Thin film solar cell electrode and preparation method thereof

A technology of solar cells and thin films, applied in the field of solar cells, can solve problems such as effective methods and technical means that have not been mentioned, and achieve the effects of improving transfer efficiency, solving binding force, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

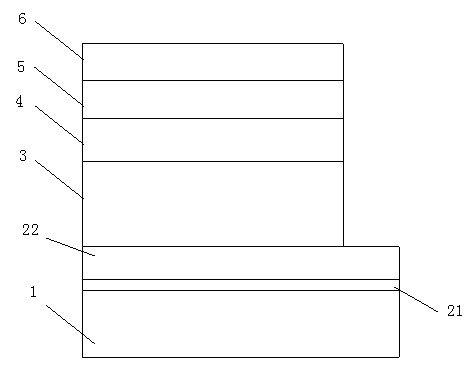

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0021] Such as figure 1 A kind of thin-film solar cell electrode shown, compares with the structure of traditional thin-film solar cell electrode, and the molybdenum thin film on the glass substrate 1 of the product of the present invention is made of two layers of molybdenum crystal grains: the grain diameter is 12-16nm coarse The molybdenum grain layer 21 and the fine molybdenum grain layer 22 with a grain size of 2-6nm, wherein the coarse molybdenum grain layer 21 is in contact with the glass substrate 1 .

[0022] Among the above two molybdenum metal grain layers, the thickness of the fine grain layer 22 is 1.6-3.3 times, preferably 2 times, the thickness of the coarse molybdenum grain layer 21 .

[0023] The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com