBiocideCapsule deliveryCorosolic acidGlycemic

A soft gelatin capsule and method to deliver an efficable dose of Lagerstroemia speciosa L. (marketed by Soft Gel Technologies under the trademark Glucosol™) for the assistance and maintenance of moderate weight loss through blood sugar maintenance. The product relies on the effects of corosolic acid on blood sugar levels to derive a healthy weight loss effect for Type II diabetics (non-insulin dependent) and healthy non-diabetics and the improved absorption of an oil based delivery system. The product provides safe and sustainable weight loss when combined with a restricted calorie diet and regular exercise. Its benefits include improvement of cardiovascular health, normalized blood sugar levels, and improved physical appearance with the positive psychological effects associated with successful and safe weight loss / maintenance.

Owner:SOFT GEL TECHNOLGIES

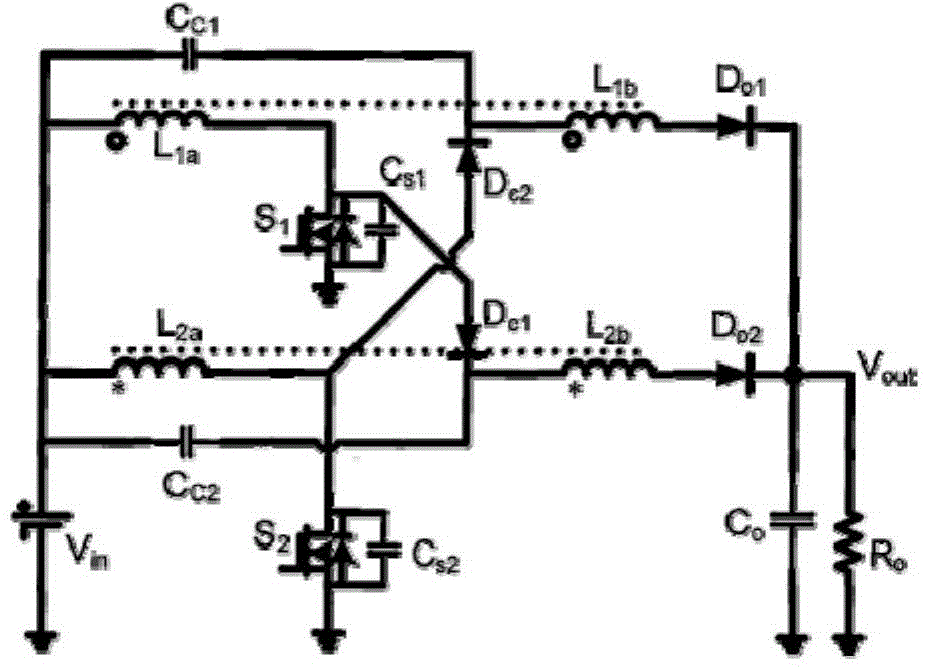

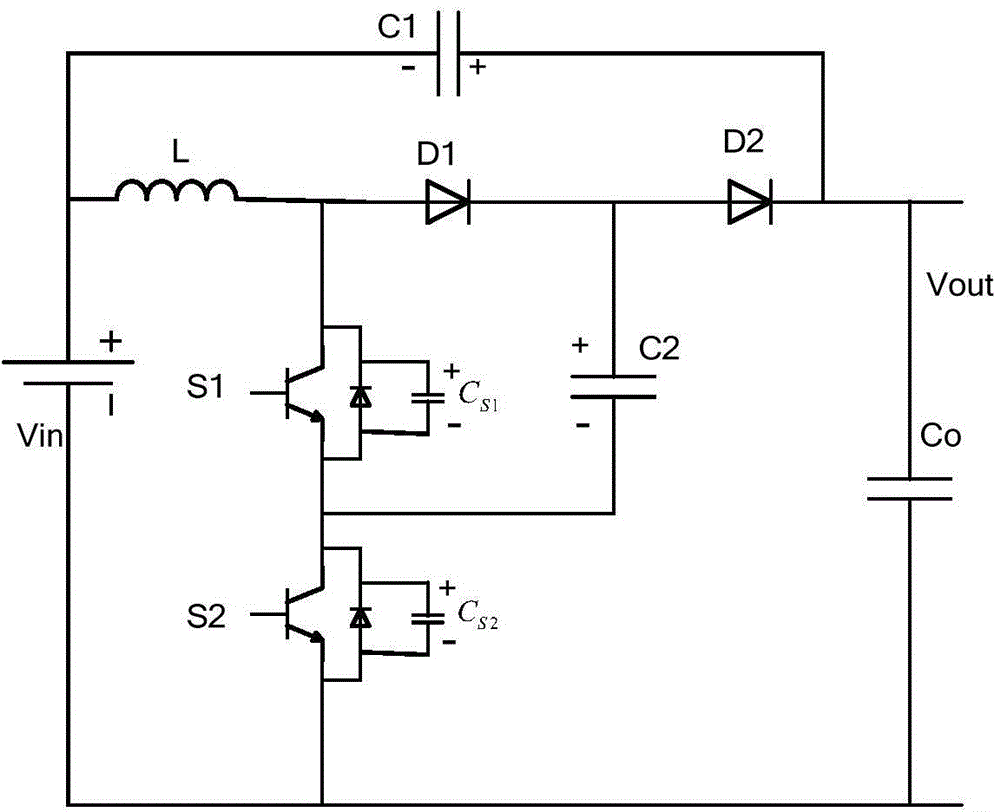

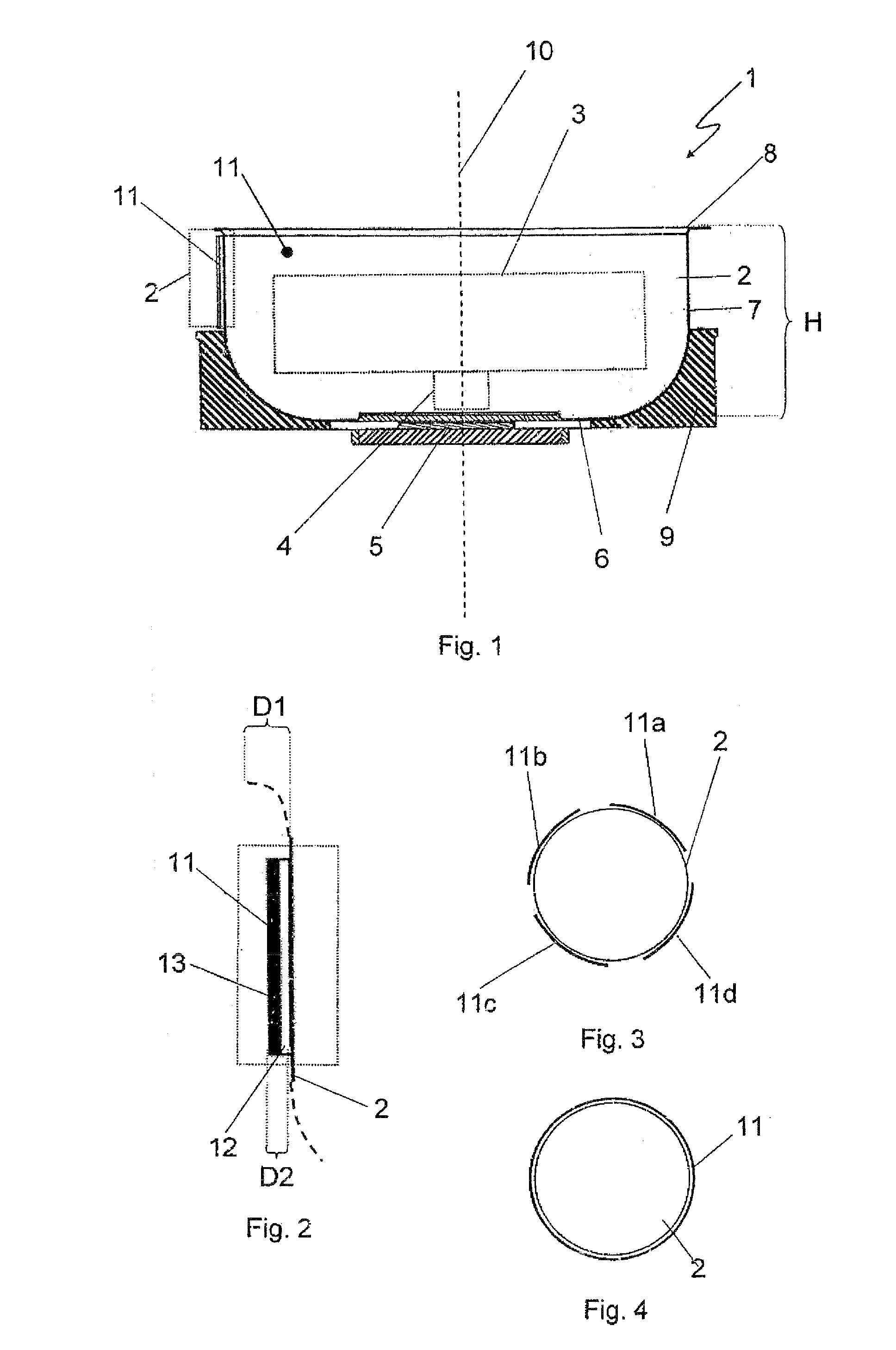

Solar cell

InactiveCN104993786AIncrease absorptionImprove battery efficiencyDc-dc conversionPhotovoltaicsElectrical batteryInductor

The invention discloses a solar cell. The solar cell comprises a light acquiring / switching module and a voltage increasing module. The voltage increasing module is formed by a voltage increasing circuit capable of reducing stress of a voltage switch. The voltage increasing circuit is comprises the voltage Vin input by the light acquiring / switching module, switch elements S1, S2, diodes D1, D2, an inductor L, an input capacitor C1, a middle capacitor C2 and an output capacitor Co. An input power supply generates input voltage Vin. The switch elements S1, S2 are respectively provided with stray capacitors CS1, CS2. By controlling on and off of the switch elements S1, S2, output voltage of the solar cell is increased and energy loss is reduced.

Owner:武汉绿鼎天舒科技发展有限公司

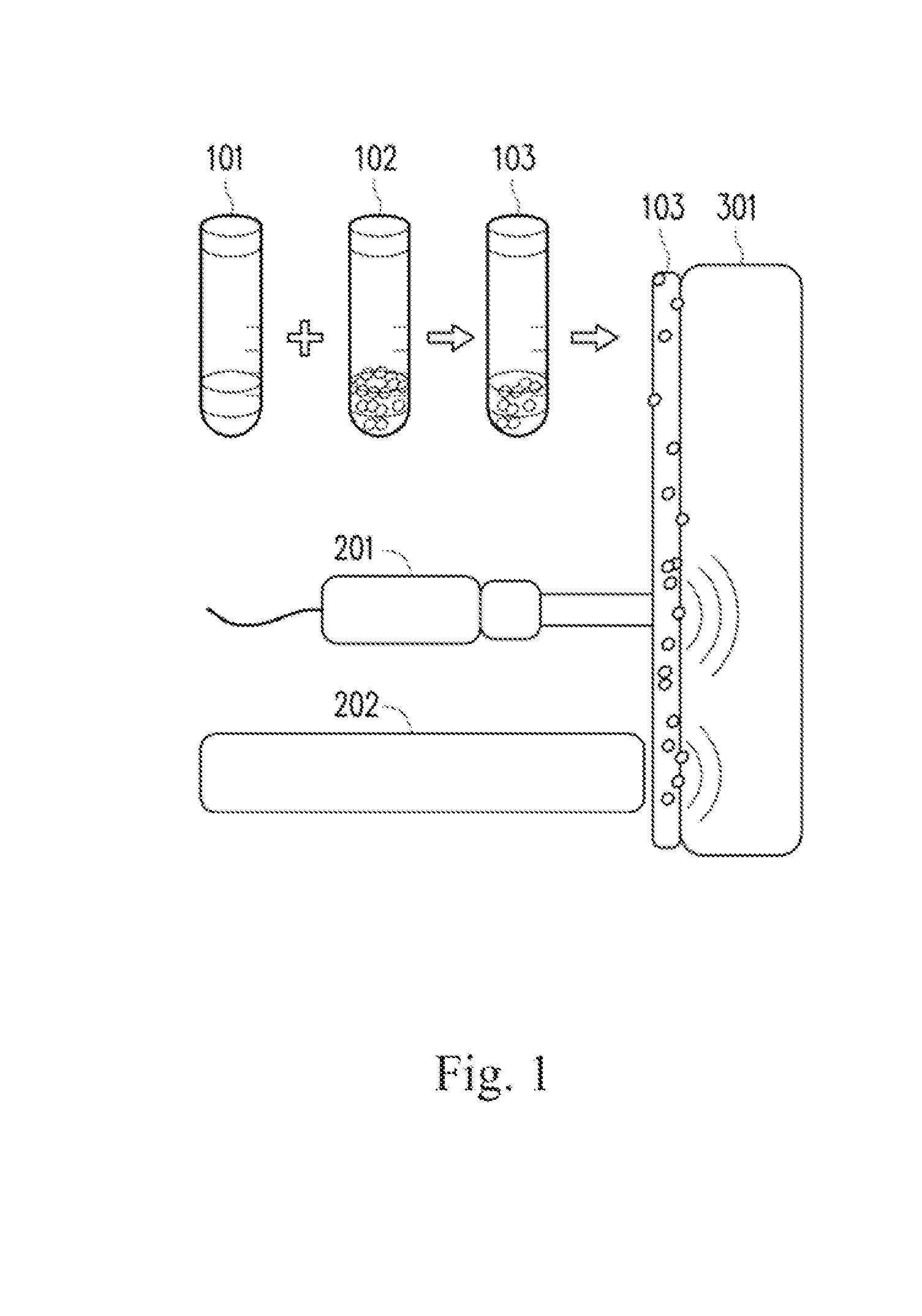

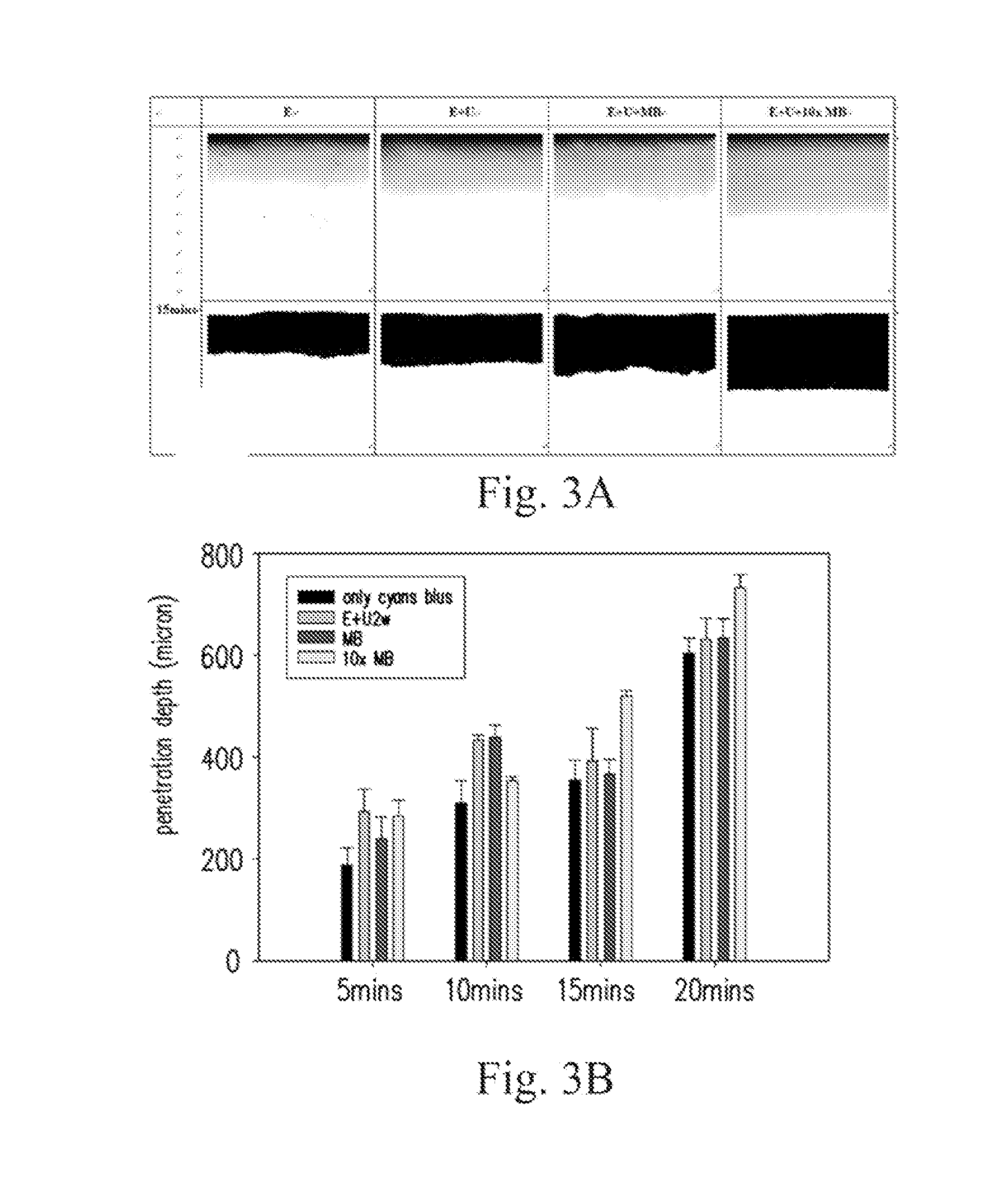

Microbubble ultrasound contrast agent for external use

InactiveUS20150056273A1Increase absorptionIncreasing percutaneous absorptionPowder deliveryMacromolecular non-active ingredientsPercutaneous absorptionBiological body

A microbubble ultrasound contrast agent for external use is provided. The microbubble ultrasound contrast agent applied externally can safely and efficiently enhance the permeation and absorption of the drug or small molecules in the local region of the body surface. A method of preparing the microbubble ultrasound contrast agent and a method of enhancing percutaneous absorption of a chemical or small molecules through a topical region of a biological body surface are provided.

Owner:NAT TAIWAN UNIV OF SCI & TECH +1

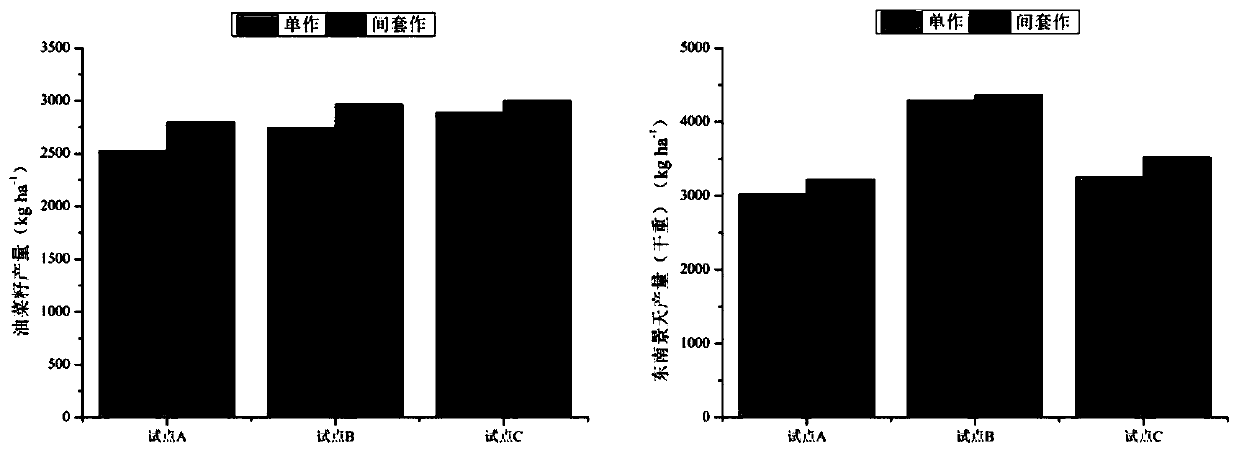

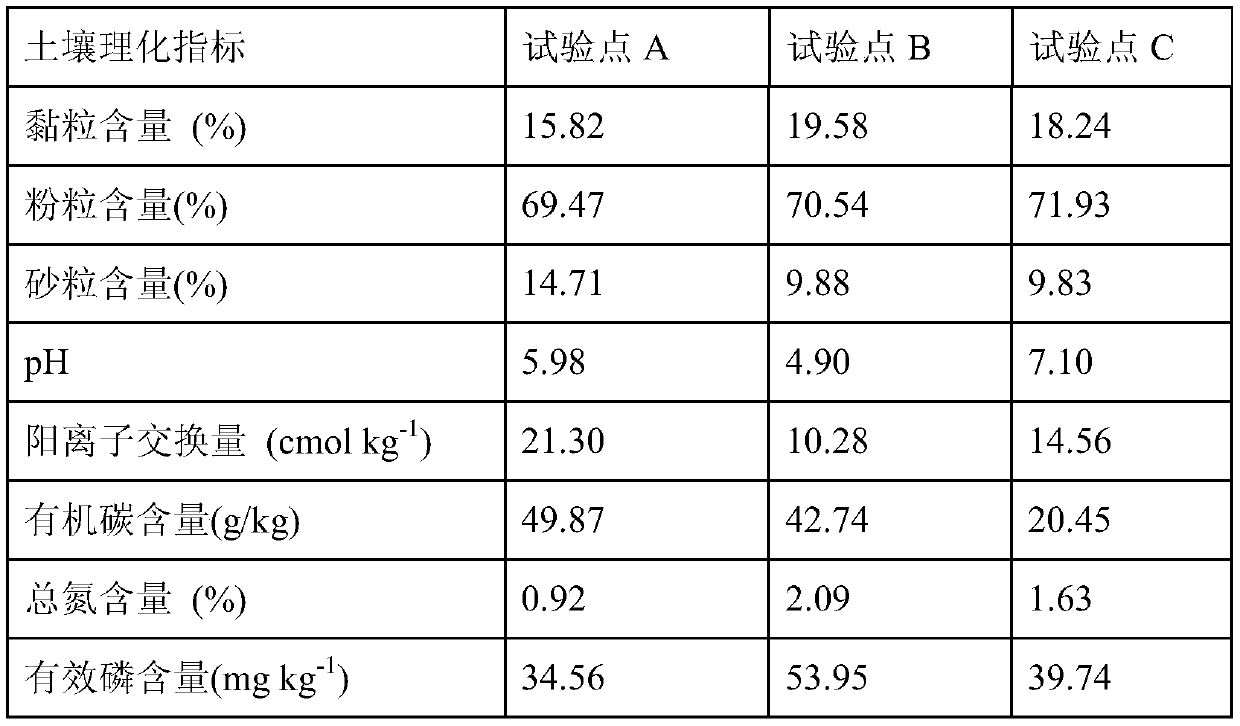

Method for enhanced extraction and repair of moderately cadmium contaminated farmland through intercropping of oilseed rape and sedum alfredii

ActiveCN110052485AImprove modification effectIncrease absorptionContaminated soil reclamationSedum alfrediiHeavy metals

The invention discloses a method for enhanced extraction and repair of moderately cadmium contaminated farmland through intercropping of oilseed rape and sedum alfredii. The method includes transplanting the oilseed rape subjected to seedling culture into to-be-repaired soil, and in the bolting and flowering stages of the oilseed rape, applying heavy metal activators to the soil in a root region of the oilseed rape; transplanting seedlings of the sedum alfredii into to-be-repaired soil of the moderately cadmium contaminated farmland, and performing intercropping cultivation management; in theseedling and rapid growth stages of the sedum alfredii, spraying enhanced repairing agents onto leaves of the sedum alfredii; and harvesting oilseed rape plants and sedum alfredii plants. The method has the advantages that the oilseed rape and the sedum alfredii are intercropped, the heavy metal activators and the enhanced repairing agents are applied cooperatively, the absorption of cadmium in the to-be-repaired soil by the oilseed rape and the sedum alfredii is remarkably improved, and the soil repairing effect on the moderately cadmium contaminated farmland is further improved.

Owner:ZHEJIANG UNIV

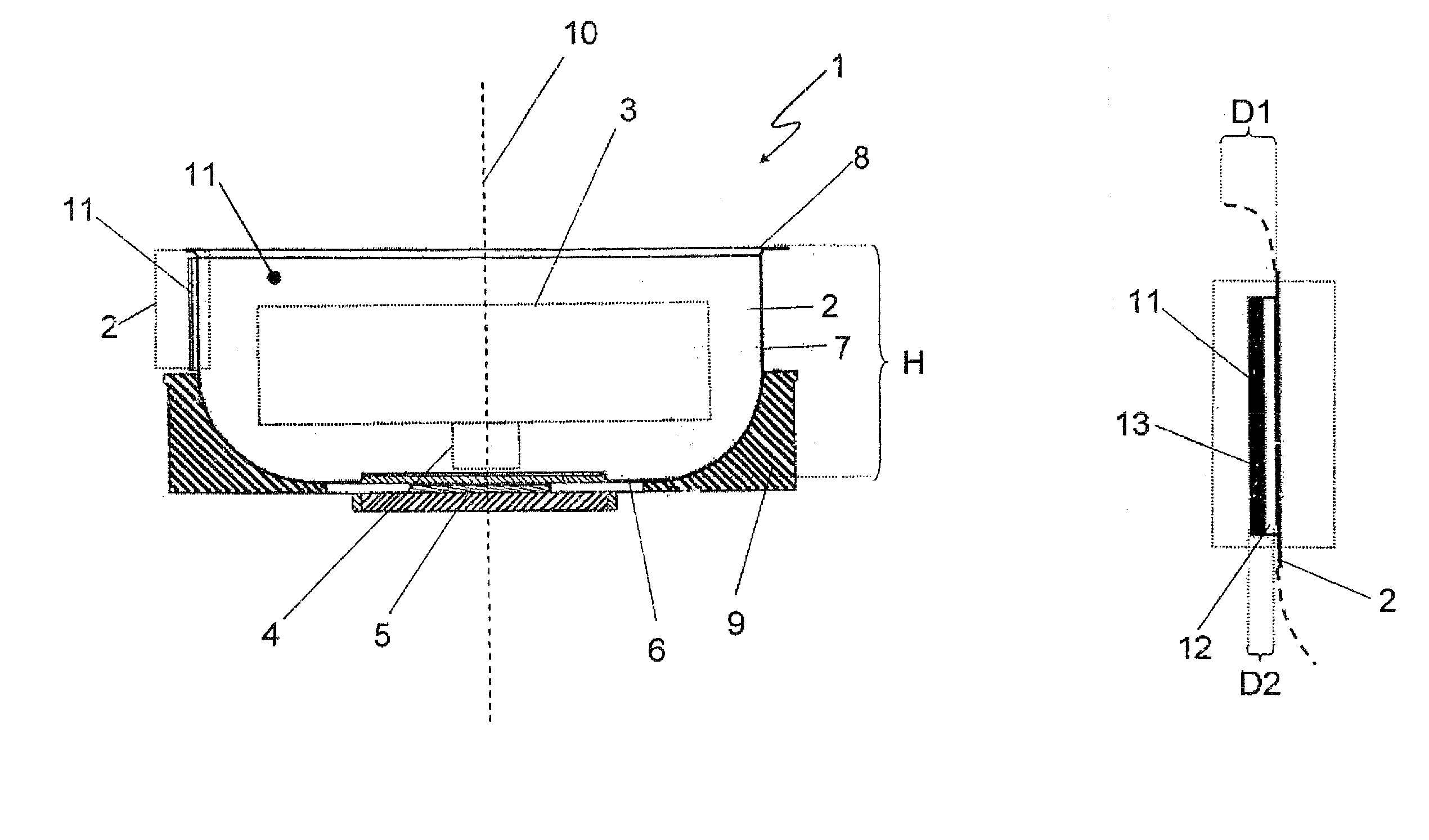

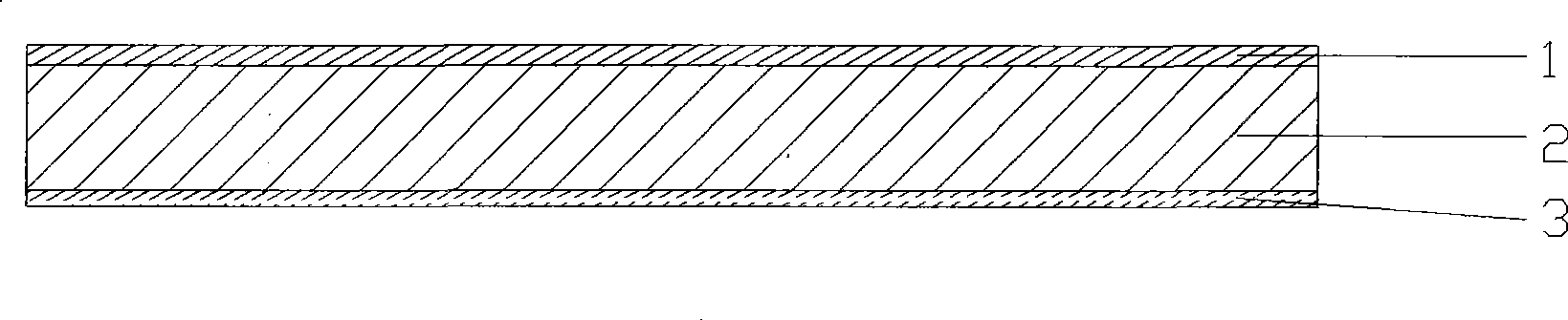

Low-Noise Rotor Chamber For A Centrifuge

ActiveUS20100179043A1Reduce soundIncrease absorptionDispersed particle separationCentrifugal force sediment separationEngineeringLow noise

The present invention relates to a rotor chamber for a centrifuge, in particular an air-cooled laboratory centrifuge, having a chamber wall, comprising an inner side facing toward the chamber interior, the chamber interior being implemented to receive a centrifuge rotor, and an outer side facing away from the chamber interior, and having a sound barrier which is implemented to reduce the sound emitted from the rotor chamber, which comprises a multilayer damping lining. The present invention also relates to a centrifuge having such a rotor chamber, and methods for reducing the sound emanating from the rotor chamber of a centrifuge, in particular an air-cooled laboratory centrifuge.

Owner:QIAGEN

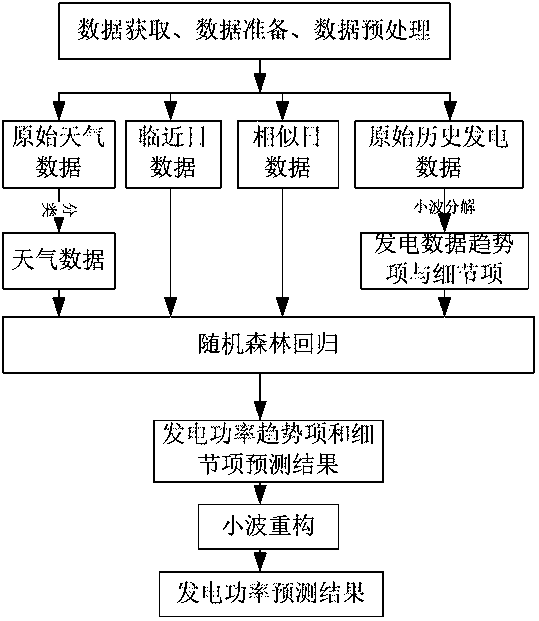

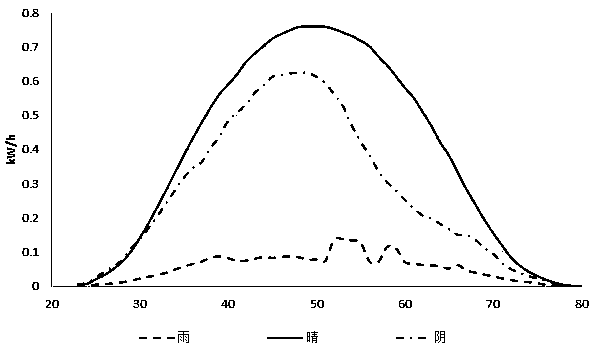

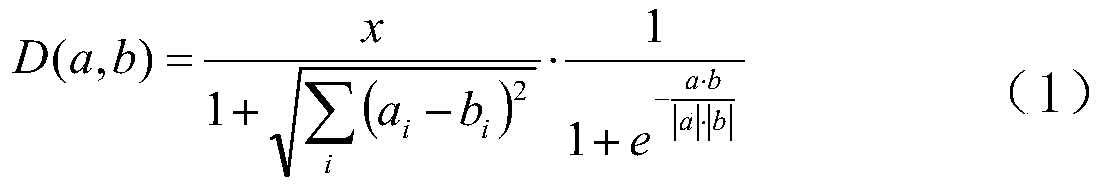

Distributed photovoltaic short-term output prediction method

ActiveCN111598337AGuaranteed real-timeGuaranteed accuracyForecastingCharacter and pattern recognitionWavelet decompositionPower grid

The invention relates to a distributed photovoltaic short-term output prediction method. The distributed photovoltaic short-term output prediction method comprises the following steps: collecting photovoltaic distribution transformer data, geographic information and weather condition data; preprocessing data, and constructing adjacent day and similar day characteristics of the prediction day; performing wavelet transform algorithm decomposition on the historical power generation data to obtain a main body sequence and a detail sequence; according to the power generation data and weather data,dividing weather into a sunny day, a shady day and a rainy day; combining weather data, adjacent days, similar days and wavelet decomposition results as input features; modeling in different weather categories by using a random forest regression algorithm respectively to obtain three prediction models of sunny, shady and rainy days; judging the weather category to which the weather data of the next day belongs; and inputting the algorithm model corresponding to the weather category to obtain a power generation data main body sequence and detail sequence prediction data. According to the distributed photovoltaic short-term output prediction method, the friendly grid connection level of distributed power generation is improved; the light abandoning rate is effectively reduced; clean energy consumption is promoted; and safe and stable operation of a power grid is guaranteed; and the distributed photovoltaic short-term output prediction method has extremely high generalizability.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +3

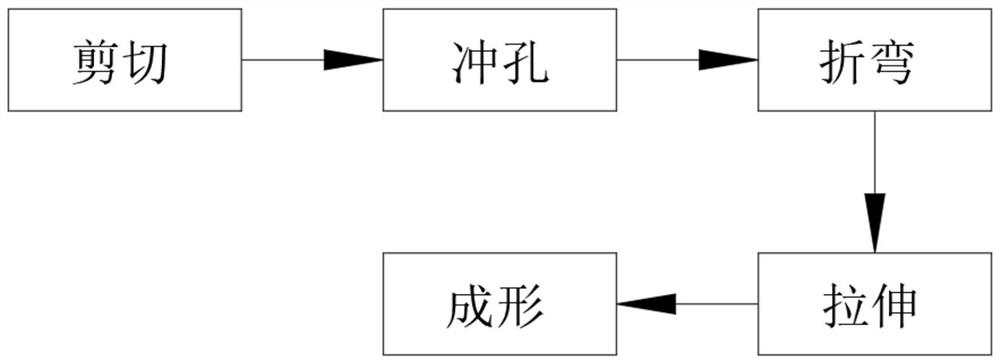

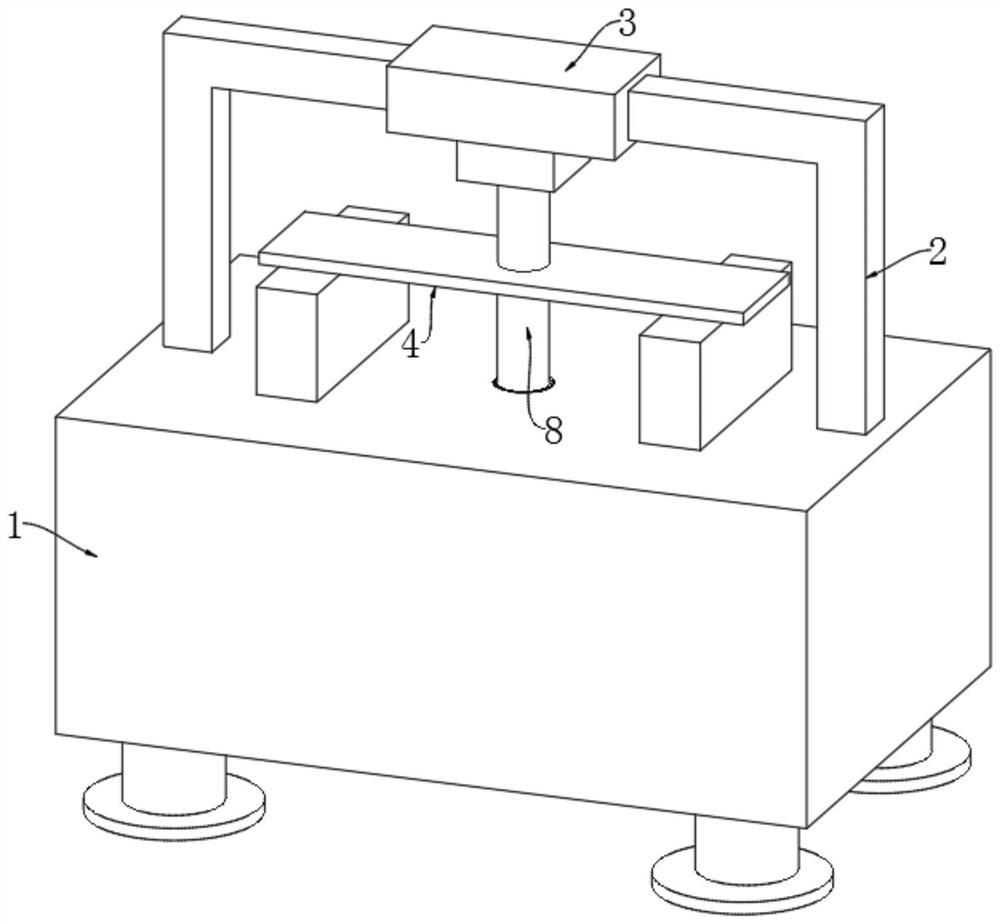

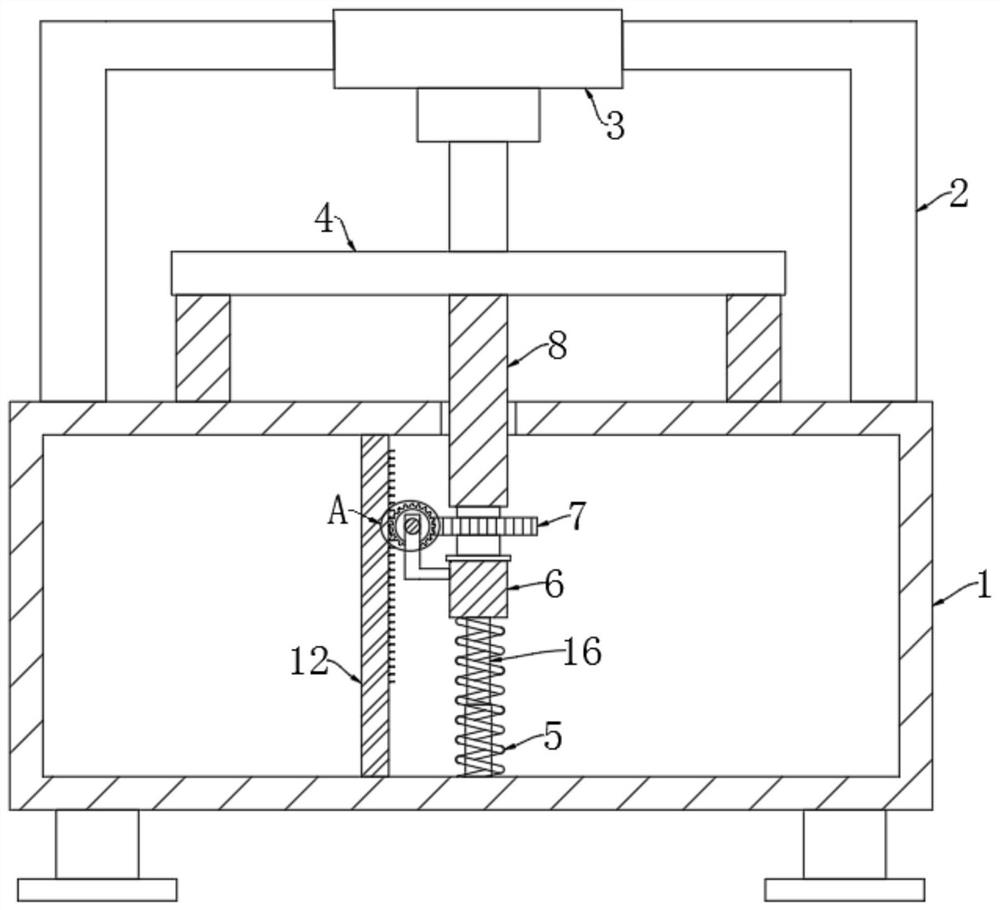

Sheet metal machining method for automatically polishing hole based on punching potential energy

InactiveCN111644509AImprove processing efficiencyAffect the effect of punchingRevolution surface grinding machinesDirt cleaningPunchingMetal machining

The invention belongs to the field of sheet metal machining and particularly relates to a sheet metal machining method for automatically polishing a hole based on punching potential energy. The methodmainly comprises the steps of shearing, punching, bending, stretching and forming. Punching equipment used in the sheet metal machining process comprises a box, wherein a support is fixedly connectedto the box, a puncher is arranged on the support, and a metal plate is placed on the box. According to the method, through cooperation of a polishing rod and a compression spring, the press-down potential energy of the puncher can be accumulated in the compression spring; after punching is completed, the reactive force of the compression spring is utilized to drive the polishing rod to ascend; and under the transmission action of a worm and a worm gear, rotation of the polishing rod is realized, the polishing rod can polish the inner wall of the hole in the process of penetrating through thehole, waste of time in late polishing is avoided, and sheet metal machining efficiency is greatly improved.

Owner:何国崇

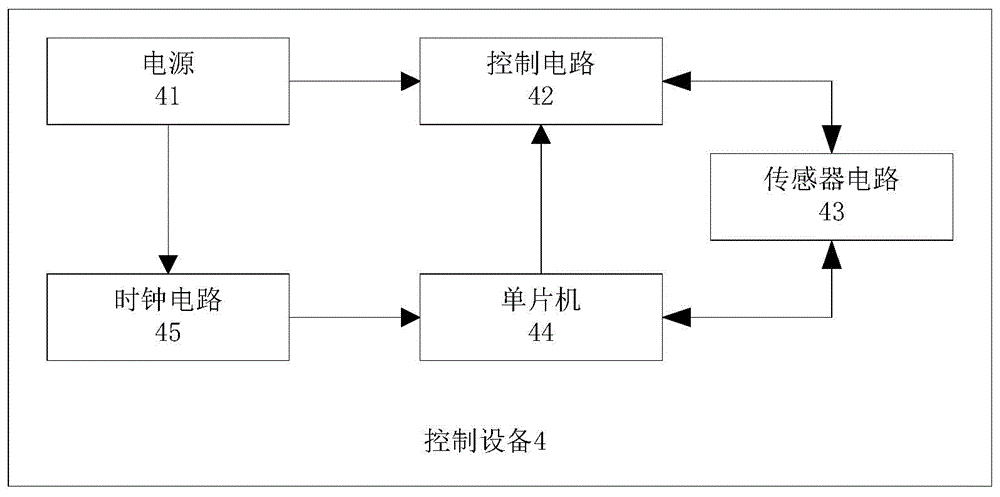

Flexible solar cell module

ActiveCN104917449AIncrease profitIncrease absorptionPhotovoltaic supportsPhotovoltaic energy generationControl equipmentEngineering

The invention discloses a flexible solar cell module. The flexible solar cell module comprises a flexible solar cell, a support, a driving device and control equipment, wherein the driving device is mounted on the support; the driving device is connected with the flexible solar cell and is used for driving the flexible solar cell to deform along with an illumination angle; and the control equipment is used for controlling the driving device. The flexible solar cell module provided by the invention does not need a light tracing device, and has the advantages of high photoelectric conversion efficiency, low power consumption and low cost.

Owner:陈惠远

Human liquid material absorbing material and sanitary towel, wound-surface dressing made by the same material

InactiveCN101417143APromote wound healingIncrease absorptionAbsorbent padsBandagesActive carbonAbsorption effect

The invention discloses a liquid matter absorbing material for human bodies and a sanitary towel and a wound dressing prepared by the liquid matter absorbing material. The components of the liquid matter absorbing material for human bodies comprise macromolecular resin, active carbon, white lime and cotton pulp. The liquid matter absorbing material for human bodies can be used as the materials for manufacturing the sanitary towel and the wound dressing. As the invention comprises the four components of the macromolecular resin, the active carbon, the white lime and the cotton pulp, wherein, the macromolecular resin has excellent seal performances and can lead a contact surface to maintain proper humidity after absorbing water; the cotton pulp has the effect of flow conduction; the white lime has the effects of stanching, sterilizing and resisting infection; the active carbon and the cotton pulp can absorb poisonous matters; and the four components all have the absorption effect, thereby the absorption amount is large. The comprehensive effects of the four matters can improve the absorption speed; therefore, the invention can solve the problem existing in the existing liquid matter absorbing material for human bodies.

Owner:魏炜

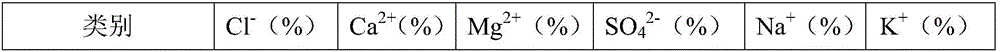

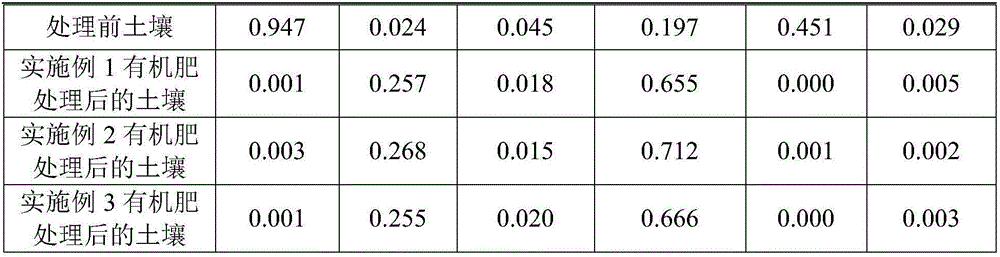

Organic fertilizer containing desulphurization gypsum, and preparation method and application of organic fertilizer

InactiveCN106187597AIncrease absorptionInhibited transportCalcareous fertilisersExcrement fertilisersGypsumChemistry

The invention belongs to the technical field of control on saline and alkaline land, and particularly relates to an organic fertilizer containing desulphurization gypsum and a preparation method and application of the organic fertilizer. The organic fertilizer is prepared from the following components in parts by weight: 35 to 45 parts of desulphurization gypsum, 20 to 30 parts of livestock and poultry manure and withered grasses and leaves, 5 to 10 parts of peat, 1 to 5 parts of pyrite and 1 to 5 parts of fly ash. The prepared organic fertilizer has the advantages that the organic fertilizer is suitable for improving the saline and alkaline land, the desalting is quick, the control cost is low, and the use effect is obvious.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

A multi-station automatic welding method for fan impeller processing

ActiveCN109249120BAdsorption area maximizationIncrease absorptionWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSpot welding

Owner:FOSHAN GOOGOL AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com