Coating dispersion machine capable of moving left and right

A technology of moving left and right and dispersing machine, which is applied in the direction of shaking/oscillating/vibrating mixer, mixing machine, dissolving, etc. It can solve the problems of affecting the quality of coating products, low efficiency of dispersing machine, uneven dispersion, etc., to increase the range of agitation, Improve mixing efficiency and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

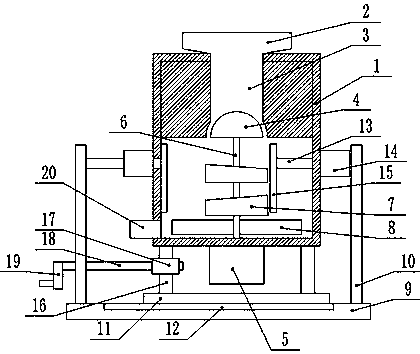

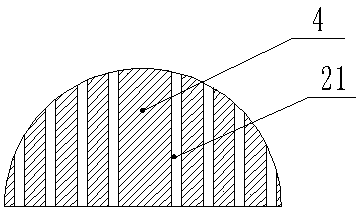

[0015] Please refer to the figure, in the embodiment of the present invention, a paint disperser that moves left and right includes a housing 1, a feed hopper 2, a motor 5 and a base 9; the base 9 is provided with a horizontal chute 12, the chute 12 is slidably connected with a horizontal sliding seat 11, and the sliding seat 11 moves left and right on the upper surface of the base 9. The housing 1 is located above the sliding seat 11, and a vertical joint is fixedly welded between the housing 1 and the sliding seat 11. The supporting legs 16 are used to support the housing 1; the feed hopper 2 is connected to the top of the housing 1, and the housing 1 corresponding to the feed hopper 2 is connected with a vertical deceleration chamber 3, and the diameter of the deceleration chamber 3 is It is 1 / 4~1 / 3 of the inner diameter of the housing 1, so that the loaded paint flows downward along the deceleration chamber 3; the deceleration chamber 3 is fixedly installed with a motor 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com