Container for nuclear fuel transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

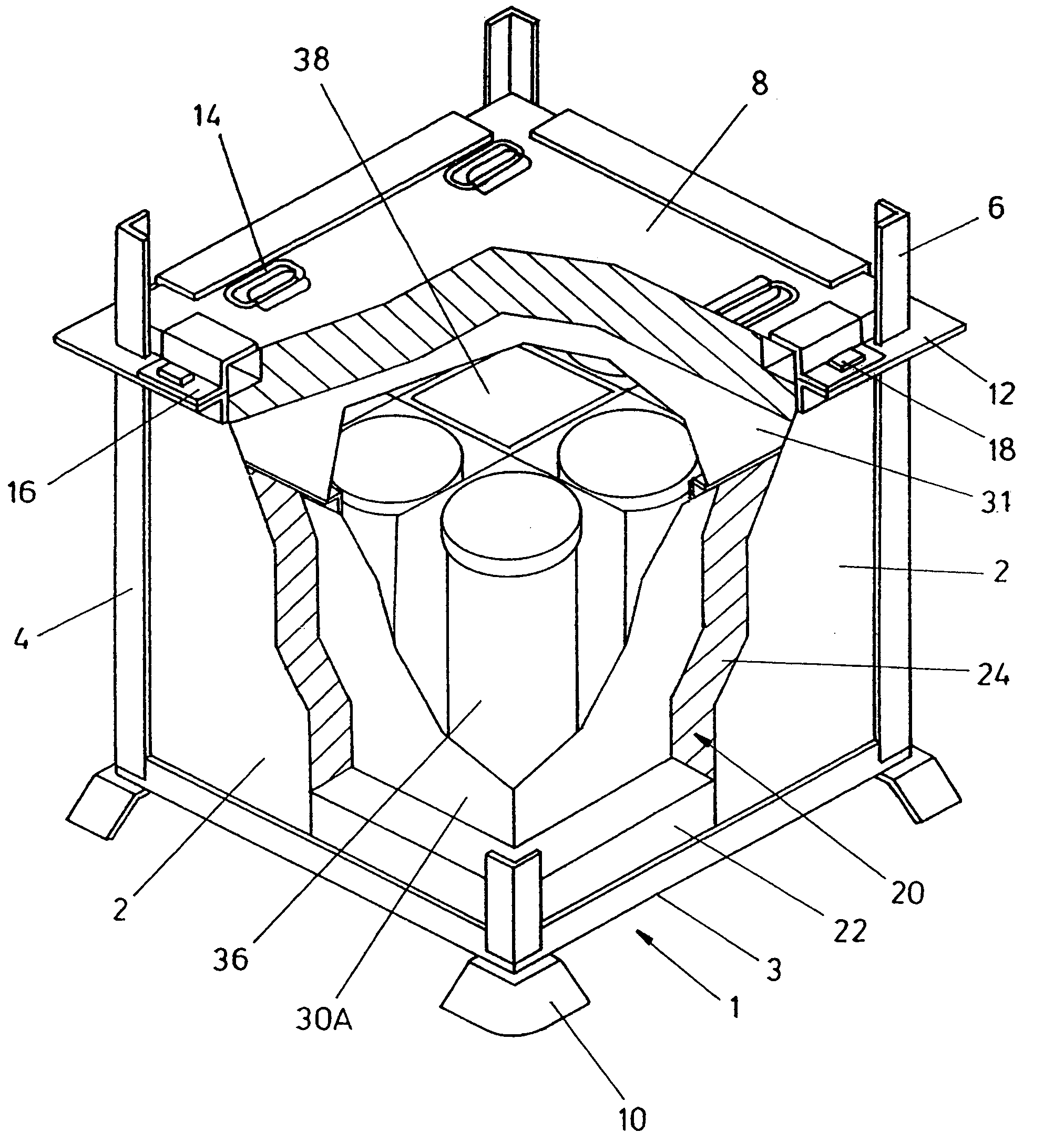

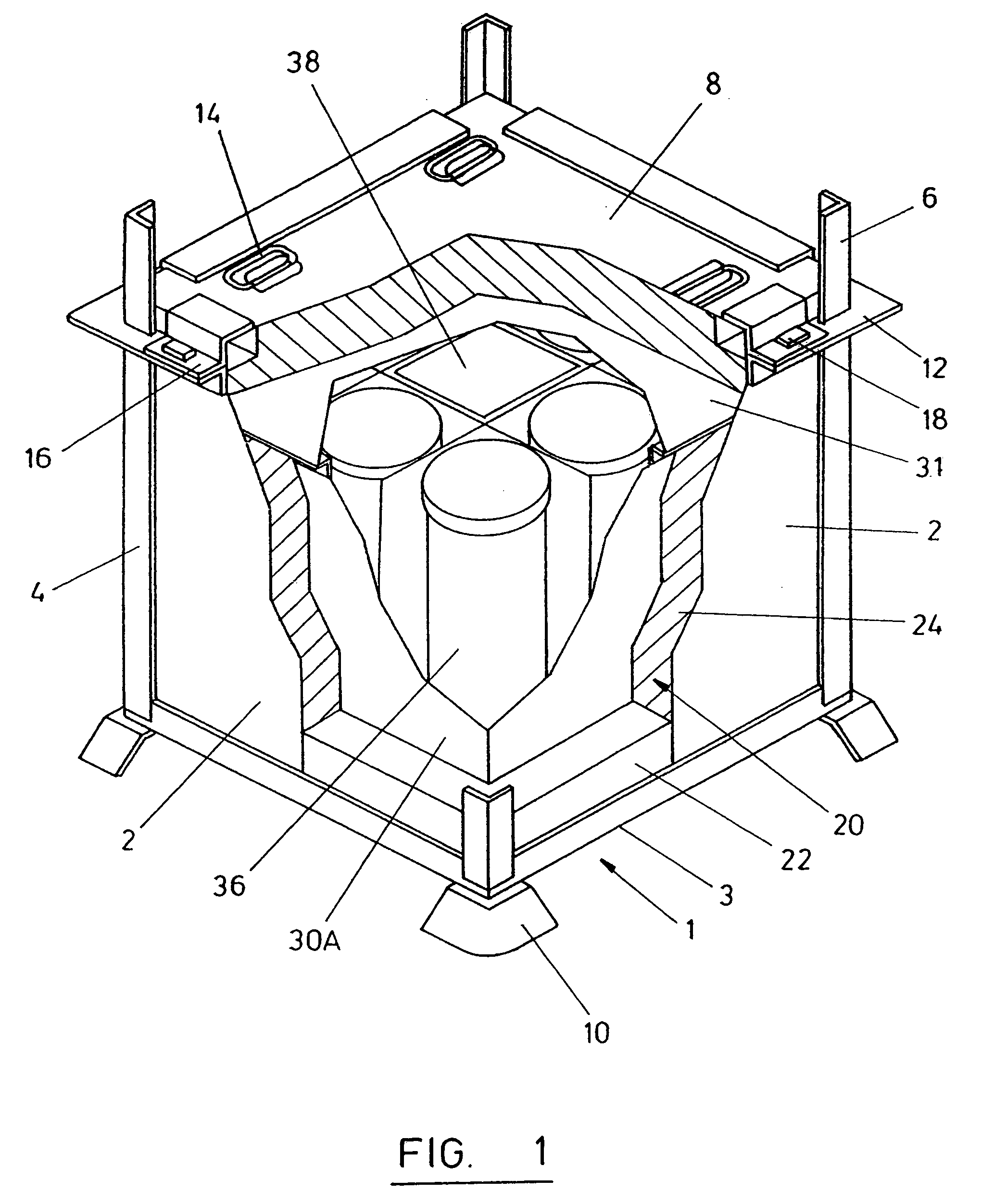

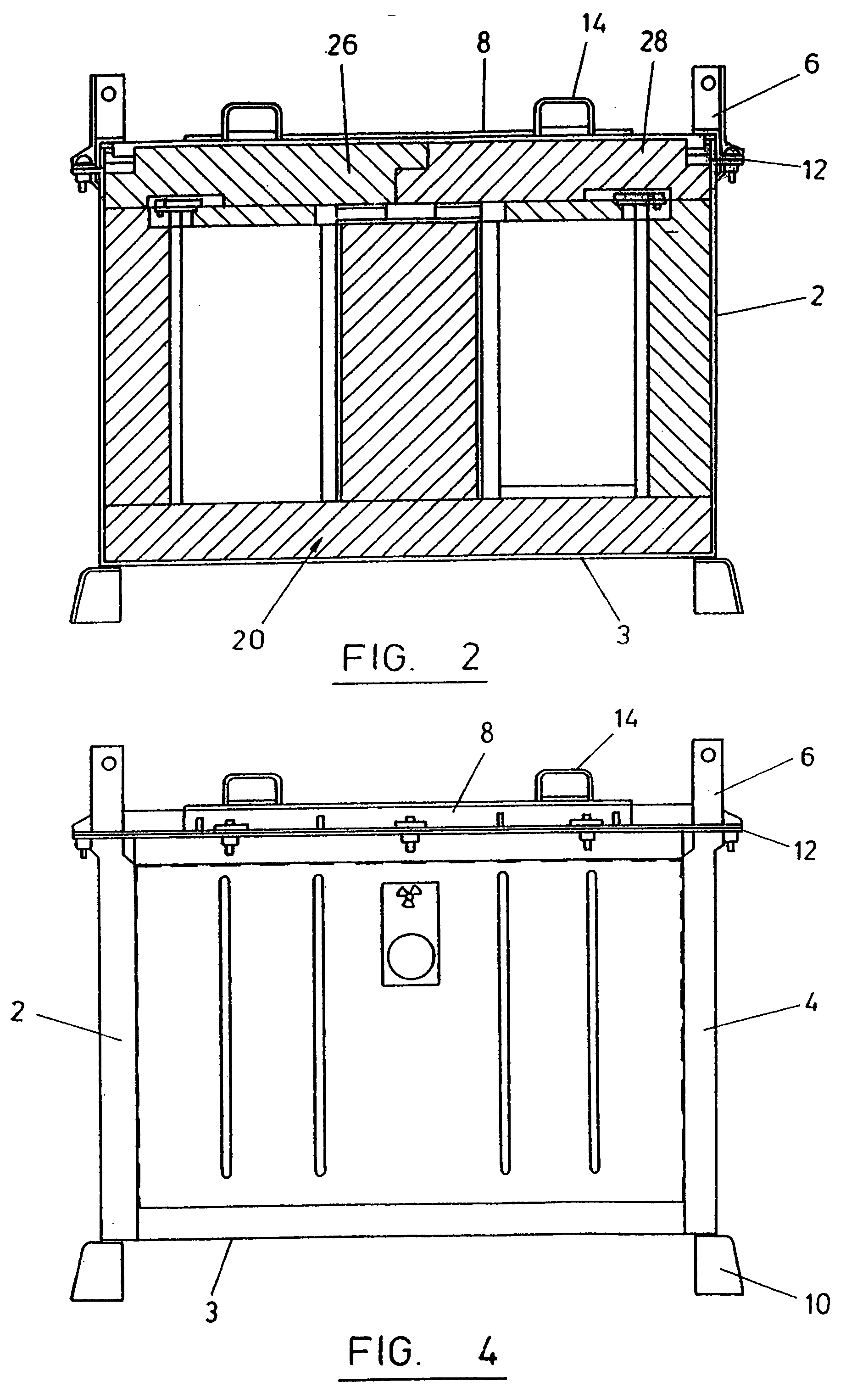

[0050] The container as illustrated in FIG. 1 has the general form of a rectangular box. The container 1 is defined by four vertically arranged walls 2 and a base wall 3. The walls are provided at the corner joints with strengthening elements 4 in the form of L-shaped strips. The vertical strengthening elements 4 have portions 6 which extend beyond the lid 8 of the container. Feet 10 are provided on each corner of the base and engage with the portion 6 for easy and stable stacking.

[0051] The outer skin forming the walls 2, base 3 and separate lid 8 are made of stainless steel.

[0052] A peripheral flange 12 is provided around the container. The lid 8 is dimensioned to be slidably received within the boundaries of the L-shaped elements 4. The lid 8 has a flange 16 which corresponds with the peripheral flange 12 of the container. Handles 14 on the lid aid in its removal and insertion.

[0053] In the closed and retained position shown the lid 8 is retained by a series of quick release n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com