Valve-regulated lead acid storage battery polar group and polar plate packaging method thereof

A lead-acid battery, valve-controlled technology, applied in the direction of lead-acid battery electrodes, lead-acid batteries, lead-acid battery construction, etc., can solve the problems of plate connection and wrapping methods, shortened life, and long life. , to achieve the effect of high current discharge and charge acceptance, increased maximum current density, and thin plate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

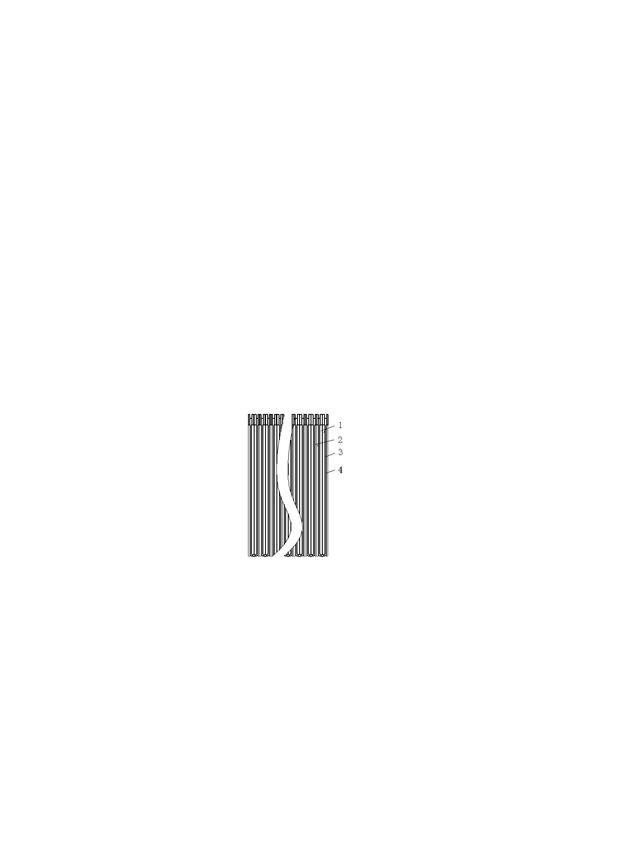

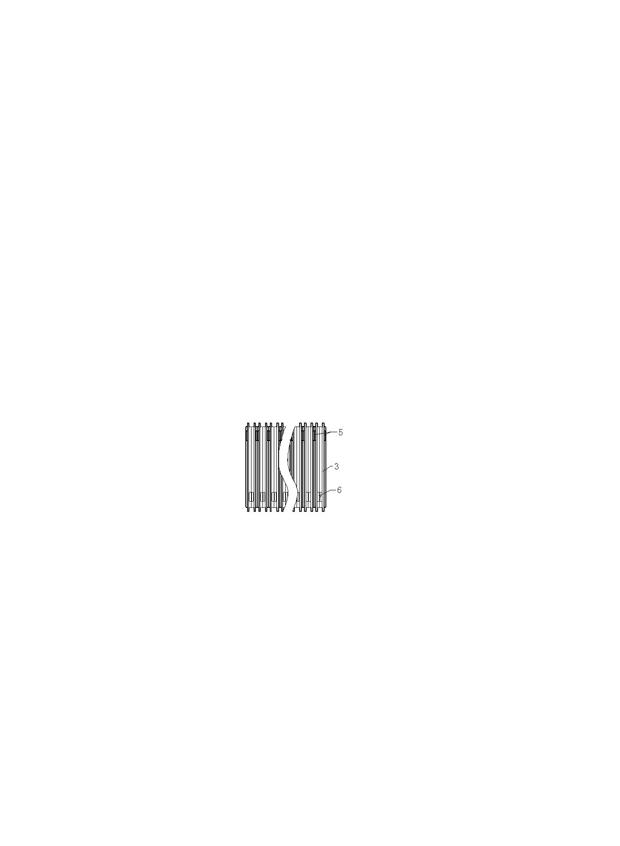

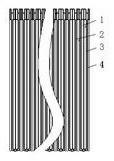

[0020] In this embodiment, an electric bicycle battery 12v12Ah pole group is taken as an example. like figure 1 , 2 As shown, an electrode group of a valve-regulated sealed lead-acid battery includes negative plates 4 located on both sides of the electrode group, and a separator 3 arranged between the positive and negative plates. still as figure 1 , 2 As shown, the positive and negative plates between the two negative plates 4 are respectively separated by two plates of the same polarity as a group and separated by a separator 3, and the positive plate group 1 and the negative plate group 2 are continuously arranged in order to set Count and end with positive plate group 1, the total number of positive plates and negative plates in each group is equal. The single plate thickness of the positive plate group 1 is 1.5 mm, and the single plate thickness of the negative plate group 2 is 1 mm. The total number of positive plates in the pole group is 12, and the total number of...

Embodiment 2

[0025] The single plate thickness of the positive plate group 1 is 2.5 mm, and the single plate thickness of the negative plate group 2 is 2 mm. The total number of positive plates is 8, and the total number of negative plates is 8. All the other implementations are as in Example 1.

Embodiment 3

[0027] The single plate thickness of the positive plate group 1 is 2 mm, and the single plate thickness of the negative plate group 2 is 1.2 mm. The total number of positive plates is 10, and the total number of negative plates is 10. All the other implementations are as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com