Solar module and manufacturing method thereof

A solar energy and module technology, applied in final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problems of uncovered transparent conductive oxide layer, uneven thickness of transparent conductive oxide layer and semiconductor layer, etc. The effect of increasing the amount of absorbed light and widening the wavelength range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

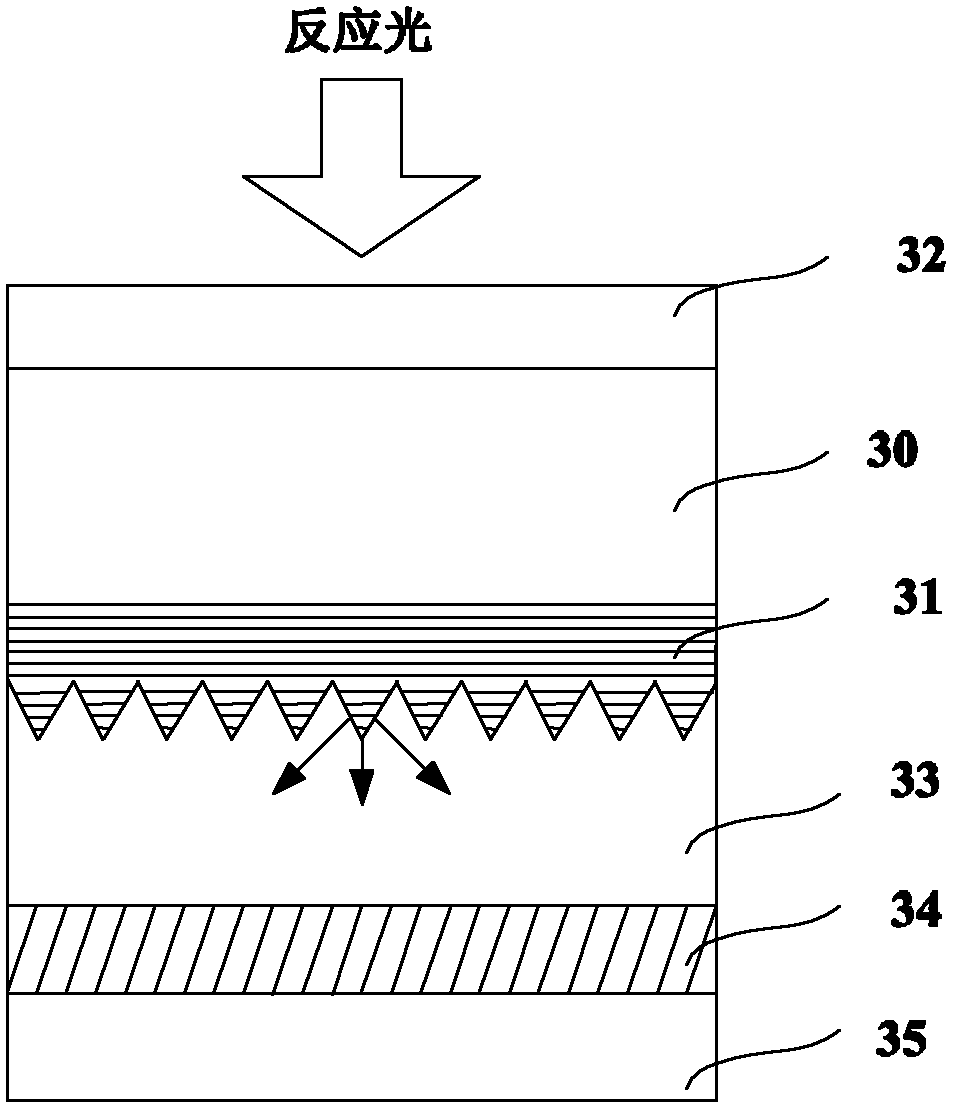

[0019] Such as Figure 4 Shown is a TCO glass structure diagram according to an embodiment of the solar module of the present invention, which sequentially includes a scattering film 45, a glass layer 40, a front transparent conductive oxide layer 41, a semiconductor layer 42, and a rear conductive layer from the light incident surface 43 and encapsulation material 44. The front transparent conductive oxide layer 41 is used as a front electrode, the rear conductive layer 43 is used as a back electrode, and the semiconductor layer 42 is a light absorbing layer.

[0020] Wherein, the scattering film 45 includes an adhesive (not shown), a solvent (not shown) and nanoparticles 451 , and the diameter of the nanoparticles 451 is smaller than or equal to the wavelength of the reaction light.

[0021] The nanoparticles 451 can scatter the reaction light, increase the transmission path of the reaction light in the TCO glass, increase the probability of the reaction light being absorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com