Preparation method for forming metal organic framework ZIF-67 film by utilizing cobalt nano array layer conversion

A technology of ZIF-67 and metal-organic framework, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of weak carrier binding force, difficulty in heterogeneous nucleation of metal-organic framework membrane, and easy cracking, etc. problem, to achieve the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

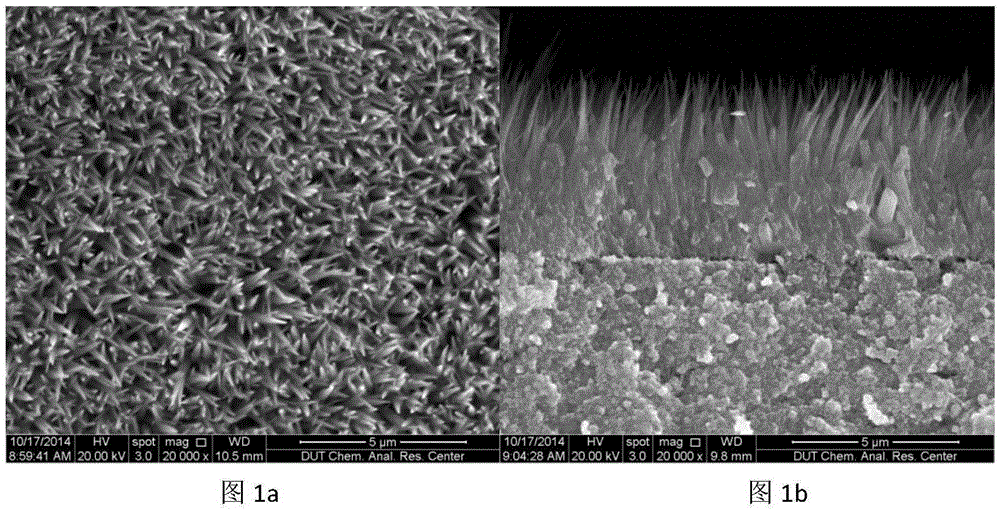

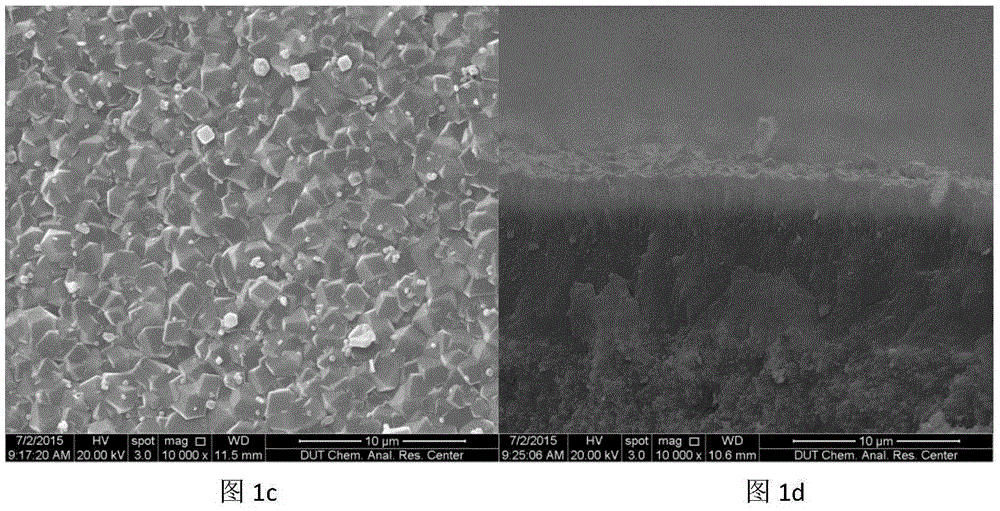

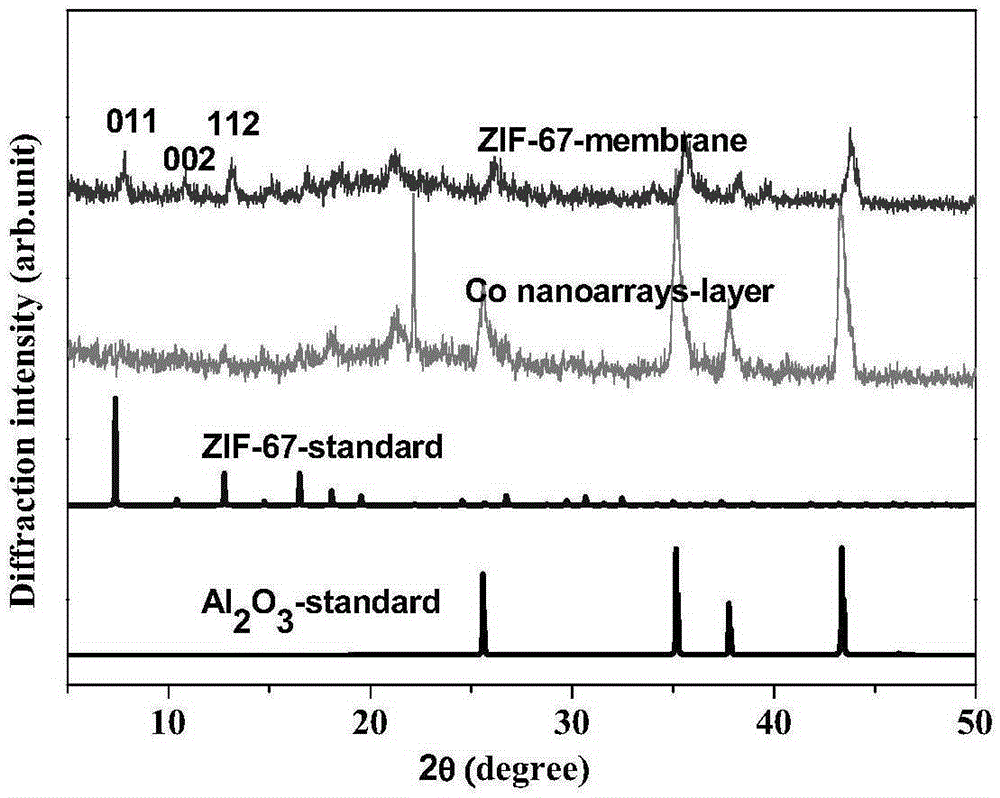

[0034] Example 1: In situ and green synthesis of a ZIF-67 film on an alumina ceramic tube using needle-like basic cobalt carbonate nanowire arrays.

[0035] (1) The carrier is an alumina ceramic tube carrier with an average pore diameter of about 0.1-2 μm. Before synthesis, use deionized water and ethanol to ultrasonically wash several times to remove surface particles and stains, and dry them for later use.

[0036] (2) Using 1mol / LNaOH and 1mol / LHNO respectively 3 Treat at 60°C for 2h, APTMS:C 2 h 5 OH=1:30(v:v) treated at 75°C for 3h, and dried at room temperature.

[0037] (3) The inner surface of the alumina ceramic tube introduces needle-like basic cobalt carbonate nanowire arrays: the molar ratio is Co(NO 3 ) 2· 6H 2 O:NaF:CO(NH 2 ) 2 :H 2 The solution of O=1:2:5:555 is a synthetic solution. The outer wall of the ceramic tube is tightly wrapped with polytetrafluoroethylene tape, suspended vertically in the kettle, reacted at 75°C for 12-24 hours, dried naturall...

Embodiment 2

[0040] Example 2: In situ and green synthesis of a ZIF-67 film on a single crystal silicon wafer by using rhombic cobalt oxyhydroxide nanorod arrays.

[0041] (1) The carrier is a single crystal silicon wafer, which is cut into a square silicon wafer of 15mm×15mm before use. Before synthesis, the carrier was placed in a beaker, cleaned ultrasonically with deionized water and ethanol, and dried at 60°C for later use.

[0042] (2) Introduce diamond-shaped cobalt fluoride hydroxide nanorod arrays on the silicon wafer: the molar ratio is Co(NO 3 ) 2 ·6H 2 O: NH 4 F: C 6 h 12 N 4 (hexamethylenetetramine): H 2 The solution of O=1:1.4:2:555 is the synthesis solution. Hang the treated silicon wafer in the kettle with a polytetrafluoroethylene tape, react at 75°C for 12-24 hours, dry it naturally, and rinse with deionized water , cobalt oxyhydroxide nanorod array layers are grown on both sides of the silicon wafer.

[0043] (3) Formation of the ZIF-67 film: use sandpaper to po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com