A vertical rotation cooling system for lead-acid batteries

A technology of cooling system and lead-acid battery, which is applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc. It can solve the problems of slow water heat dissipation, low cooling efficiency, and easy shaking of lead-acid batteries, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

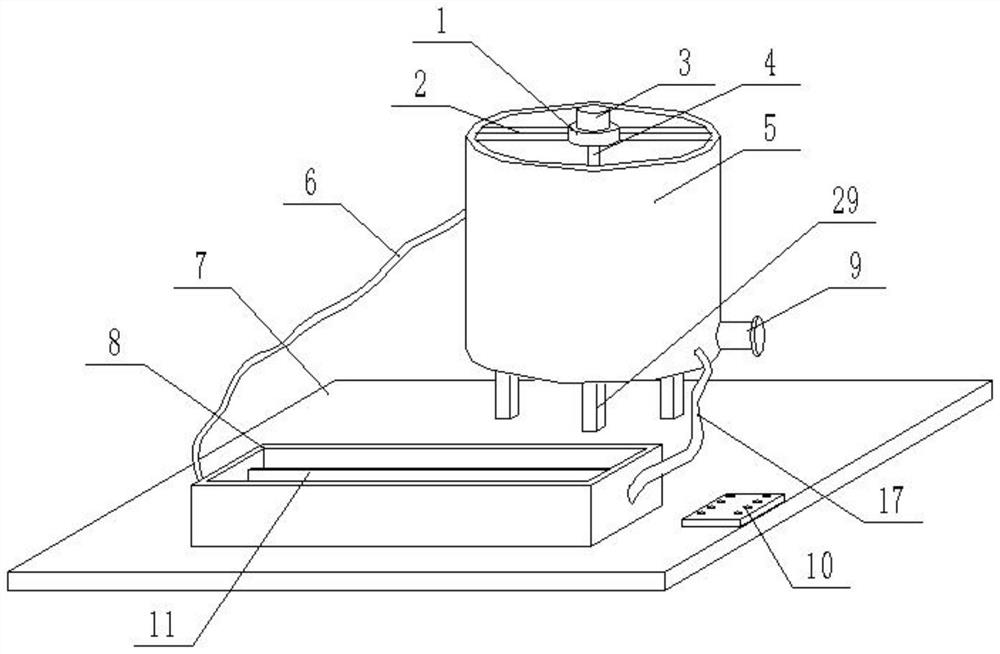

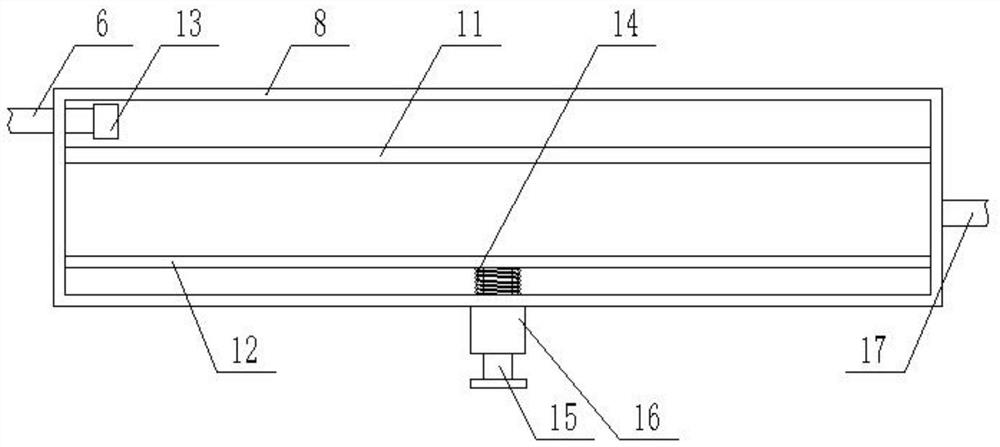

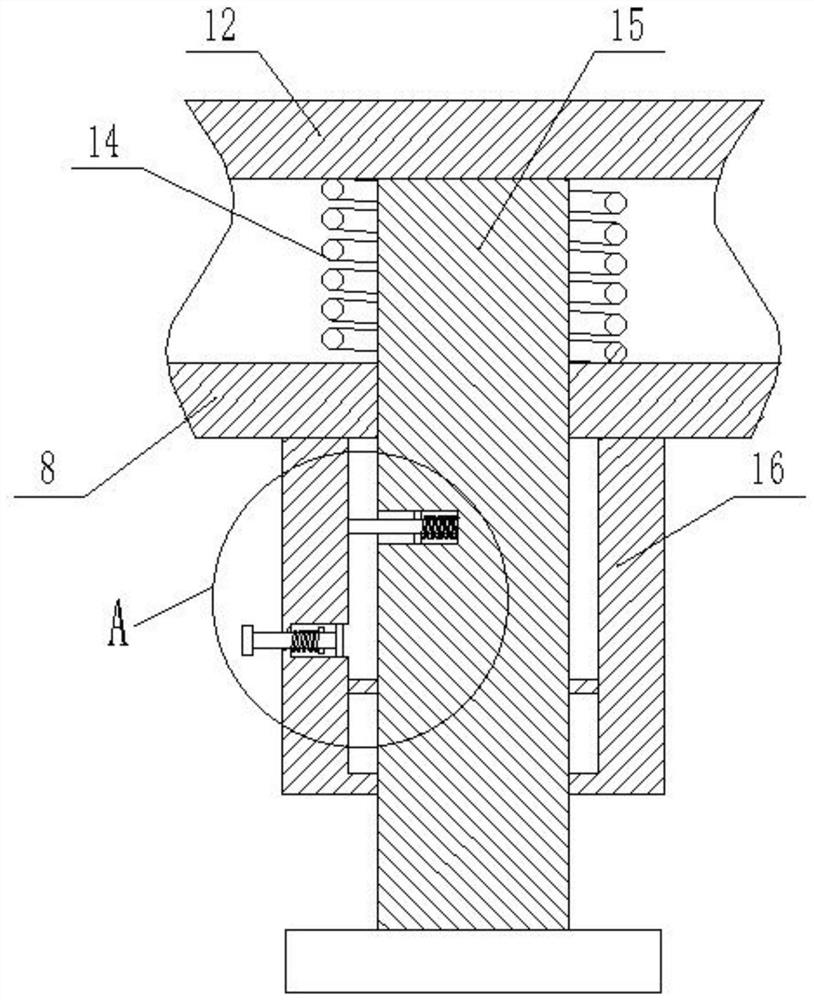

[0027] see Figure 1-6 , a lead-acid battery up and down rotary cooling system, comprising a base 7, the upper end of the base 7 is fixedly equipped with a control panel 10, the upper end of the base 7 is provided with a mixing box 5, and the bottom end of the mixing box 5 is connected with a drain pipe 9, the drain pipe 9 upper threads are connected with a pipe cover, the water in the mixing box 5 can be emptied through the drain pipe 9, the lower end of the mixing box 5 is fixedly connected with the upper surface of the base 7 through the support legs 29, the upper end opening of the mixing box 5 is set, and the stirring The middle part of the upper end of the box 5 is fixedly connected with a support rod 2, the middle part of the support rod 2 is fixedly connected with a support plate 1, the upper middle part of the support plate 1 is fixedly installed with a stirring motor 3, the input end of the stirring motor 3 is connected with the output end of the control panel 10 Ele...

Embodiment 2

[0033] see Figure 7 , a lead-acid battery up and down rotary cooling system, comprising a base 7, the upper end of the base 7 is fixedly equipped with a control panel 10, the upper end of the base 7 is provided with a mixing box 5, and the bottom end of the mixing box 5 is connected with a drain pipe 9, the drain pipe 9 upper threads are connected with a pipe cover, the water in the mixing box 5 can be emptied through the drain pipe 9, the lower end of the mixing box 5 is fixedly connected with the upper surface of the base 7 through the support legs 29, the upper end opening of the mixing box 5 is set, and the stirring The middle part of the upper end of the box 5 is fixedly connected with a support rod 2, the middle part of the support rod 2 is fixedly connected with a support plate 1, the upper middle part of the support plate 1 is fixedly installed with a stirring motor 3, the input end of the stirring motor 3 is connected with the output end of the control panel 10 Elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com