Condensed polyvinyl alcohol medium main agent and preparation process and products use thereof

A polyvinyl alcohol medium, polyvinyl alcohol technology, applied in the field of shrinkage polyvinyl alcohol medium main agent and its preparation process and products, can solve the problem of low cohesion of surface coating, easy damage of film, inferior clear and bright effect of traditional photos And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

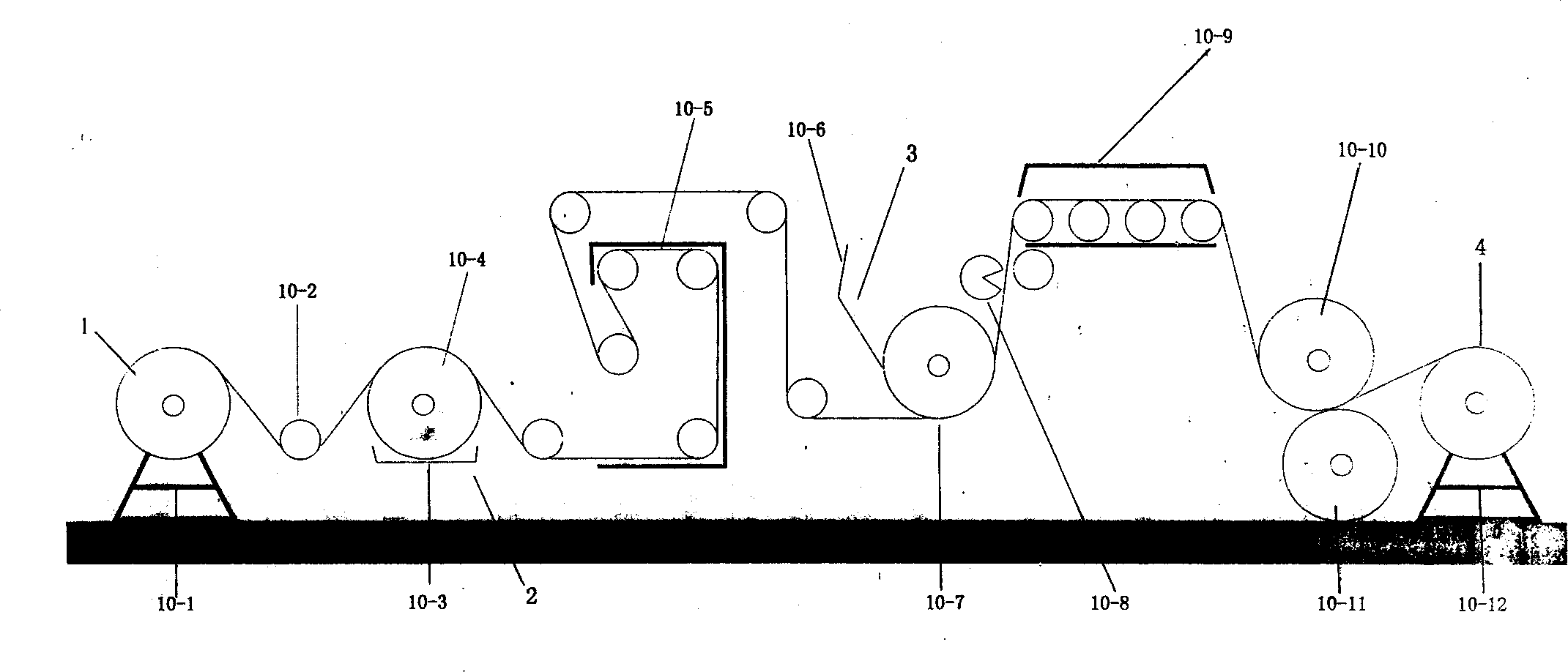

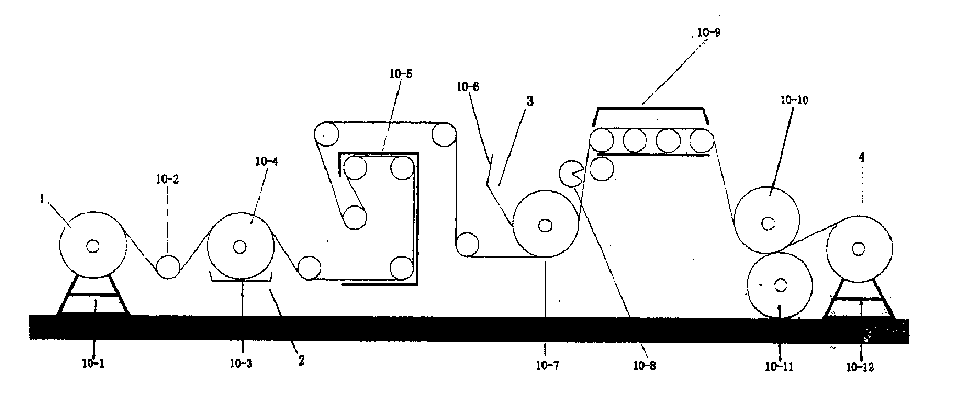

[0005] The preparation process of the shrinkable polyvinyl alcohol medium main agent is: 1. The ratio of the mixed solution is: Weigh 800kg of deionized water and 300kg of isopropanol, put them into a PVC dissolution tank, and stir evenly: the stirring speed is 60-80RPM / min, 30 minutes in total, 300kg in barrels for additional storage, keep 800kg of mixed solution in the dissolution tank, turn on the heating steam pipe and heat to 30°C-40°C, pour 200kg of polyvinyl alcohol powder, keep the temperature for 30 minutes, and promote polyethylene Alcohol powder is in water-saturated state. 2. The polyvinyl alcohol can be completely dissolved by heating to 80°C ~ 85°C. After the heat preservation lasts for 1 hour, close the steam pipe valve, stop heating, and when the cooling water pipe is cooled to 60°C, add 300kg of the mixed solution in step 1. . 3. When the temperature of the material drops to 35°C-40°C, it can be filtered and loaded into barrels, and it will become the main a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com