Human liquid material absorbing material and sanitary towel, wound-surface dressing made by the same material

An absorbent material, sanitary napkin technology, applied in absorbent pads, medical science, bandages, etc., can solve the problems of poor disinfection and anti-infection, small absorption, slow absorption, etc., to promote wound healing, large absorption, improve The effect of absorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment is described by taking sanitary napkin as an example.

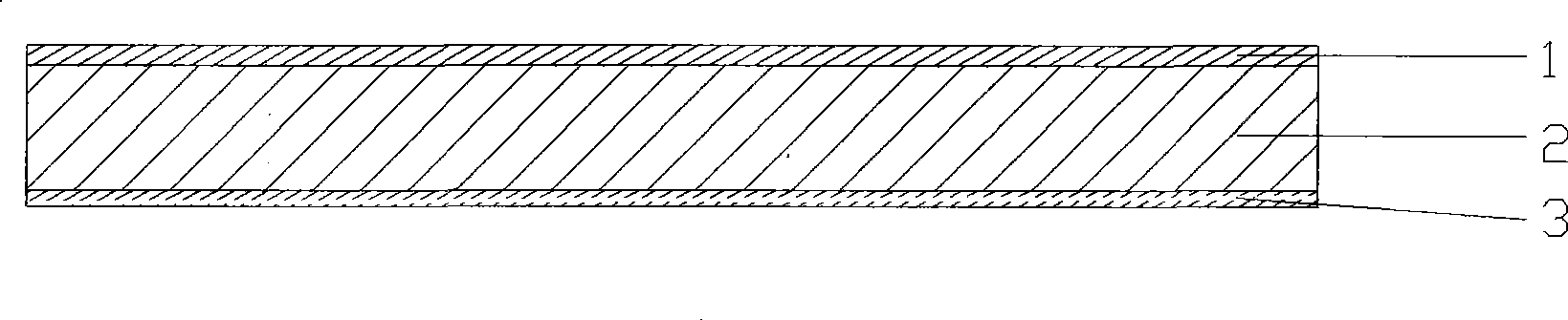

[0023] Such as figure 1 As shown, the sanitary napkin includes a surface layer 1, an absorbing layer 2, and a bottom layer 3. The absorbing layer 2 is a human body liquid substance absorbing material, and the human body liquid substance absorbing material has a layered structure, and its components include polymer resin, activated carbon , slaked lime, cotton pulp. The weight ratio of each component is 15% of activated carbon, 5% of slaked lime, 10% of cotton pulp and 70% of polymer resin.

[0024] Certainly when implementing, the weight ratio of each component also can have different selections, as following three groups:

[0025] Activated carbon 10%, slaked lime 5%, cotton pulp 5%, polymer resin 80%;

[0026] Activated carbon 30%, slaked lime 18%, cotton pulp 9%, polymer resin 43%;

[0027] Activated carbon 50%, slaked lime 30%, cotton pulp 15%, polymer resin 5%.

[0028] The following is a ...

Embodiment 2

[0033] In this embodiment, the wound dressing is taken as an example for illustration.

[0034] The wound dressing in this embodiment comprises two layers, respectively a backing material and an absorbent material. The absorbent material is a human body liquid substance absorbent material, which has a layered structure, and its components include polymer resin, activated carbon, and slaked lime. 1. Cotton pulp, the weight ratio of each component is 30% of activated carbon, 18% of slaked lime, 9% of cotton pulp, and 43% of polymer resin.

[0035] Certainly when implementing, the weight ratio of each component also can have different selection, as following two groups:

[0036] Activated carbon 10%, slaked lime 5%, cotton pulp 5%, polymer resin 80%;

[0037] Activated carbon 50%, slaked lime 30%, cotton pulp 15%, polymer resin 5%.

[0038] The following is a brief description of the production process of the human body liquid substance-absorbing material. The process in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com