A method for repairing titanium alloy damaged parts by electroless nickel plating

A technology of electroless nickel plating and titanium alloy, applied in the field of surface treatment, can solve the problems of no process technology, can not solve the problem of repairing the size of titanium alloy damaged parts, and no chemical nickel plating repair process of titanium alloy damaged parts, and achieves great promotion. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] Electroless nickel plating on damaged parts of TC6 titanium alloy is used to illustrate the production of this process in combination with the process of electroless nickel plating on titanium alloy.

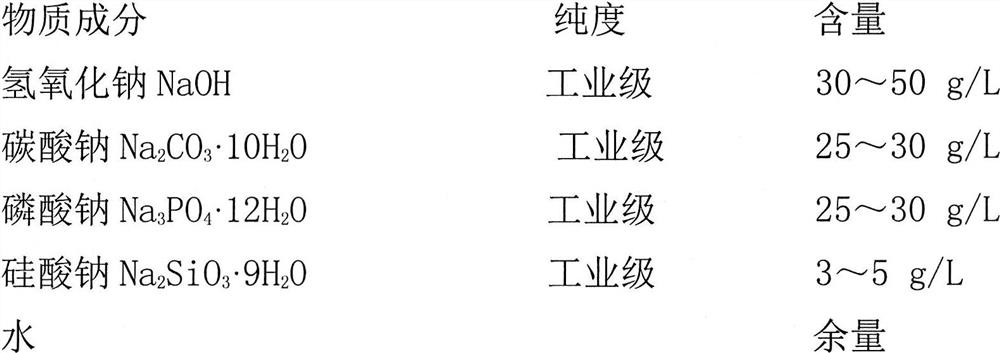

[0047] 1) Degreasing

[0048] Solution component content and process conditions:

[0049] Element purity content Sodium Hydroxide (NaOH) industrial grade (30~50)g / L Sodium carbonate (Na 2 CO 3 10H 2 O)

industrial grade (25~30)g / L Sodium phosphate (Na 3 PO 4 12H 2 O)

industrial grade (25~30)g / L Sodium silicate (Na 2 SiO 3 9H 2 O)

industrial grade (3~5)g / L water margin total alkalinity (equivalent to NaOH) 70g / L

[0050] Process conditions: temperature 75°C, time 15min

[0051] 2) Protection

[0052] Insulate and protect the non-plated parts of titanium alloy damaged parts with clamps.

[0053] 3) Blow abrasive treatment

[0054] The air pressure of the abrasive blowing is 0.2...

example 2

[0068] Electroless nickel plating on damaged parts of TC2 titanium alloy is used, and the production of this process is illustrated in combination with the process of electroless nickel plating on titanium alloy.

[0069] 1) Degreasing

[0070] Solution component content and process conditions:

[0071] Element purity content Sodium Hydroxide (NaOH) industrial grade (30~50)g / L Sodium carbonate (Na 2 CO 3 10H 2 O)

industrial grade (25~30)g / L Sodium phosphate (Na 3 PO 4 12H 2 O)

industrial grade (25~30)g / L Sodium silicate (Na 2 SiO 3 9H 2 O)

industrial grade (3~5)g / L water margin total alkalinity (equivalent to NaOH) 70g / L

[0072] Process conditions: temperature 75°C, time 15min

[0073] 2) protection

[0074] Insulate and protect the non-plated parts of titanium alloy damaged parts with clamps.

[0075] 3) Blow abrasive treatment

[0076] The air pressure of the abrasive blowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com