Suction type robot hand grab applied to circular arc surface workpieces

A technology of arc surface and robot, which is applied in the direction of manipulator, object destacking, manufacturing tools, etc. It can solve the problems of easy damage to the outer surface of workpieces, poor balance and stability, and workpiece falling, so as to enhance the suction force and stabilize the grasping , The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, two driving devices and two suction units respectively connected to the driving devices are used as an example to describe the following.

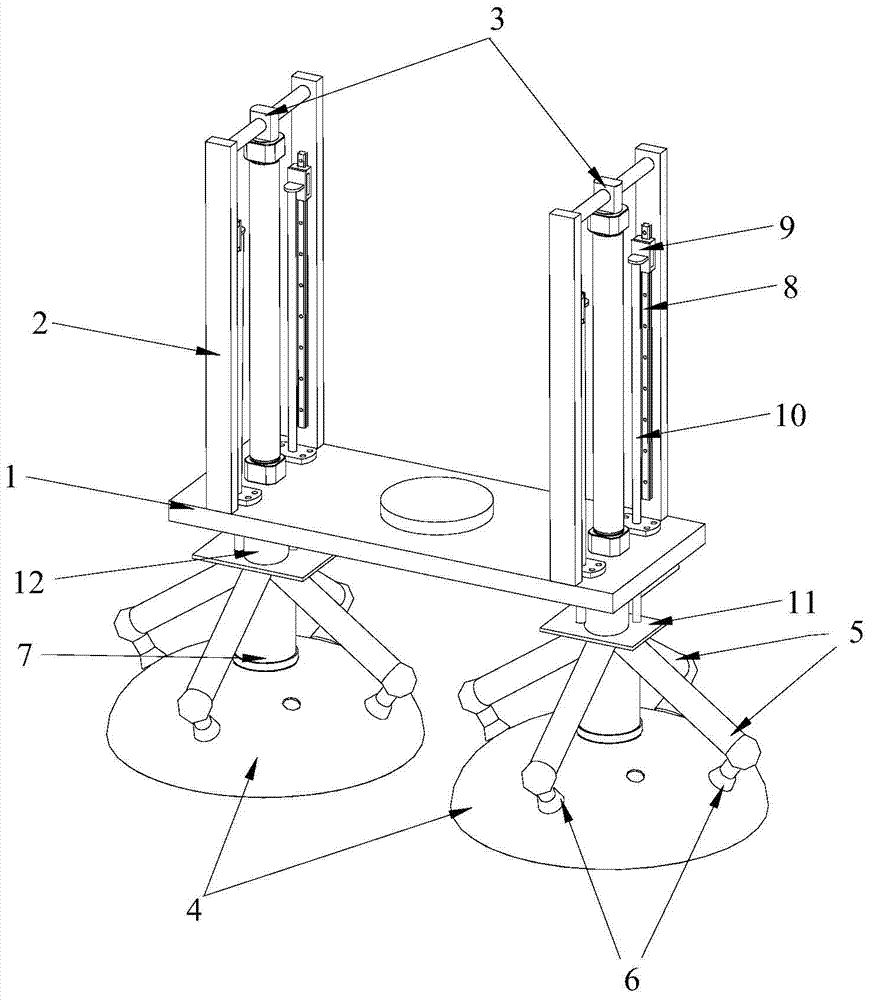

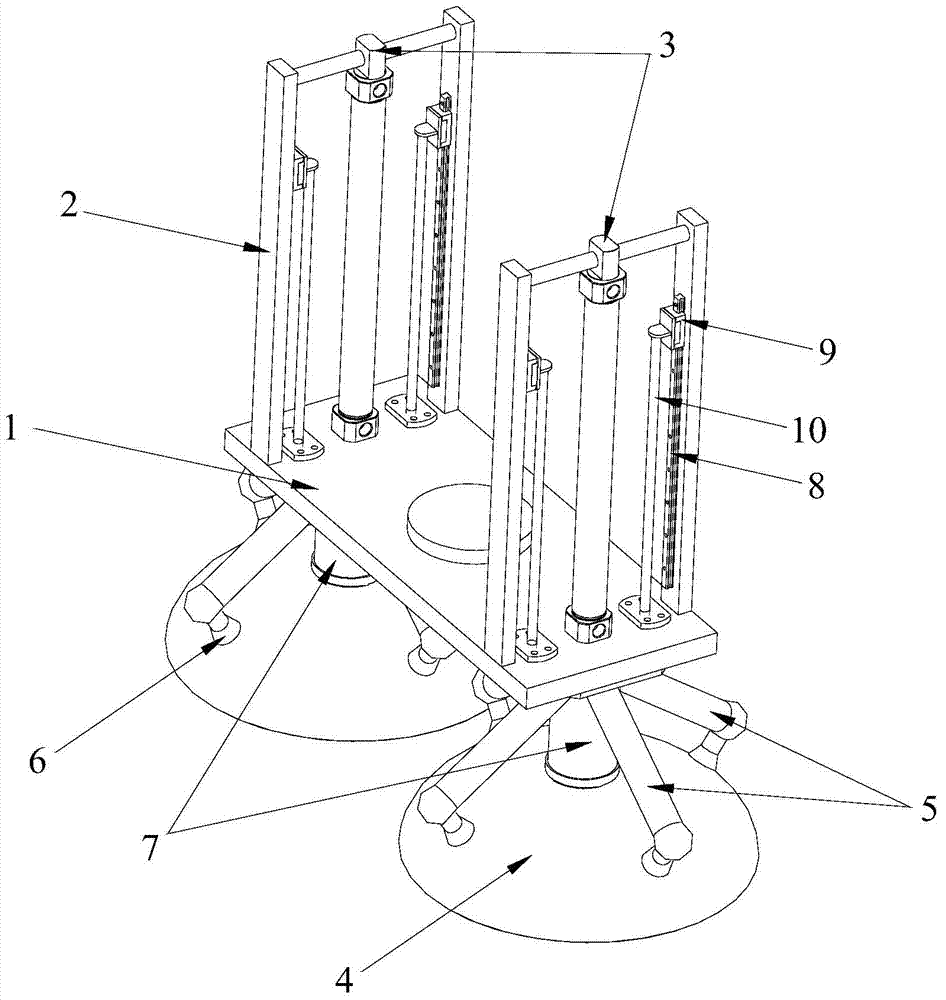

[0028] Such as figure 1 with 2 As shown, the robot suction gripper suitable for circular arc curved workpieces of the present invention is installed on the movable end of the robot for grabbing circular arc curved workpieces; the gripper includes a connecting plate 1 connected with the movable end of the robot and a set Two brackets 2 on the connecting plate 1, wherein each bracket 2 is provided with a driving device 3 and a suction unit connected to the driving device 3. The driving device 3 is installed on the bracket 2 and its pushing part 12 is connected with the suction unit, The suction unit is arranged at the bottom of the connecting plate 1, and the suction points between the suction unit and the workpiece 4 are distributed in a circle with the center of the workpiece 4 as a circle.

[0029] The suction unit o...

Embodiment 2

[0035] This embodiment is different from the first embodiment only in that: the suction gripper of the present invention can be provided with a driving device and a suction unit connected to the driving device according to requirements, or three or more driving devices and corresponding to The suction unit connected to the drive device. For the structure of three or more suction units, each bracket in this embodiment is provided with a driving device and a suction unit connected to the driving device. Three or more suction units can simultaneously suck three or more pieces at a time. A curved surface workpiece, thereby improving the practicability, grasping efficiency and production efficiency of the suction gripper. Or, three or more suction units can simultaneously suck a long piece of workpiece with a curved surface. For large or heavy workpieces, this can ensure the balance and stability of the gripper.

[0036] The other structures of this embodiment are consistent with the...

Embodiment 3

[0038] The only difference between this embodiment and the first embodiment is that it does not include the positioning device, the guiding device and the connecting block. One end of the connecting rod of the suction device of this embodiment is connected with the pushing part of the driving device, and the other end is connected with the suction cup. The driving device of this embodiment can directly drive the lifting and lowering of the suction device through the pushing part to realize the grasping of the workpiece with the circular arc surface.

[0039] The other structures of this embodiment are consistent with the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com