Multi-layer board hole metallization method

A processing method and hole metallization technology, which are applied in the directions of metal pattern materials, electrical connection formation of printed components, printed circuit components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of graphene slurry: 8% graphene, 0.5% tristyrene phenol polyoxyethylene ether phosphate potassium salt, 2% propylene glycol, 3.5% diethylene glycol phenyl ether, mixed with water, prepared by ball milling Slurry, solid content is 14%;

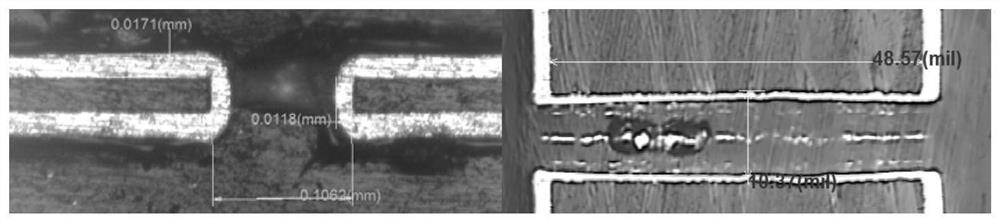

[0035] Preparation of conductive paste: adding 0.1% of palladium nanowire dispersion (such as figure 2 shown), 0.1% silver nanowire dispersion, 10% polyalkoxy modified thiophene, and 0.8% water-based polyamide wax were dispersed into a stable paste with a solid content of 25%.

Embodiment 2

[0037] Preparation of graphene slurry: 10% of graphene, 0.5% of tristyrene phenol polyoxyethylene ether phosphate potassium salt, 0.5% of tristyrene phenol polyoxyethylene ether acetate potassium salt, and 4% of diethylene glycol phenyl ether , mixed with water, and prepared into a slurry by ball milling, with a solid content of 15%;

[0038] Preparation of conductive paste: 0.05% of copper nanowire dispersion, 0.15% of silver nanowire dispersion, 6% of polyalkoxy modified thiophene, and 3% of polystyrene sulfonic acid were added to graphene slurry with a solid content of 15%. %, fumed silica 0.1%, water-based polyamide wax 0.4%, high-speed dispersion into a stable paste with a solid content of 24.7%.

Embodiment 3

[0040] Preparation of graphene slurry: 9% graphene, 0.1% potassium tristyrene phenol polyoxyethylene ether phosphate, 0.4% potassium tristyrene phenol polyoxyethylene ether acetate, 2% propylene glycol, diethylene glycol 3% phenyl ether, mixed with water, prepared into a slurry by ball milling, with a solid content of 14.5%;

[0041] Preparation of conductive paste: Add 0.1% silver nanowire dispersion liquid, 7% alkoxy modified thiophene, 2.5% polystyrene base sulfonic acid, 0.1% carbomer to the graphene slurry with a solid content of 14.5%, water-based Polyamide wax 0.4%, high-speed dispersion into a stable paste, solid content of 24.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com