Water-soluble cutting fluid recovery treatment method

A technology for recycling and processing cutting fluid, which is applied in the field of recycling and processing water-soluble cutting fluid. It can solve the problems of incomplete adsorption of debris, poor filtering effect of cutting fluid, clogged or scratched filter paper, etc., to increase the range of agitation and easy operation , the effect of preventing the reduction of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

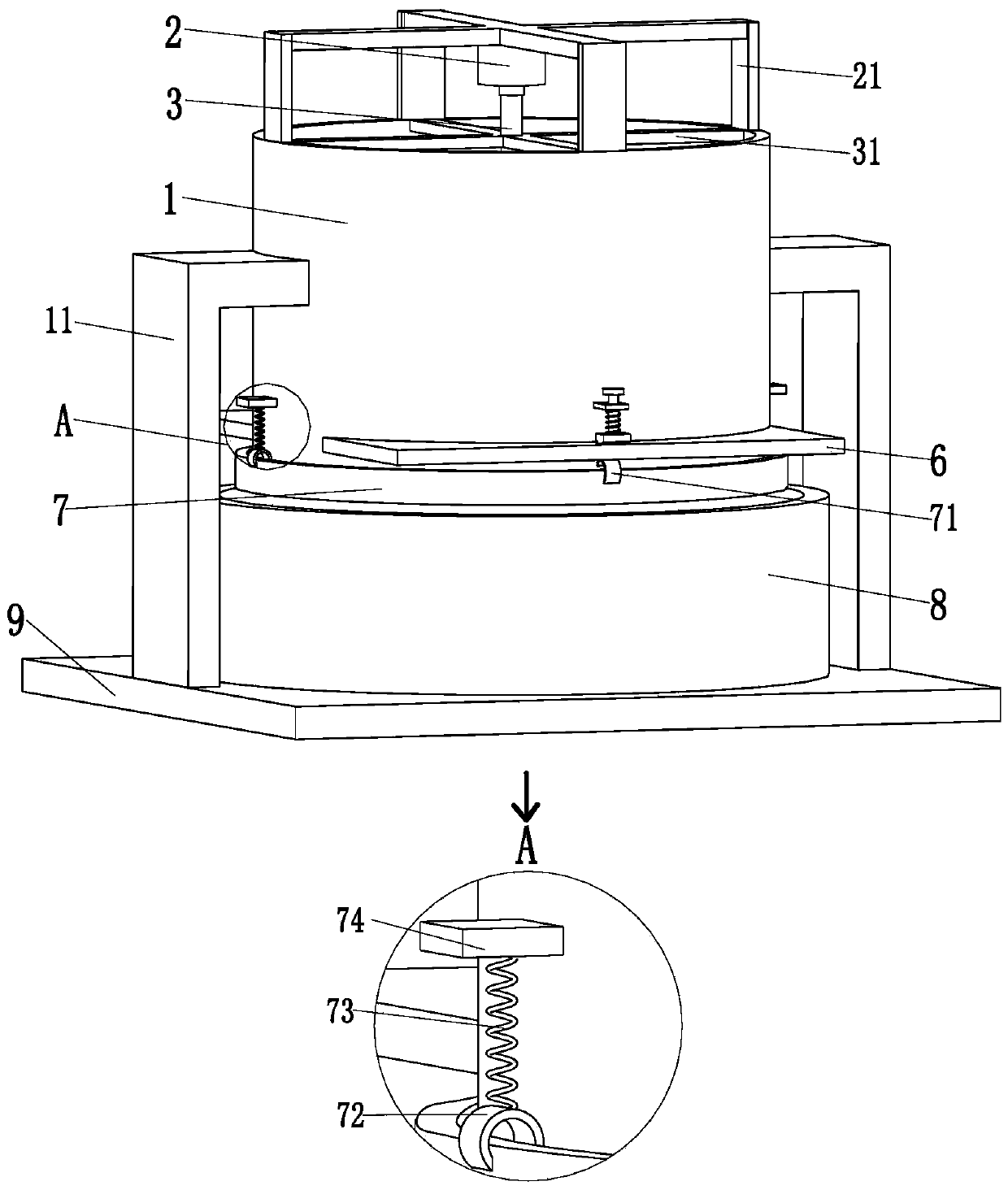

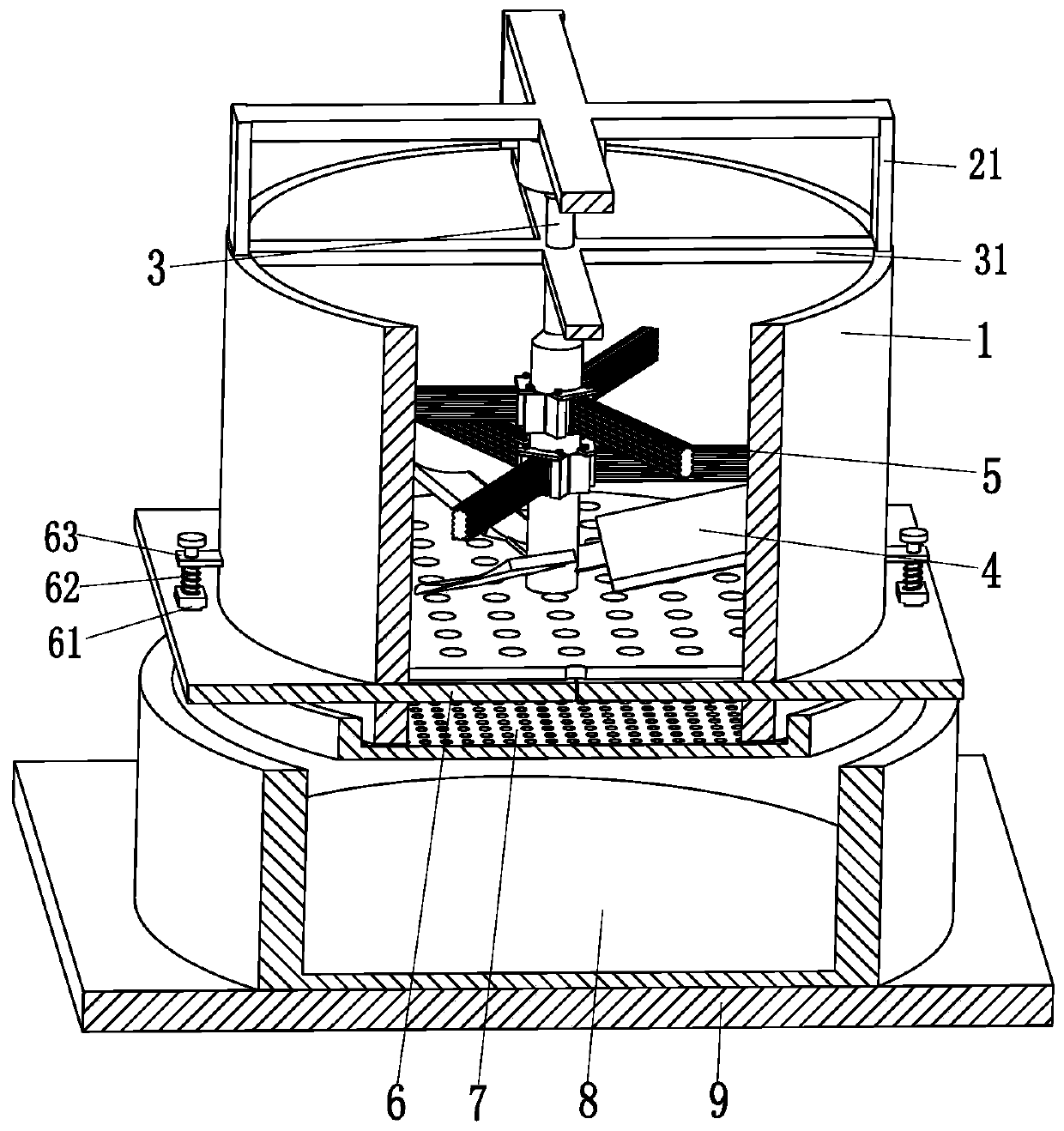

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

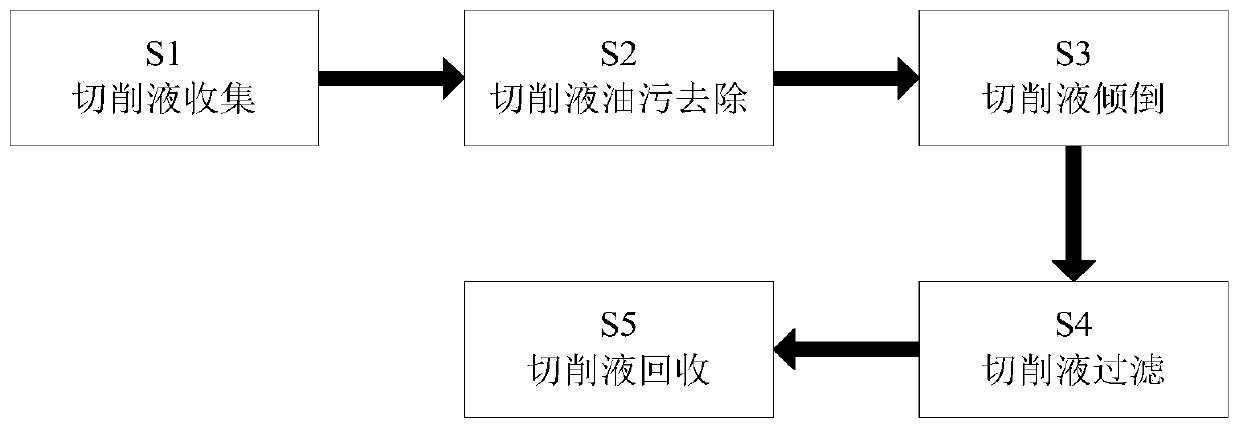

[0037] Such as Figure 1 to Figure 6 Shown, a kind of water-soluble cutting fluid recovery processing method comprises the following steps:

[0038] S1. Cutting fluid collection: place the cutting fluid that needs to be recovered in a storage bucket and let it stand for a period of time, so that the oil and light debris in the cutting fluid can float on the liquid surface of the cutting fluid;

[0039] S2. Cutting fluid oil removal: dump and remove the oil and other sundries floating on the cutting fluid surface in step S1;

[0040] S3. Dumping of cutting fluid: Pour the oil-removed cutting fluid into the mixing tank 1. By turning on the stirring motor 2 installed on the mixing tank 1, the stirring rod 3 can be driven to rotate clockwise. The blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com