Method for integral micromachining multilayer composite structure

A technology of complex structure and seed layer, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as affecting normal work, increasing the difficulty of precision assembly work, and weak mechanism integrity, and achieves widening processing. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

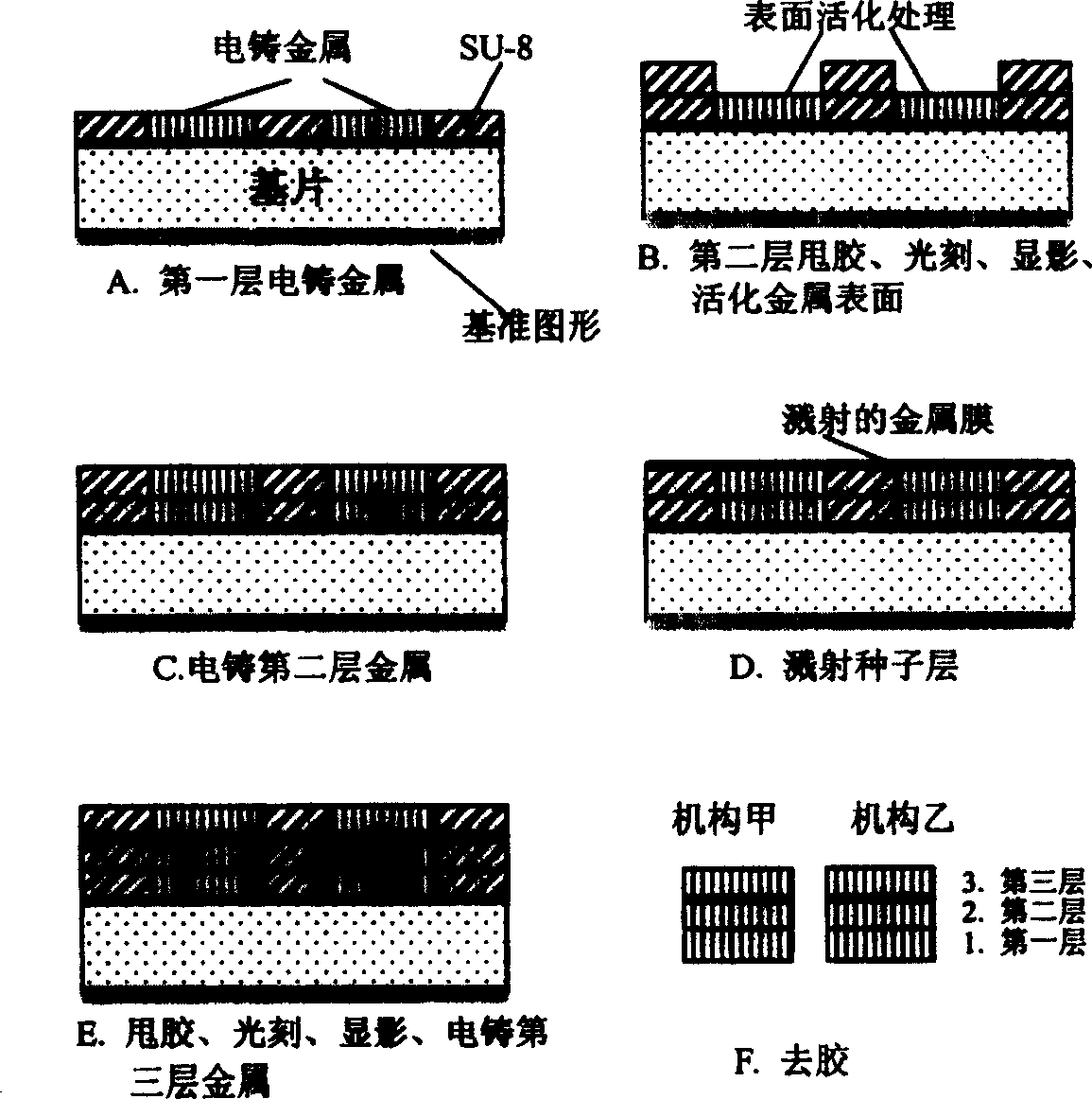

[0016] Process two three-layer structures that are used in conjunction with each other. In this structure, the first and third layers of graphics are larger than the second layer of graphics. The electroforming material is Ni, and a double-sided exposure lithography machine is used. The specific processing method is as follows:

[0017] A photolithography reference pattern is first made on the bottom surface of the substrate, and subsequent photolithography processes are all based on it.

[0018] Such as figure 1 As shown in middle A, the first layer of photoresist SU-8, after photolithography and development according to the reference pattern on the bottom surface, Ni is electroformed, and the surface of the electroformed layer is planarized after electroforming.

[0019] Such as figure 1 As shown in middle B, after the second layer of glue removal, photolithography (based on the bottom surface pattern), and development, the surface of Ni is subjected to surface activation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com