Preparation method of metal organic framework ZIF-8 (zero insert force-9) film

A metal-organic framework, ZIF-8 technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Scale-up preparation, high effective mass, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

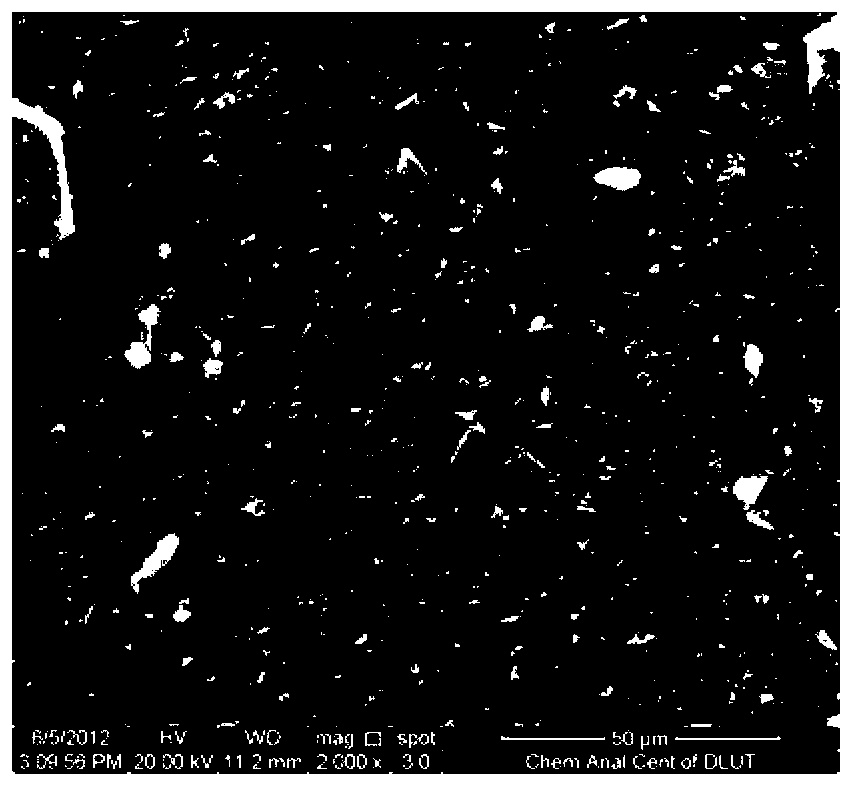

[0038] (1) The porous support is α-Al with an average pore diameter of about 0.1 μm 2 o 3 Ceramic carrier tube. Before the synthesis, the carrier is firstly cleaned with deionized water under ultrasonic vibration, dried and roasted for use.

[0039] (2) Configuration and pulling of zinc-containing sol to introduce the surface of the carrier: a certain amount of zinc acetate is dissolved in ethylene glycol methyl ether solvent and ethanolamine is used as a stabilizer, and the mass fraction of zinc is 14.3%. , and then dipped and pulled to coat the pre-configured zinc sol, dried at 100°C for 2 hours, and then placed in a muffle furnace for 100 minutes at 400°C, and the heating rate was set at 0.5°C / min. Cool down to room temperature; repeat 2-3 times.

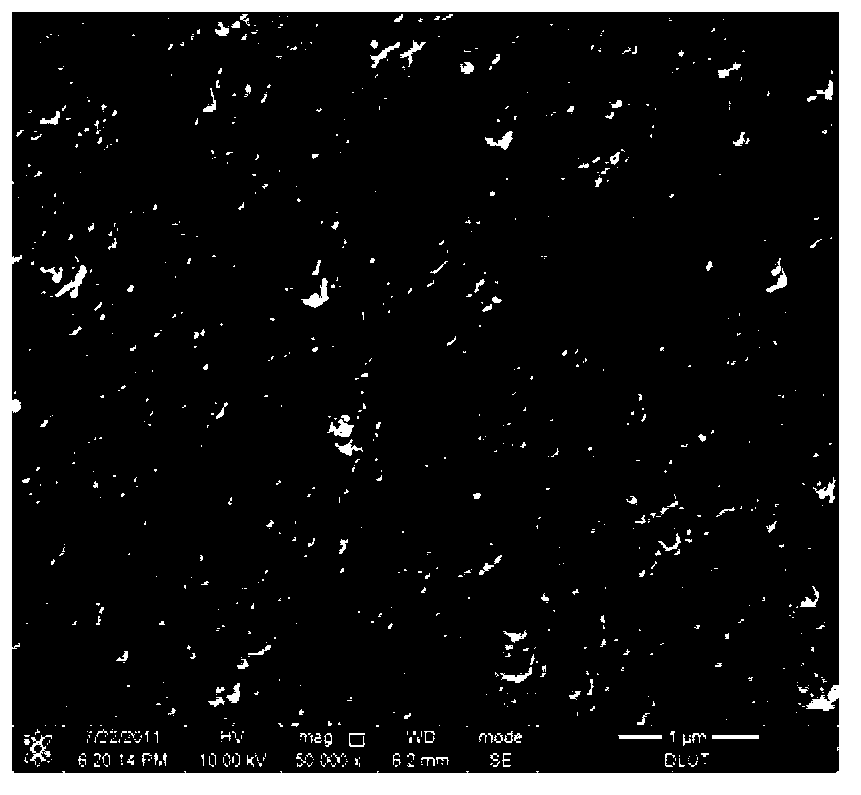

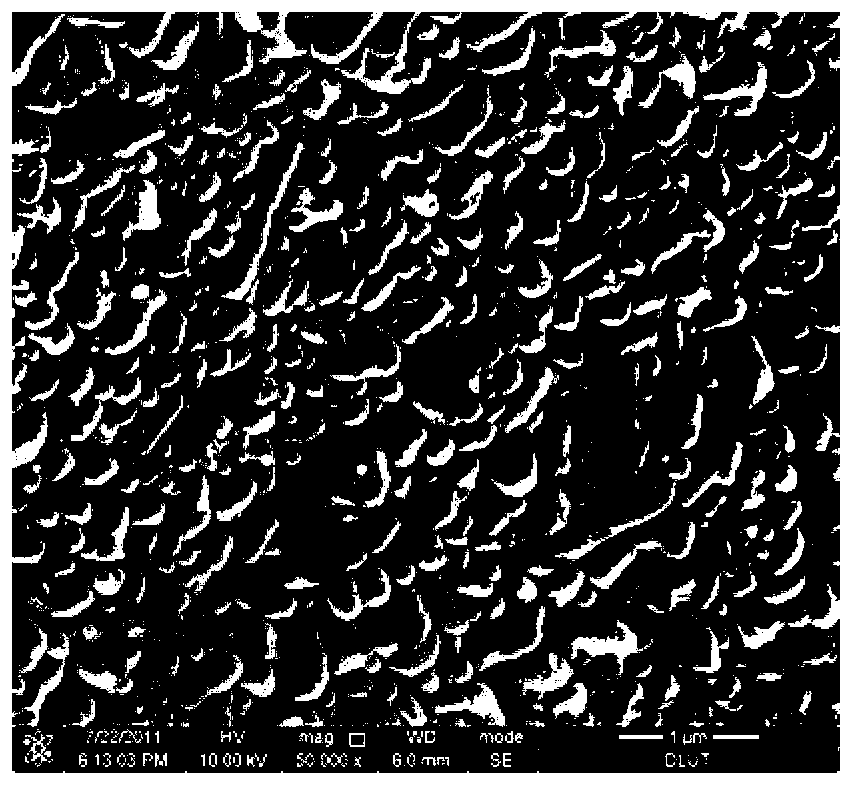

[0040] (3) Film formation on the surface of the porous ceramic tube carrier: Put the porous ceramic tube coated with zinc oxide layer into the prepared 0.5M 2-methylimidazole methanol solution for activation at 50°C for 1 hour...

Embodiment 2

[0043] (1) The porous support is α-Al with an average pore diameter of about 0.1 μm 2 o 3 Ceramic carrier tube. Before the synthesis, the carrier is firstly cleaned with deionized water under ultrasonic vibration, dried and roasted for use.

[0044](2) Configuration and introduction of zinc-containing synthetic solution to the surface of the carrier: use hexamethylenetetraammonium (C6H12N4) and zinc nitrate as raw materials, and prepare a zinc oxide layer growth solution according to the ratio of 2Zn(NO3)2:0.3C6H12N4:230H2O, Put the porous carrier in the zinc oxide layer growth solution and react at 90°C for 6 hours to grow a zinc oxide layer;

[0045] (3) Synthesis of ZIF-8 membrane: Put the porous ceramic carrier with the zinc oxide layer into the prepared 0.5M 2-methylimidazole methanol solution for activation at 50°C for 1 hour, take it out and dry it in the air; 0.65HCOONa: 1.0ZnCl2: 1.52-meIM: 450MeOH to configure a stable ZIF-8 membrane solution, and aged for 2h. Th...

Embodiment 3

[0048] (1) The porous support is α-Al with an average pore diameter of about 0.1 μm 2 o 3 Ceramic carrier tube. Before the synthesis, the carrier is firstly cleaned with deionized water under ultrasonic vibration, dried and roasted for use.

[0049] (2) Configuration and pulling of zinc-containing sol to introduce the surface of the carrier: a certain amount of zinc acetate is dissolved in ethylene glycol methyl ether solvent and ethanolamine is used as a stabilizer, and the mass fraction of zinc is 14.3%. , and then dipped and pulled to coat the pre-configured zinc sol, dried at 100°C for 2 hours, and then placed in a muffle furnace for 100 minutes at 400°C, and the heating rate was set at 0.5°C / min. Cool down to room temperature; repeat 2-3 times.

[0050] (3) Configuration of zinc-containing synthetic solution and introduction to the surface of the carrier: use hexamethylenetetraammonium (C6H12N4) and zinc nitrate as raw materials, and prepare a zinc oxide layer growth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com