Fibre deep-dyeing agent emulsions and manufacture method thereof

A technology of deepening agent and emulsion, applied in the direction of fiber type, fiber treatment, textile and papermaking, etc., can solve the problem of insufficient performance, increase the amount of absorbed light, good storage and dilution stability, and will not cause environmental damage. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

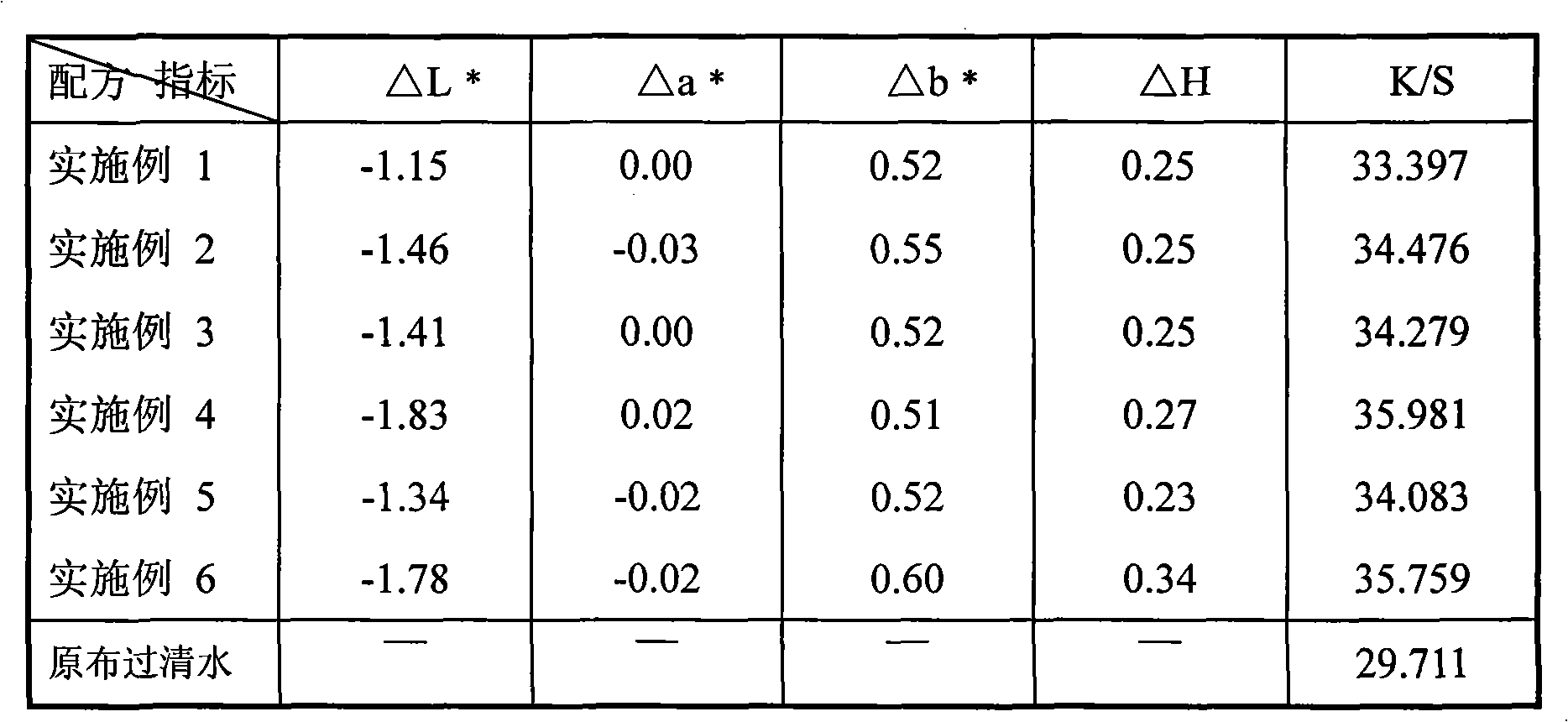

Examples

Embodiment 1

[0034] In a 500ml beaker, dissolve 5.6g of cationic emulsifier cetyltrimethylammonium bromide and 1.4g of nonionic emulsifiers AEO-9 and AEO-3 in 170g of water. After they are completely dissolved, add Mixed monomers of 80g methyl methacrylate (MMA), 0.8g hydroxy silicone oil with an average molecular weight of 1500 and 0.04g vinyltrimethoxysilane (KH-151), high-speed stirring, and then in a high-shear dispersing emulsifier , with a rotating speed of 8000rmp, shear emulsification for 15 minutes to obtain a monomer pre-emulsion;

[0035] In a 500ml four-necked flask, add 0.8g cetyltrimethylammonium bromide, 0.2g each of AEO-9 and AEO-3 and 120g water, and pass N 2 , and gradually warming up to 70°C, adding 15g of monomer pre-emulsion and 5ml volume concentration of 2,2'-azobis(2-amidinopropane) dihydrochloride of 3% (w / v), After polymerization to form a blue translucent seed emulsion, add the pre-emulsion and 15 ml of 2,2'-azobis(2-amidinopropane)di hydrochloride solution, an...

Embodiment 2

[0037] In a 500ml beaker, dissolve 5.6g of cationic emulsifier cetyltrimethylammonium bromide, 1.4g of nonionic emulsifiers AEO-9 and AEO-6, and 2g of N-methylolacrylamide in 90g of water , after it is completely dissolved, add 90g of methyl methacrylate (MMA), 2g of tert-butyl methacrylate, 8g of hydroxyl silicone oil with an average molecular weight of 10000 and 0.02g of vinyltrimethoxysilane (KH-151) The monomer was stirred at high speed, and then sheared and emulsified for 15 minutes in a high-shear dispersing emulsifier at a speed of 10,000 rpm to obtain a monomer pre-emulsion;

[0038] In a 250ml four-necked flask, add 0.8g cetyltrimethylammonium bromide, 0.2g each of AEO-9 and AEO-6 and 20g of water, and pass N 2, and gradually warming up to 70°C, adding 15g of monomer pre-emulsion and 5ml volume concentration of 2,2'-azobis(2-amidinopropane) dihydrochloride of 3% (w / v), After polymerization to form a blue translucent seed emulsion, add the remaining monomer pre-emulsi...

Embodiment 3

[0040] In a 500ml beaker, dissolve 2.8g of cationic emulsifier cetyltrimethylammonium bromide and 1.4g of nonionic emulsifier AEO-9 in 170g of water. After they are completely dissolved, add 40g of methyl methacrylate ester (MMA), 40g of ethyl methacrylate, 13.0g of hydroxyl silicone oil with an average molecular weight of 500 and 6.6g of methacryloxypropyltrimethoxysilane (KH-570), 0.5g of hydroxyethyl methacrylate Mix the monomers, stir at high speed, and then shear and emulsify for 15 minutes in a high-shear dispersing emulsifier at a speed of 8000rmp to obtain a monomer pre-emulsion;

[0041] In a 500ml four-necked flask, add 0.4g cetyltrimethylammonium bromide, 0.2g AEO-9 and 50g water, pass N 2 , and gradually warming up to 70°C, adding 15g of monomer pre-emulsion and 5ml volume concentration of 2,2'-azobis(2-amidinopropane) dihydrochloride of 4% (w / v), After polymerization to form a blue translucent seed emulsion, add the remaining monomer pre-emulsion and 15 ml of 2,2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com