Mechanical dehydration multifunctional slurry conditioner for River and lake contaminated sediment treatment

A technology for conditioning polluted bottom sludge and mud, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. It can solve problems such as easy sedimentation and hardening, and avoid sedimentation and hardening. Accumulated on the bottom of the pool for a long time, the effect of agitation is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

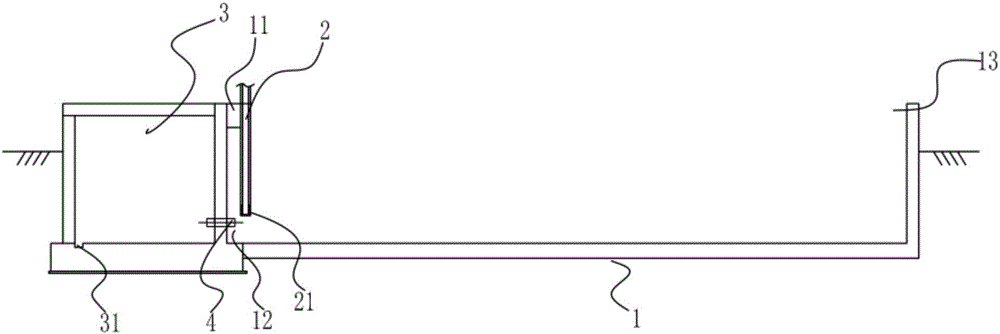

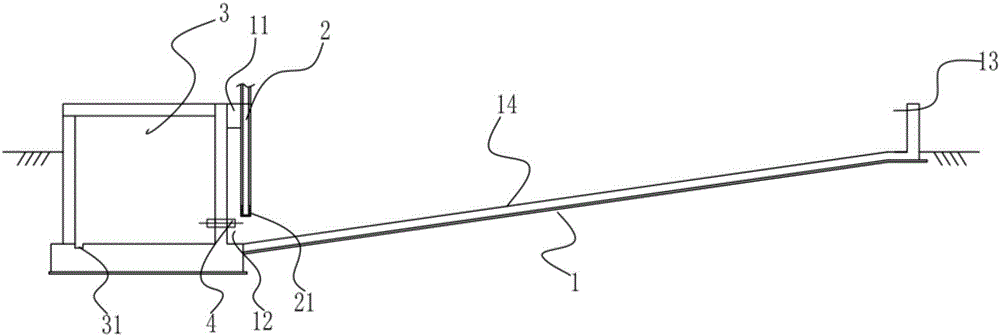

[0029] see figure 1 The first embodiment of the present invention provides a mechanical dehydration multifunctional mud conditioning pond for processing polluted bottom sludge in rivers and lakes, including a conditioning pond body 1, and the conditioning pond body 1 is provided with a slurry inlet 11, a slurry outlet 12, and a water outlet 13. The tank body 1 is provided with an air intake pipe 2 near the slurry outlet 12, and the air intake pipe 2 is provided with a plurality of ventilation holes 21, and the plurality of ventilation holes 21 are arranged on the air intake pipe 2 in different directions.

[0030] The first embodiment of the present invention provides a mechanical dehydration multi-functional mud conditioning pool for processing polluted sediment in rivers and lakes. By setting an air intake pipe 2 in the conditioning pool body 1 and ventilating the air into the air intake pipe 2, the gas is discharged in the conditioning pool body 1. The mud is disturbed, so ...

Embodiment 2

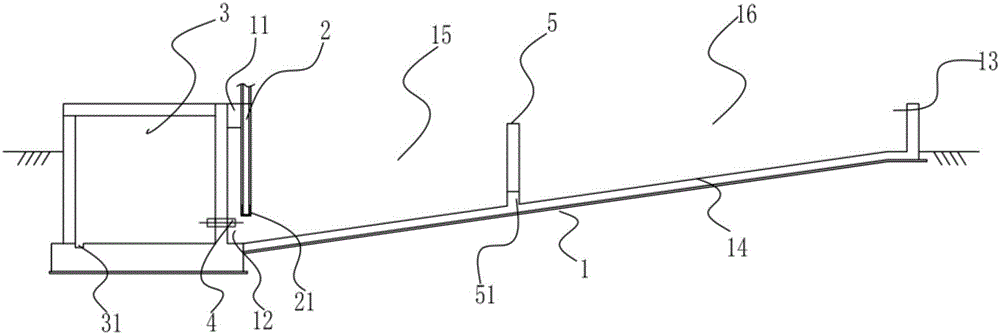

[0037] Another embodiment provided by the present invention differs from Embodiment 1 only in that: Please refer to image 3, the conditioning tank body 1 also includes a first conditioning chamber 15 and a second conditioning chamber 16, the first conditioning chamber 15 and the second conditioning chamber 16 are separated by a partition wall 5, and the bottom of the partition wall 5 is provided with a wall that communicates with the first conditioning chamber 15. and the channel 51 of the second conditioning chamber 16, the height of the top surface of the partition wall 5 is lower than the height of the top surfaces of the first conditioning chamber 15 and the second conditioning chamber 16. By setting the first conditioning chamber 15 and the second conditioning chamber 16, when the gas is introduced to stir the mud, only the pool of the first conditioning chamber 15 is stirred, and the second conditioning chamber 16 is convenient for sedimentation and precipitation of supe...

Embodiment 3

[0039] Another embodiment provided by the present invention differs from Embodiment 1 only in that: Please refer to Figure 4 A decanter 6 for discharging the supernatant liquid in the conditioning tank body 1 is provided at the water outlet 13 . By setting a decanter 6 at the water outlet 13 in the conditioning tank body 1, the supernatant liquid in the conditioning tank body 1 is discharged in time through the water decanter 6, which further helps to adjust the mud in the conditioning tank body 1. Concentration: By adjusting the concentration of the mud in the conditioning tank body 1 in time, it is helpful for the deep dehydration of the subsequent filter press. The description of the value is that the decanter 6 can also adopt the existing conventional technology, preferably a rotary decanter. The description of the value is that the effluent discharged from the decanter 6 can be further introduced into the sedimentation tank to carry out the next step. Sedimentation tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com