Patents

Literature

48results about How to "Solve the bonding problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of metal organic framework ZIF-8 (zero insert force-9) film

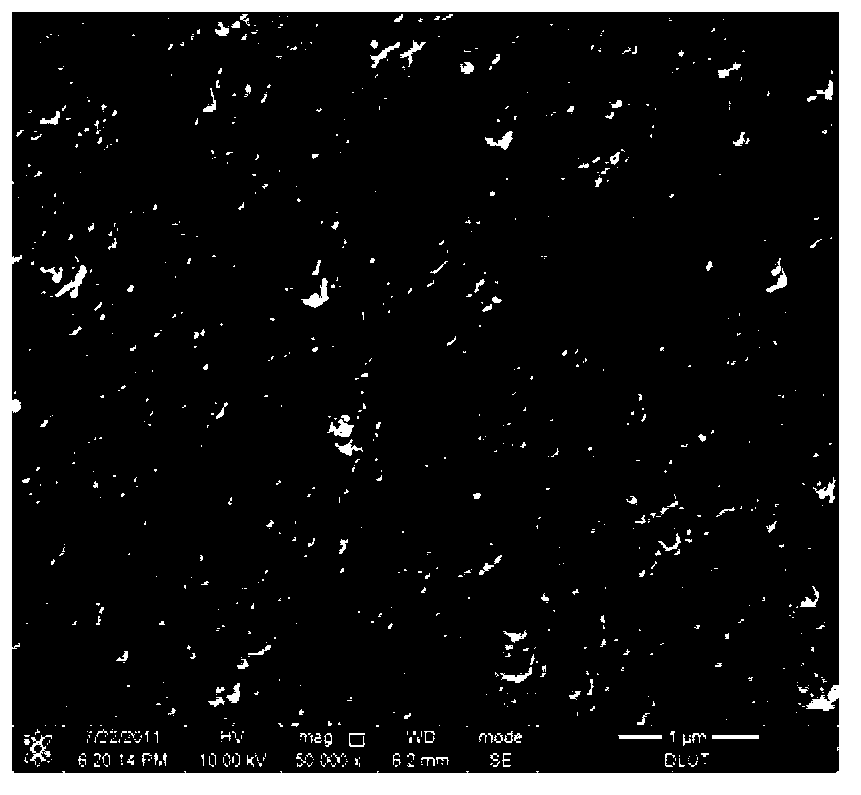

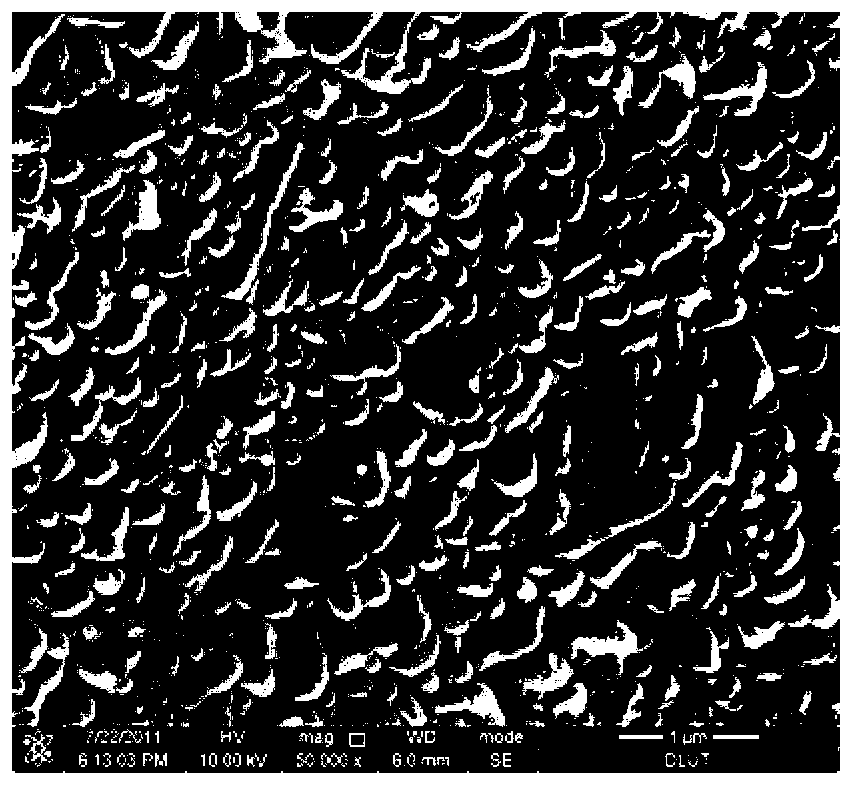

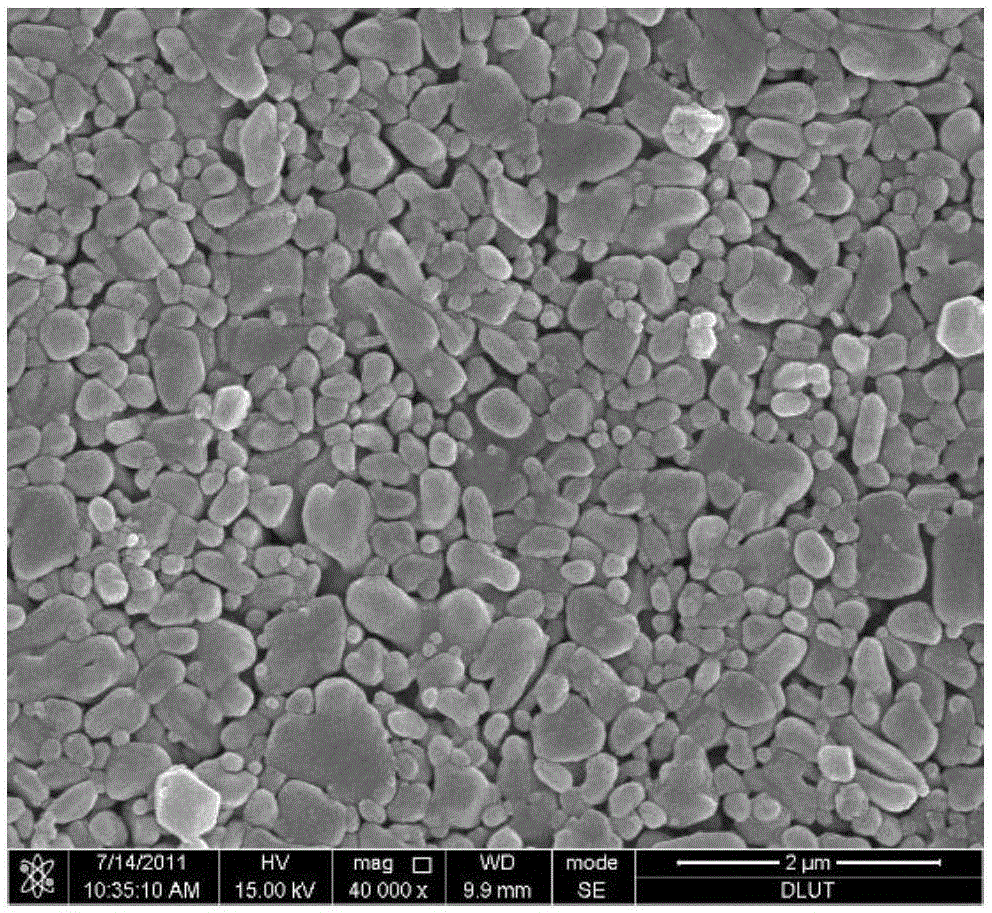

ActiveCN102794115ASolve the bonding problemEvenly distributedSemi-permeable membranesMetal-organic frameworkActive point

The invention provides a novel preparation method of a high-performance continuous ZIF-8 (zero insert force-8) film for the high-performance separation and purification of gas, and mainly aims at solving the combination problem among a continuous even growth film, a film and a carrier of the ZIF-8 film. The preparation method is mainly characterized by comprising the following steps of: previously introducing growth point and a combination point on the surface of a porous carrier to form a thin layer of zinc oxide coating layer taken as a finished film, and growing in an inducing way to form the continuous even ZIF-8 film. An active point of the film homogeneous nucleation is introduced, the combination force problem between the film and the surface of the carrier is solved, and the surface of the carrier is modified by the coating layer, so that the high-quality film can be preferably formed. Compared with the conventional preparation method of the ZIF-8 film, the novel method adopted by the invention not only is high in film-forming effective mass, simple in process, and convenient for large-scale preparation and amplification, so that the method has a potential application prospect and a wide application value.

Owner:DALIAN UNIV OF TECH

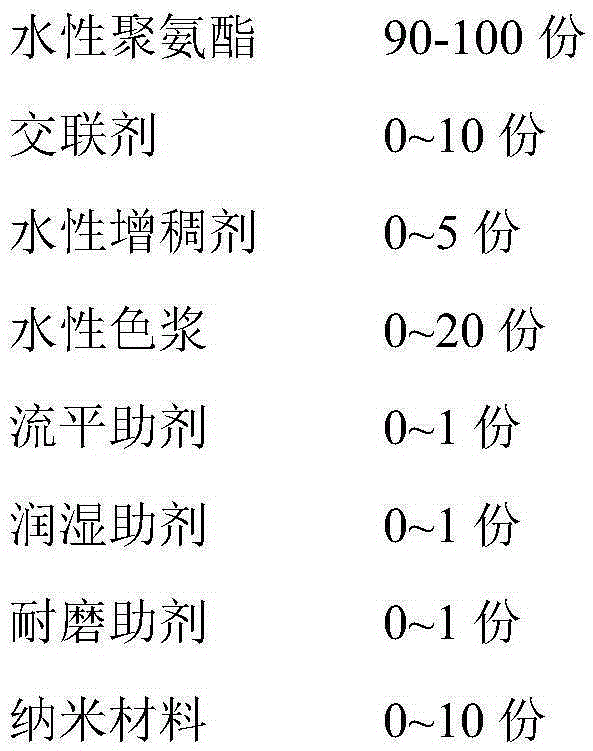

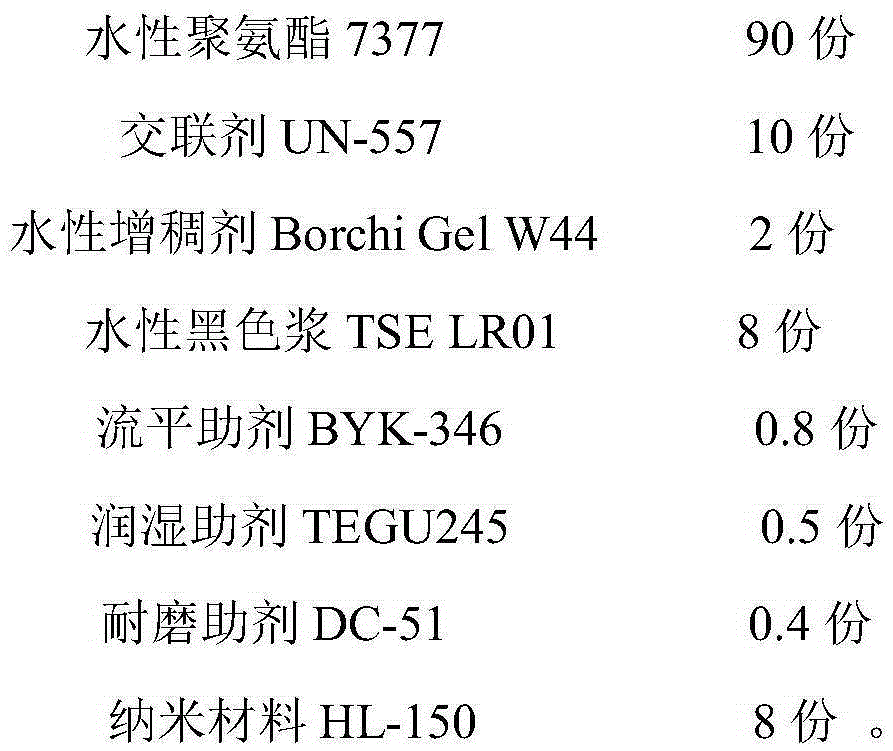

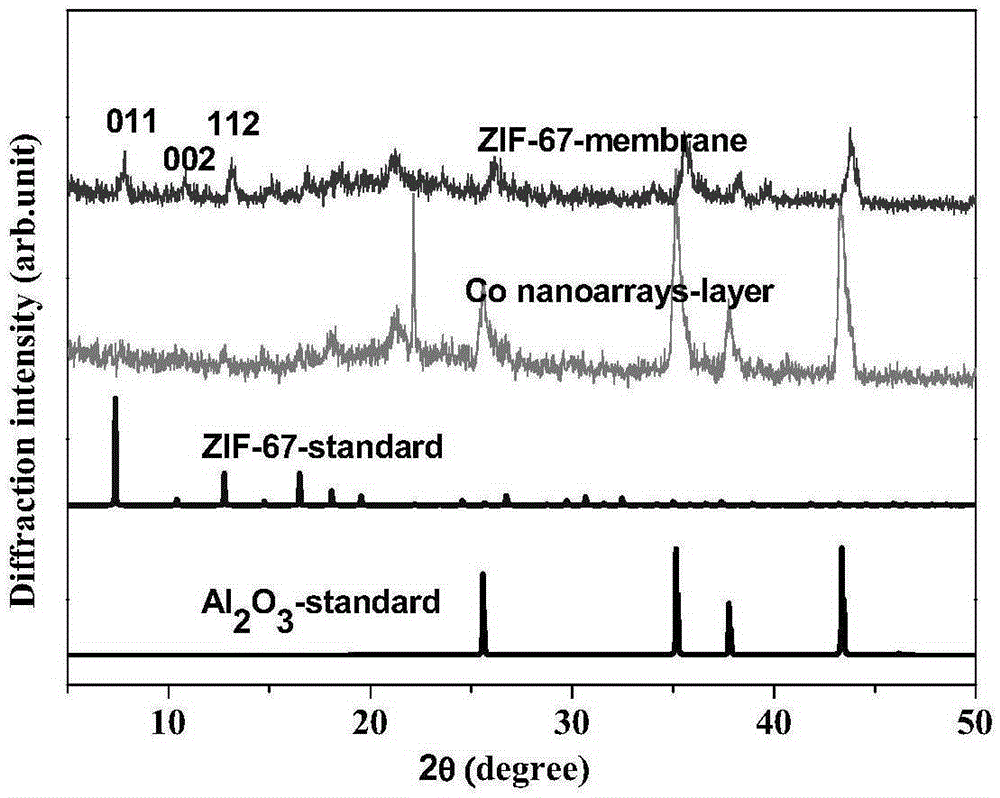

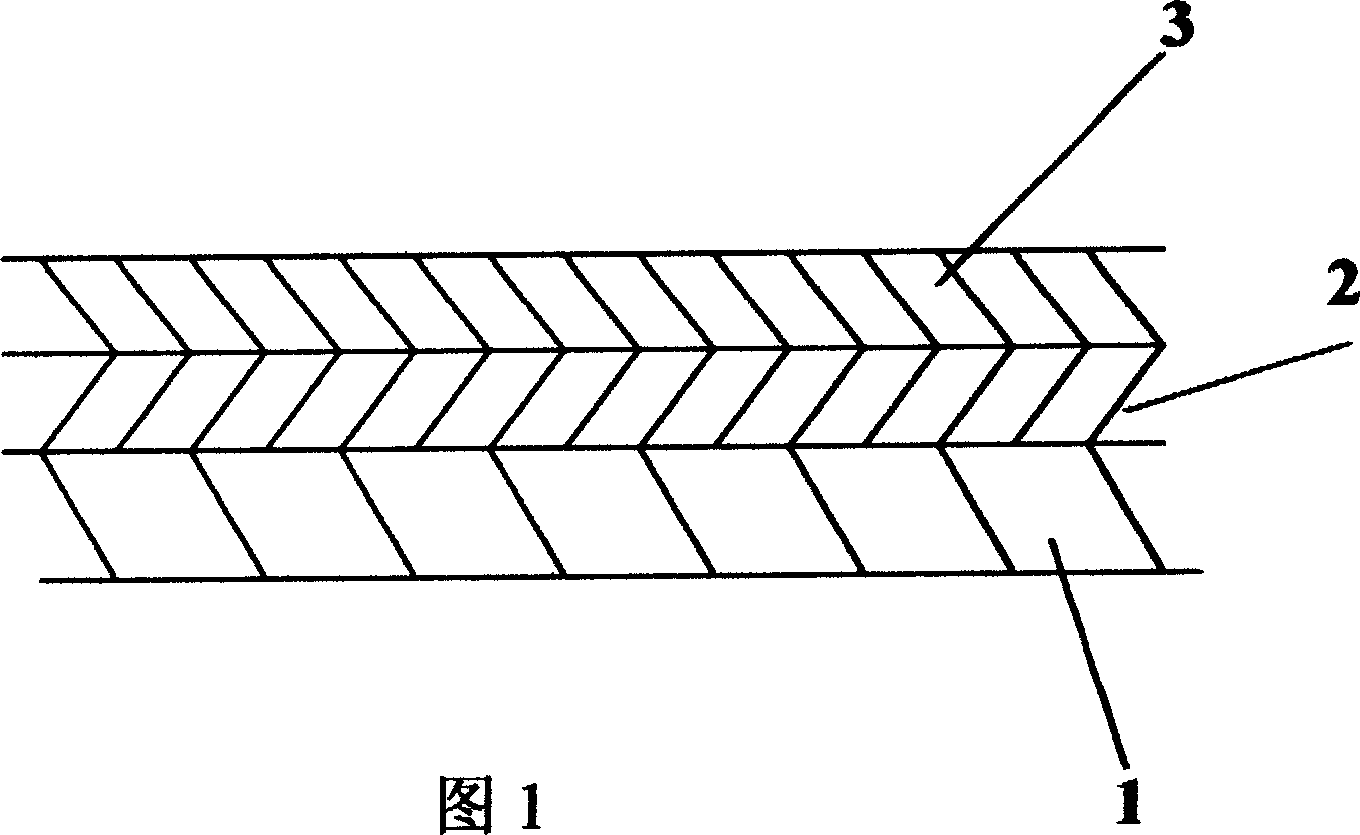

Preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather

ActiveCN105350342AStrong three-dimensional senseSoft touchFootwearTextiles and paperElastomerOrganic solvent

The present invention discloses a preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather, the synthetic leather comprises an aqueous elastomer surface layer and a solvent-free foaming intermediate layer, the aqueous elastomer surface layer resin is thermosetting polyether aqueous polyurethane resin, the solvent-free foaming intermediate layer is thermosetting two-component polyether solvent-free foaming polyurethane resin, and the two-component material is polyether combination A material and polyether B material prepolymer. The preparation process does not use any organic solvent, achieves the synthetic leather production and processing, finished product zero solvent use and health and environmental friendliness; at the same time, the advantages of the aqueous polyurethane resin and the solvent-free polyurethane resin are combined, and the obtained synthetic leather products has strong pattern stereoscopic impression, soft hand feeling, superior hydrolysis resistance and other physical properties, and skin and leather feeling equivalent to natural dermis.

Owner:ANHUI ANLI MATERIAL TECH

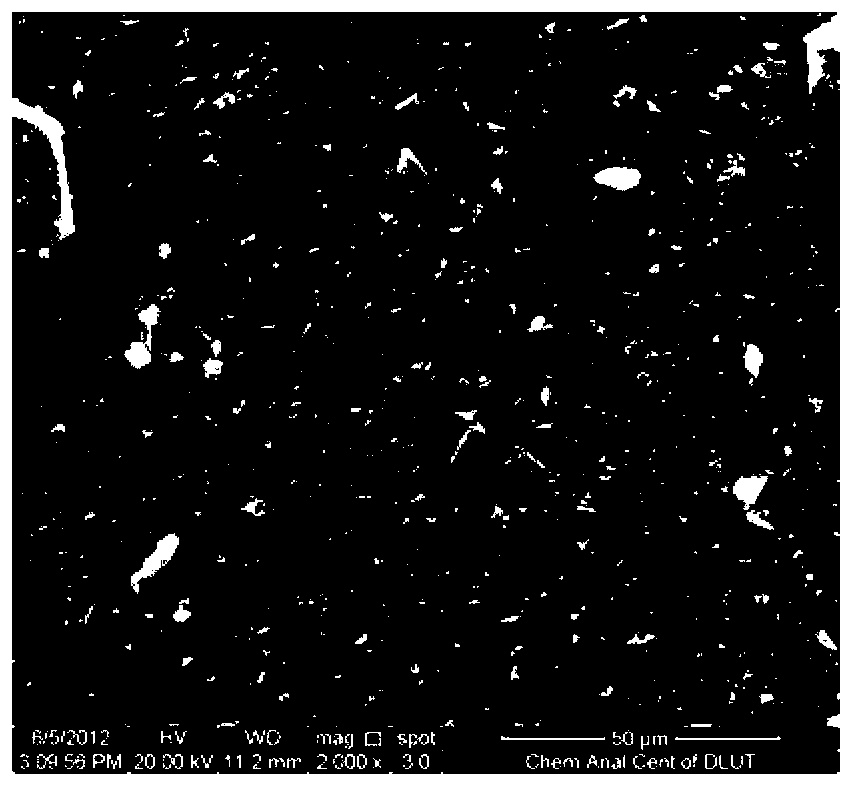

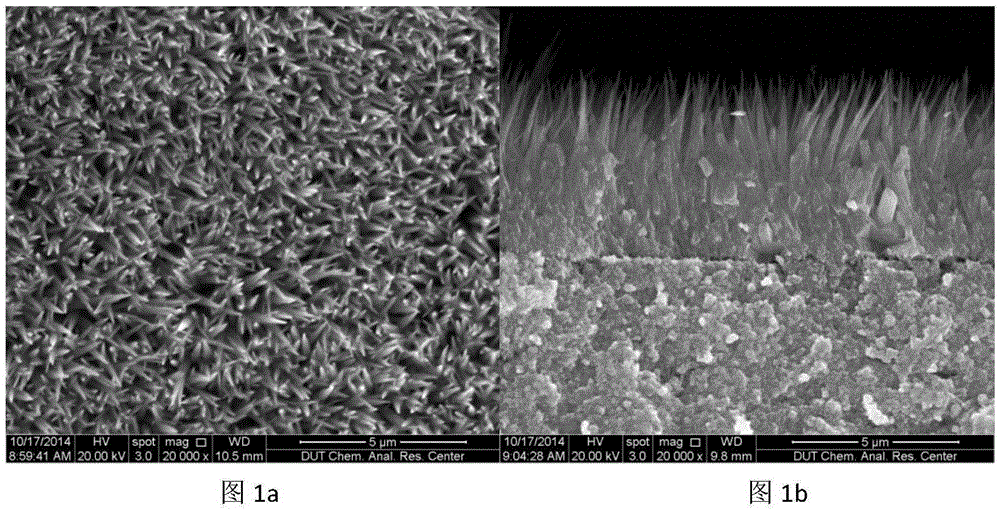

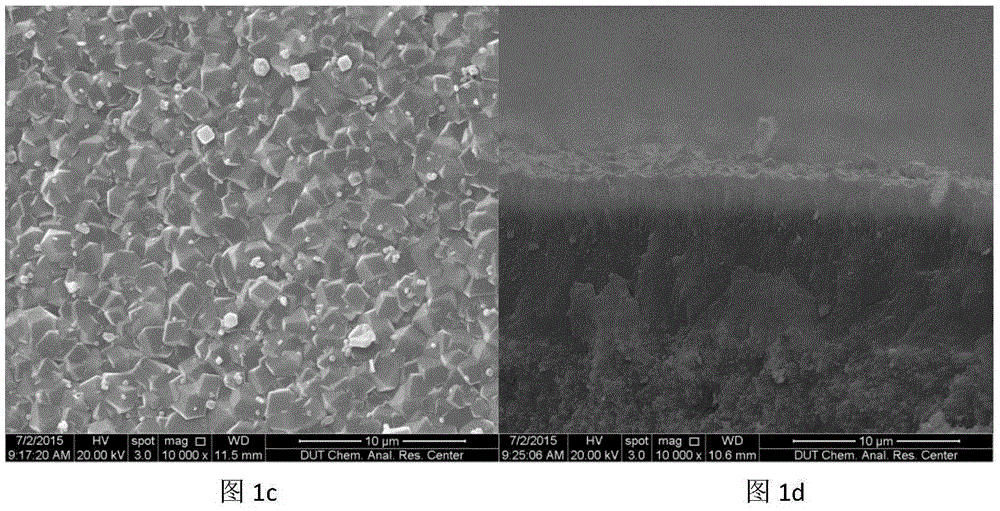

Preparation method for forming metal organic framework ZIF-67 film by utilizing cobalt nano array layer conversion

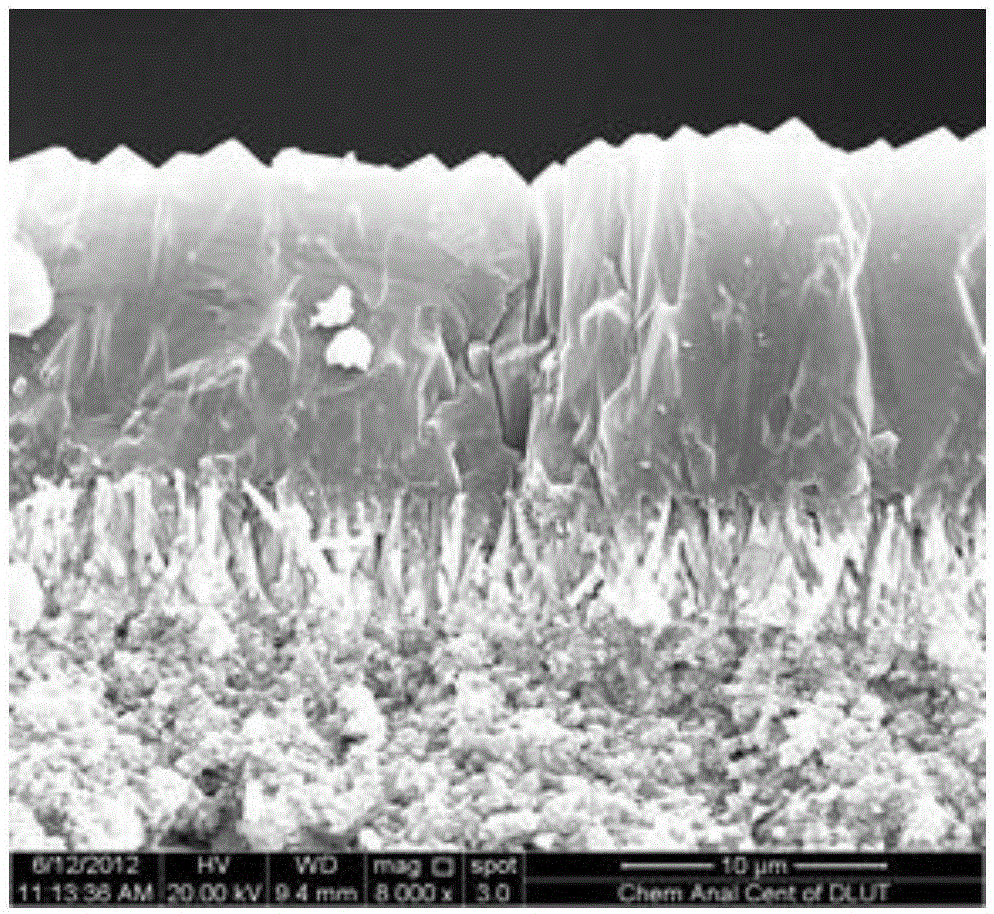

ActiveCN105233702ASolve the difficulty of heterogeneous nucleationSolve associativitySemi-permeable membranesMetal-organic frameworkSolvent

The invention relates to a preparation method for forming a metal organic framework ZIF-67 film. Through hydrothermal synthesis, first a cobalt nano array layer firmly combined with a carrier is introduced to the carrier, and the carrier with the cobalt nano array layer is obtained; in the aftertreatment process, the cobalt nano array layer provides a metal source for growth of the ZIF-67 film and serves as a growing point and bonding point for forming the film, the continuous and uniform ZIF-67 film is formed by growth. According to the method, the problems that the metal organic framework film has difficulty in heterogeneous nucleation, is weak in binding force with the carrier and is easily subjected to embrittlement are solved. In the cobalt nano array growth process or in the ligand growth process, only water is used as a solvent, and no other organic solvent participates. The environmental pollution is small, and the preparation method conforms to the green chemical development requirements. In the film forming process, the cobalt nano array layer has dual functions of providing a metal cobalt source and enhancing binding force between the carrier and the ZIF-67 film.

Owner:DALIAN UNIV OF TECH

Manufacturing method of zinc-nickel double-layer electroplating steel plate

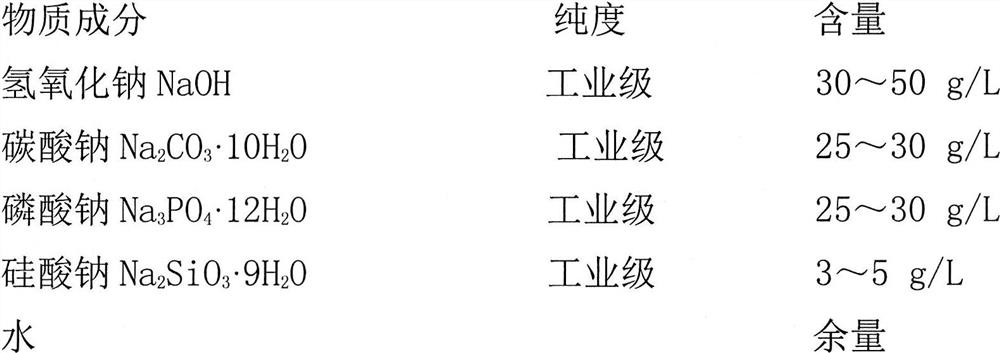

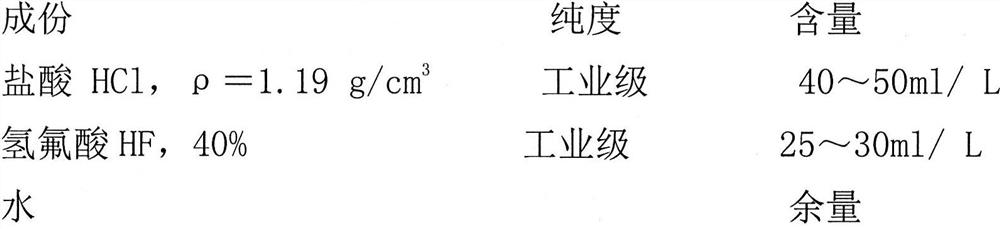

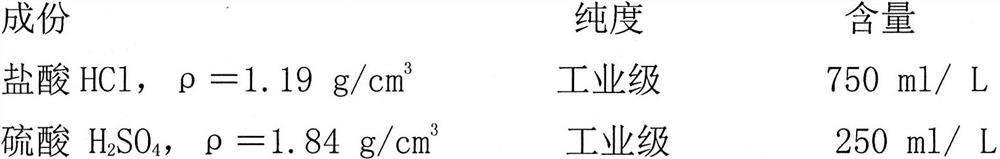

The invention discloses a manufacturing method of a zinc-nickel double-layer electroplating steel plate, which comprises the following steps: derusting a cold rolled steel plate or descaling a hot rolled steel plate, and cleaning the steel plate with water; activating the cleaned steel plate with diluted acid; electronickelling the activated steel plate, wherein a nickelling solution comprises the components of 240-280g / L of nickel sulfate, 40-65g / L of nickel chloride, 25-45g / L of boric acid and 1-3 g / L of acetic acid, and the pH value is controlled to be 4-4.5; annealing the steel plate by using hydrogen gas or nitrogen gas as a protective gas at the temperature of 550-650 DEG C, and forming a ferronickel alloy layer on the surface of the steel plate; then, electrogalvanizing the surface of the ferronickel alloy layer, wherein a galvanizing solution comprises the components of 250-300g / L of zinc sulfate, 1-2g / L of aluminum sulfate, 240-260g / L of sodium sulfate, 20-25g / L of boric acid and 2-3g / L of glucose, and the pH value is controlled to be 4.5-5.5; and washing the galvanized steel plate with water to acquire a finished product. Tests indicate that the corrosion resisting property of the acquired steel plate can be greatly improved, and a bonding force problem of a plating layer and a basal body is also solved.

Owner:武钢集团有限公司

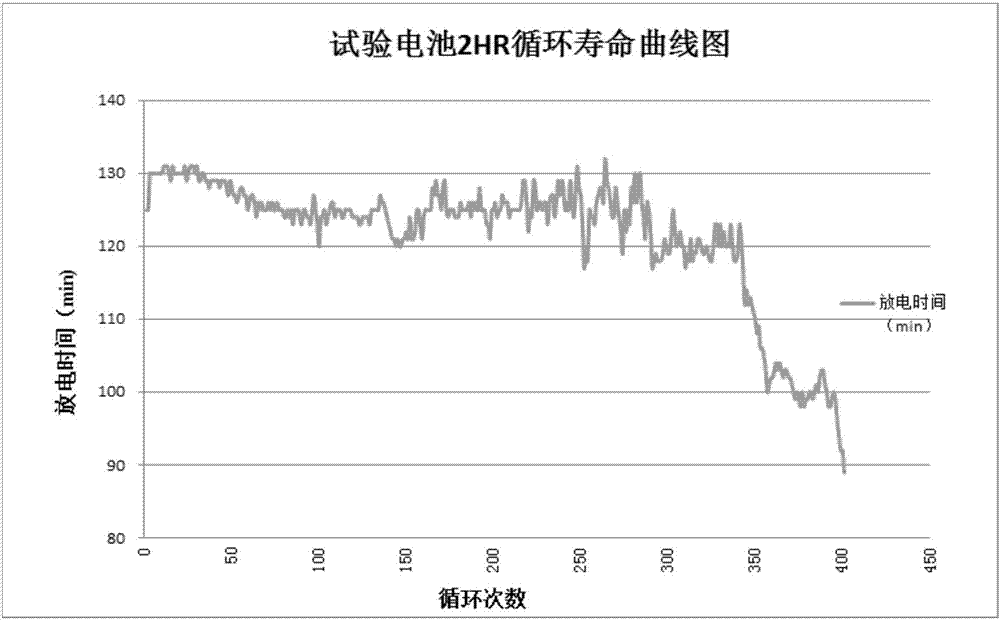

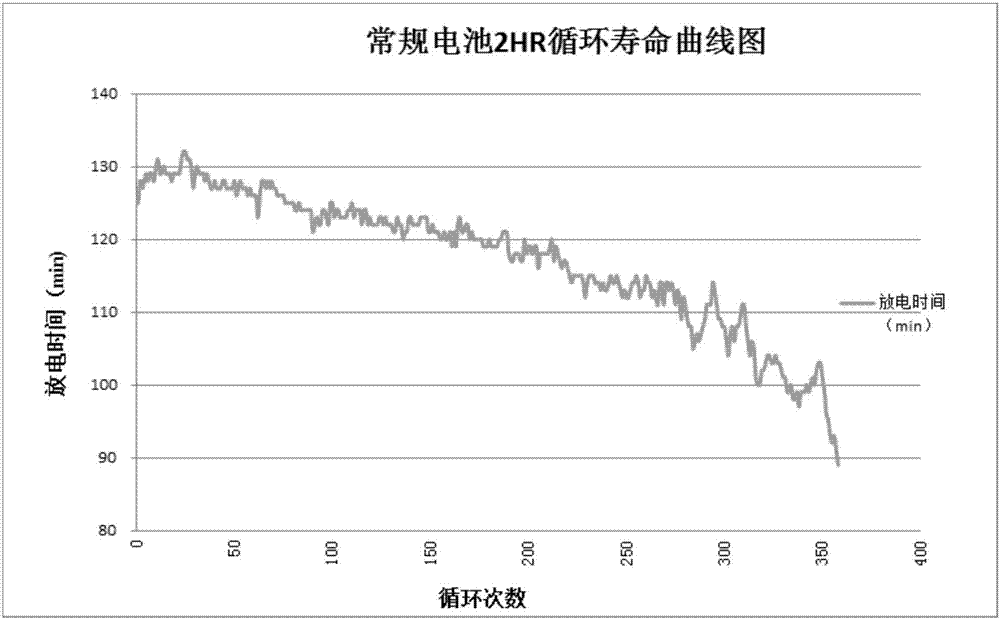

Mixed lead paste capable of improving binding force of positive grid of lead-acid storage battery and lead paste and preparation method of mixed lead paste

InactiveCN107887591AEffective solution to bindingSolve the bonding problemLead-acid accumulatorsCell electrodesFiberBinding force

The invention discloses mixed lead paste capable of improving the binding force of a positive grid of a lead-acid storage battery and lead paste and a preparation method of the mixed lead paste. The method comprises the following steps of adding lead powder which is 80-90% of total mass to a paste mixing machine, adding the following raw materials by percentages: 8-10% of sulfuric acid, 0.1-0.3% of stannous sulfate, 0.08-0.10% of conductive fiber, 0.3-0.5% of colloidal graphite, 0.05-0.15% of sodium borate and 1.0-1.2% of antimonic oxide, carrying out dry mixing for 8-10min, adding deionized water, carrying out wet mixing for 2min, adding residual paste and carrying out wet mixing for 8-10min; and dropwise adding the sulfuric acid which is 8-10% of total mass and stirring for 10-12min to obtain the lead paste of which the apparent density is 4.4+ / -0.02g / cm<3>. According to the mixed lead paste, the interface problem between an existing battery grid and an active material of the lead paste can be effectively solved, the bonding force between the positive grid and the lead paste is improved, the strength of a polar plate is improved and the cycle life of the battery is prolonged.

Owner:HENAN CHAOWEI POWER SUPPLY

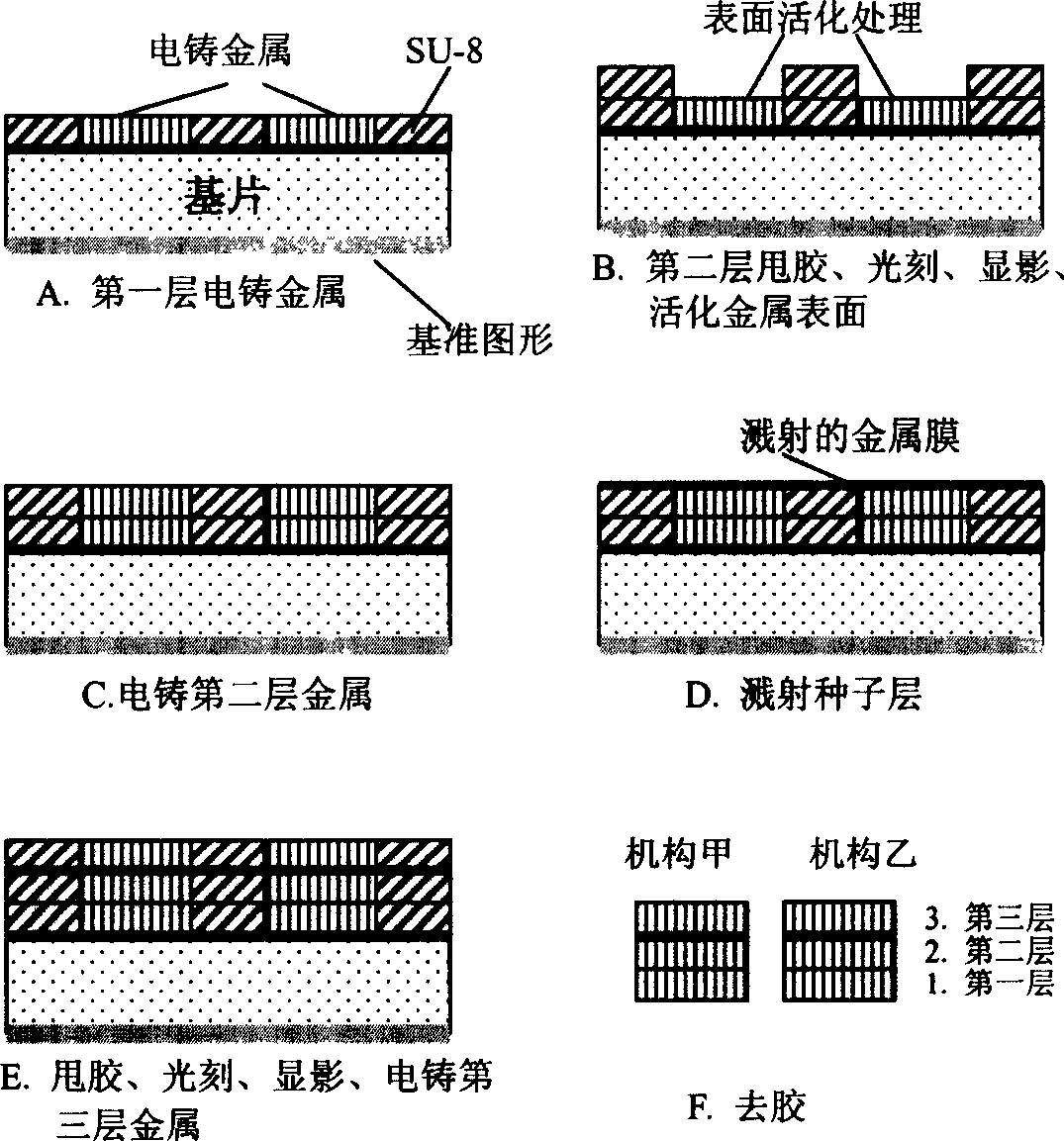

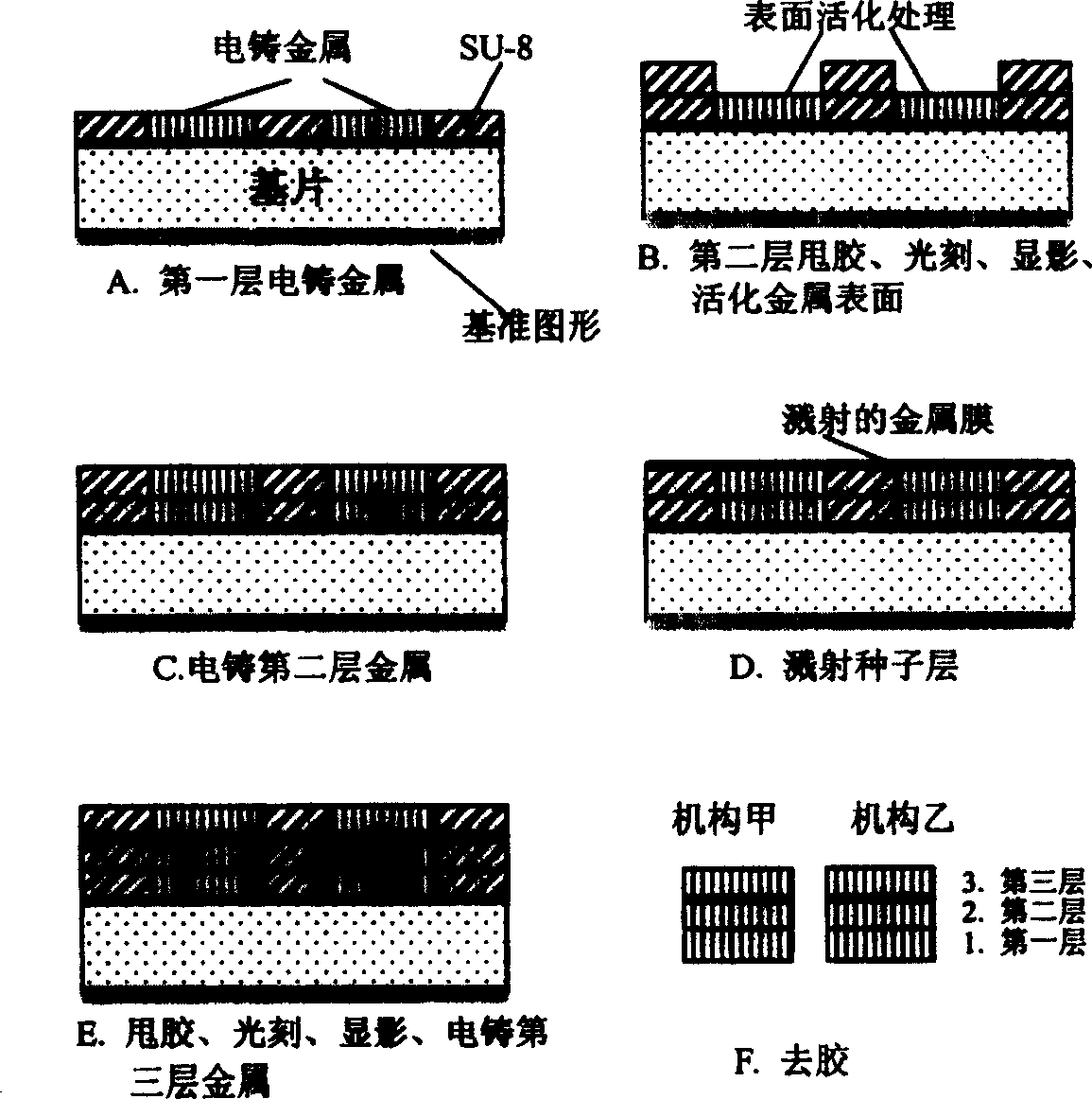

Method for integral micromachining multilayer composite structure

InactiveCN1583543AReduce mistakesSolve the problem of relative position accuracy between layersDecorative surface effectsPhotomechanical apparatusPosition errorPhotoresist

A method for integrally microprocessing copmlex multi-layer structure features that the photoresist SU-8 and quisi-LIGA processing are used, the multiple layers are simultaneously etched to reduce the relative position error between layers, a surface activating technique is used to improve the binding force between electrocast layers, and the seed layer techinque is used for generating big electrocasting pattern.

Owner:SHANGHAI JIAO TONG UNIV

Composite chemical nickel and phosphor plating method

ActiveCN101514449AImprove bindingImprove corrosion resistanceLiquid/solution decomposition chemical coatingSodium acetateHigh adhesion

The invention relates to a composite chemical nickel and phosphor plating method, characterized by comprising the following steps: 1) the pH value of the chemical nickel and phosphor plating solution containing nickel sulfate with the concentration being 26 to 30 g / l, sodium hypophosphite with the concentration being 23 to 27 g / l, sodium citrate with the concentration being 38 to 42 g / l and sodium acetate with the concentration being 23 to 27 g / l is adjusted to be 9 to 10, neodymium(III) sulfate octahydrate is mixed with the chemical nickel and phosphor plating solution uniformly at the addition amount is 0.4 to 0.8 g / l, the above solution is plated on the pretreated neodymium iron boron magnet under the effect of the ultrasonic wave for 10 to 60 minutes to obtain a nickel and phosphor plating layer with the crystal grain size of 5 to 8 nm; 2) the pH value of the chemical nickel and phosphor plating solution containing nickel sulfate with the concentration being 22 to 26 g / l, sodium hypophosphite with the concentration being 28 to 32 g / l, sodium citrate with the concentration being 43 to 47 g / l and sodium acetate with the concentration being 28 to 32 g / l is adjusted to be 4.2 to 5.6, the plated neodymium iron boron magnet in the step(1) is placed into the chemical nickel and phosphor plating solution in the step(2) for plating for 30 to 120 minutes, the amorphous nickel and phosphor plating layer is obtained. Compared with the prior art, the plating layer has high adhesion and good corrosion resistance, the thickness of the plating layer can be reduced and the loss of the magnetic property can be lowered.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

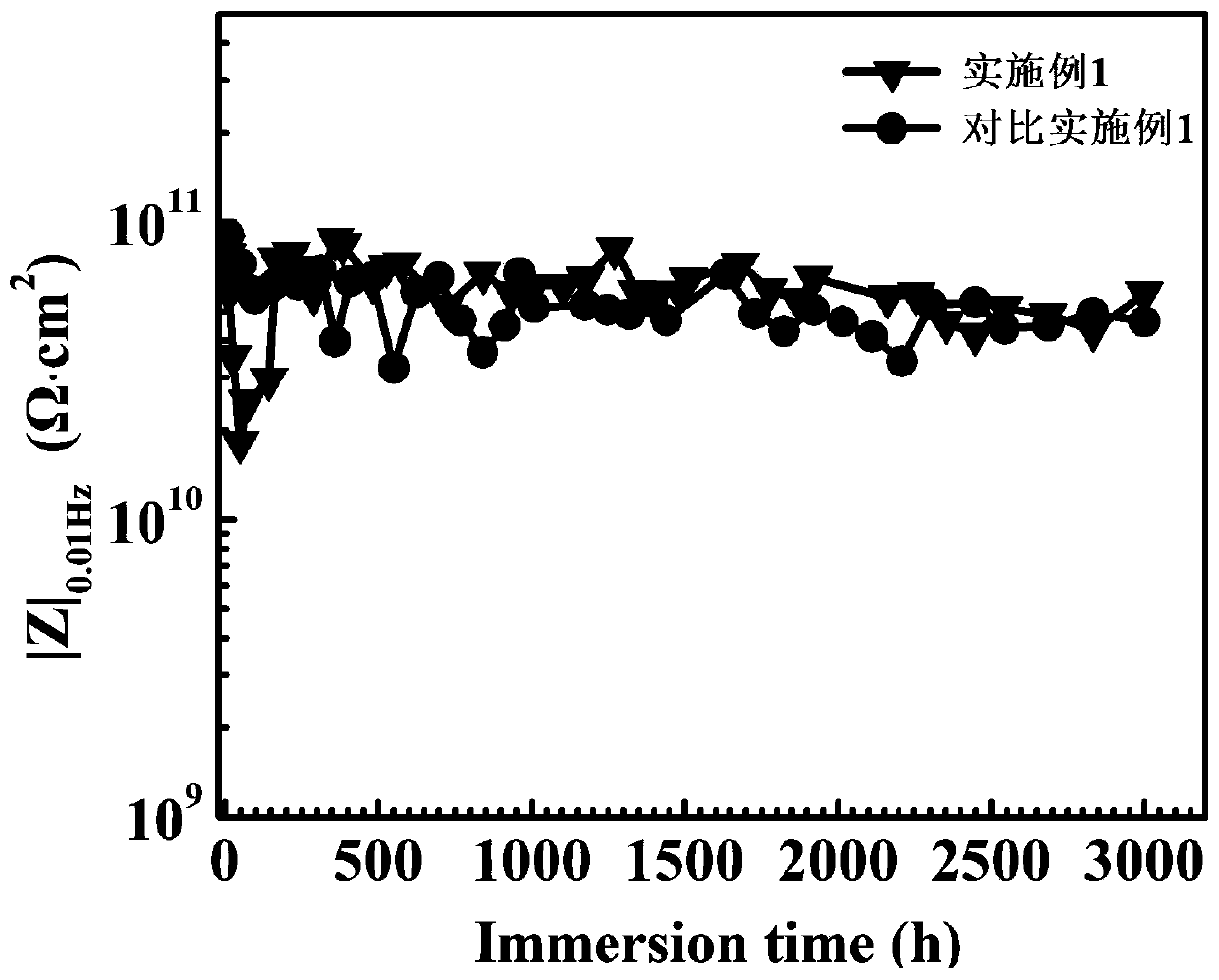

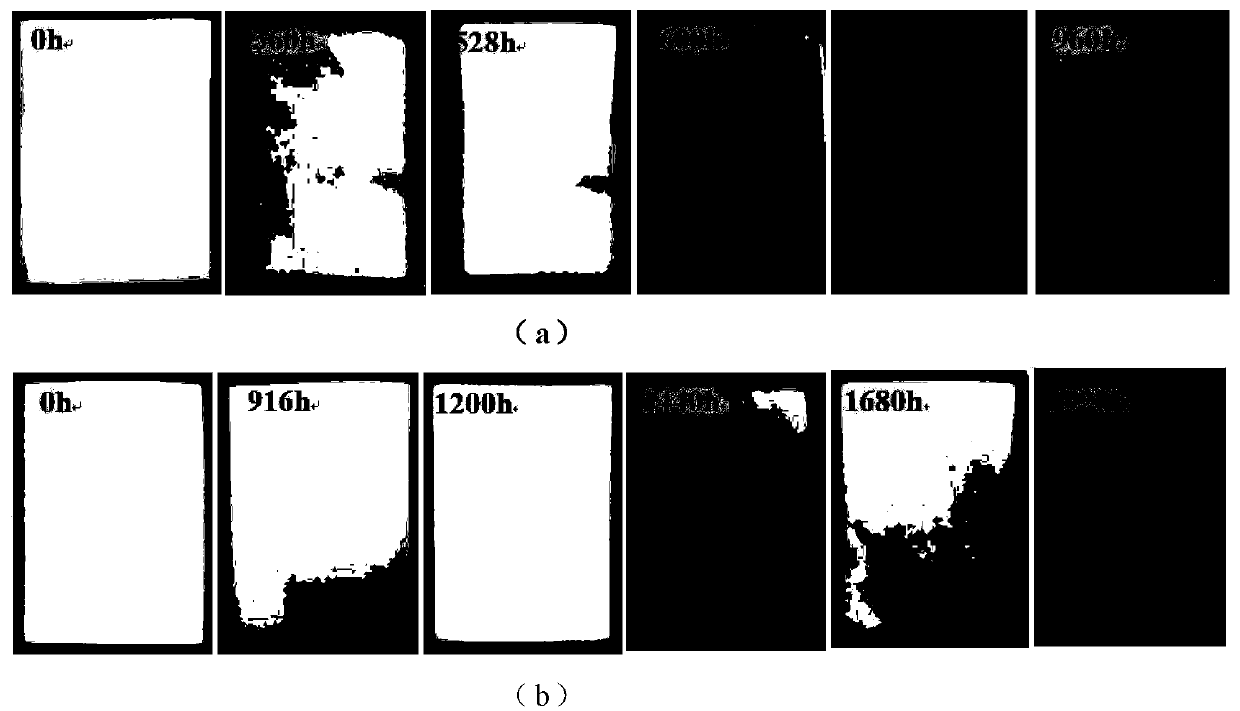

Preparation method of high-adhesion high-corrosion-resistant fluorinated graphene coating

PendingCN111451107ASolve the bonding problemPromote hydrolysisPretreated surfacesAnti-corrosive paintsGraphene coatingFirming agent

The invention discloses a preparation method of a high-adhesion high-corrosion-resistant fluorinated graphene coating. The preparation method of the high-adhesion high-corrosion-resistant fluorinatedgraphene coating comprises the following steps of uniformly mixing a silane coupling agent, alcohol, a corrosion inhibitor, butyl titanate and deionized water so as to form mixed liquor; then adjusting a pH value of the mixed liquor to range from 3 to 5; then after uniformly mixing by adopting ultrasonic oscillation, hydrolyzing for 12 to 72h at 25 to 50 DEG C, and obtaining a silane hydrating solution; mixing epoxy resin, fluorinated graphene and a diluent, ball-milling and stirring for 0.5 to 10h, then adding a curing agent, uniformly mixing, and obtaining fluorinated graphene modified epoxyresin; soaking a pretreated metal matrix in the silane hydrating solution for 30 to 120s, and then drying and curing; and coating the fluorinated graphene modified epoxy resin with the thickness ranging from 30 to 200mum on the surface of the silanized metal matrix, then drying and curing, and obtaining the high-adhesion high-corrosion-resistant fluorinated graphene coating. The fluorinated graphene coating obtained through the method has high corrosion resistance, the bonding strength of the coating and the metal matrix is improved, and the metal matrix can be protected for a long time.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Metallization process for honeycomb epoxy glass fiber reinforced plastic antenna

ActiveCN103741148AWith heat conductionWith magnetic permeabilityRadiating elements structural formsLiquid/solution decomposition chemical coatingEpoxyAntenna design

The invention discloses a metallization process for a honeycomb epoxy glass fiber reinforced plastic antenna. The metallization process comprises a sequential technological process of antenna surface sealed modification treatment and antenna pre-treatment, oil-removing coarsening and modified sealed material coarsening and antenna metallization, and chemical formation of a metal film, electroplating and thickening and three-proofing post-treatment of a metal film layer. After being metalized, the honeycomb interlayer structure epoxy glass fiber reinforced plastic antenna has a metal appearance; surface conduction, heat conduction, magnetism conduction, solvent etching resistance, good conduction resistance and various electrical performance indexes can meet antenna design requirements. Compared with a conventional glass fiber reinforced plastic non-metal material metallization process, the antenna sealed modification treatment is simple in technological process and does not need special technological equipment including plasmas or laser induction and the like; the metallization process has high practicability and reliability and is convenient for use properties of promoting production and machining.

Owner:36TH RES INST OF CETC

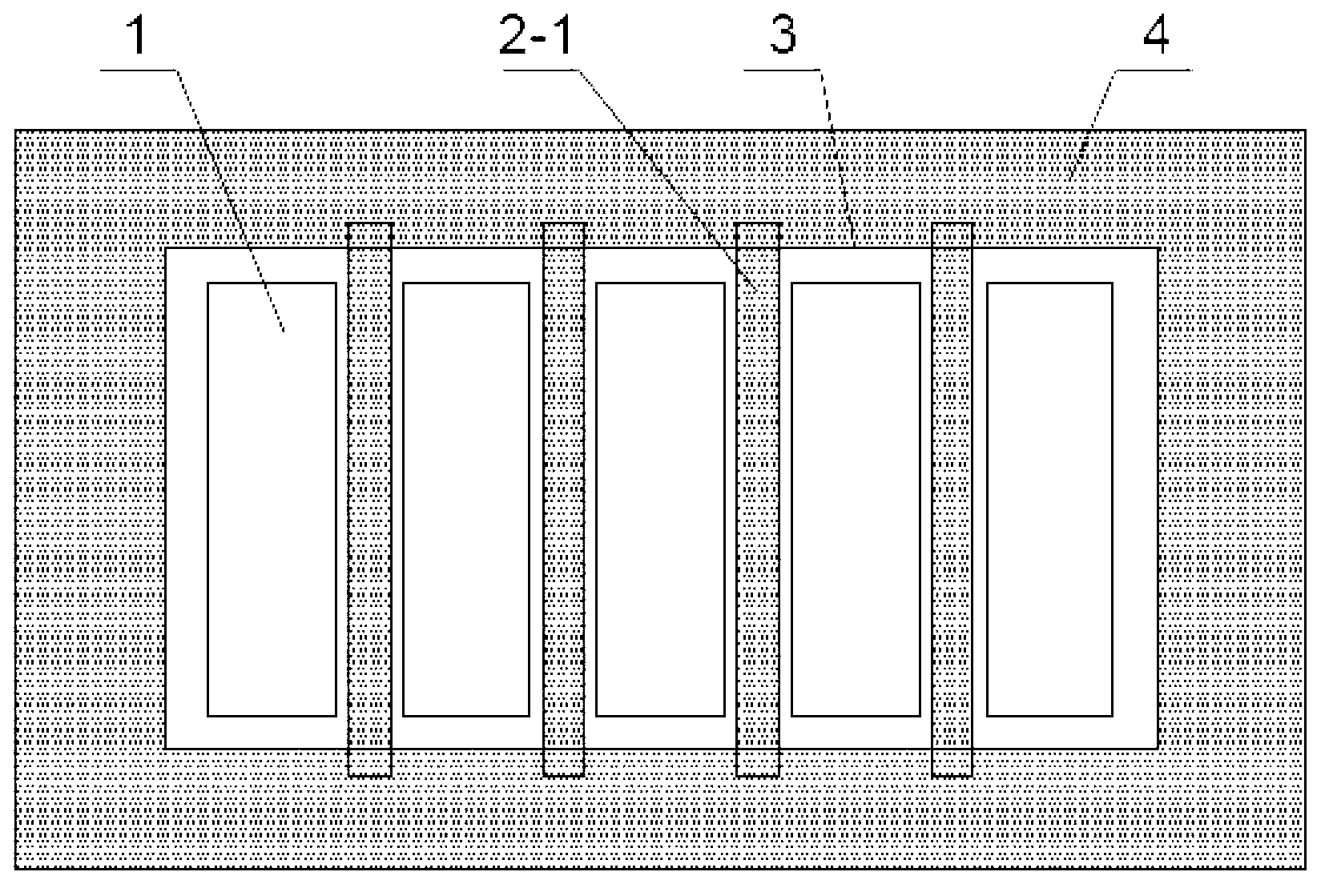

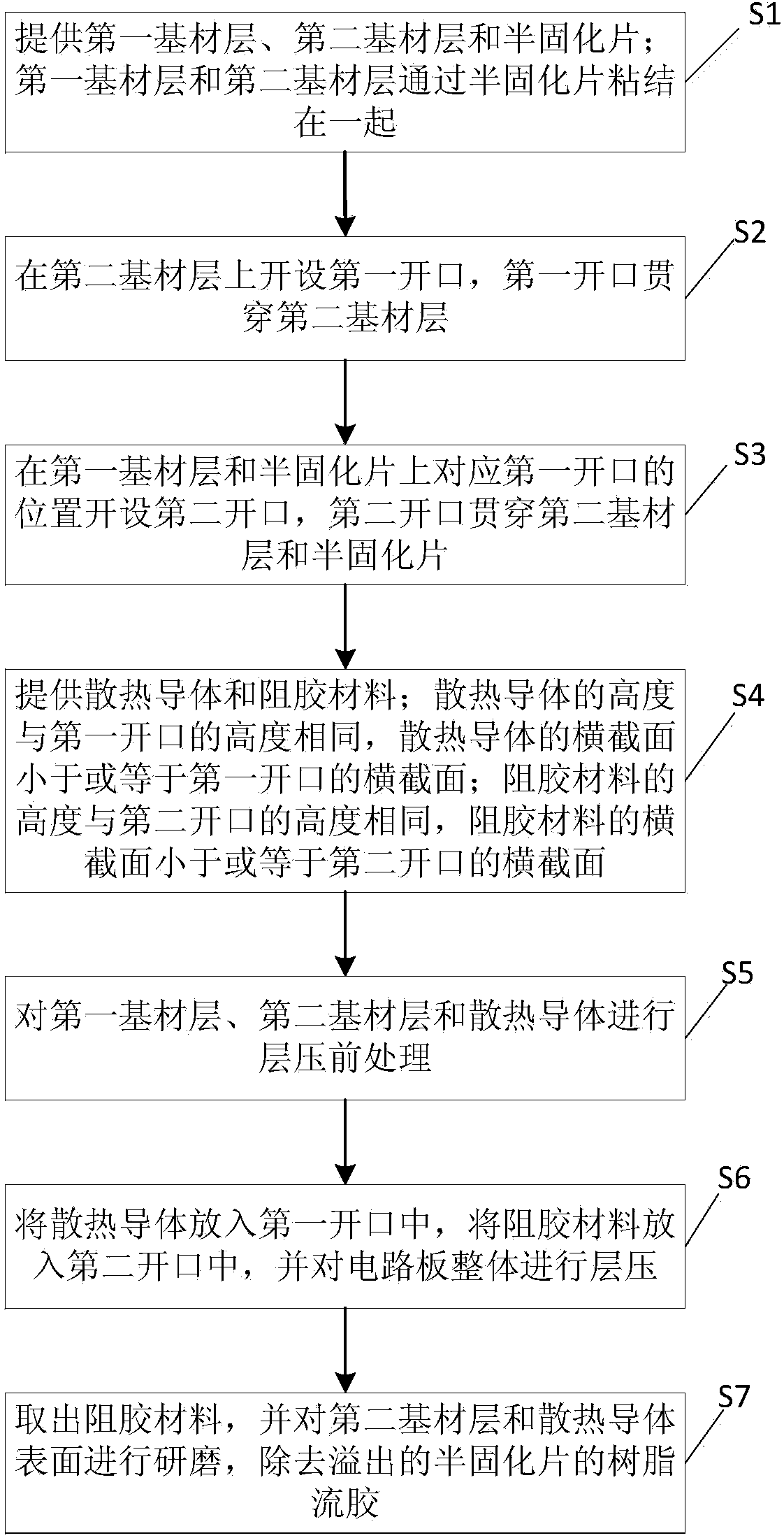

Manufacturing method for locally burying copper block and conducting internal-layer lead wire

InactiveCN106341941ASolve the bonding problemMake sure it's onPrinted circuit non-printed electric components associationCircuit thermal arrangementsElectrical conductorHigh pressure

The invention discloses a manufacturing method for locally burying a copper block and conducting an internal-layer lead wire. The method comprises the following steps: 1, arranging a groove and burying copper; 2, filling; 3, pressing; 4, boring; 5, metallization; and 6, subsequent processing. By use of high pressure in a lamination process and heat curing of prepreg scaled resin flow glue, the copper block or other heat dissipation conductors are fixed in a through groove of a motherboard substrate layer, the problem of poor binding force of the copper block or the heat dissipation conductors is solved, a through hole is drilled at a junction of the copper block and a motherboard printed circuit board (PCB) by use of a drilling machine tool, the aperture size is designed according to the interval between the copper block and an internal layer of the motherboard PCB, it is ensured that the copper block is connected with an internal-layer design copper lead wire, the drilled through hole is plated with a layer of copper with a thickness of 30[mu]m by use of an electroplating flow, and the copper block and the internal-layer copper lead wire are conducted. A PCB manufactured by use of the manufacturing method solves the problem of incapability of conducting the copper block with the buried motherboard internal layer and has the advantages of good heat dissipation effect, huge market potential and wide prospect.

Owner:珠海杰赛科技有限公司

Method for making double-layer alloy plating metallic film resistor

InactiveCN1547218ASolve the bonding problemOvercoming the disadvantages of brittlenessResistor manufactureNon-adjustable resistorsFilm resistanceNi cr alloy

The invention refers to a manufacturing method for a kind of dual-layer alloy coating layer metal film resistance. The character lies in: a layer of Ni-Cr alloy is splattered onto the at least a layer of insulating base, the proportion is: Ni: Cr (w / w) =75:25-85:15, then a layer of Cu-Ni alloy coating film is coated on the coating layer, the proportion is: Cu: Ni (w / w) =60:40-40:60; the steps are: with the normal spattering method, a layer of Ni-Cr alloy is splattered on the base, then with following steps: the normal temperature activating of acid liquid; rinsing with water; suspending coating or rolling coating the Cu-Ni layer; rinsing with water; drying. The invention solves the bonding force problem between the metal film and the insulating base, overcomes the deficiency that the coating layer is fracture when using laser to process, the temperature coefficient of the resistance film can maintain at í‚2%-í‚0.5%.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

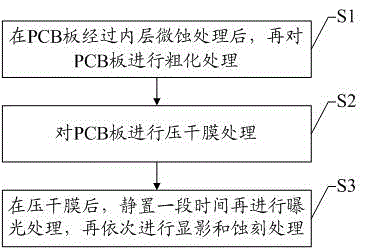

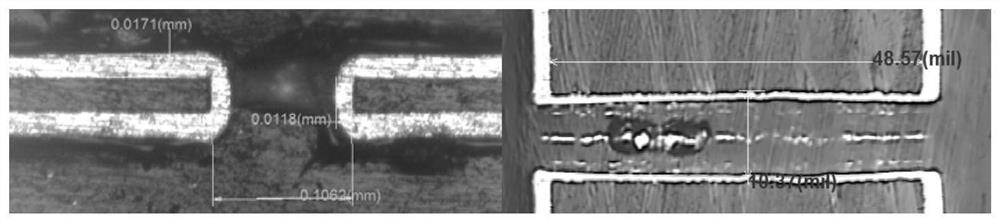

Dense PCB (printed circuit board) circuit and manufacturing method

InactiveCN106851998ASolve the bonding problemAvoid the phenomenon of open gapConductive material chemical/electrolytical removalEngineeringPrinted circuit board

The invention discloses a dense PCB (printed circuit board) circuit and a manufacturing method. The manufacturing method comprises the following steps of A, performing micro-etching treatment on an inner layer of a PCB, and roughening the PCB; B, pressing and drying a film on the PCB; C, standing for a period of time, and exposing; sequentially developing and etching. The manufacturing method has the advantages that the surface of the PCB is roughened, so as to solve the problem of bonding force of the dry film, avoid the open-loop notch, and improve the product quality and precision of a product.

Owner:SHENZHEN KINWONG ELECTRONICS

Manufacturing method of zinc-nickel double-layer electroplating steel plate

The invention discloses a manufacturing method of a zinc-nickel double-layer electroplating steel plate, which comprises the following steps: derusting a cold rolled steel plate or descaling a hot rolled steel plate, and cleaning the steel plate with water; activating the cleaned steel plate with diluted acid; electronickelling the activated steel plate, wherein a nickelling solution comprises the components of 240-280g / L of nickel sulfate, 40-65g / L of nickel chloride, 25-45g / L of boric acid and 1-3 g / L of acetic acid, and the pH value is controlled to be 4-4.5; annealing the steel plate by using hydrogen gas or nitrogen gas as a protective gas at the temperature of 550-650 DEG C, and forming a ferronickel alloy layer on the surface of the steel plate; then, electrogalvanizing the surfaceof the ferronickel alloy layer, wherein a galvanizing solution comprises the components of 250-300g / L of zinc sulfate, 1-2g / L of aluminum sulfate, 240-260g / L of sodium sulfate, 20-25g / L of boric acidand 2-3g / L of glucose, and the pH value is controlled to be 4.5-5.5; and washing the galvanized steel plate with water to acquire a finished product. Tests indicate that the corrosion resisting property of the acquired steel plate can be greatly improved, and a bonding force problem of a plating layer and a basal body is also solved.

Owner:武钢集团有限公司

Processing method of printed wiring board with ultra-small solder mask intervals

InactiveCN102938982AAlignment accuracy is easy to controlSolve the bonding problemNon-metallic protective coating applicationResistScreen printing

The invention relates to a processing method of a printed wiring board and relates to a processing method of a printed wiring board with ultra-small solder mask intervals. The method includes the following steps of firstly, subjecting the printed wiring board to surface activating treatment, and then subjecting solder resist ink separation lines of the printed wiring board to screen printing in four hours after treatment; subjecting the printed wiring board to exposing, developing and solidifying at the temperature of 150 DEG C for 30 minutes after the screen printing of the solder resist ink separation lines; subjecting the solidified printed wiring board to surface activating treatment and then subjecting the solder resist ink separation lines of of the whole printed wiring board to electrostatic spraying in four hours after treatment; subjecting the printed wiring board to preliminary drying at the temperature of 80 DEG C for 40-50 minutes; and subjecting the preliminarily dried printed wiring board to exposing, developing and solidifying at the temperature of 150 DEG C for 60 minutes. By means of the processing method, the problem of poor binding forces between separation line ink and a printed wiring board base material is solved, and dropping of the solder resist ink separation lines is prevented in the process of subsequent processing.

Owner:DALIAN PACIFIC ELECTRONICS

Rhodium plating technology of electric contact made of molybdenum copper composite material

InactiveCN106167896AImprove antioxidant capacityImprove bindingLiquid/solution decomposition chemical coatingCopperBiological activation

The invention discloses a rhodium plating technology of an electric contact made of a molybdenum copper composite material, and the technology is used for rhodium plating on the surface of the electric contact made of a molybdenum copper composite material. The electric contact is put into a plating basket to carry out the following steps in order: 1. chemical degreasing; 2. scale removal treatment; 3. activation treatment; 4. chemical flash plating of nickel; and 5. chemical plating of rhodium. The rhodium plating layer is uniformly distributed on the surface of the electric contact made of the molybdenum copper composite material and is well combined.

Owner:成都立威讯科技有限公司

Packaging carrier tape base material and preparation method thereof

ActiveCN109454955AReduce dosageThere will be no problem of excessive heightLamination ancillary operationsLayered product treatmentMetal foilEngineering

The invention provides a packaging carrier tape base material and a preparation method thereof. The packaging carrier tape substrate sequentially comprises a curing sheet, a glue film and metal foil which are laminated together from top to bottom, wherein the roughness of the side, away from the glue film, of the curing sheet is 3-10 [mu]m. By utilizing the packaging carrier tape base material, the height of UV glue is within the range of 500-580 [mu]m, application requirements can be well met, finally, binding force of a module and a card is 90 N or above, and the binding requirements of themodule and the card can also be met.

Owner:GUANGDONG SHENGYI SCI TECH

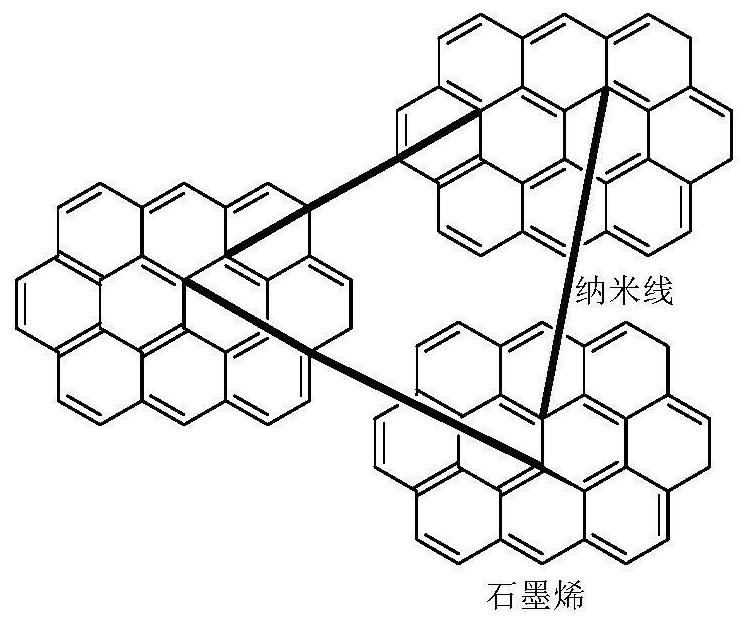

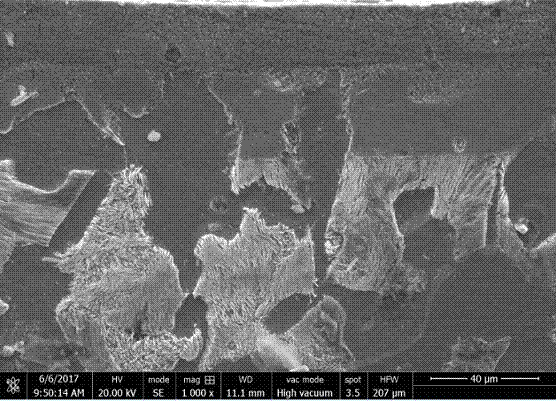

Multi-layer board hole metallization method

PendingCN113382560AEmission reductionReduce lossMetallic pattern materialsPrinted element electric connection formationConductive polymerGraphite

The invention discloses a multilayer board hole metallization method. The conductivity of graphene, a metal nanowire material and a conductive polymer material and the film-forming property of the conductive polymer material are used to perform conductive treatment on a non-metal surface, the treated non-metal surface is high in conductivity and strong in film binding force, and a traditional tin-palladium colloid treatment method can be replaced. The method provided by the invention is stable in performance, simple to operate, easy to control and low in cost, and the production process is pollution-free and more environment-friendly.

Owner:胡磊

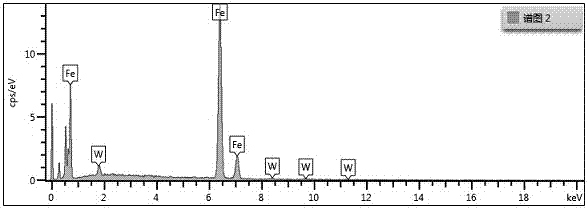

Electron beam surface alloying method for 45# steel

InactiveCN107385378AImprove corrosion resistanceImprove performanceMolten spray coatingThermal sprayingTurnover time

The invention discloses an electron beam surface alloying method for 45# steel. The electron beam surface alloying method comprises the steps of preset coating on the surface of the 45# steel and scanning through continuous electron beams, wherein the preset coating comprises the step that tungsten powder is sprayed on the surface of the 45# steel by plasma thermal spraying to form a spraying bonding layer; and scanning through continuous electron beams comprises the step that electron beam scanning is carried out on the surface of the 45# steel so as to obtain a surface alloying modification layer on the surface of the 45# steel. According to the electron beam surface alloying method, the continuous electron beam scanning technology is combined with the plasma thermal spraying, the novel medium-carbon steel-based composite material which takes a high-performance alloying element as a reinforced phase is prepared by adopting the unique advantages of the continuous surface treatment, so that the procedures are greatly simplified, the cost is reduced, the turnover time is shortened, and the surface performance of the 45# steel is improved and the service life of the 45# steel is prolonged by preparing the alloy layer with high hardness, high abrasion resistance and high corrosion resistance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

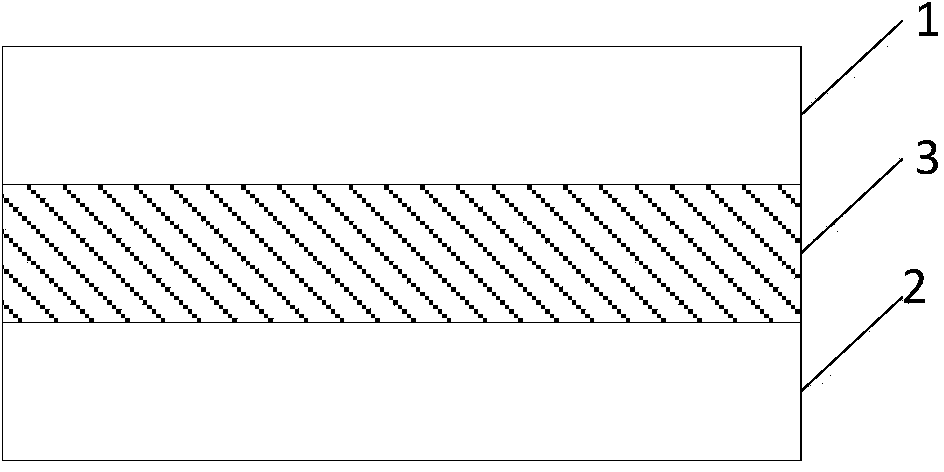

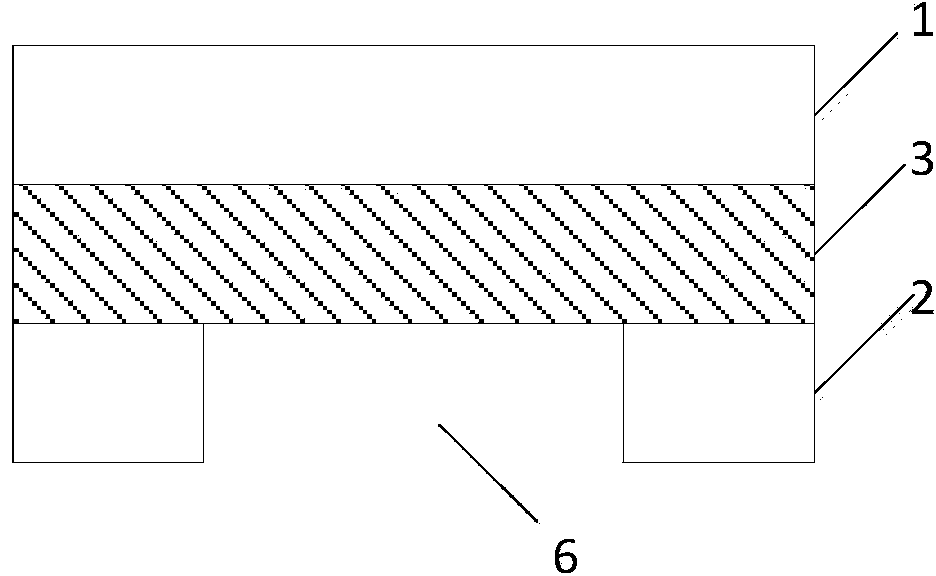

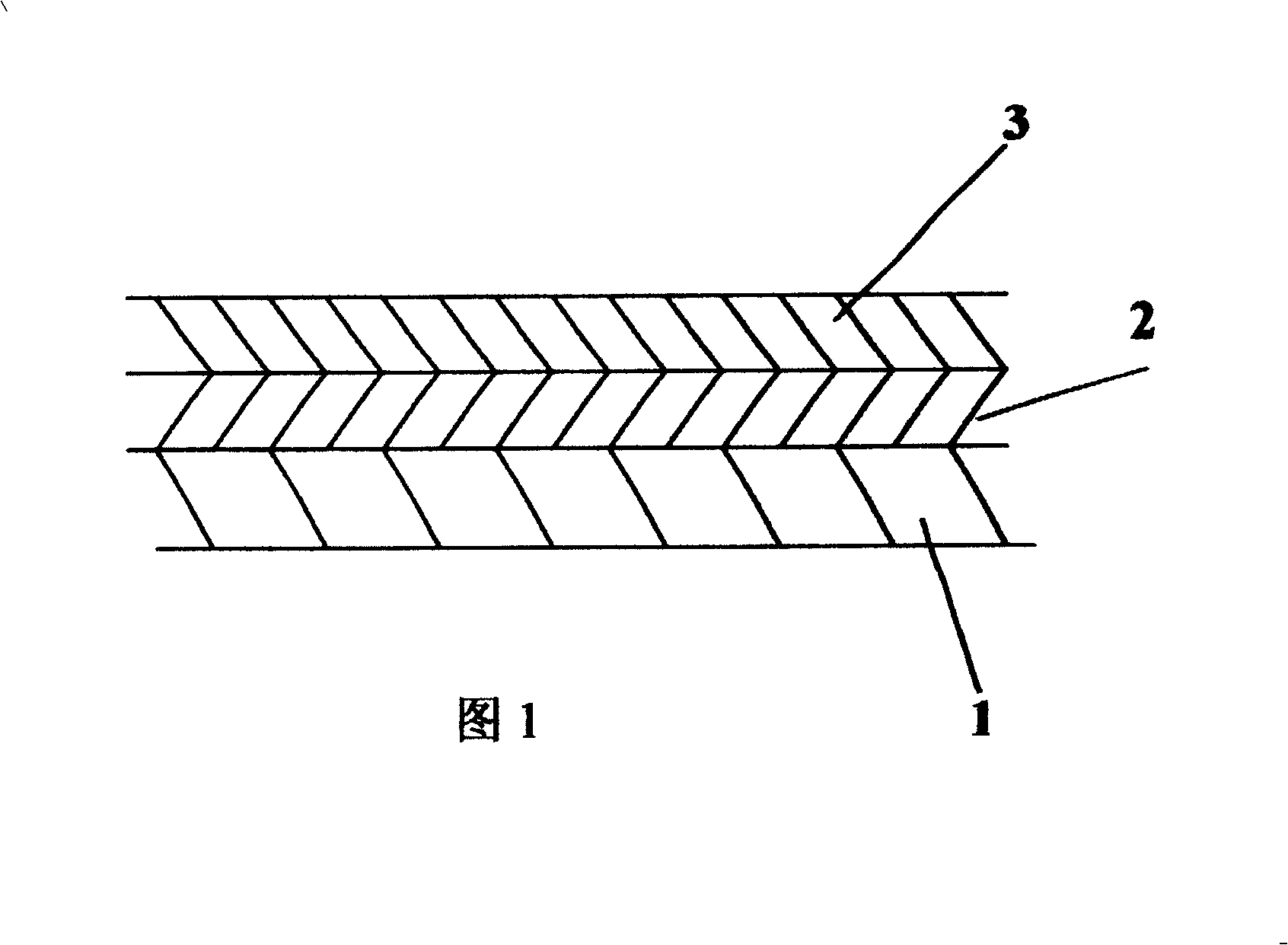

Thin film solar cell electrode and preparation method thereof

ActiveCN103022169ASolve binding forceReduce resistanceFinal product manufactureSemiconductor devicesOptoelectronicsThin film solar cell

The invention discloses a thin film solar cell electrode. The thin film solar cell electrode comprises a glass base plate and molybdenum thin film, wherein the molybdenum thin film is laid on the glass base plate. The molybdenum thin film is formed by two layers of molybdenum crystal grains, wherein the two layers of molybdenum crystal grains respectively are a layer of coarse molybdenum crystal grains with grain diameters between 12nm and 16nm and a layer of fine molybdenum crystal grains with grain diameters between 2nm and 6nm, and the coarse molybdenum crystal grain layer is contacted with the glass base plate. The invention further discloses a preparation method of the electrode. A molybdenum metal film layer in a traditional thin film solar cell electrode structure is divided into two layers, wherein the base layer is a coarse crystal grain layer, and the top layer is a fine crystal grain layer, so that not only a function of working as a back electrode is achieved, problems about percolation of sodium atoms and binding force of glass are solved, and resistance of working as the back electrode is reduced, but also switching efficiency of a copper indium gallium selenide (GIGS) thin film cell is improved greatly.

Owner:无锡爱尔华精机有限公司

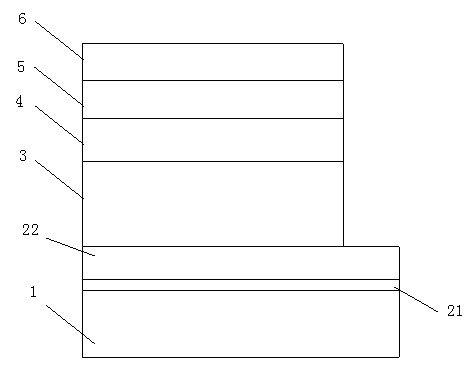

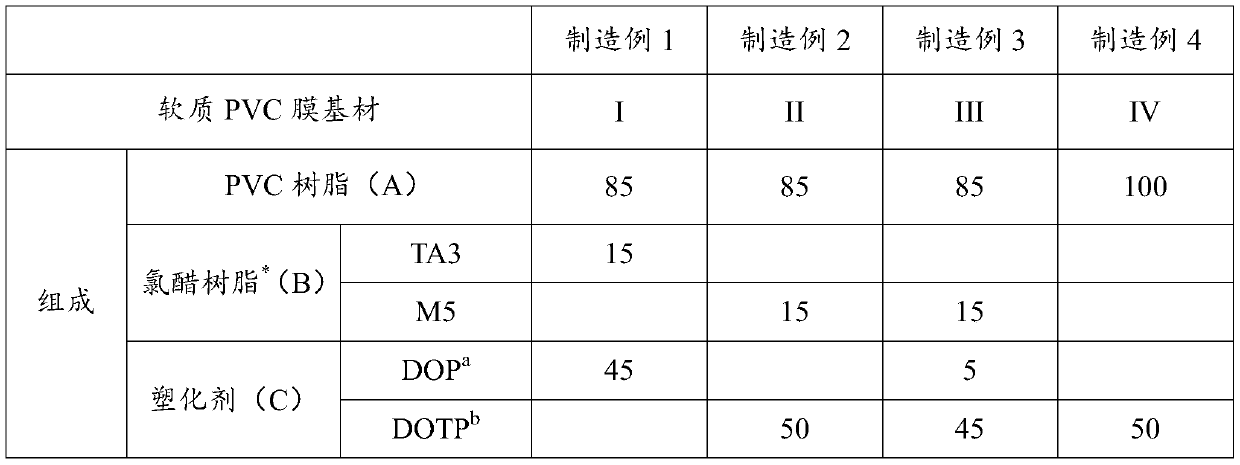

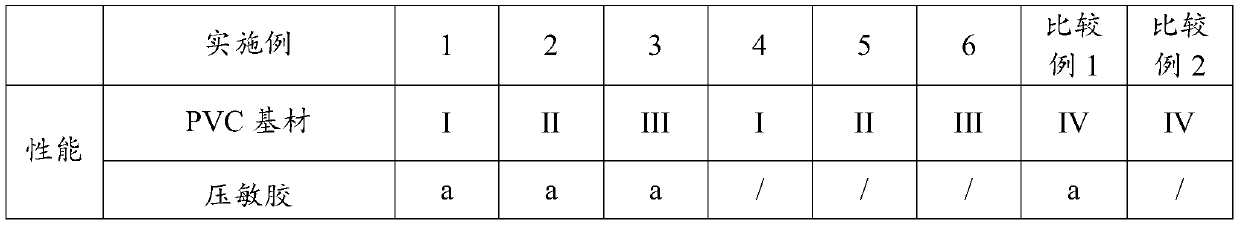

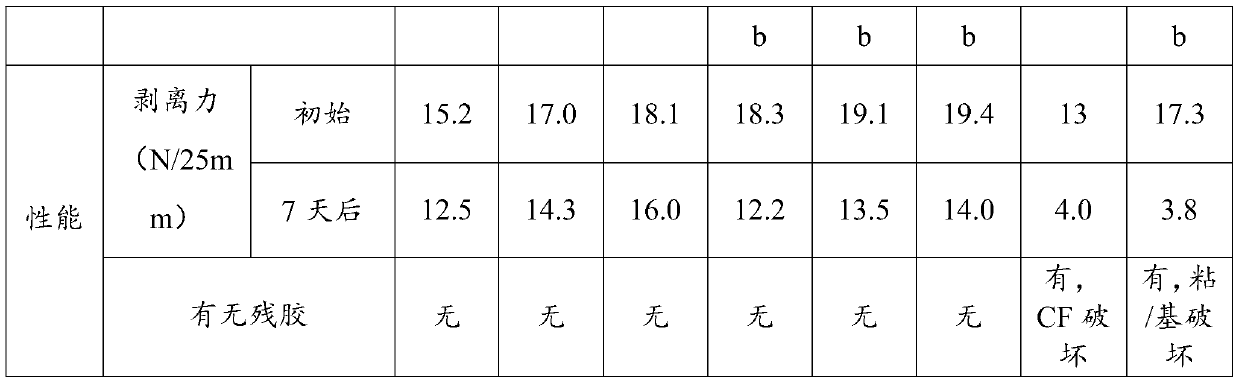

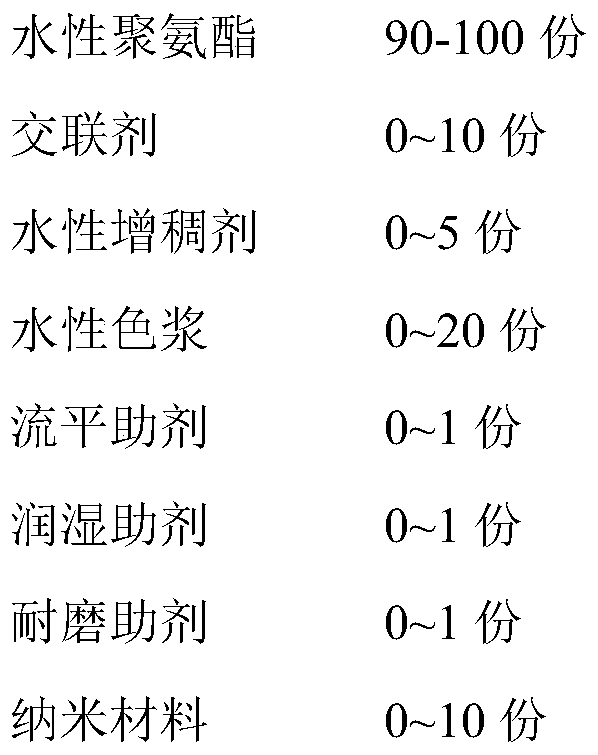

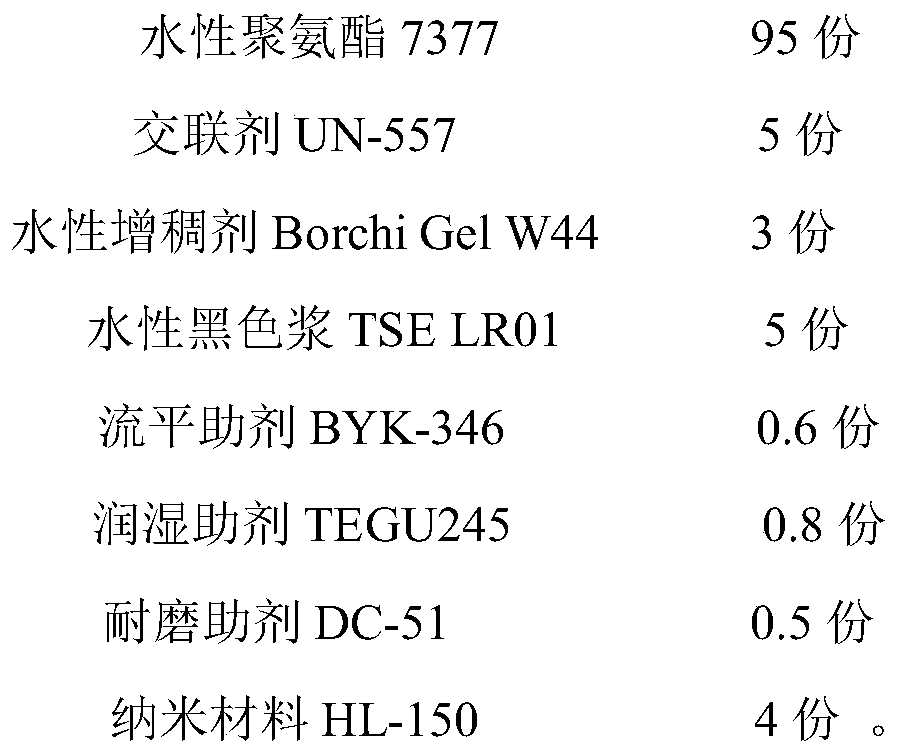

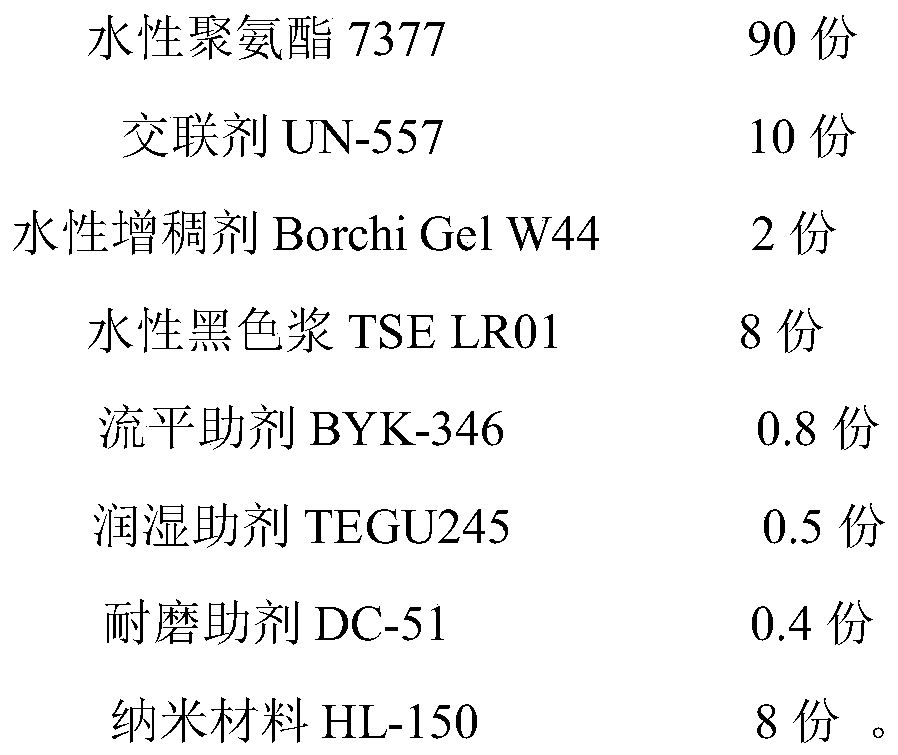

Soft PVC adhesive tape/protective film

ActiveCN111138997AInhibit migrationSolve the bonding problemEster polymer adhesivesPressure sensitive film/foil adhesivesPolymer scienceAdhesive

The invention discloses a soft PVC adhesive tape / protective film. The PVC film comprises a PVC film base material and an acrylic acid pressure-sensitive adhesive coated on the surface of the PVC filmbase material, the composition of the soft PVC film base material is as follows: the soft PVC film base material is prepared from PVC; wherein the weight ratio of the PVC resin to the vinyl chloride-vinyl acetate resin to the plasticizer is (80-90):(10-20):(30-60), the glass transition temperature of the pressure-sensitive adhesive is -30 DEG C to -10 DEG C, the number-average molecular weight is60000-250000, the molecular weight distribution is 2.0-10.0, and the acid value is 5-30 mgKOH / g. According to the soft PVC adhesive tape / protective film, the manufacturing formula of a PVC film basematerial is improved; and meanwhile, the plasticizer-resistant pressure-sensitive adhesive is used, so that under a one-step coating process, a bottom coating process is omitted, the binding force between the plasticizer-resistant pressure-sensitive adhesive and a base material is solved, the damage to a bonding / base interface over time is prevented, the migration of the plasticizer is effectivelyprevented, and the problem of adhesive residue during stripping of a PVC adhesive tape and a PVC protective film is solved.

Owner:张进波

A kind of preparation method of water-based/solvent-free compound environment-friendly polyurethane synthetic leather

ActiveCN105350342BStrong three-dimensional senseSoft touchFootwearTextiles and paperElastomerOrganic solvent

The present invention discloses a preparation method of aqueous / solvent-free composite environmentally friendly polyurethane synthetic leather, the synthetic leather comprises an aqueous elastomer surface layer and a solvent-free foaming intermediate layer, the aqueous elastomer surface layer resin is thermosetting polyether aqueous polyurethane resin, the solvent-free foaming intermediate layer is thermosetting two-component polyether solvent-free foaming polyurethane resin, and the two-component material is polyether combination A material and polyether B material prepolymer. The preparation process does not use any organic solvent, achieves the synthetic leather production and processing, finished product zero solvent use and health and environmental friendliness; at the same time, the advantages of the aqueous polyurethane resin and the solvent-free polyurethane resin are combined, and the obtained synthetic leather products has strong pattern stereoscopic impression, soft hand feeling, superior hydrolysis resistance and other physical properties, and skin and leather feeling equivalent to natural dermis.

Owner:ANHUI ANLI MATERIAL TECH

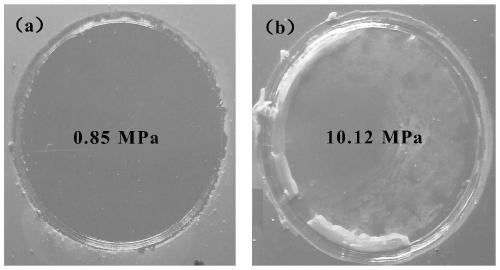

A method for preparing a sandwich-structure zinc-containing metal-organic framework membrane supported by high-temperature-resistant zinc oxide nanorods

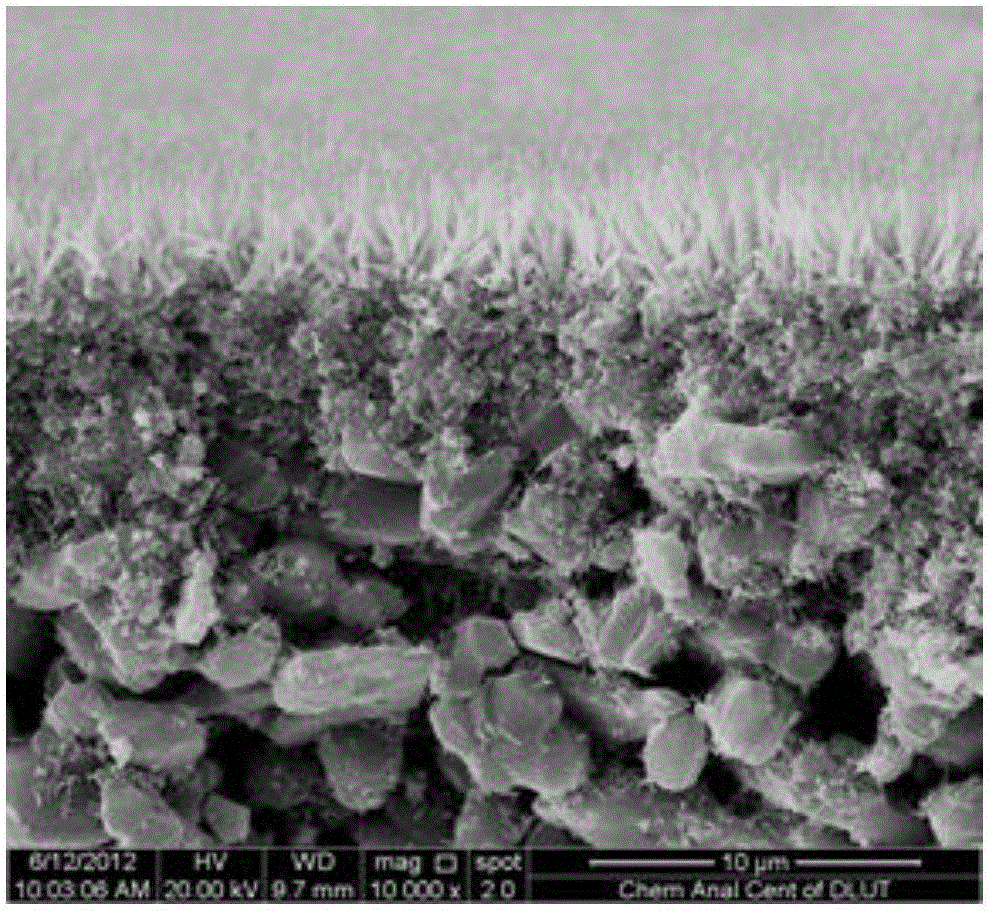

ActiveCN103406029BGuaranteed high screening performanceSolve binding problemsSemi-permeable membranesTemperature resistanceNucleation

The invention discloses a preparation method for a novel ZIFs membrane containing zinc adopting sandwich structure and supported by a high temperature resistant zinc oxide nanorod. According to the invention, by introducing a layer of zinc oxide nanorod on a porous carrier as a bridge to connect the carrier and the ZIFs membrane to construct to form the sandwich structural membrane supported by the zinc oxide nanorod. The zinc oxide nanorod has the following functions: 1, modifying the carrier surface to facilitate the uniform growth of the ZIFs membrane; 2, acting as homogeneous phase induction nucleation growing point of the continuous growth of the ZIFs membrane to guarantee the complete formation of the membrane with high sieving property; acting as bridging liking effect between the carrier and the membrane layer to solve the combination problem between the membrane and the carrier and guarantee high stability of the membrane. Compared with a traditional preparation method of a ZIFs membrane, the membrane prepared by the invention not only has high separating property, high temperature resistance, but also has simple process, good repeatability, convenience in amplification of large-scale preparation, and wide application prospect.

Owner:DALIAN UNIV OF TECH

Method for manufacturing circuit board

ActiveCN103716997ASolve sunken or raised problemsSolve the bonding problemPrinted circuit manufactureElectrical conductor

Owner:GCI SCI & TECH

Method for making double-layer alloy plating metallic film resistor

InactiveCN100456394CSolve the bonding problemOvercoming the disadvantages of brittlenessResistor manufactureNon-adjustable resistorsFilm resistanceNi cr alloy

The invention refers to a manufacturing method for a kind of dual-layer alloy coating layer metal film resistance. The character lies in: a layer of Ni-Cr alloy is splattered onto the at least a layer of insulating base, the proportion is: Ni: Cr (w / w) =75:25-85:15, then a layer of Cu-Ni alloy coating film is coated on the coating layer, the proportion is: Cu: Ni (w / w) =60:40-40:60; the steps are: with the normal spattering method, a layer of Ni-Cr alloy is splattered on the base, then with following steps: the normal temperature activating of acid liquid; rinsing with water; suspending coating or rolling coating the Cu-Ni layer; rinsing with water; drying. The invention solves the bonding force problem between the metal film and the insulating base, overcomes the deficiency that the coating layer is fracture when using laser to process, the temperature coefficient of the resistance film can maintain at + / -2%-+ / -0.5%.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

Method for integral micromachining multilayer composite structure

InactiveCN1288069CExpand the scope of processingSolve the relative position accuracy problemDecorative surface effectsPhotomechanical apparatusPosition errorPhotoresist

Owner:SHANGHAI JIAOTONG UNIV

A method for repairing titanium alloy damaged parts by electroless nickel plating

The invention discloses a method for repairing titanium alloy damaged parts by electroless nickel plating, comprising the steps of degreasing→protection→blowing abrasives→white ash degreasing→activation treatment→hydrogenation treatment→electroless nickel plating→heat treatment. The invention is a new process method for repairing the dimensions of titanium alloy damaged parts by chemical nickel plating, which solves the problem of repairing the bonding force of damaged parts, and is a key technology for repairing the size of damaged titanium alloy parts of Su-27 and Su-30 aircraft by electroless nickel plating According to the invention, the electroless nickel plating of damaged titanium alloy parts can be completed to meet the needs of guaranteeing the repair of damaged titanium alloy parts of Su-27 and Su-30 aircrafts, and has great popularization value.

Owner:国营芜湖机械厂

Condensed polyvinyl alcohol medium main agent and preparation process and products use thereof

The present invention relates to a condensed polyvinyl alcohol medium main agent, its preparation process and application of its product. Its formula includes water and polyvinyl alcohol. It is characterized by that its formula also contains isopropanol, water is deionized water and polyvinyl alcohol is its power material. Its formula ratio of deionized water 800 kg, isopropanol 300 kg and polyvinyl alcohol powder 200 kg. Its preparation process includes the following steps: according to the formula ratio stirring and mixing them above-mentioned materials at normal temp., taking 1 / 3 quantity of the above-mentioned mixture and heating other portion, adding polyvinyl alcohol powder, constant-temp. dissolving, forced cooling, adding the above-mentioned 1 / 3 liquid mixture, mixing so as to obtain the invented product. It possesses extensive application range.

Owner:上海杭州湾数码科技发展有限公司

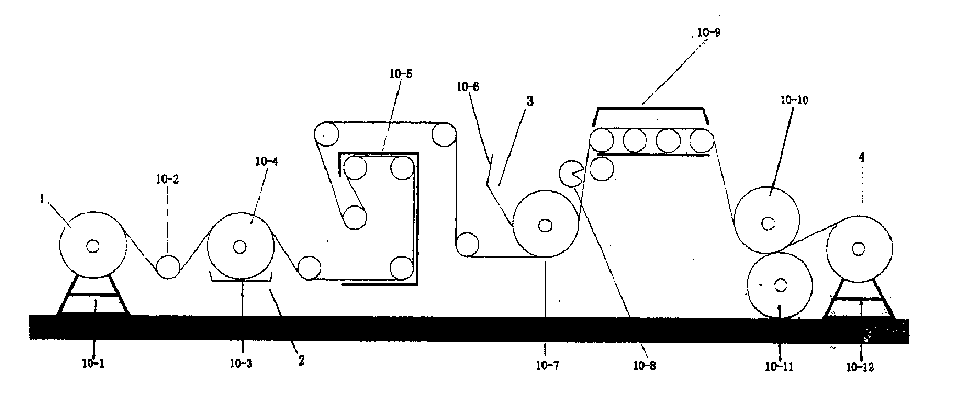

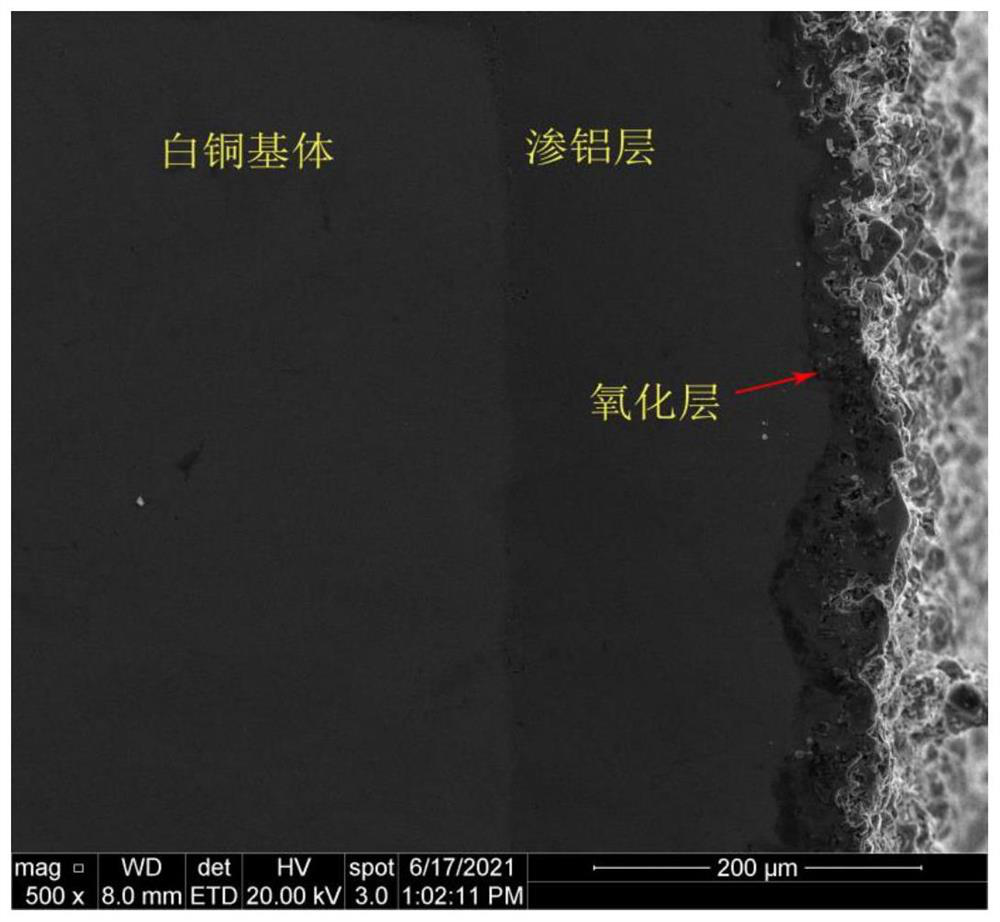

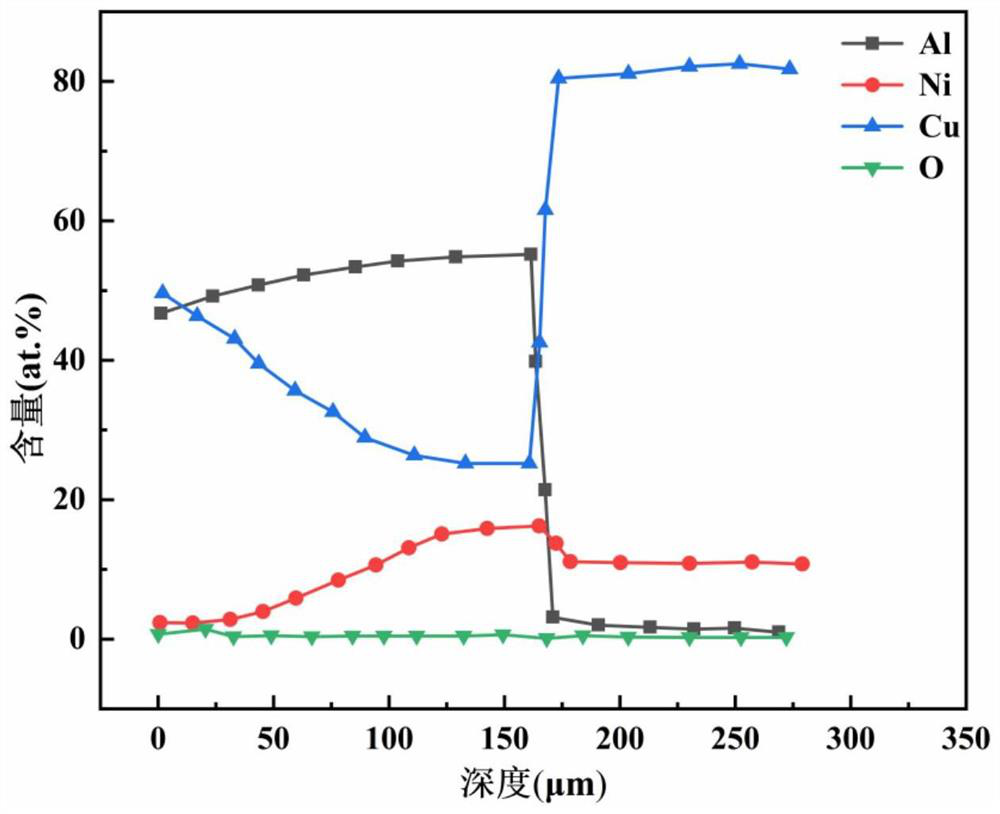

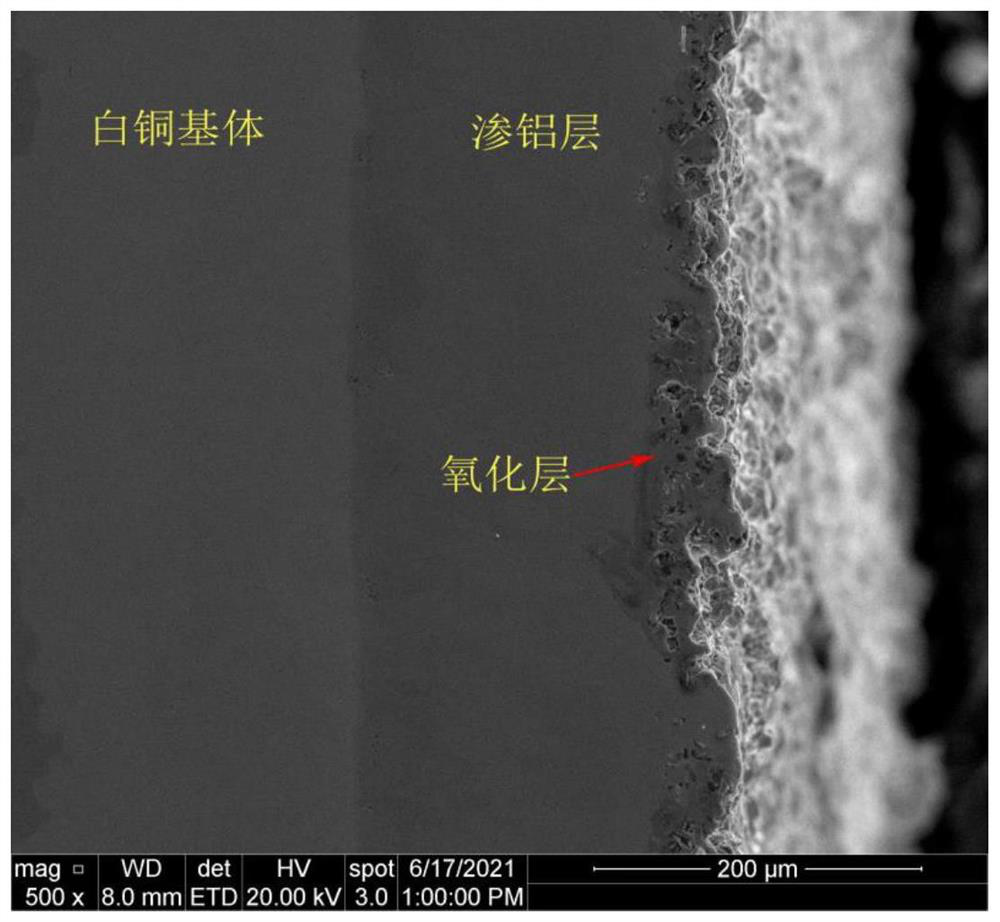

Corrosion-resistant coating on surface of cupronickel alloy and preparation method of corrosion-resistant coating

PendingCN114293142AImprove corrosion resistanceSolve the interface binding problemSolid state diffusion coatingCupronickelNitrogen gas

The invention relates to a cupronickel alloy surface corrosion-resistant coating and a preparation method thereof, the coating is prepared by combining a powder coating method with a high-temperature diffusion heat treatment process, the coating is heated to an aluminized layer growth temperature through heat treatment, nitrogen is accompanied in the heating process, after growth is finished, when the temperature is reduced to a certain temperature, the nitrogen is closed, and furnace cooling is carried out; the process enables the aluminum source to form a diffusion aluminizing layer with a certain thickness and high binding force on the surface of the cupronickel alloy under the thrust of thermodynamic power, and the process comprises the process of diffusing aluminum atoms to a cupronickel matrix and the process of diffusing nickel atoms from the interior of the cupronickel to the aluminizing layer. The coating forms a diffusion aluminizing layer with the thickness of 120-200 [mu] m along with the change of the aluminum content from inside to outside, and the obtained cupronickel surface corrosion-resistant coating can improve the corrosion resistance of the cupronickel alloy on the basis of ensuring the interface bonding force.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Composite chemical nickel and phosphor plating method

ActiveCN101514449BImprove bindingImprove corrosion resistanceLiquid/solution decomposition chemical coatingSodium acetateHigh adhesion

The invention relates to a composite chemical nickel and phosphor plating method, characterized by comprising the following steps: 1) the pH value of the chemical nickel and phosphor plating solution containing nickel sulfate with the concentration being 26 to 30 g / l, sodium hypophosphite with the concentration being 23 to 27 g / l, sodium citrate with the concentration being 38 to 42 g / l and sodium acetate with the concentration being 23 to 27 g / l is adjusted to be 9 to 10, neodymium(III) sulfate octahydrate is mixed with the chemical nickel and phosphor plating solution uniformly at the addition amount is 0.4 to 0.8 g / l, the above solution is plated on the pretreated neodymium iron boron magnet under the effect of the ultrasonic wave for 10 to 60 minutes to obtain a nickel and phosphor plating layer with the crystal grain size of 5 to 8 nm; 2) the pH value of the chemical nickel and phosphor plating solution containing nickel sulfate with the concentration being 22 to 26 g / l, sodium hypophosphite with the concentration being 28 to 32 g / l, sodium citrate with the concentration being 43 to 47 g / l and sodium acetate with the concentration being 28 to 32 g / l is adjusted to be 4.2 to 5.6, the plated neodymium iron boron magnet in the step(1) is placed into the chemical nickel and phosphor plating solution in the step(2) for plating for 30 to 120 minutes, the amorphous nickel and phosphor plating layer is obtained. Compared with the prior art, the plating layer has high adhesion and good corrosion resistance, the thickness of the plating layer can be reduced and the loss of the magnetic property can be lowered.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

A Metallization Process of Honeycomb Epoxy FRP Antenna

ActiveCN103741148BWith heat conductionWith magnetic permeabilityRadiating elements structural formsLiquid/solution decomposition chemical coatingEpoxyAntenna design

The invention discloses a metallization process for a honeycomb epoxy glass fiber reinforced plastic antenna. The metallization process comprises a sequential technological process of antenna surface sealed modification treatment and antenna pre-treatment, oil-removing coarsening and modified sealed material coarsening and antenna metallization, and chemical formation of a metal film, electroplating and thickening and three-proofing post-treatment of a metal film layer. After being metalized, the honeycomb interlayer structure epoxy glass fiber reinforced plastic antenna has a metal appearance; surface conduction, heat conduction, magnetism conduction, solvent etching resistance, good conduction resistance and various electrical performance indexes can meet antenna design requirements. Compared with a conventional glass fiber reinforced plastic non-metal material metallization process, the antenna sealed modification treatment is simple in technological process and does not need special technological equipment including plasmas or laser induction and the like; the metallization process has high practicability and reliability and is convenient for use properties of promoting production and machining.

Owner:36TH RES INST OF CETC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com