Cosmetic raw material stirring device

A technology of stirring device and cosmetics, which is applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

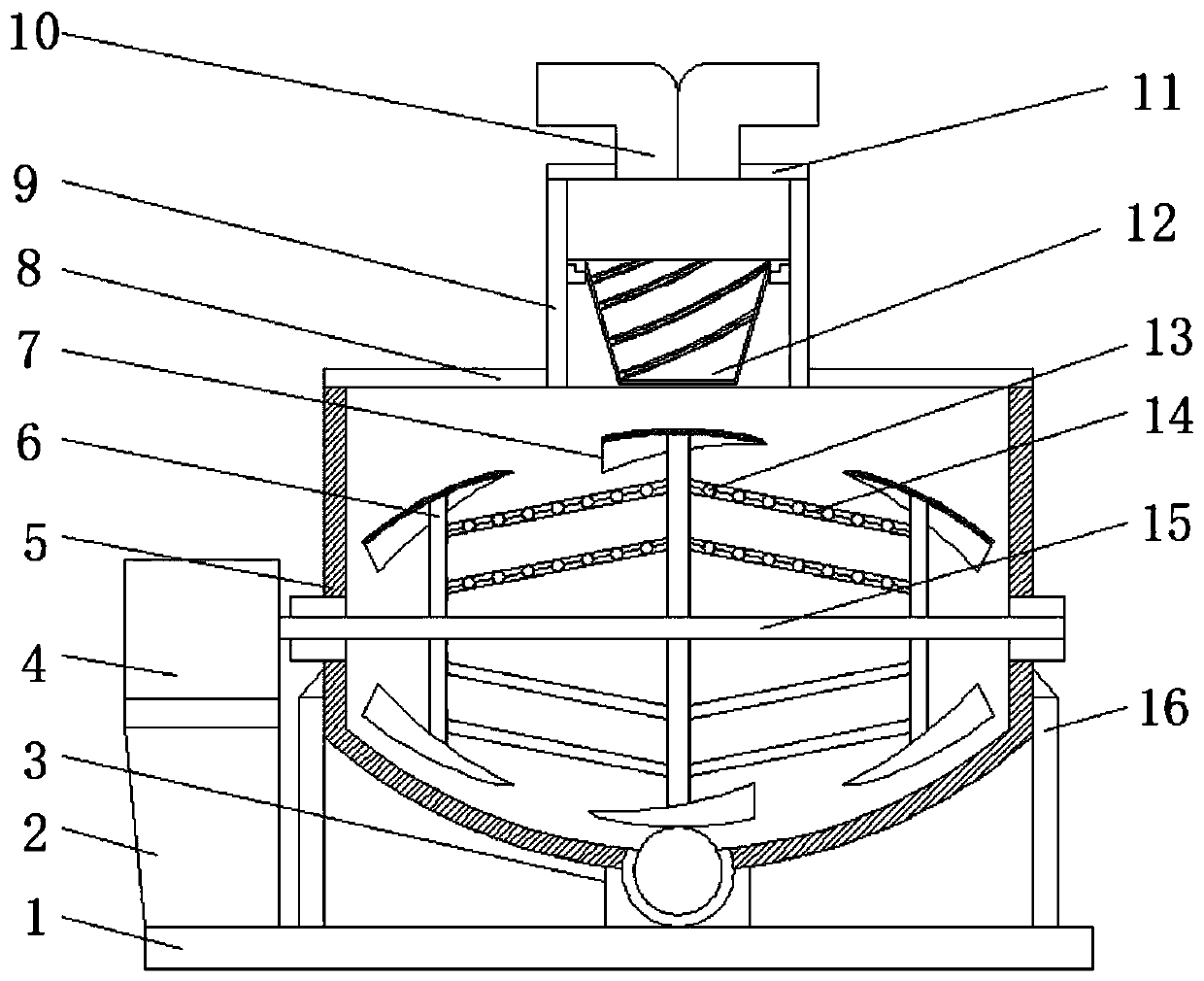

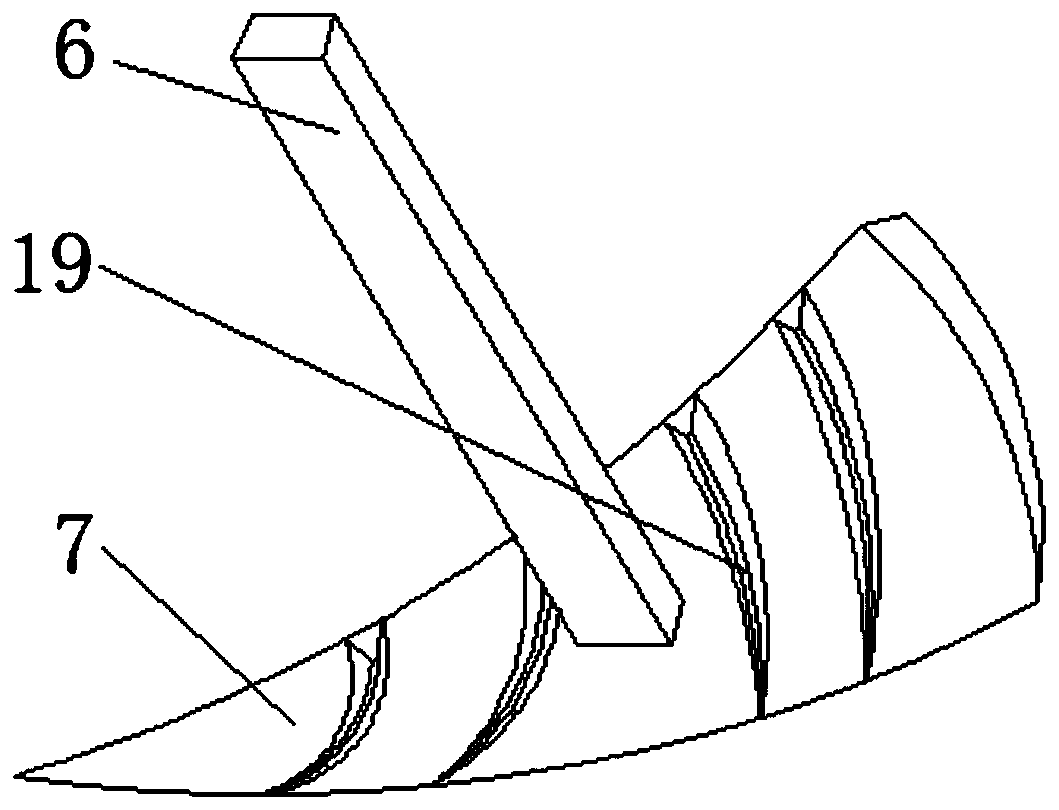

[0026] refer to Figure 1-3 , a raw material stirring device for cosmetics, comprising a base 1, two support frames 16 are fixedly installed on the top of the base 1, and a tank body 5 is fixedly installed between the top ends of the two support frames 16, and the top of the tank body 5 is fixedly installed There is a cover 8, a liquid pump 3 is installed at the bottom of the tank body 5, a drive mechanism is fixedly installed at the top of the base 1, and a drive shaft 15 is installed between the inner walls of both sides of the tank body 5 through mechanical seals, and the drive shaft The outer side of 15 is fixedly installed with a plurality of agitating rods 6, and the end of the drive shaft 15 is connected with the drive mechanism transmission, and the end of the agitating rod 6 is fixedly equipped with a stirring paddle 7 of a helical structure, and the side of the agitating paddle 7 is in contact with the tank. The inner wall of the bottom of the body 5 is tangent, and ...

Embodiment 2

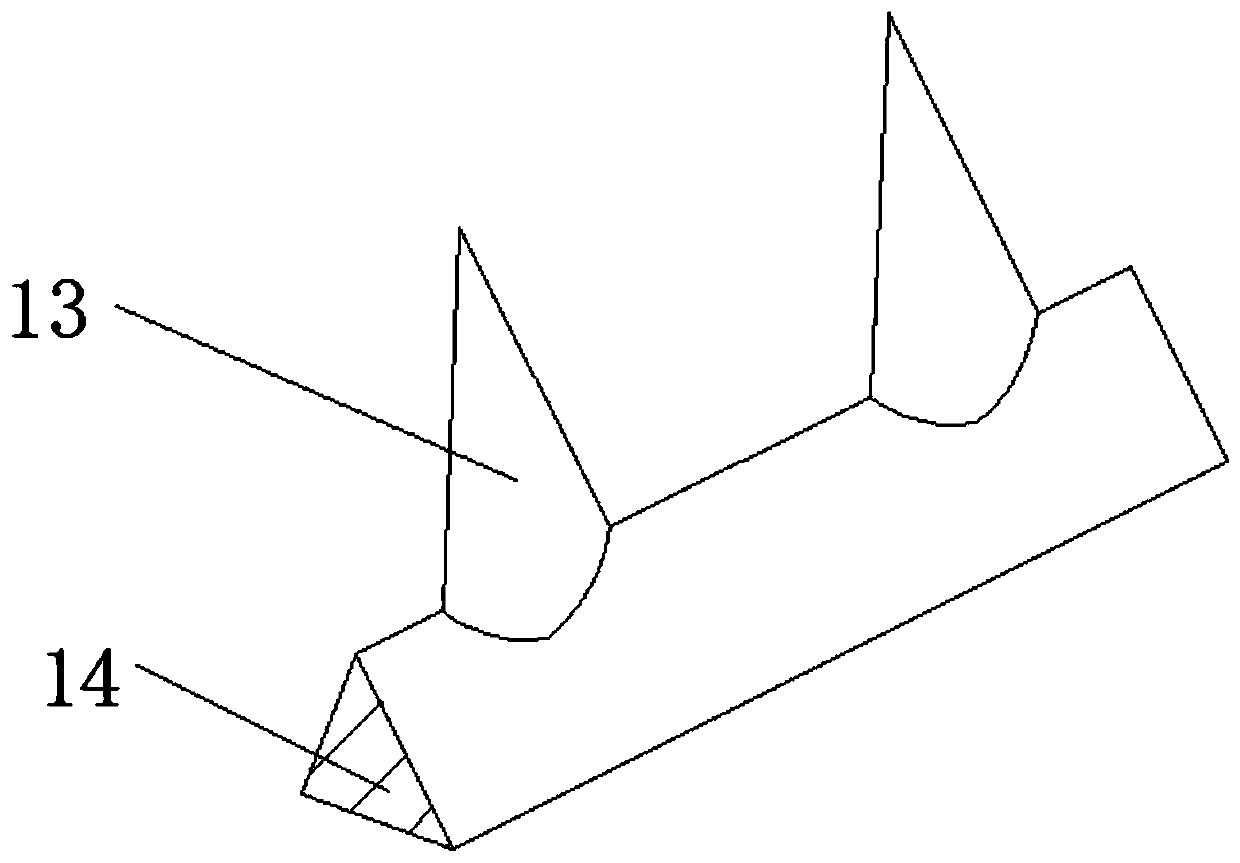

[0033] refer to Figure 1-4 , a raw material stirring device for cosmetics, a fixed ring is welded inside the cylinder body 9, and a confluence mechanism is installed inside the fixed ring;

[0034] The confluence mechanism includes a support ring 18, a confluence barrel 12 with a horn-shaped structure, and a propeller blade 17 arranged inside the confluence barrel 12, and the support ring 18 is welded to the top end of the confluence barrel 12;

[0035] The outer bottom end of the support ring 18 and the inner wall of the fixed ring are provided with matching thread grooves.

[0036] In this embodiment, a confluence mechanism that is easy to disassemble is installed inside the cylinder body 9. When the raw materials are added through the feed pipe 10, they are initially contacted and collected inside the confluence cylinder 12 with a horn-shaped structure, and then drained by the internal propeller blades 17. The effect is to make the converging raw materials flow downward i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com