Method for making double-layer alloy plating metallic film resistor

A metal film resistor, alloy coating technology, applied in the manufacture of resistors, non-adjustable metal resistors, resistors, etc., can solve the problems of poor adhesion between the coating and the insulator, the yield of the coating brittle crack, and the decline, so as to overcome the brittleness of the coating. cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

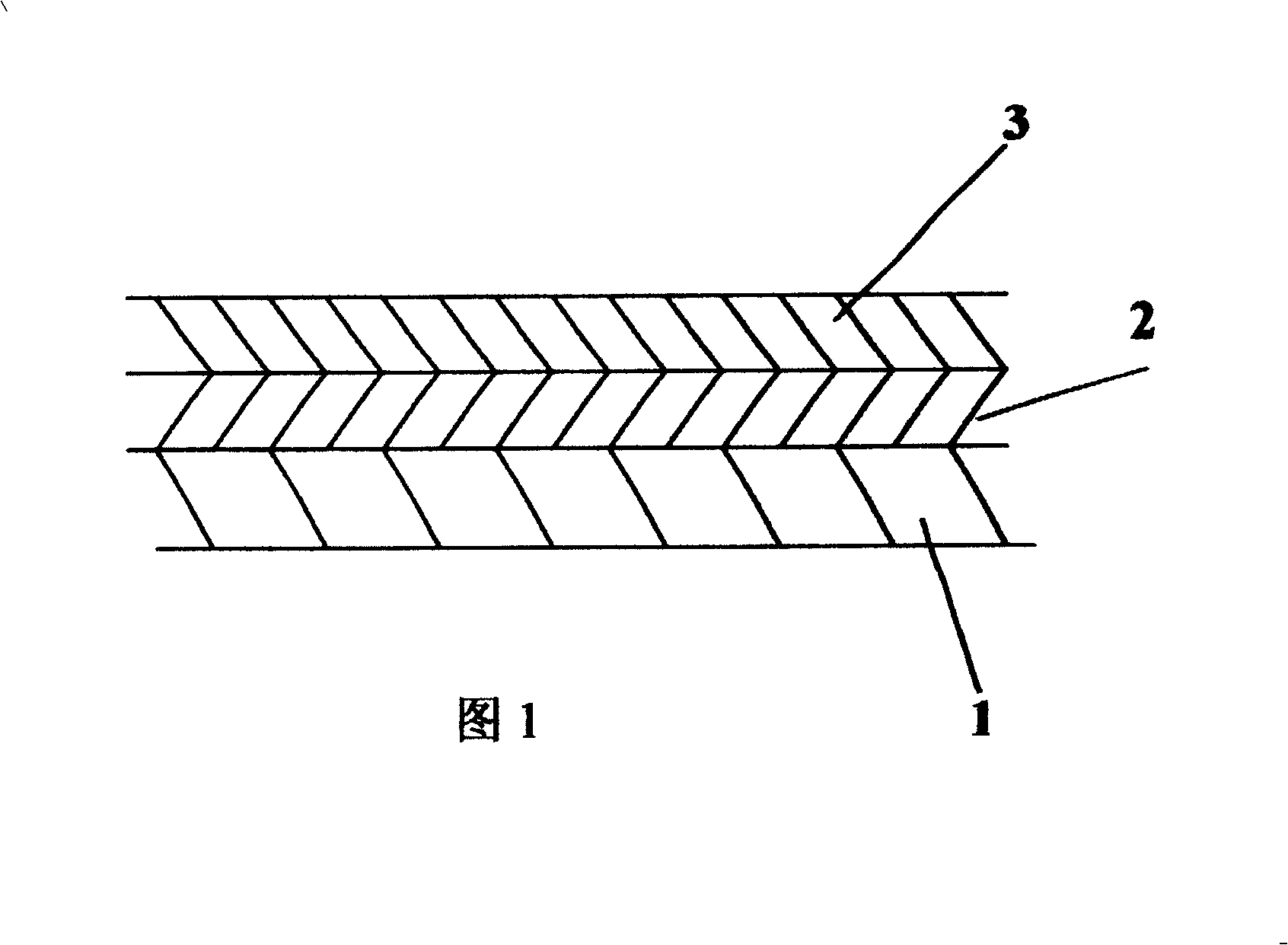

[0012] As shown in Figure 1, a layer of Ni-Cr alloy 2 is first sputtered on at least one layer of insulating substrate 1, and its composition ratio is Ni:Cr (w / w)=75:25~85:15, and then This Ni-Cr alloy 2 layer is plated one deck Cu-Ni alloy coating 3, and its composition ratio is Cu: Ni (w / w)=60: 40~40: 60; The specific steps of method are to use existing routine The sputtering method, after sputtering a layer of Ni-Cr alloy on at least one layer of insulating film material, then go through the following steps:

[0013] 1. Acid solution activation at room temperature;

[0014] 2. Wash with water;

[0015] 3. Suspension plating or barrel plating of Cu-Ni alloy layer in Cu-Ni alloy plating solution, barrel plating for 0.5-6 hours or longer according to the requirements of resistance value;

[0016] 4. Wash with water;

[0017] 5. Dry.

[0018] The composition of the acid used for activation described in step 1 is hydrochloric acid or sulfuric acid, concentration of hydrochlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com