Corrosion-resistant coating on surface of cupronickel alloy and preparation method of corrosion-resistant coating

A corrosion-resistant coating and copper alloy technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of corrosion resistance of white copper alloy, etc., to improve corrosion resistance, good bonding, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

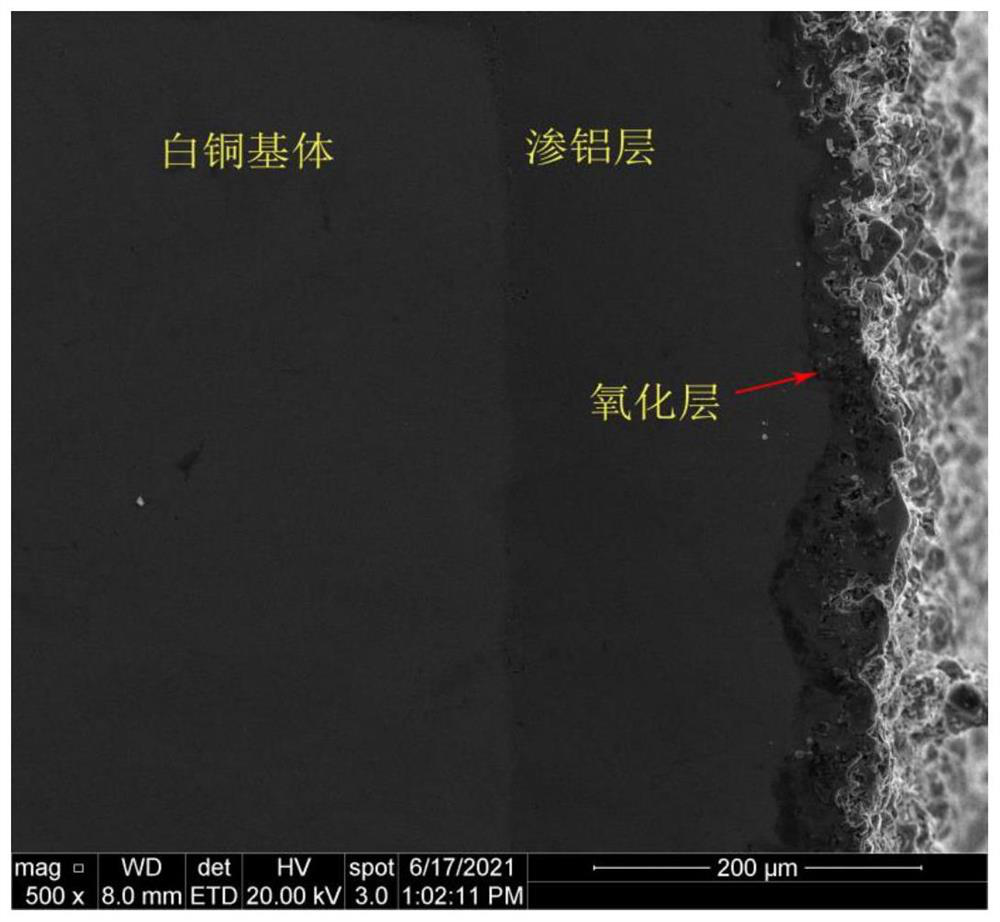

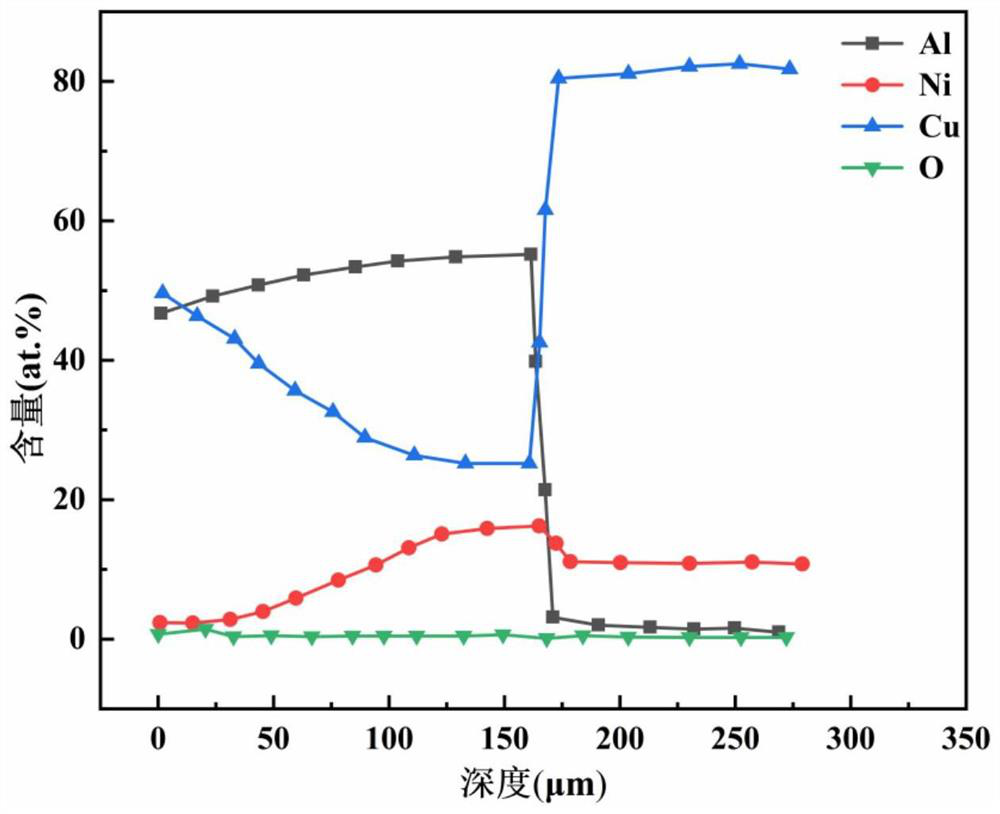

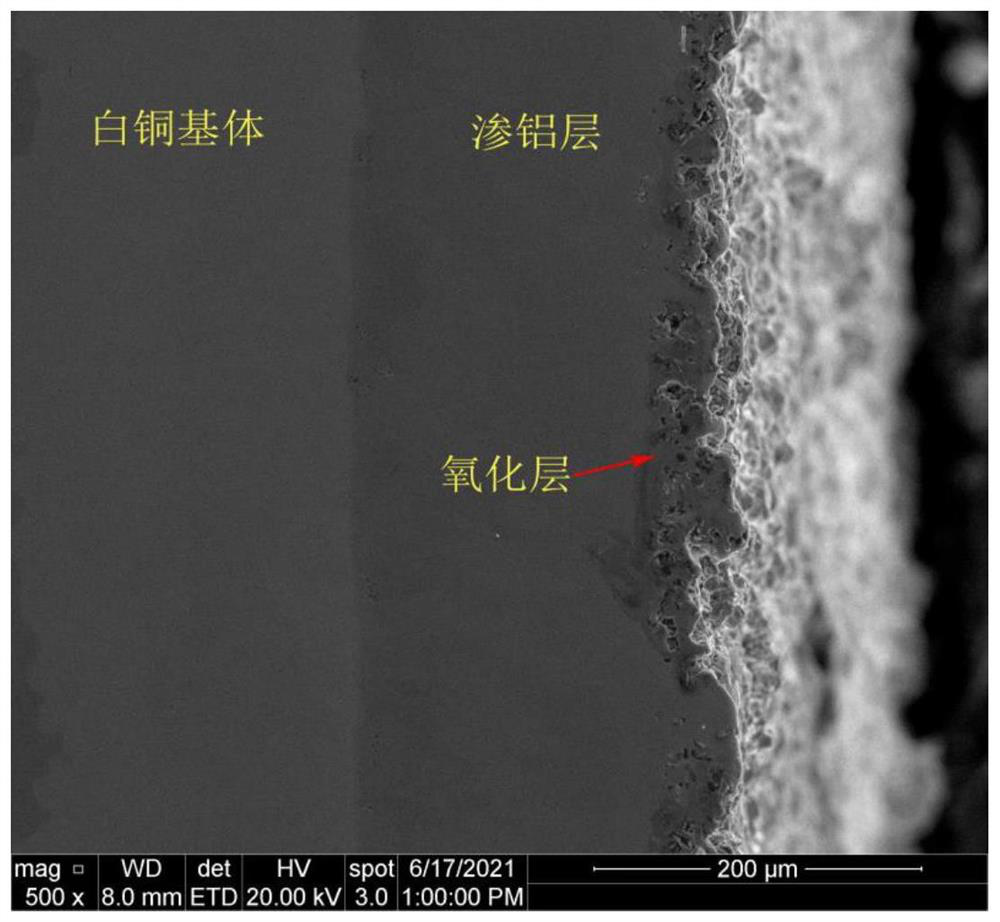

Image

Examples

Embodiment 1

[0024] 1) The steps of grinding and mechanically polishing the surface of the cupronickel alloy

[0025] The surface of the cupronickel alloy is polished step by step with sandpaper, then ultrasonically cleaned in absolute ethanol, and dried in an oven to obtain the polished surface of the cupronickel alloy.

[0026] 2) Preparation steps of aluminizing agent

[0027] Take copper-aluminum alloy powder, aluminum powder, aluminum oxide powder and ammonium chloride particle according to mass percentage, described copper-aluminum alloy powder (copper content 60%), copper-aluminum alloy powder content 70%, described copper-aluminum alloy powder granularity 40 μm, the aluminum powder content is 5%, the aluminum powder particle size is 60 μm, the ammonium chloride particle content is 1.6%, the balance is alumina powder, the alumina particle size is 10 μm, and the mixed powder is fully mechanically mixed to obtain an aluminizing agent .

[0028] 3) Preparation steps of high temperatu...

Embodiment 2

[0036] 1) The steps of grinding and mechanically polishing the surface of the cupronickel alloy

[0037] The surface of the cupronickel alloy is polished step by step with sandpaper, then ultrasonically cleaned in absolute ethanol, and dried in an oven to obtain the polished surface of the cupronickel alloy;

[0038] 2) Preparation steps of aluminizing agent

[0039] Take copper-aluminum alloy powder, aluminum powder, aluminum oxide powder and ammonium chloride particle according to mass percentage, described copper-aluminum alloy powder (copper content 60%), copper-aluminum alloy powder content 60%, described copper-aluminum alloy powder granularity 40 μm, the aluminum powder content is 4.5%, the aluminum powder particle size is 60 μm, the ammonium chloride particle content is 1.6%, the balance is alumina powder, the alumina particle size is 10 μm, and the mixed powder is fully mechanically mixed to obtain an aluminizing agent ;

[0040] 3) Preparation steps of high tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com