Processing method of printed wiring board with ultra-small solder mask intervals

A technology for printed circuit boards and processing methods, which is applied to the secondary treatment of printed circuits and the application of non-metallic protective layers. It can solve problems such as wire separation, achieve easy control, prevent falling off, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] First, surface activation treatment is carried out on the printed circuit board, and screen printing of the solder resist ink is carried out within 4 hours after the treatment; after the screen printing of the solder resist ink, it is exposed→developed→cured deal with.

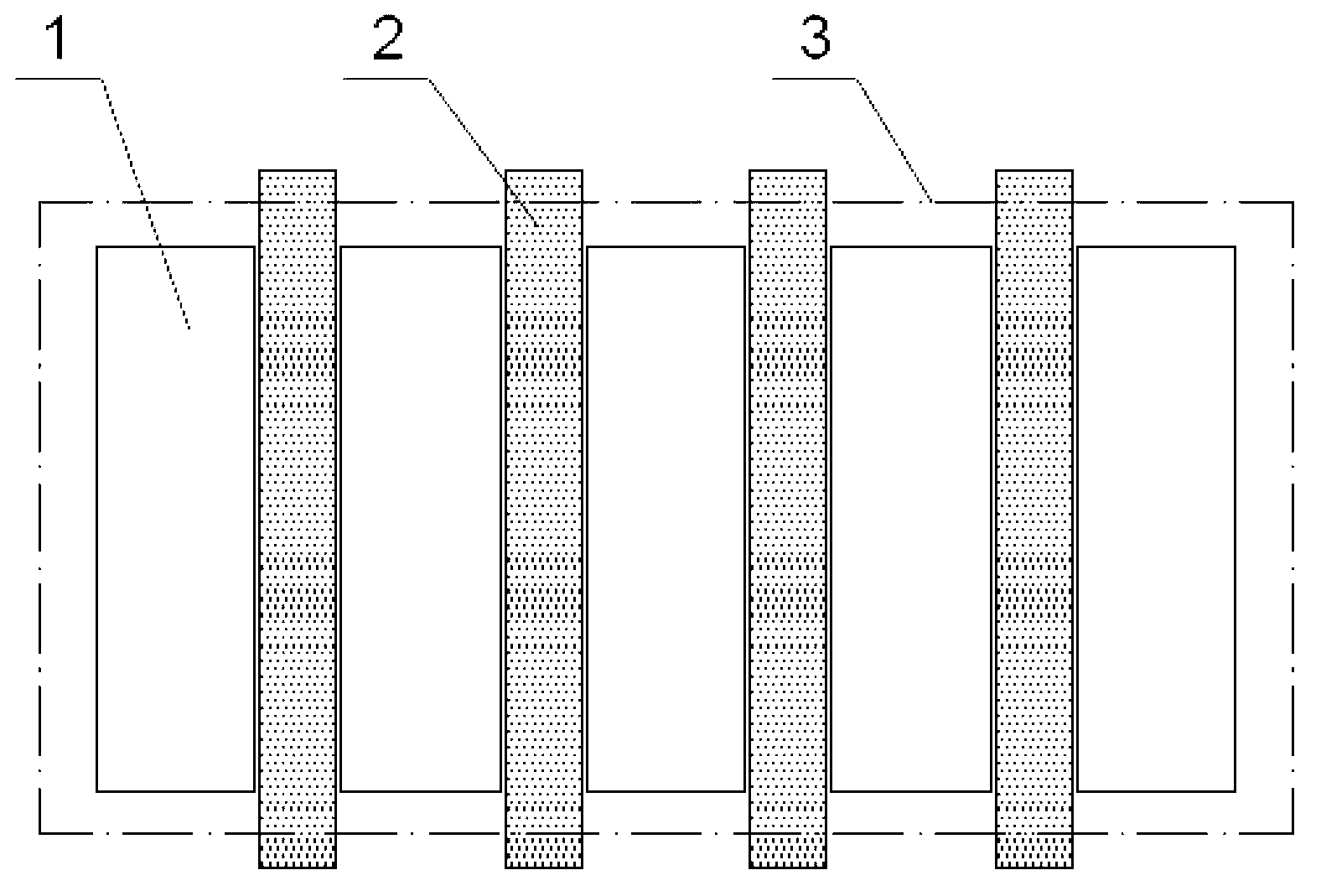

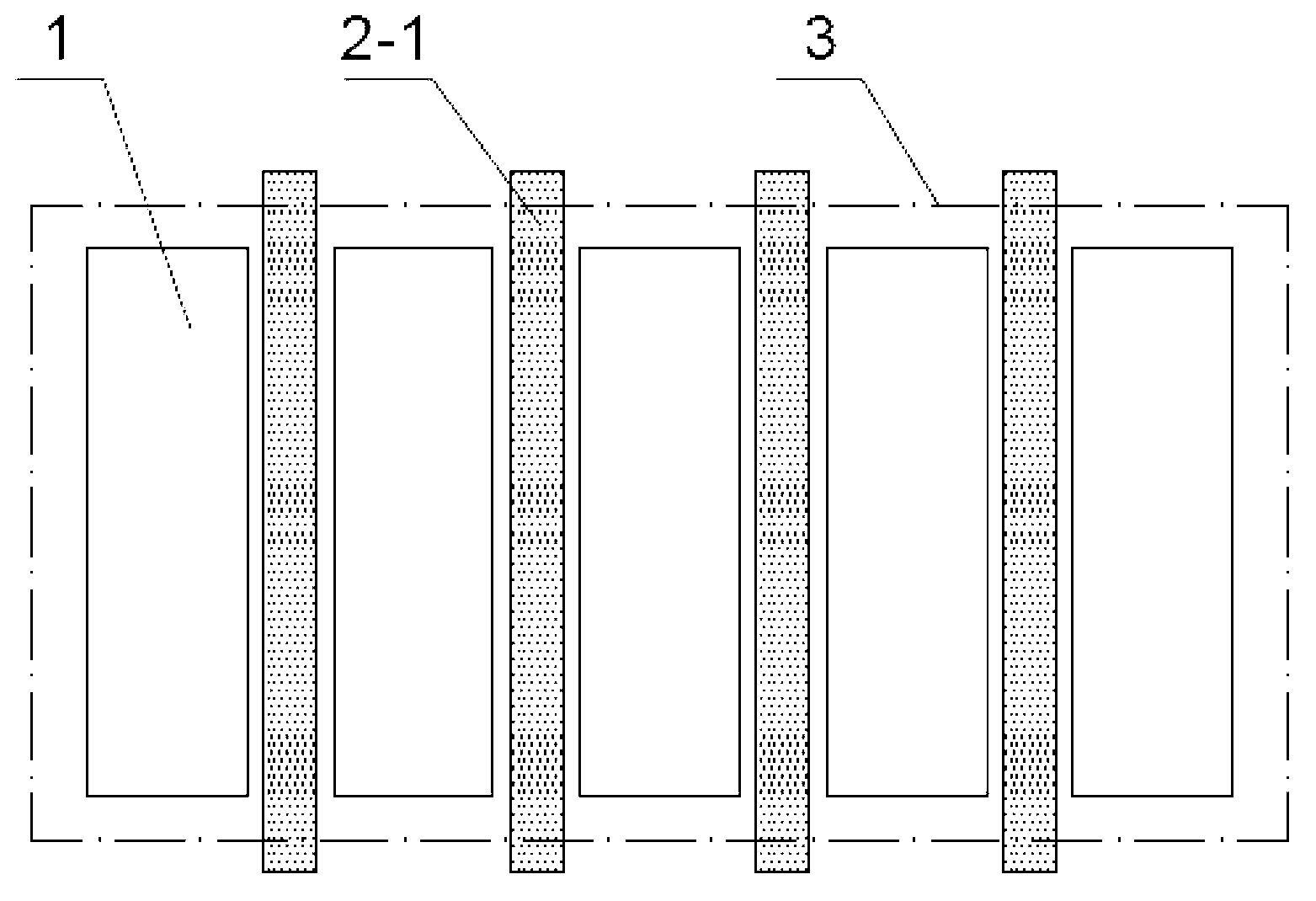

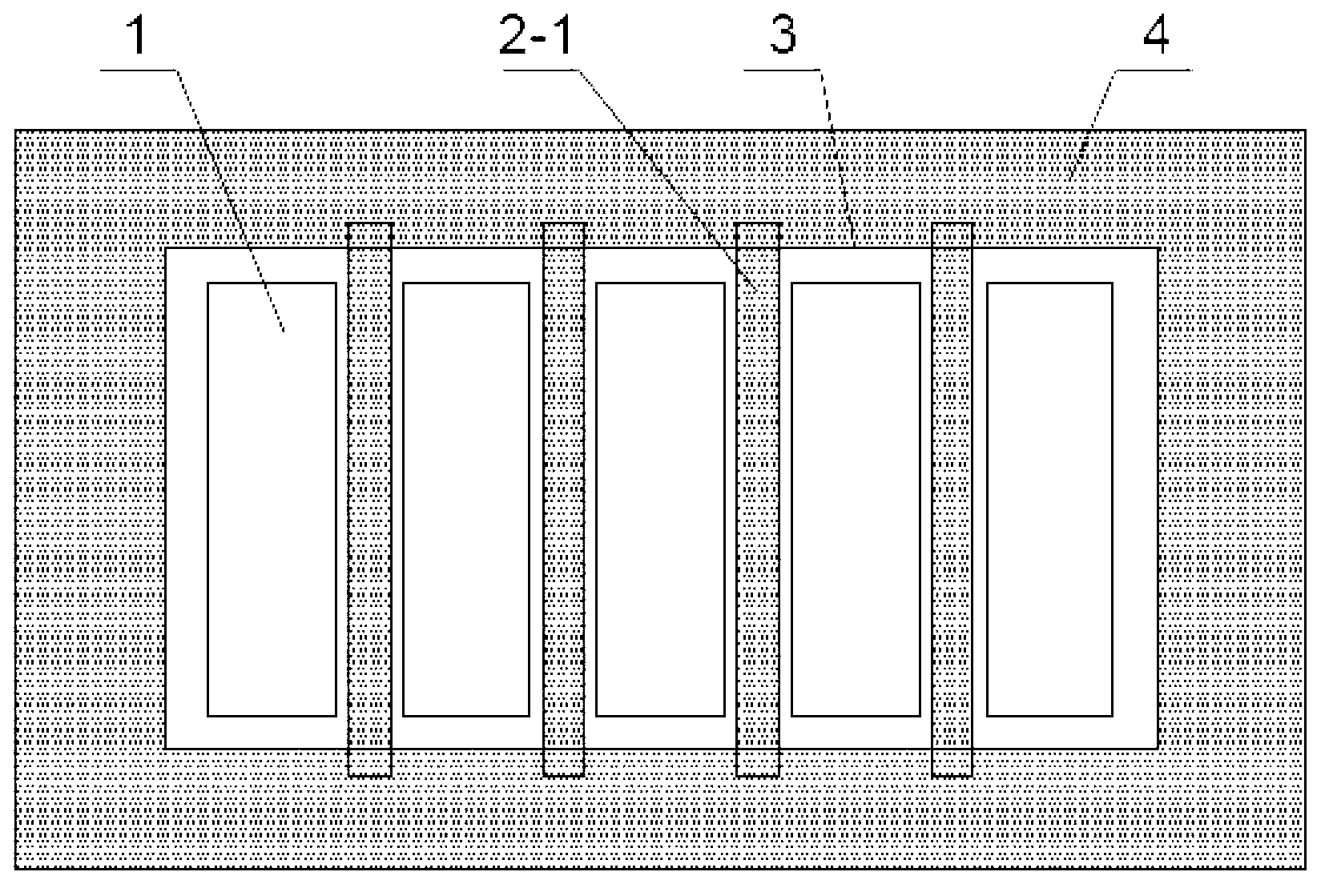

[0021] Such as figure 1 As shown, the screen printing ink 2 is printed between the SMD pads 1, the thickness of the solder resist ink of the screen printing is half the ink thickness according to the customer's requirement, and the spacer 2-1 Both ends of the printing length exceed the annual ring of the SMD pad space by 1-1.5mil. When exposing, the film used is only designed to expose the exposure area at the line 2-1, and the other areas are black areas without exposure, and the annual ring of the empty area of the SMD pad 1 at the line 2-1 is designed to be 1mil. The curing temperature is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com