Processing method of ultra-small welding-proof spacing circuit board

A processing method and printed circuit board technology, applied in the direction of coating non-metallic protective layer, secondary treatment of printed circuit, etc., can solve the problem of wire-separation falling off, etc., achieve the effect of easy control, prevent falling off, and solve the problem of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

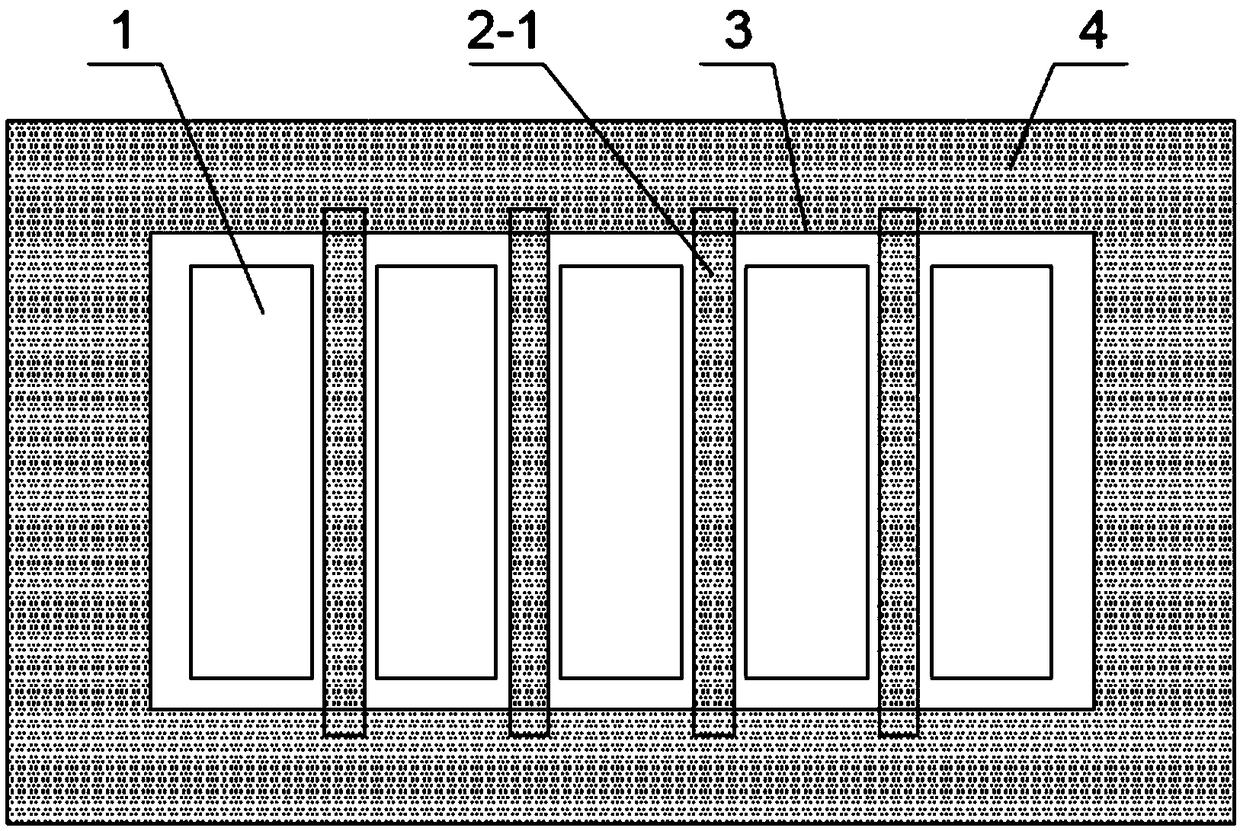

[0019] The present invention relates to a processing method of a printed circuit board, more specifically, to a processing method of a circuit board made of an ultra-small solder mask spacing (0.08 mm), which firstly performs surface activation treatment on the printed circuit board, and then Within 4 hours after that, perform screen printing of the solder resist ink line separation; after the screen printing of the solder resist ink line separation, it is subjected to exposure→development→curing treatment.

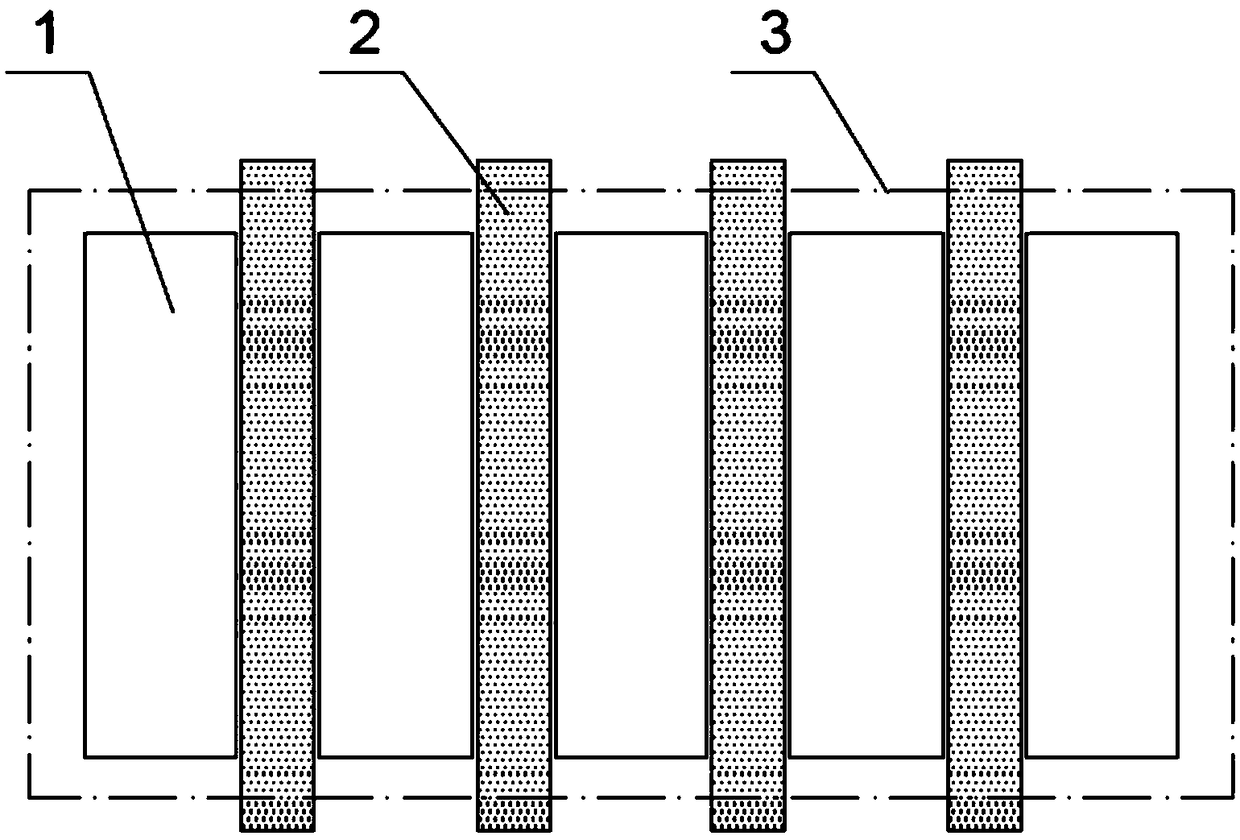

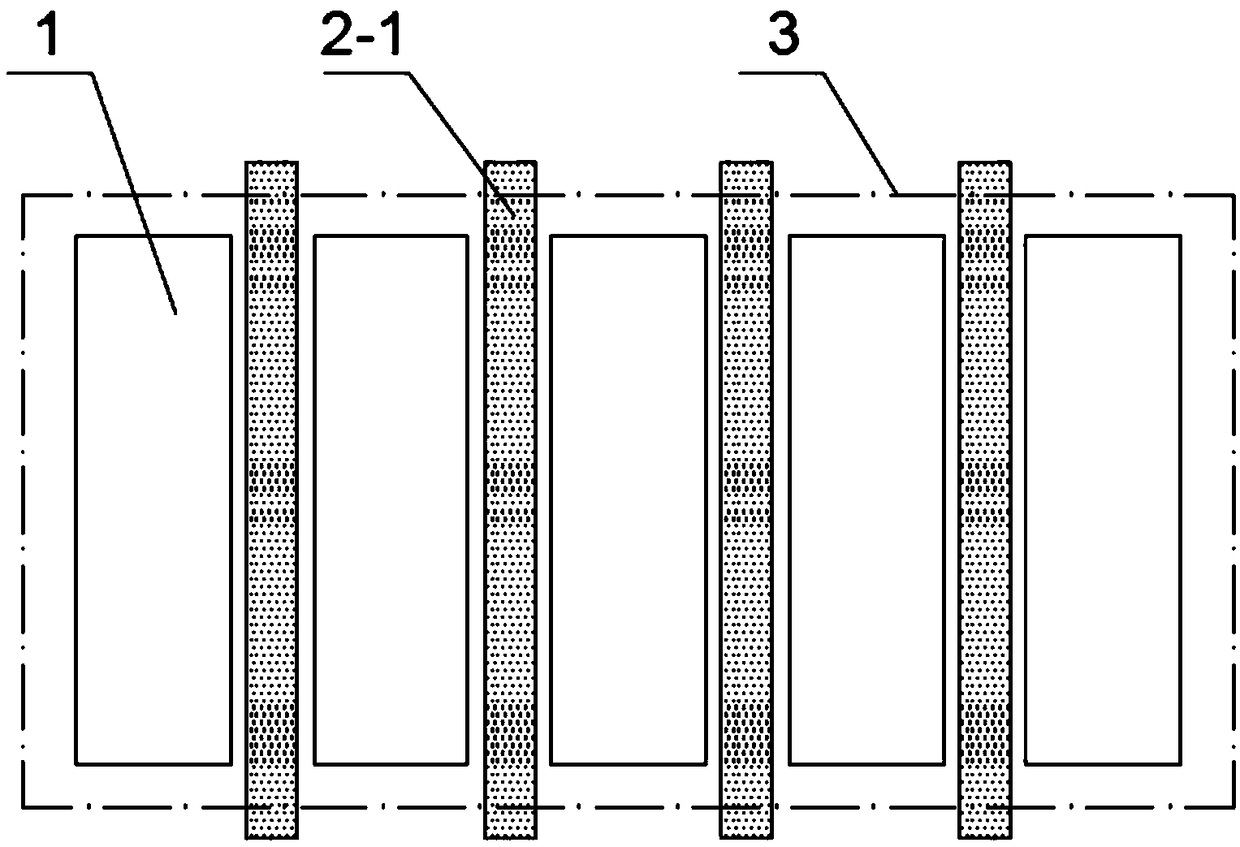

[0020] like figure 1 As shown, the screen printing ink 2 is printed between the SMD pads 1, the thickness of the solder resist ink of the screen printing is half the ink thickness according to the customer's requirement, and the spacer 2-1 Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com