Ice conveying system for refrigerator

A technology for conveying systems and refrigerators, applied in applications, making ice, household appliances, etc. It can solve the problems of complex structure of ice conveying systems, high motor requirements, and difficult separation, and achieve enhanced ice stirring effect, low power requirements, and increased The effect of ice storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

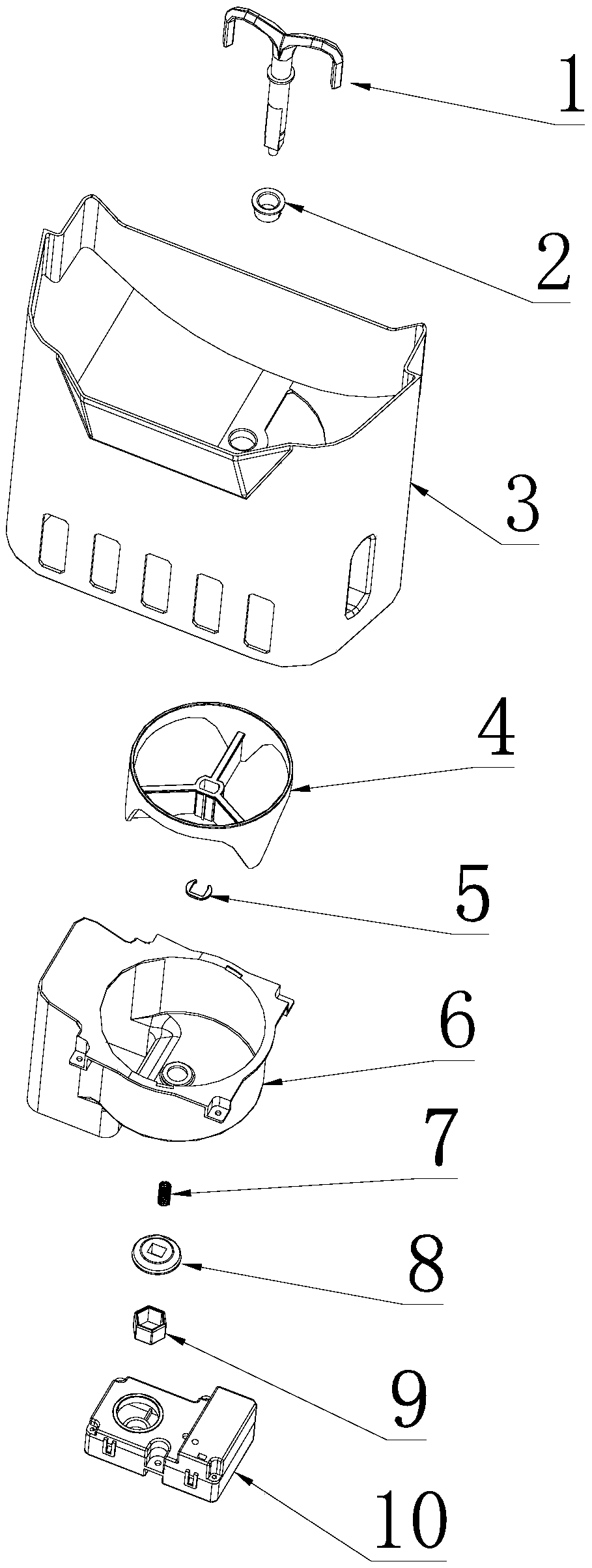

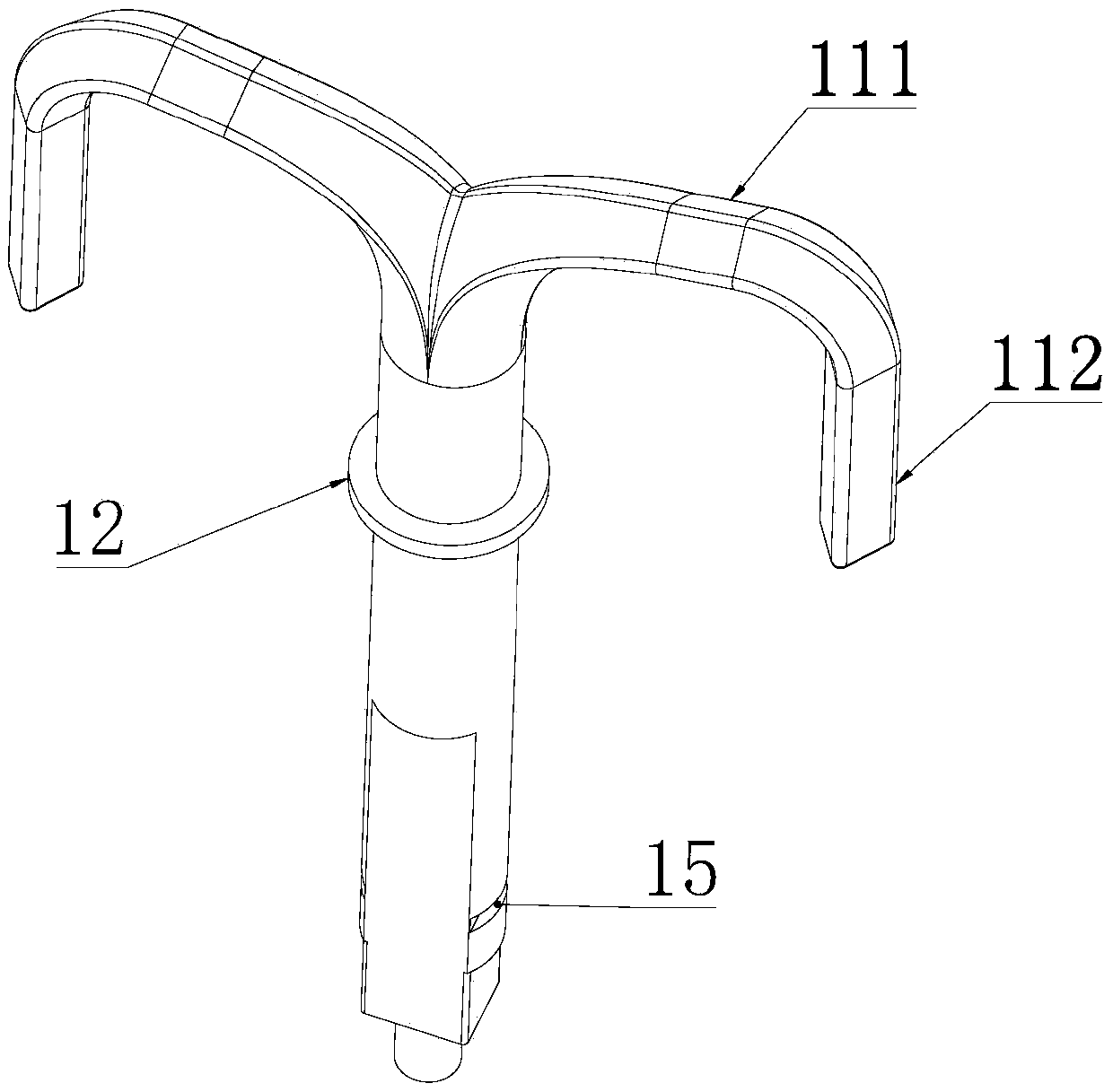

[0035] Based on the above, such as figure 2 with 3 As shown, in this embodiment, the second branch 112 and the rod body are located on the same side of the first branch 111 . That is, the second branch 112 is bent downward relative to the first branch 111 . This structure can be used when the first branch 111 is at a higher position in the ice storage box 3 and there are more ice cubes below it, and the second branch 112 is bent downward to help stir the ice in the lower part of the ice storage box 3 blocks to prevent dead ends.

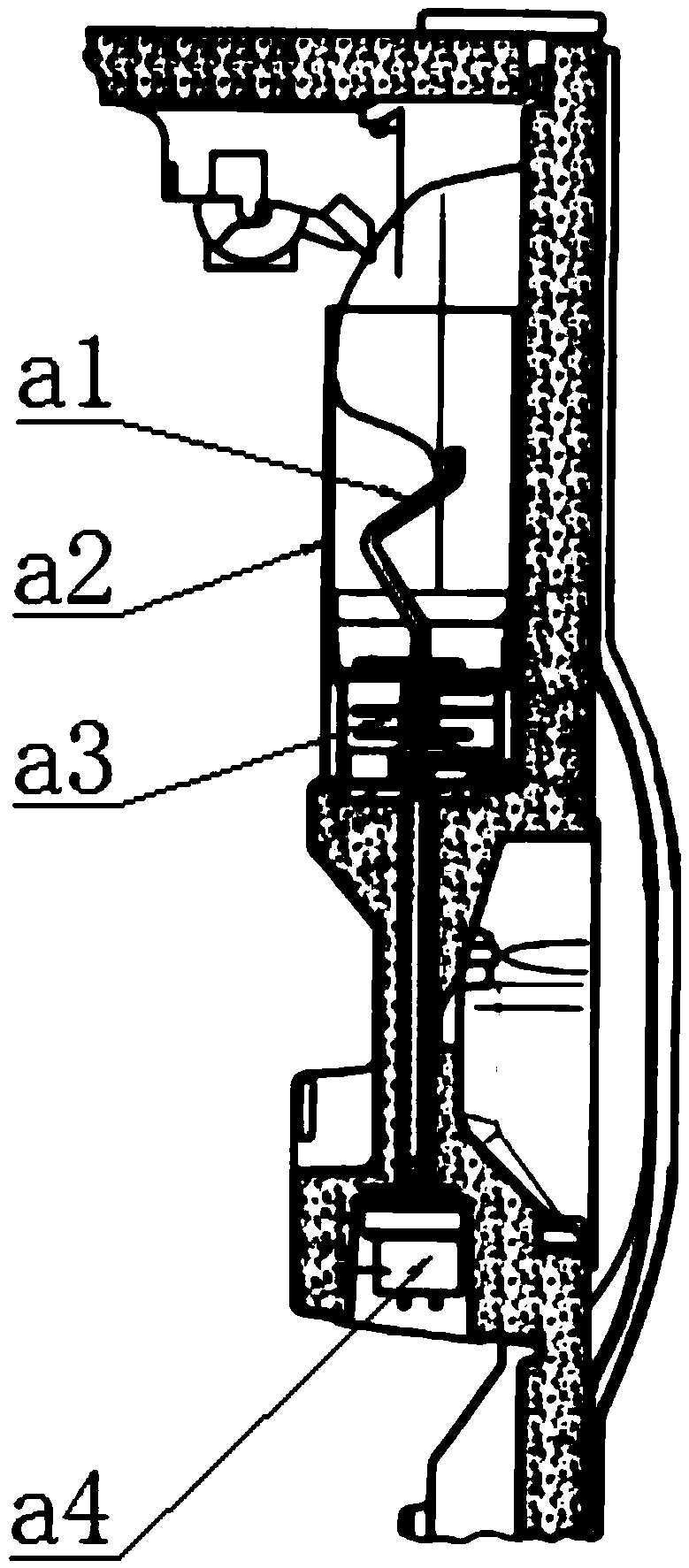

[0036]Below the ice storage box 3 is connected an ice outlet passage 6 connected with the ice outlet, and the ice outlet passage 6 is provided with an ice selection cylinder 4, and the ice selection cylinder 4 is arranged on the side of the ice outlet. Below, the ice selection cylinder 4 is used to transport the ice cubes from the ice outlet to the outlet of the ice outlet channel 6 by rotating; the rod body passes through the ice storage box 3, ...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, the only difference is that, as Figure 4 with 5 As shown, the second branch 112 and the rod body are respectively located on two sides of the first branch 111 . That is, the second branch 112 is bent upward relative to the first branch 111 . This structure can be used when the first branch 111 is at a lower position in the ice storage box 3 and there are more ice cubes above it, and the second branch 112 is bent upwards to help stir the ice cubes on the upper part of the ice storage box 3 , to prevent dead ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com