Patents

Literature

35results about How to "Change horizontal position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel wall-mounted type bedside lamp applied to bedroom

ActiveCN106958765AChange horizontal positionInterestingLighting support devicesLight fasteningsEngineeringBedroom

The invention relates to a bedside lamp, in particular to a novel wall-mounted type bedside lamp applied to a bedroom. The invention aims to provide the novel wall-mounted type bedside lamp applied to the bedroom, wherein the light color is plentiful, and the illumination range and position are adjustable. The novel wall-mounted type bedside lamp applied to the bedroom, provided by the invention, comprises a mounting plate, first screws, a fixing plate, a first connecting plate, a first bearing seat, a first rotating rod, a connecting rod, a multi-color bar, a connecting block, a second bearing seat and the like, wherein the upper and lower sides of the mounting plate are each provided with a threaded hole; each first screw is screwed inside the corresponding threaded hole and is matched with the corresponding threaded hole; and each first screw is screwed into the wall of the right side of the mounting plate. The novel wall-mounted type bedside lamp provided by the invention realizes the effects that the light color is relatively plentiful and the illumination range and position are adjustable, and can change the light color quickly by controlling the rotation way of the multi-color bar by rotating a first rocking handle.

Owner:江苏百株家具有限公司

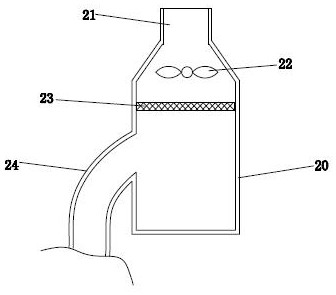

Multifunctional automobile handrail box

InactiveCN108189768AChange horizontal positionAvoid spillingPassenger spaceArm restsHandrailEngineering

The invention discloses a multifunctional automobile handrail box, which comprises a base; the upper end of the base is provided with a supporting plate, and the base is fixedly connected with the supporting plate through a lifting mechanism; the upper end of the supporting plate is provided with a box body, and the supporting plate is glidingly connected with the box body through a gliding mechanism; a first limiting mechanism capable of limiting the gliding mechanism to glide is arranged on the side wall of the supporting plate, one end of a second circular block closing to a first circularblock is provided with a first groove; the first circular block is rotationally connected with the second circular block through a rotary shaft, the upper end of the rotary shaft is provided with a locking rotary button; a water cup placing cylinder and a storage cavity are arranged in the box body, a buckling mechanism, the upper end of the box body is provided with a matched box cover, one end of the box cover is rotationally connected with the box body. The multifunctional automobile handrail box is reasonable in structure, position and height of the handrail box can be adjusted; the handrail box can adapt to habits of drivers with different heights; meanwhile, the handrail box has functions of an ashtray and can adapt to different sizes of water cups.

Owner:YANCHENG GAOYUE MACHINERY

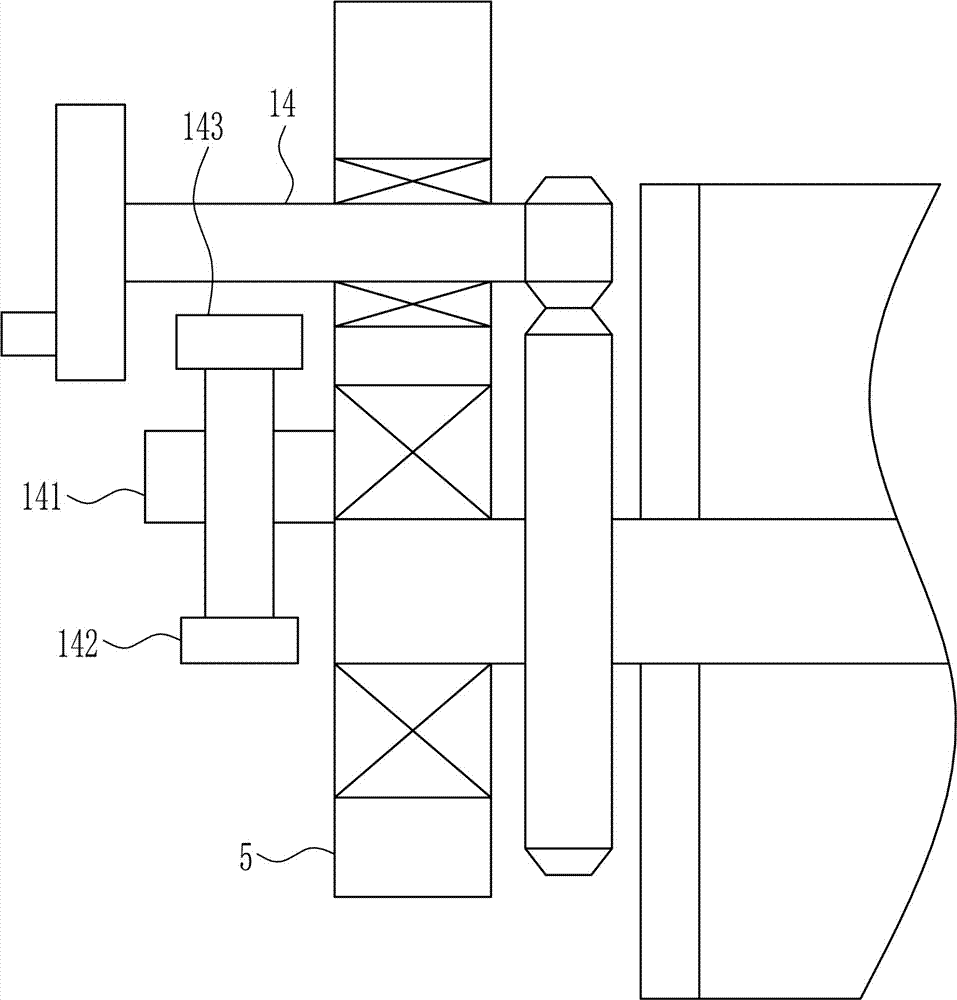

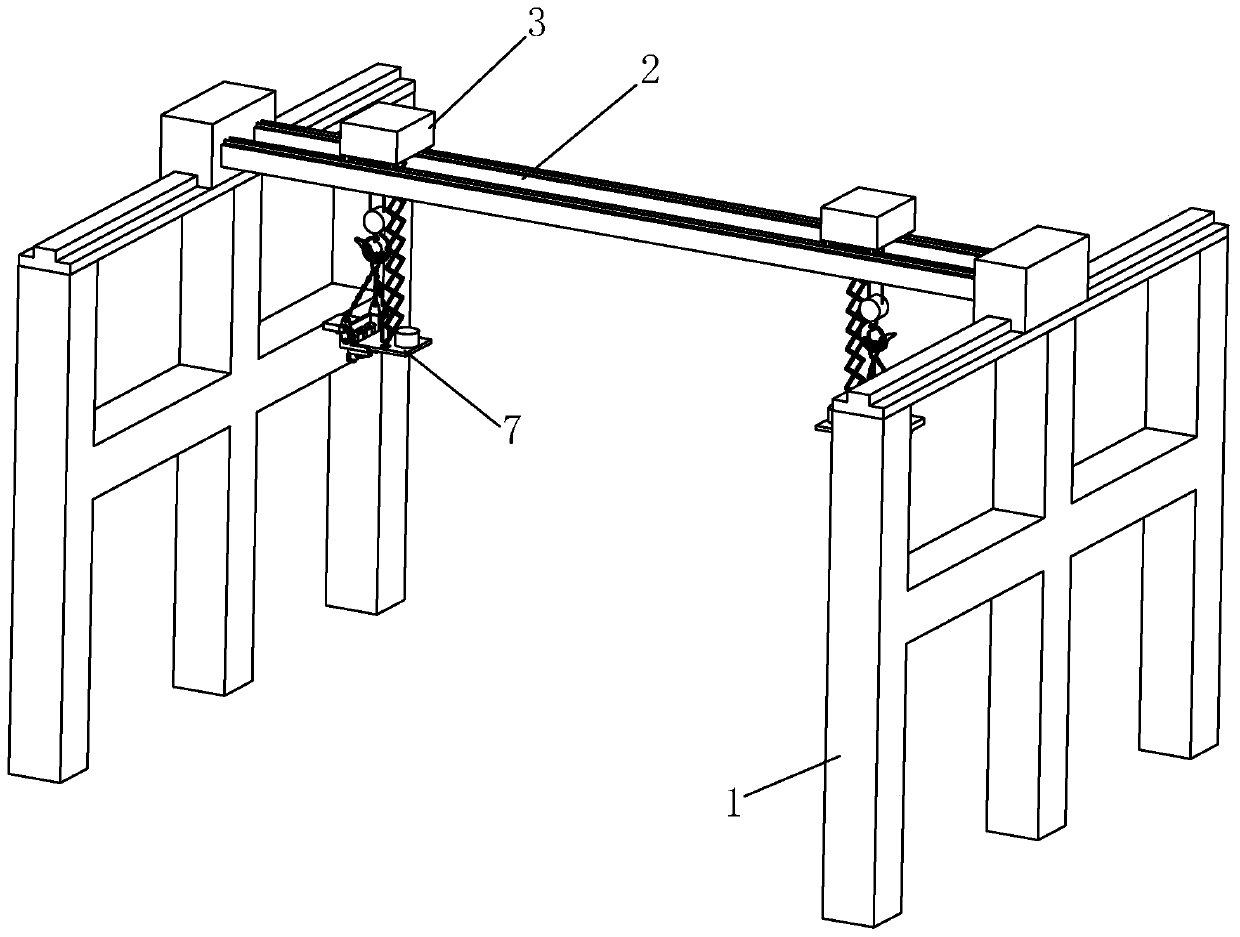

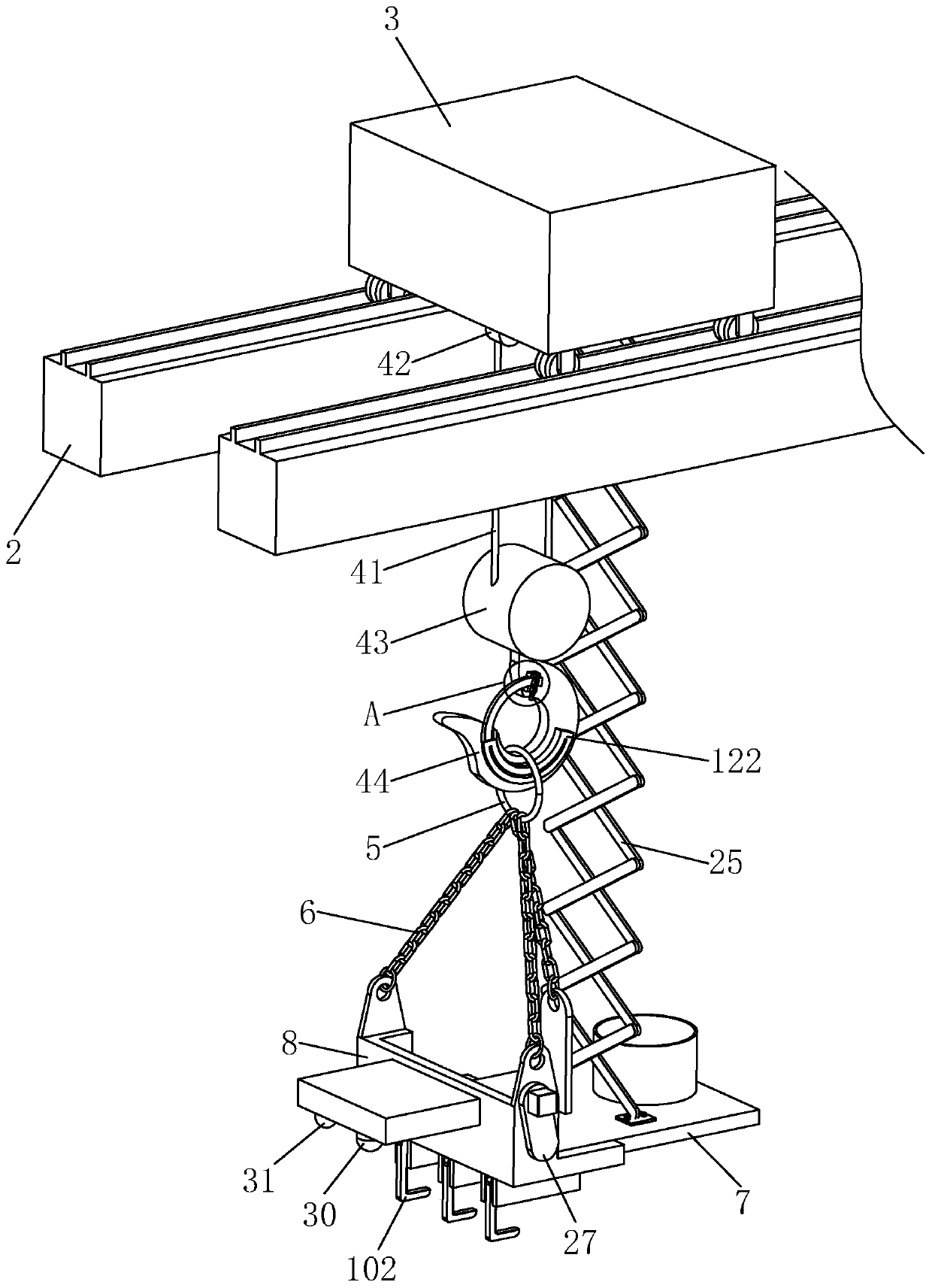

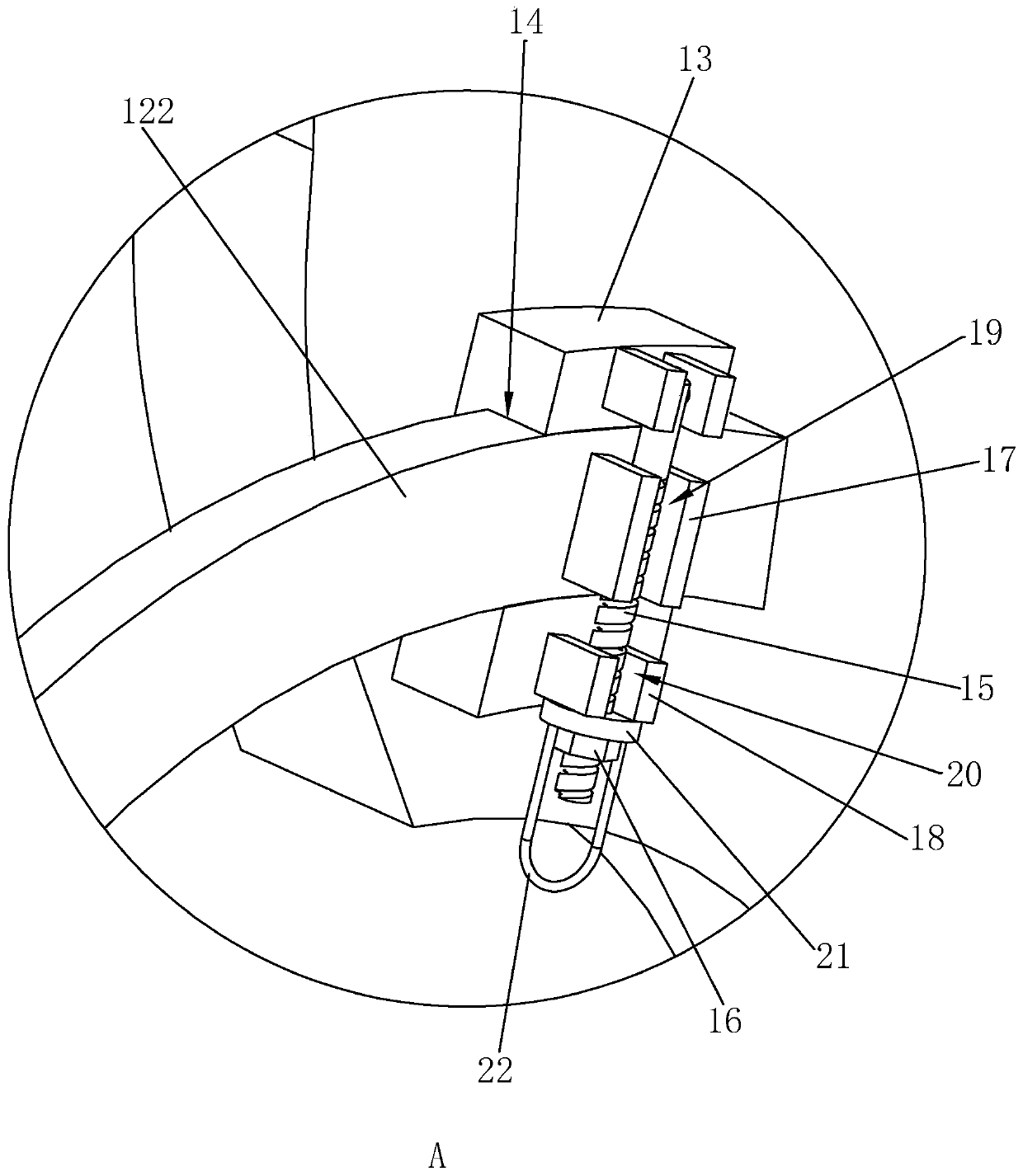

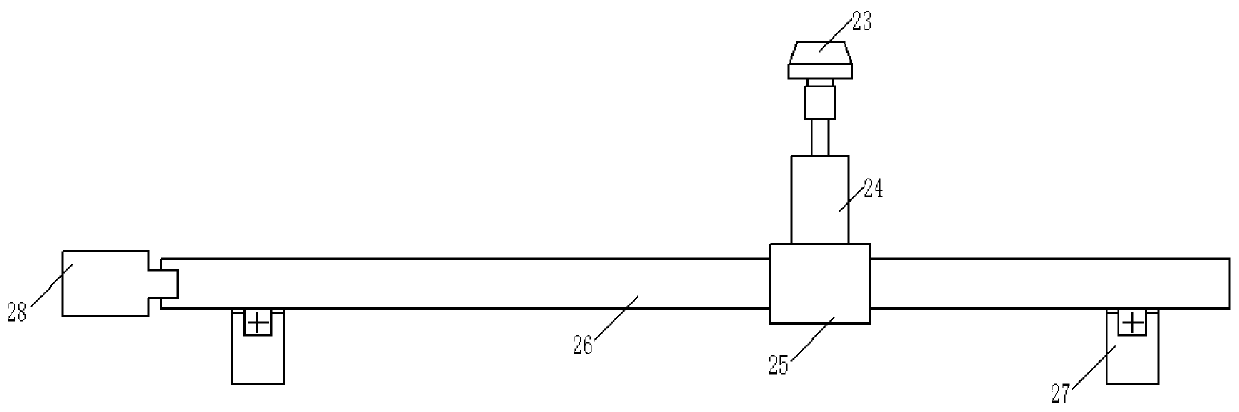

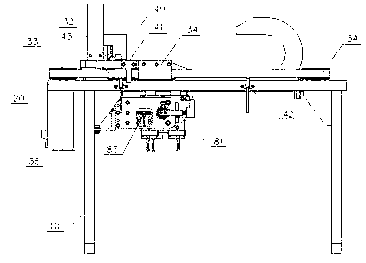

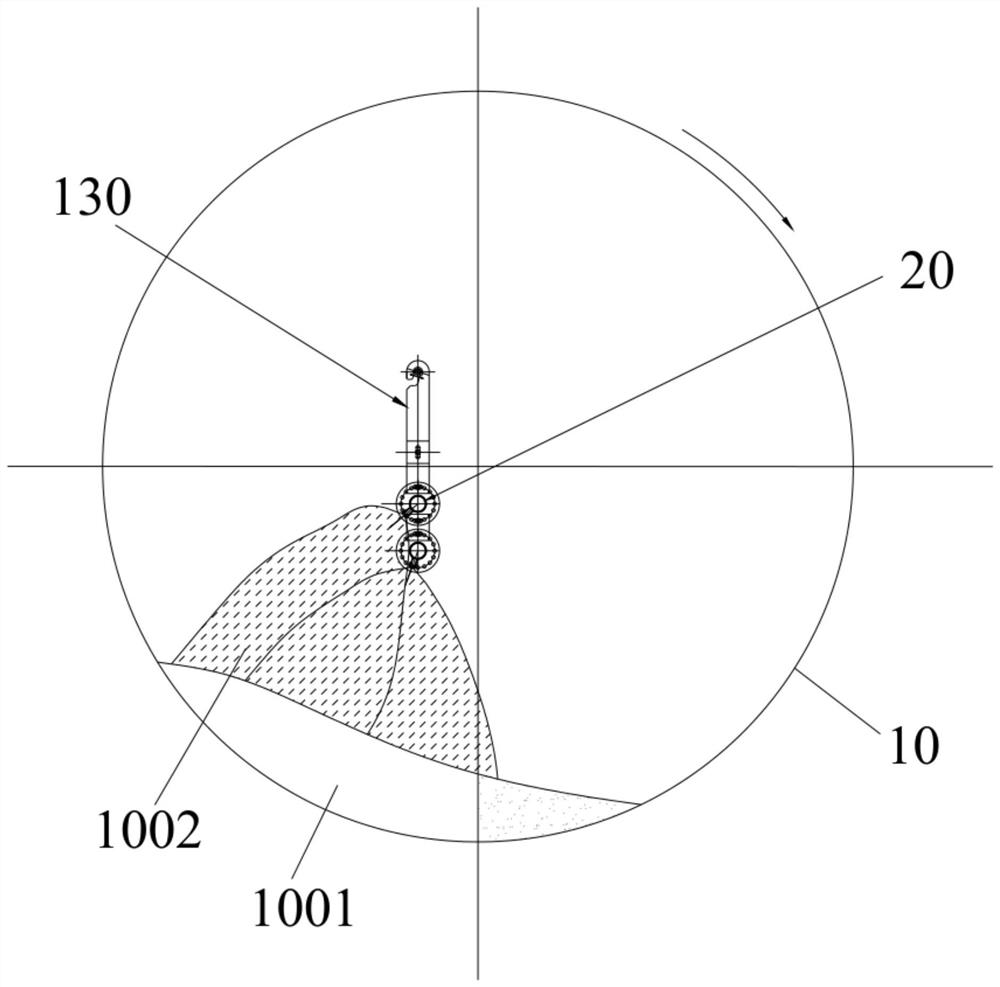

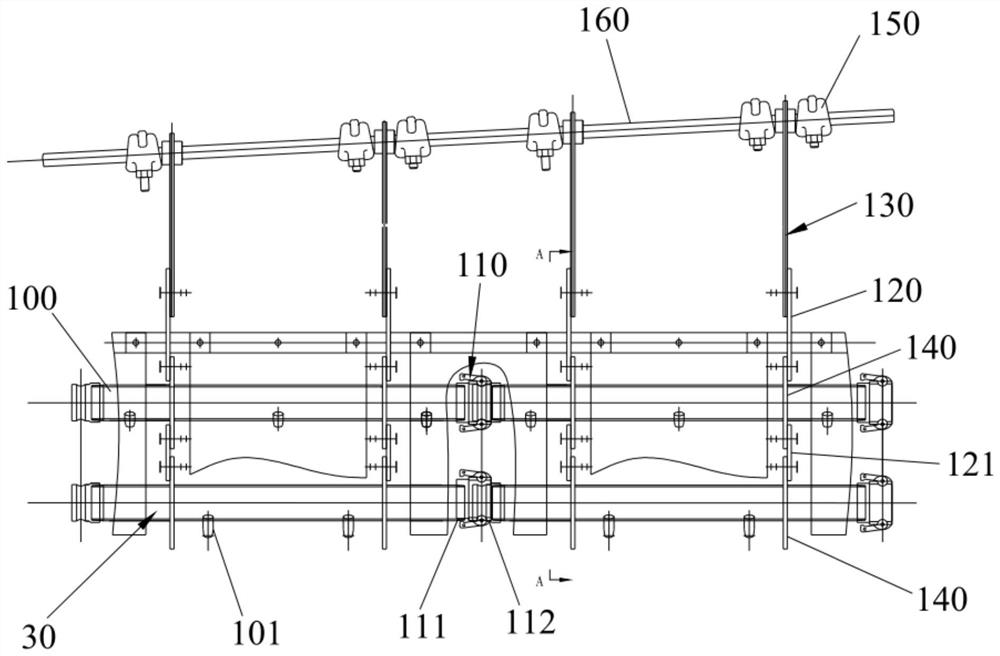

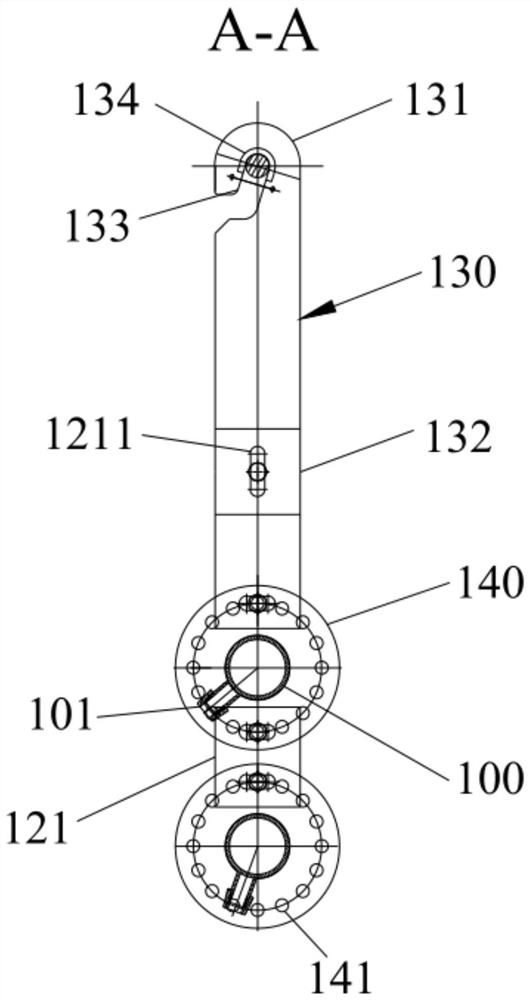

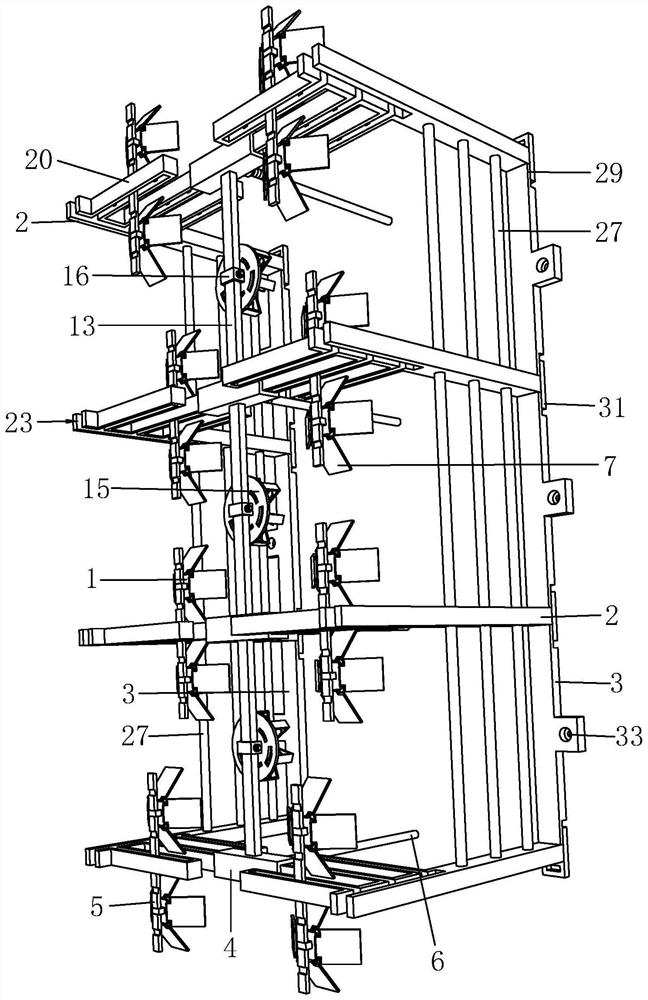

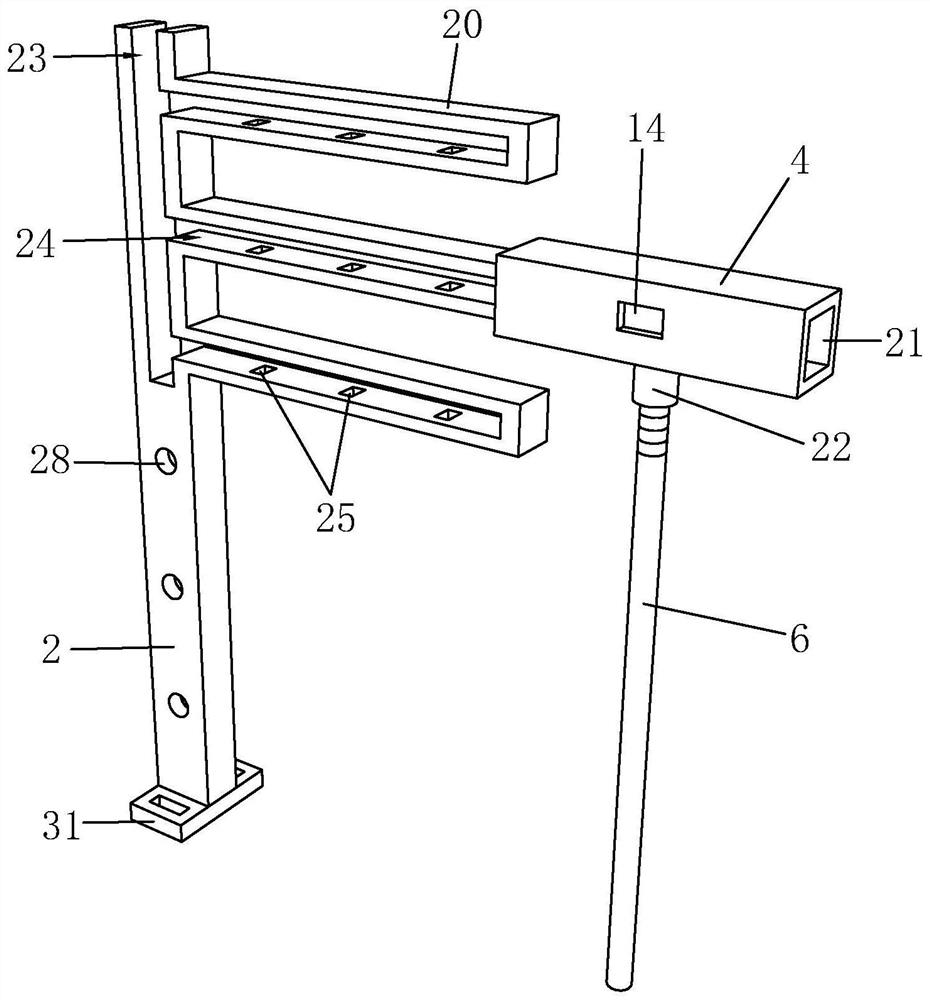

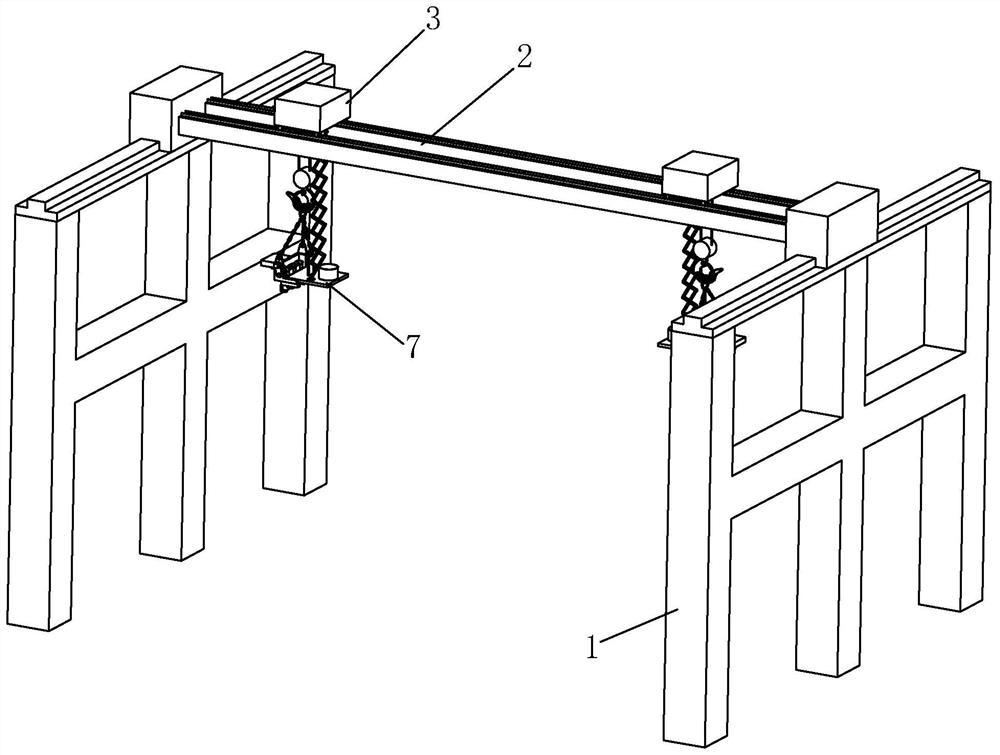

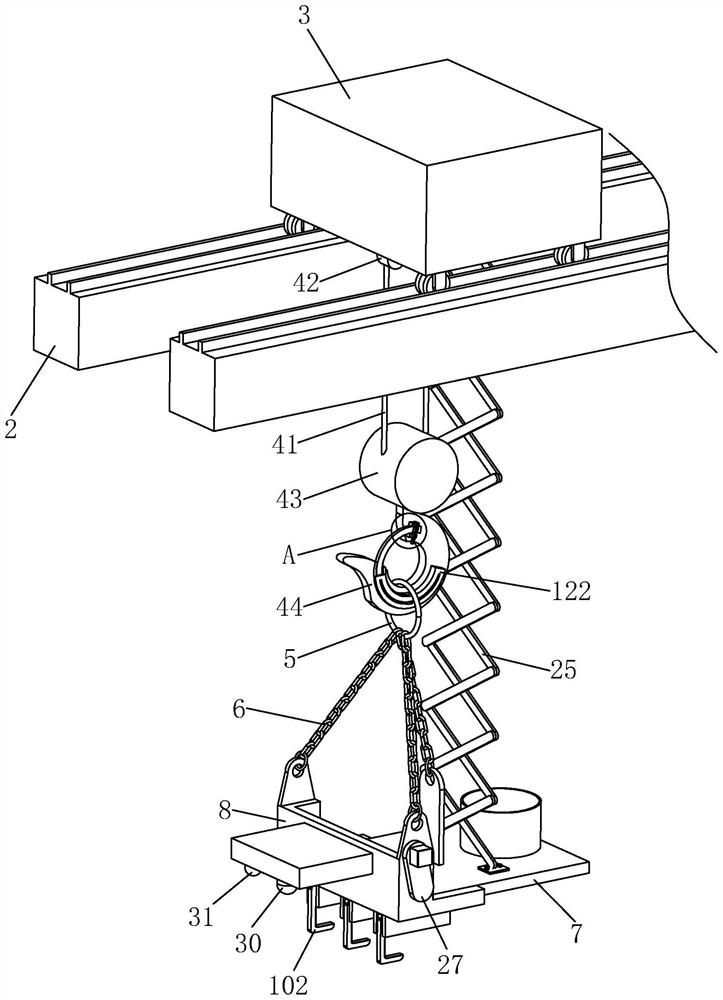

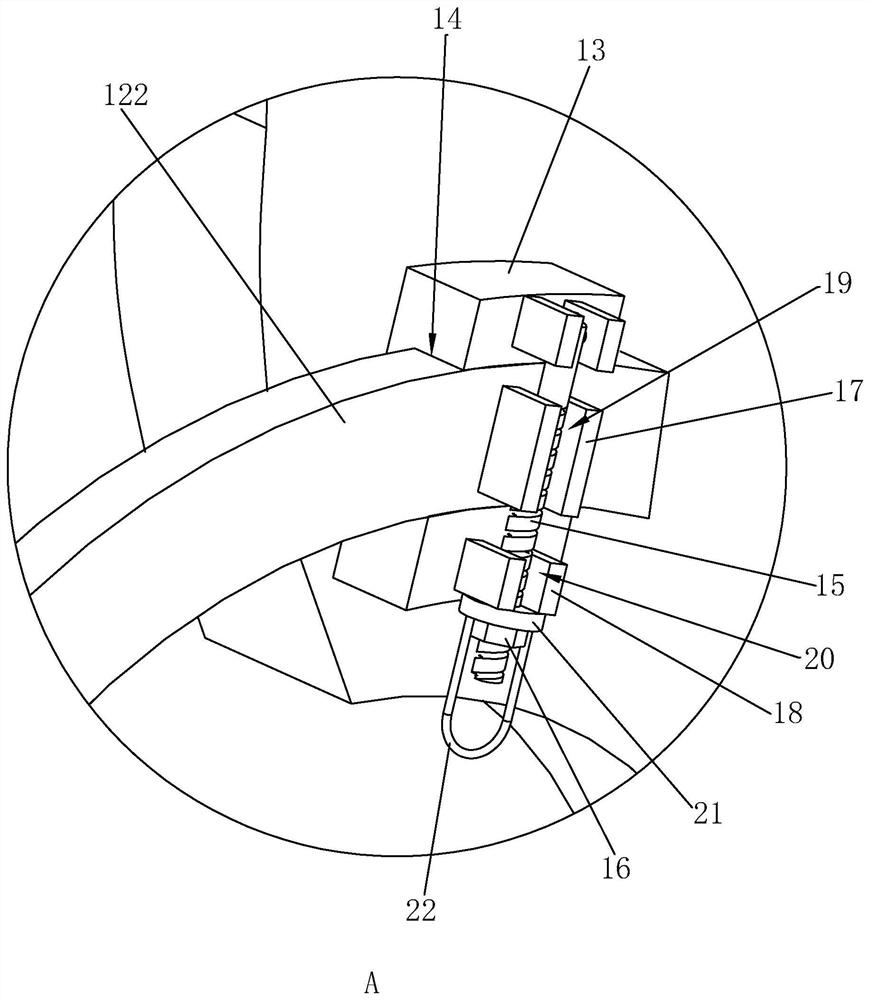

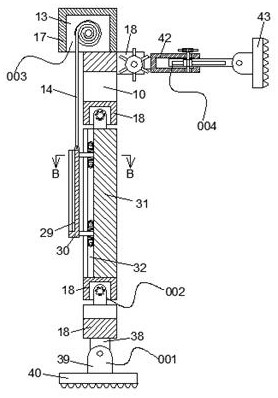

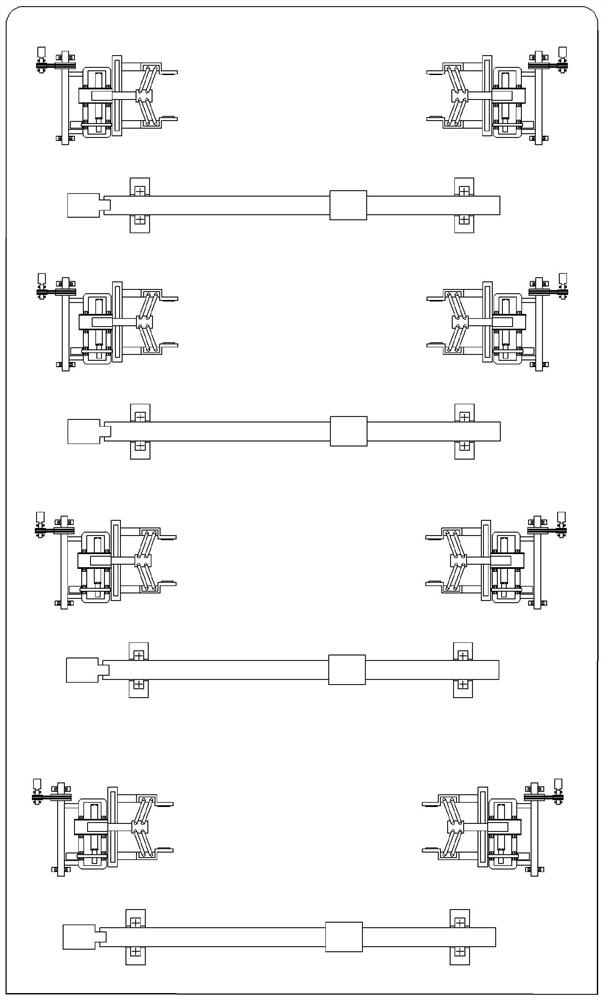

Lifting appliance of concrete pipe piles

ActiveCN110054091AHorizontal spacing changesChange horizontal positionTrolley cranesTrolleysOperation safetyAxial length

The invention relates to a lifting appliance, in particular to a lifting appliance of concrete pipe piles. According to the technical scheme, a support, a transverse supporting rail, two conveying vehicles and lifting mechanisms are involved, wherein the transverse supporting rail is arranged on the top of the support in a sliding mode in the horizontal direction, the two conveying vehicles are arranged on the transverse supporting rail in a sliding mode in the length direction of the transverse supporting rail correspondingly, and the lifting mechanisms are correspondingly connected to the bottoms of the conveying vehicles; the lifting mechanisms are connected with lifting appliance frame bodies through hanging rings and a chain in a matched mode, and a lifting hook units are installed onthe lifting appliance frame bodies; and the lifting hook units comprise mounting bases and main shafts, wherein the mounting bases are fixedly arranged on the lifting appliance frame bodies, the mainshafts are rotationally arranged on the mounting bases in a rotating and penetrating mode, lifting hooks are pivoted to the main shafts in the length directions of the main shafts, and the mounting bases are provided with driving mechanisms used for driving the lifting hooks to rotate up and down in the axial length directions of the main shafts so as to hook the pipe piles. The lifting appliancedoes not need people to run beside the pipe piles, and then the pipe piles are bundled and then hoisted, the operation is simple, the hoisting process is stable, the manpower resources are saved, andthe operation safety is improved as well at the same time.

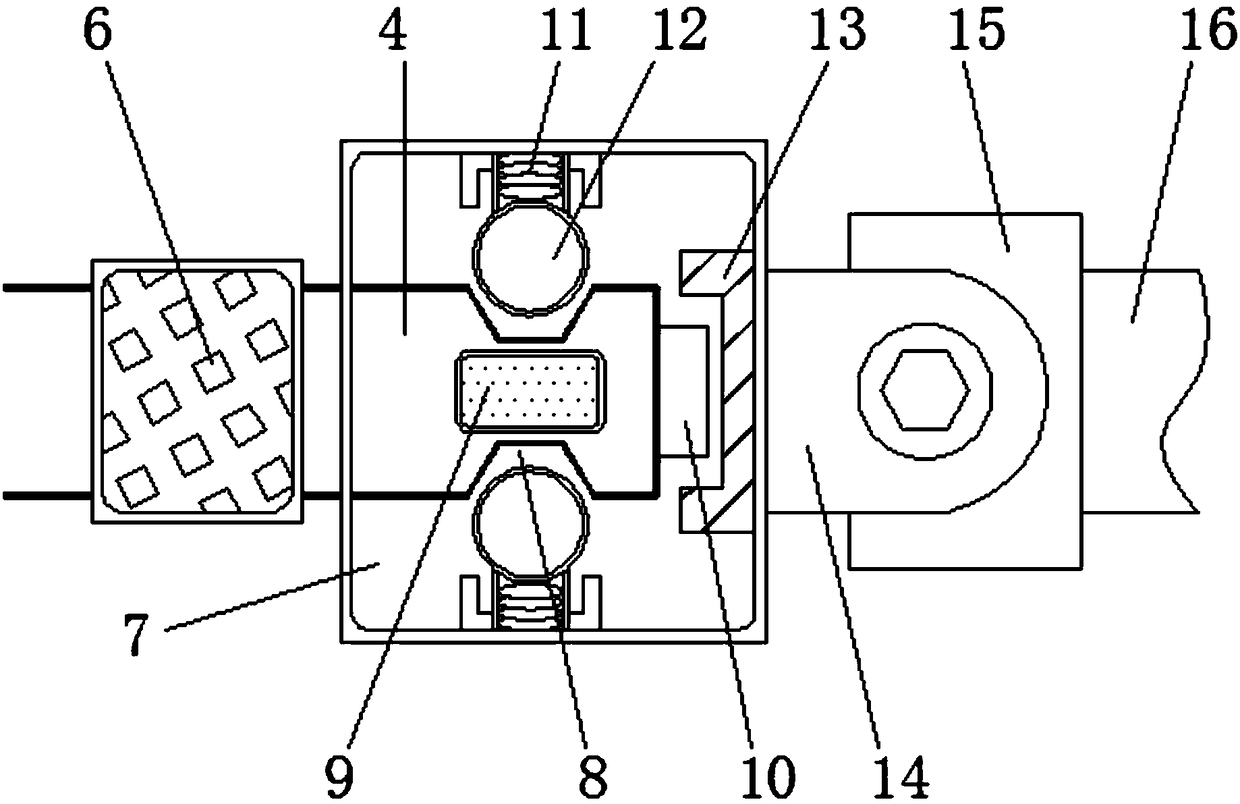

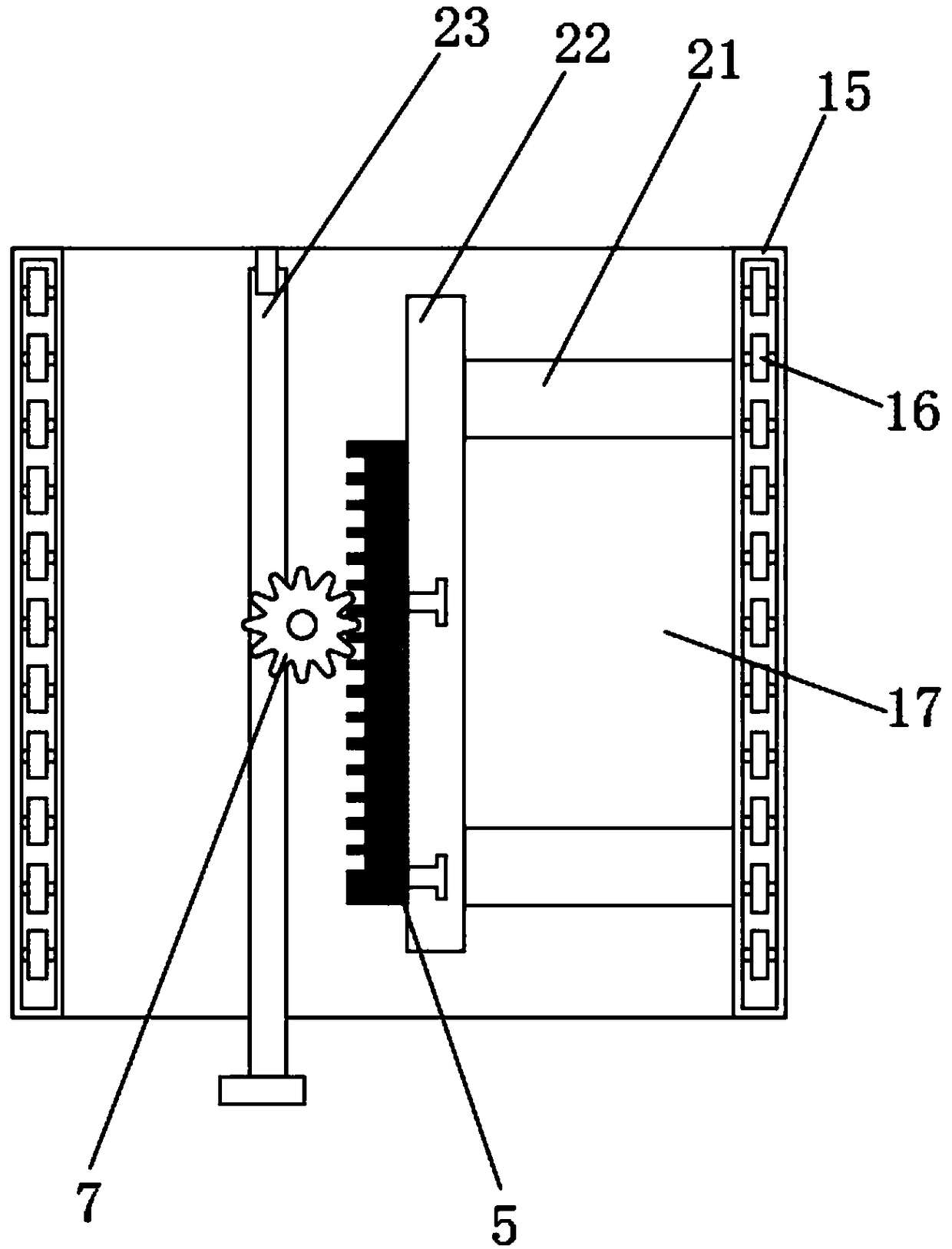

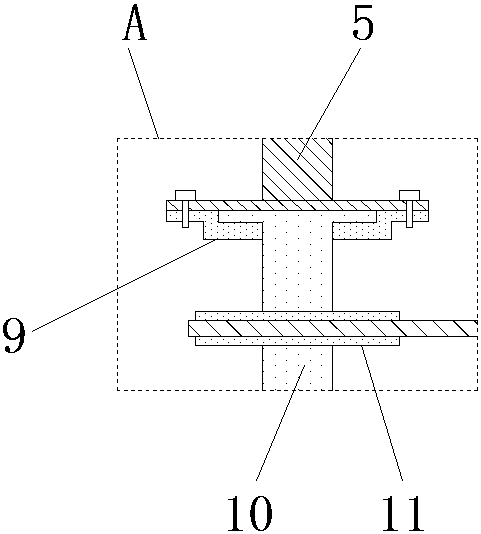

Adjustable unbalanced rectangular plane magnetron sputtering cathode

PendingCN113073301AChange horizontal positionReduced etch unevennessVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention discloses an adjustable unbalanced rectangular plane magnetron sputtering cathode. The adjustable unbalanced rectangular plane magnetron sputtering cathode comprises a frame body, wherein a telescopic device is fixedly installed at the bottom in the frame body, a power device is fixedly installed at the upper end of the telescopic device, a storage device is fixedly installed on each of the two sides of the power device, and telescopic rods are fixedly installed at the ends, away from the power device, of the storage devices; a T-shaped rod is fixedly installed at the end, away from each storage device, of each telescopic rod, a sliding groove is formed in the side wall of the frame body, and the T-shaped rods are located in the sliding groove and is in sliding connection with the side wall of the sliding groove. By arranging the power device and the storage device, the horizontal position of a target material can be changed at any time, the situation that the target material is etched unevenly is reduced, the utilization rate of the target material is improved, the waste of the target material is reduced, by arranging the telescopic device, the distance between the target material and an anode can be changed, the etching degree of the target material can be controlled, and great convenience is brought to daily use.

Owner:斡兹真空科技(嘉兴)有限公司

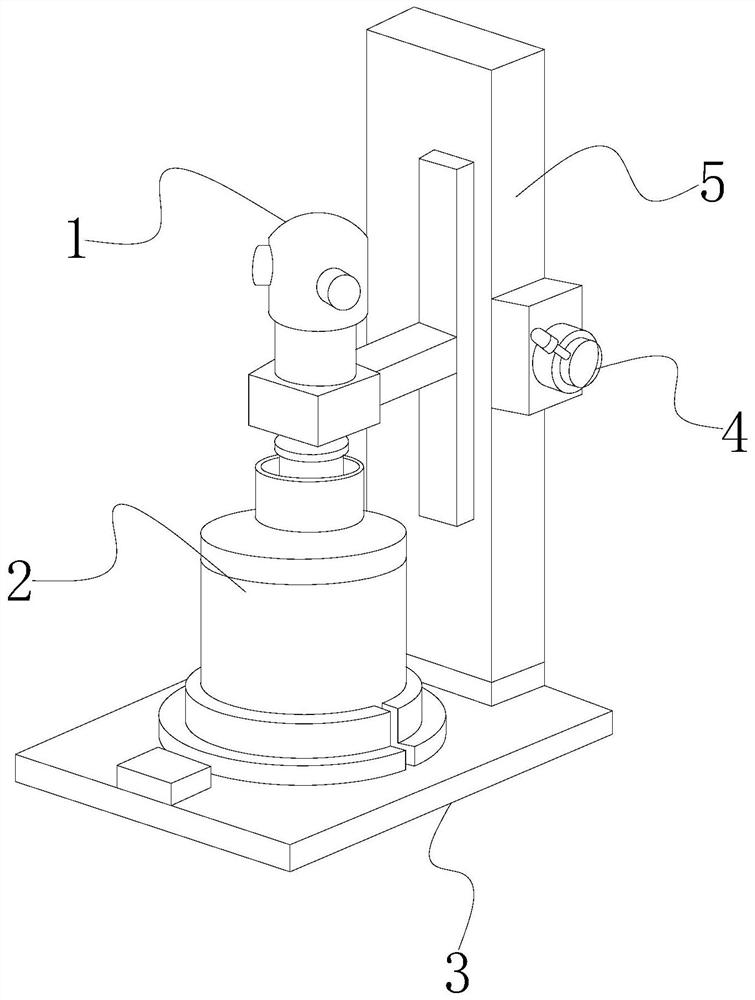

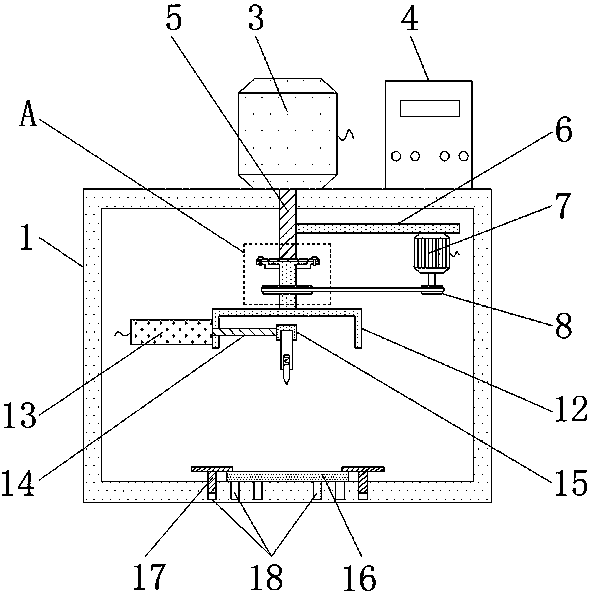

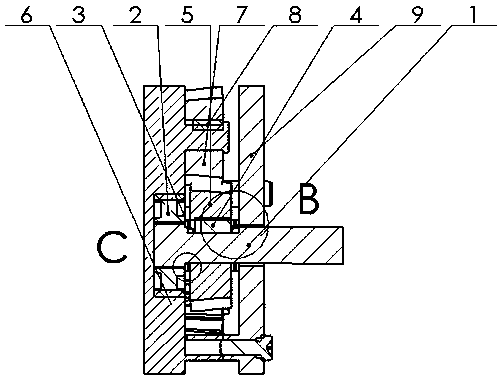

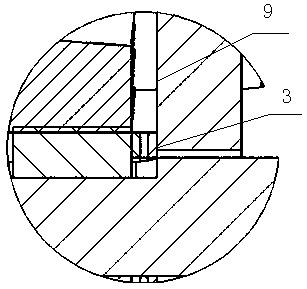

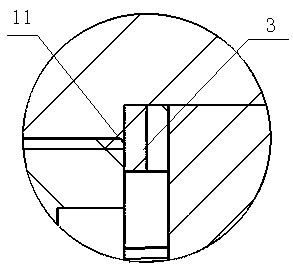

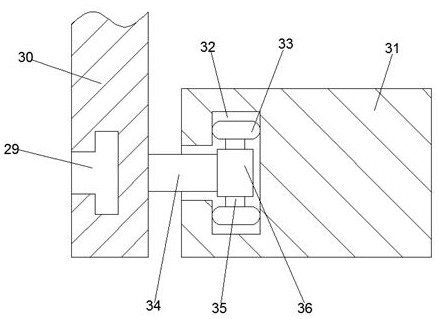

Intelligent positioning device for machining

ActiveCN111037323AIncrease costEasy to operateWork clamping meansPositioning apparatusElectric machineryThin walled

The invention provides an intelligent positioning device for machining. The intelligent positioning device comprises a positioning plate. A plurality of clamping mechanisms for clamping thin-walled parts at different positions are arranged on the upper surface of the positioning plate; the clamping mechanism comprises two clamping arms, the two clamping arms are connected with the plate body in asliding mode, the left ends of the two clamping arms are fixedly connected with a block body through a connecting rod, the block body is fixed to the telescopic end of a first telescopic piece, and the fixed end of the first telescopic piece penetrates through the plate body and is fixedly connected with the plate body; a first rotating shaft is fixed to the side face of the plate body and connected with the output shaft of a first motor through a rotating mechanism, the first rotating shaft is connected with a shell used for supporting the rotating mechanism through a bearing, and the left end and the right end of the shell are each fixedly provided with a lug plate connected with a pitch angle adjusting mechanism. A plurality of supporting mechanisms are also arranged on the upper surface of the positioning plate. According to the intelligent positioning device for machining, the intelligent positioning device is suitable for machining and positioning of thin-walled curved-surface parts and can clamp the parts and support the parts through the supporting mechanisms.

Owner:XINXIANG UNIV

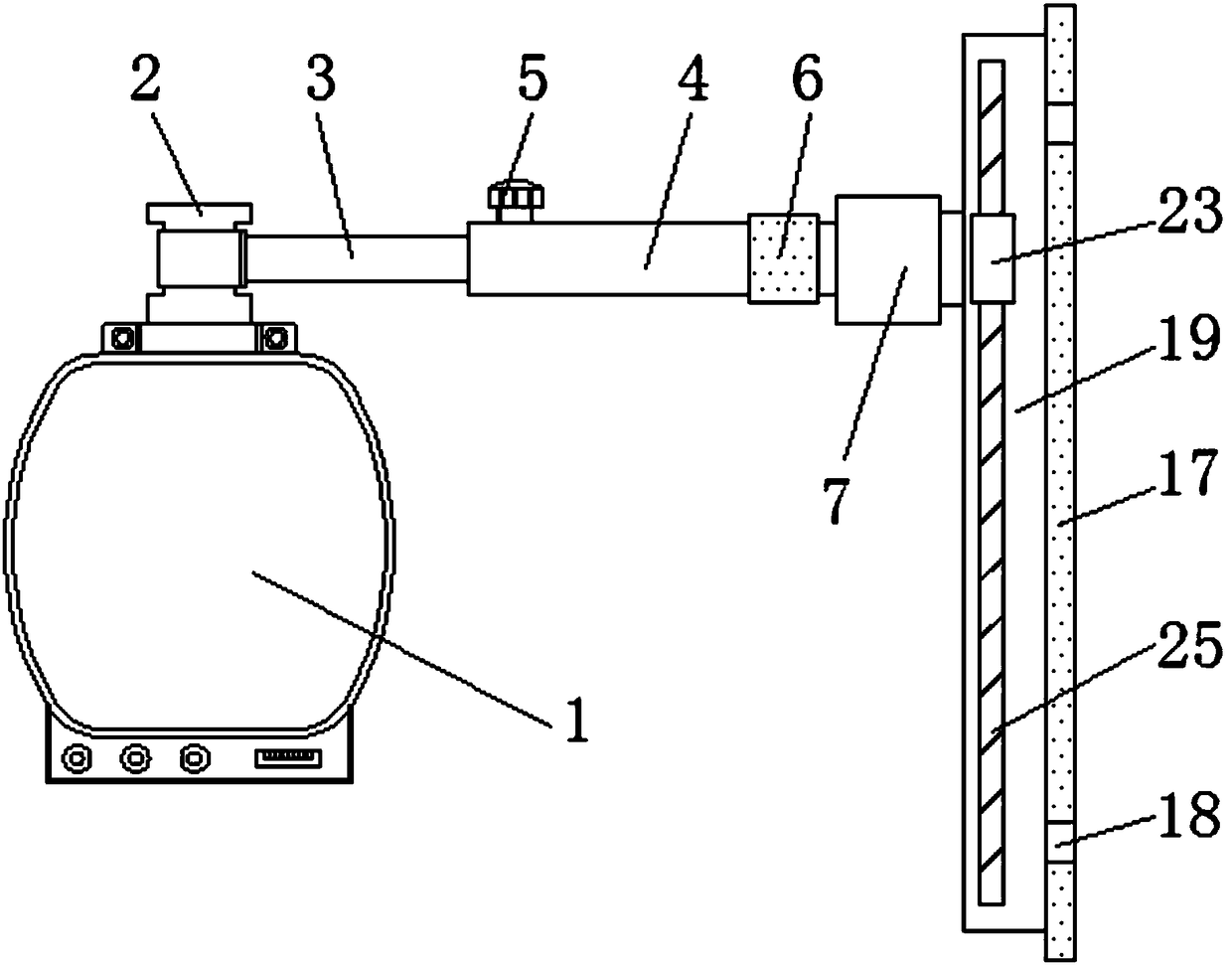

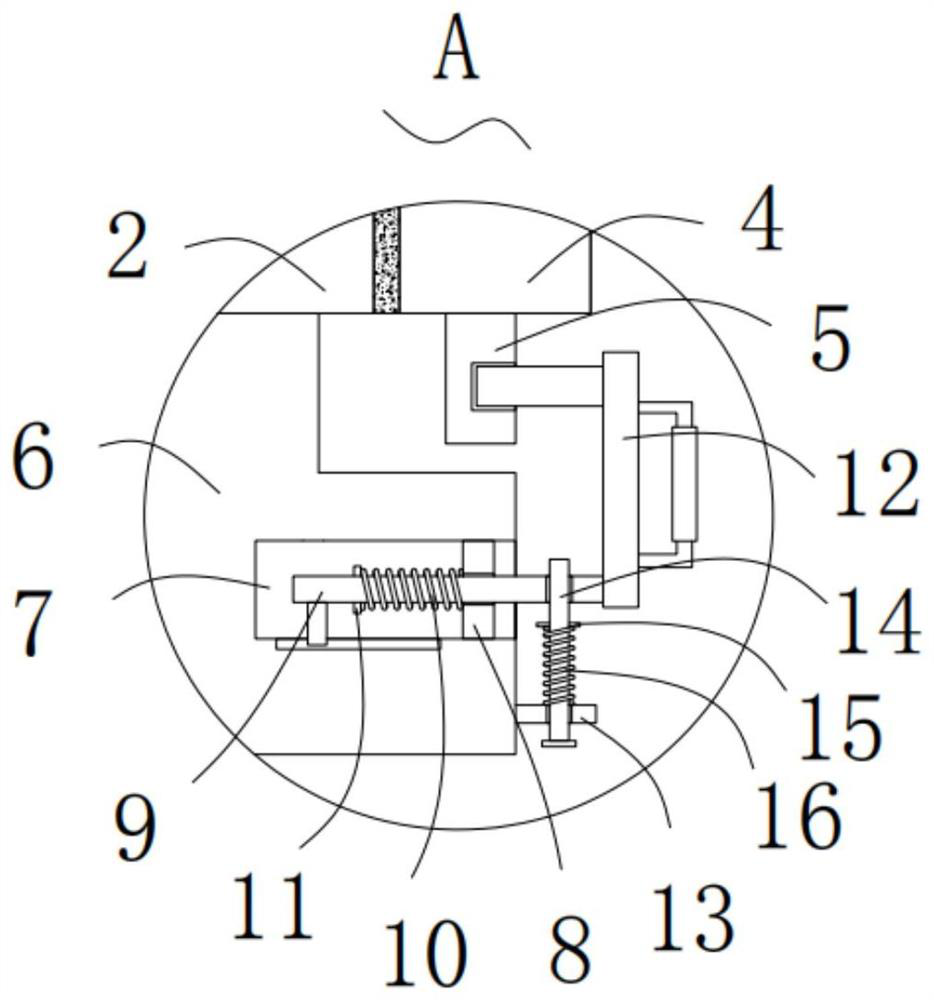

Wall-mounted table lamp

InactiveCN108332112AChange horizontal positionImprove stabilityLighting support devicesFixed installationWall mountComputer engineering

The invention provides a wall-mounted table lamp. The wall-mounted table lamp mainly comprises a lamp body, a storage sleeve, a mounting bottom plate and a second reset spring. A joint is arranged above the lamp body, and the joint penetrates through the surface of the left end of a load-bearing rod. The load-bearing rod is arranged on the left side of the storage sleeve, and an adjustment bolt isarranged on the upper portion of the storage sleeve. Bolt holes and a storage box are arranged on the surface of the mounting bottom plate, and the bolt holes are formed in the two sides of the storage box. First clamping blocks are arranged on the two sides of the inner wall of the storage box. Balance plates are connected between the two sides of the second reset spring. A pressing block penetrates through sliding grooves, and the sliding grooves are located on the both sides of the storage box. According to the wall-mounted table lamp, the length between the load-bearing rod and the storage sleeve can be changed to adjust the horizontal position of the suspension of the lamp body, the first clamping block and a second clamping block are separated when two extrusion blocks are pinched,then upper and lower sliding can be carried out, so that the height of the protective plate is changed.

Owner:广州元坤新材料有限公司

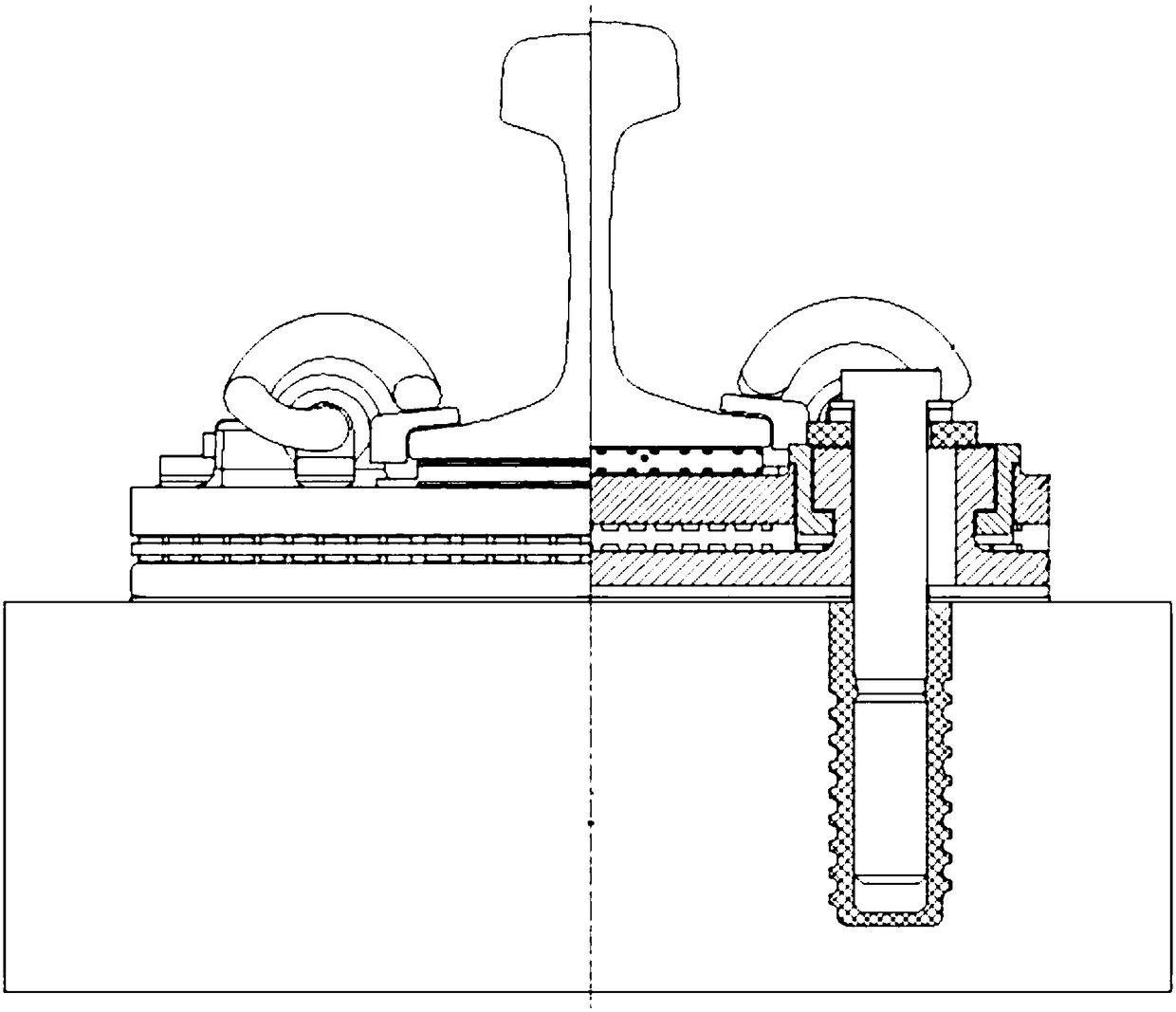

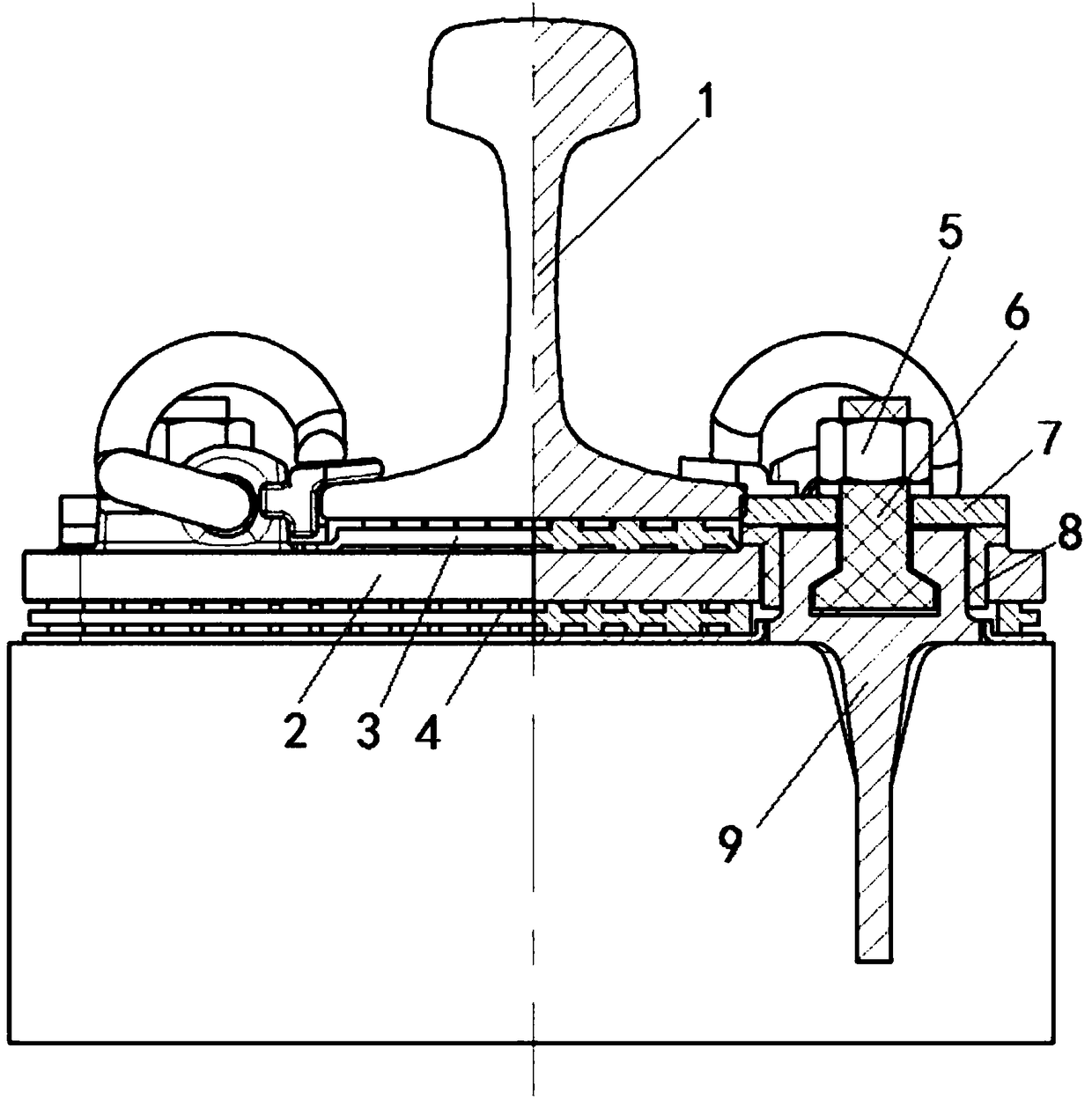

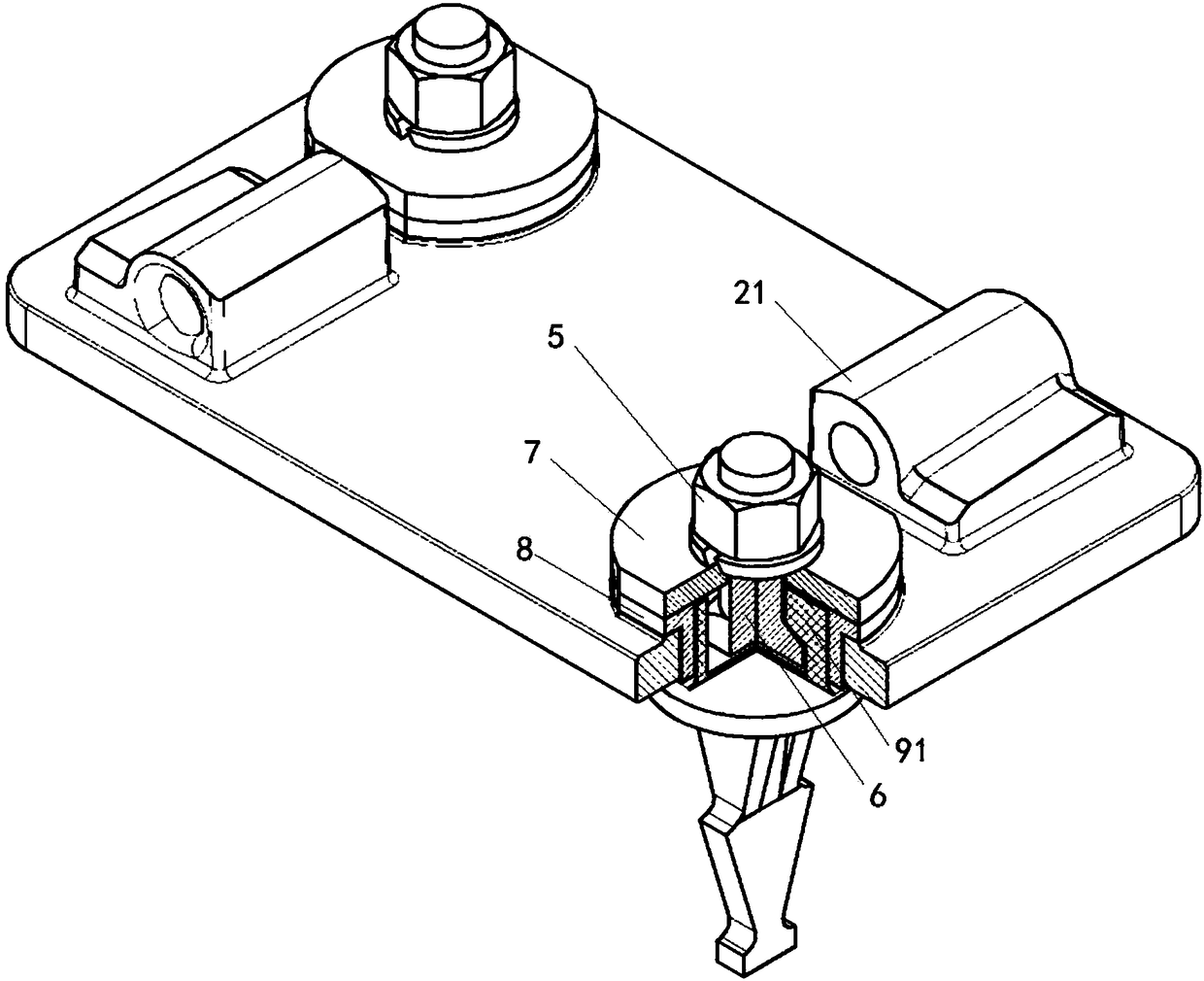

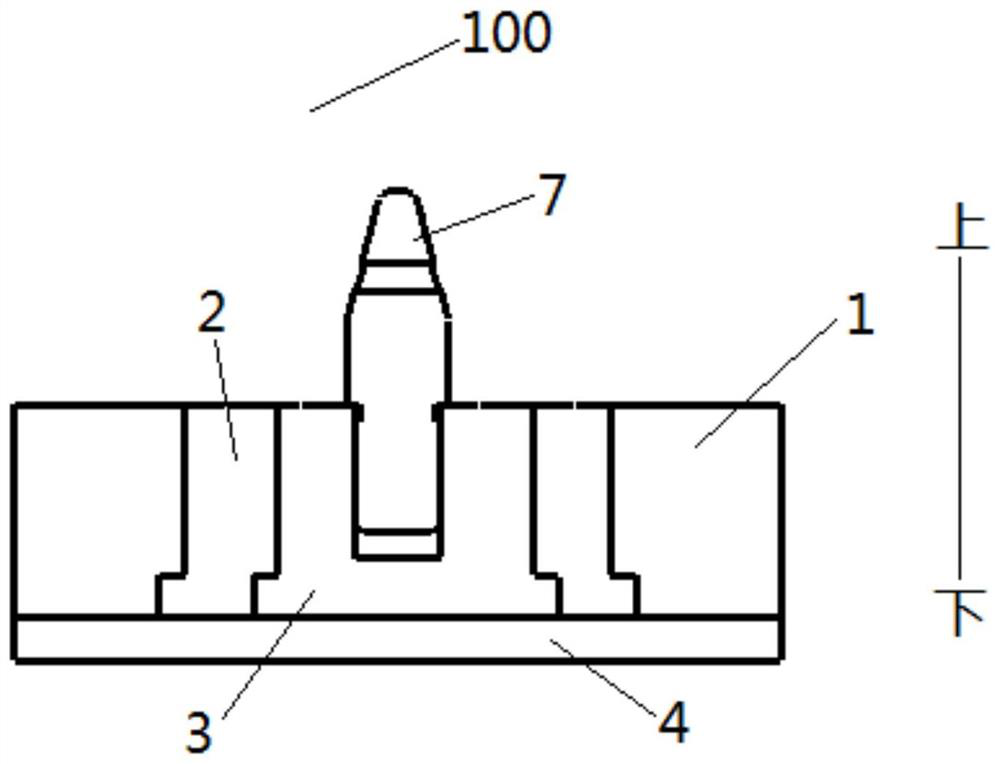

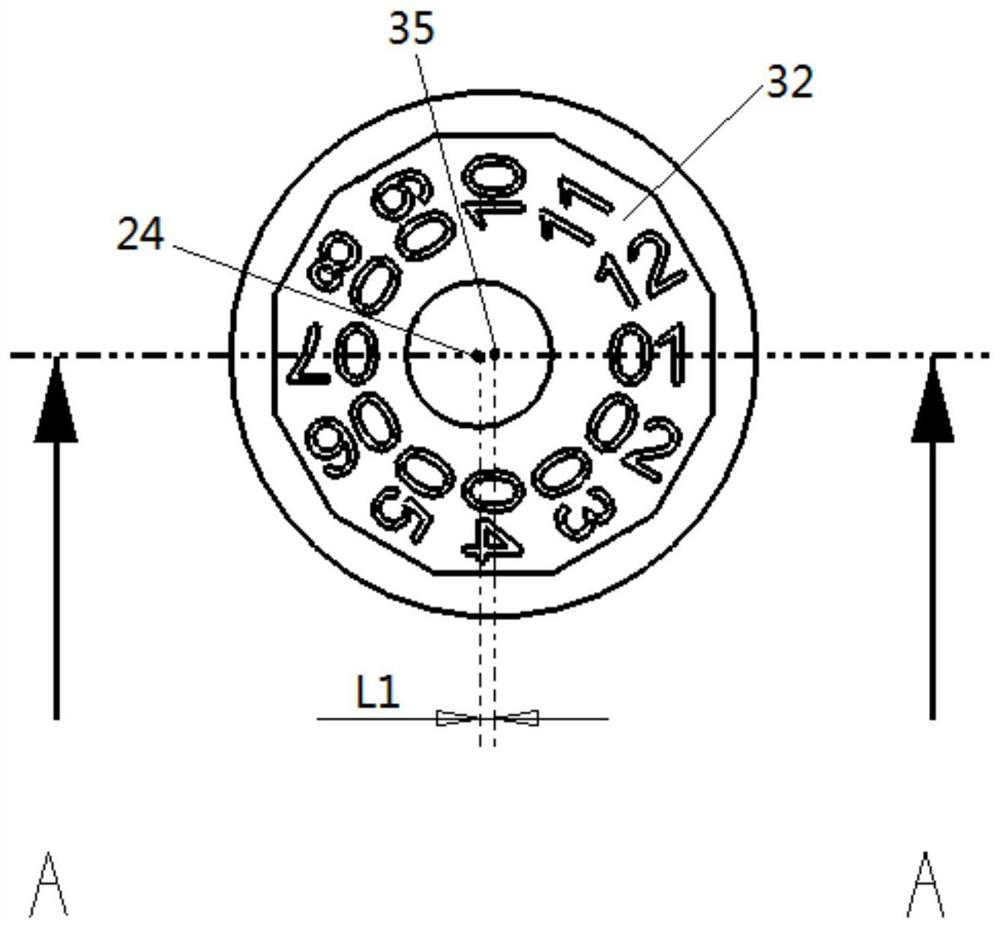

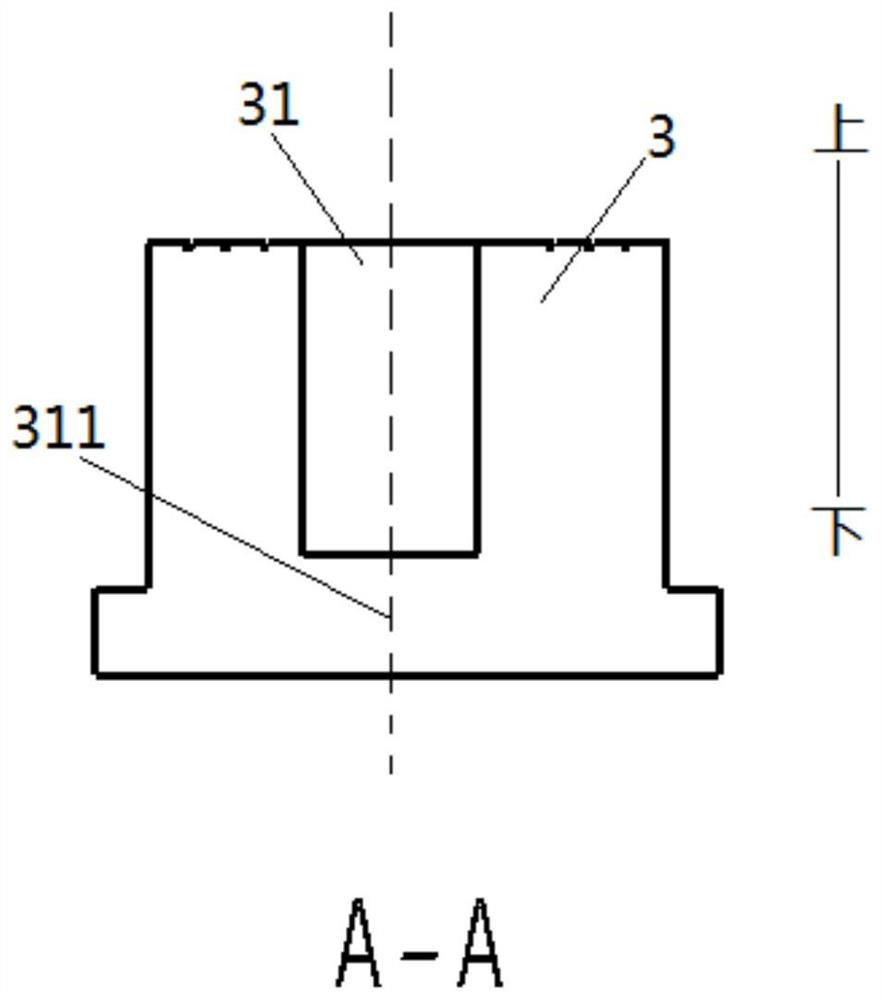

Vibration-reduction fastener system

PendingCN108265571AReduce weightLower installation heightRail fastenersEngineeringUltimate tensile strength

The invention discloses a vibration-reduction fastener system which comprises position-fixing bases, a rail-bearing plate and locking structures, wherein the lower parts of the position-fixing bases are column bodies used for being embedded in a rail foundation; the upper parts of the position-fixing bases are bosses used for being connected to the rail-bearing plate; the rail-bearing plate is provided with elastic bar bases and first through holes through which the bosses penetrate; and the locking structures are used for realizing the locking connection between the rail-bearing plate and theposition-fixing bases. The vibration-reduction fastener system is applicable to the field of rail transit. The vibration-reduction fastener system is capable of effectively overcoming the defects inthe prior art, effectively reducing the cost of the fastener system, effectively improving the overall strength and the service life of a fastener and effectively reducing the installation height of arail, thereby effectively avoiding the increase in tunnel construction cost due to high installation height and effectively improving the transverse stability of the rail at the same time.

Owner:洛阳科博思新材料科技有限公司

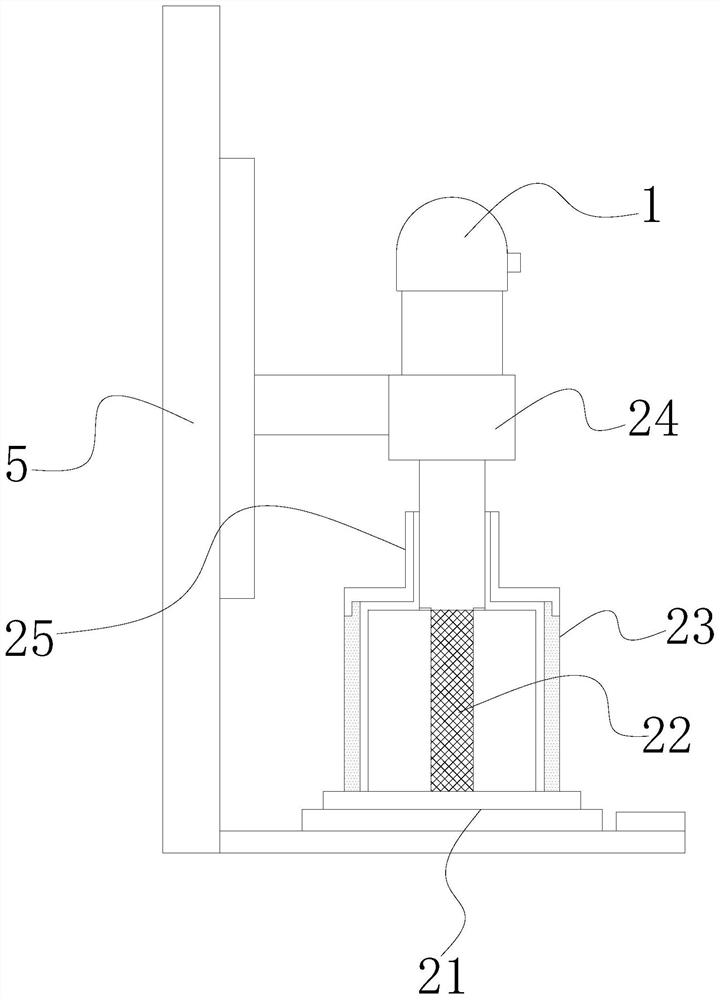

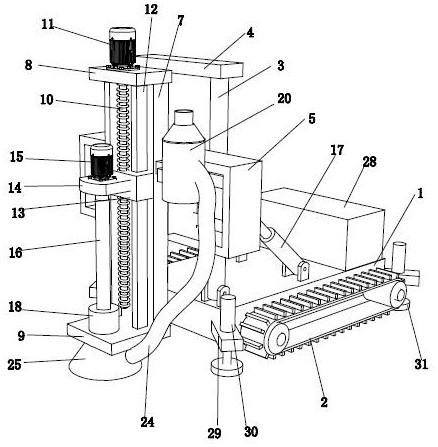

Stirrer for plant cell culture device

InactiveCN112266872ARelieve pressureAvoid breakingBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyElectric machinery

The invention discloses a stirrer for a plant cell culture device. The stirrer structurally comprises a motor, a stirring mechanism, a fixation plate, a controller and a lifting plate, wherein the stirring mechanism is provided with a fixation groove, a stirring device, a placing tank, a fixer and a blocking cover. Liquid generates inward force under the action of rotating force, and the effect ofreducing the rotating force is achieved; the law that liquid rotates along the inner wall is destroyed through staggering of circulating grooves, so that the liquid circulates back and forth, the pressure of rotation on the liquid is reduced, and cells in the liquid are prevented from being broken; the liquid moves upwards along drainage grooves in the inner sides of sliding plates under the action of rotating force, and therefore the horizontal position of the liquid is changed; and according to mechanical principles, liquid is expanding outwards, and moves upwards along inclined sealing grooves under the rotating force to compress sealing grooves, so that stress blocks are stressed, liquid on the inner sides of rubber plates fluctuates, the fluctuation applies upward pressure under therotating force, then the liquid is driven to be stirred upwards, and the mixing degree of the liquid is improved.

Owner:徐智勇

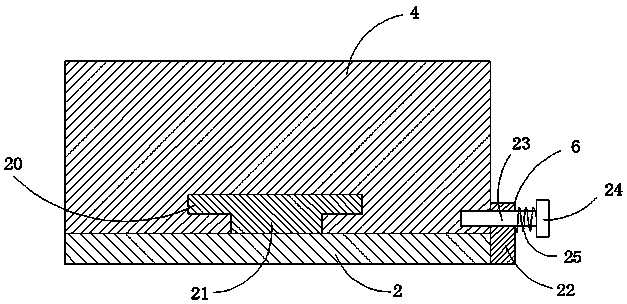

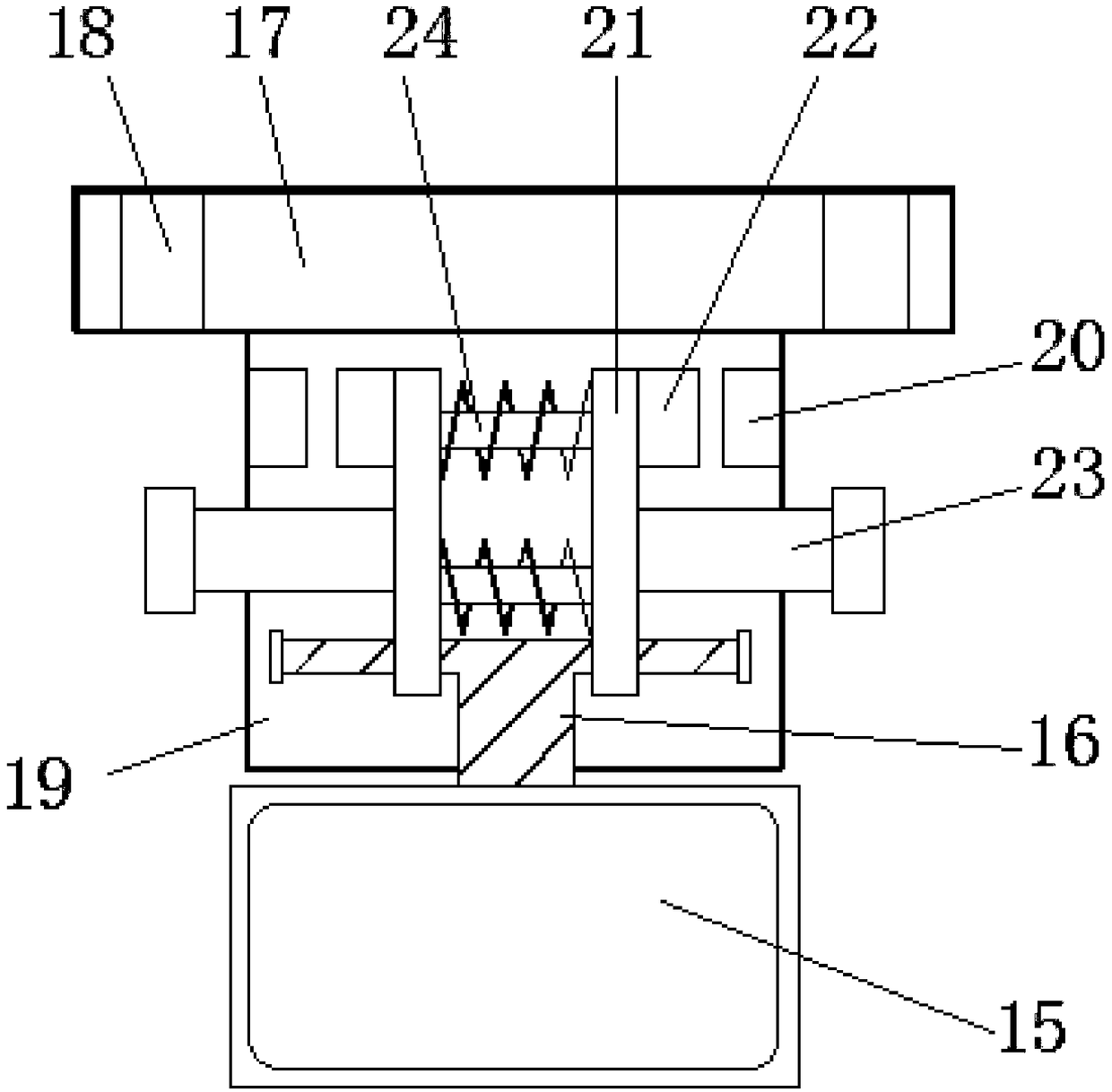

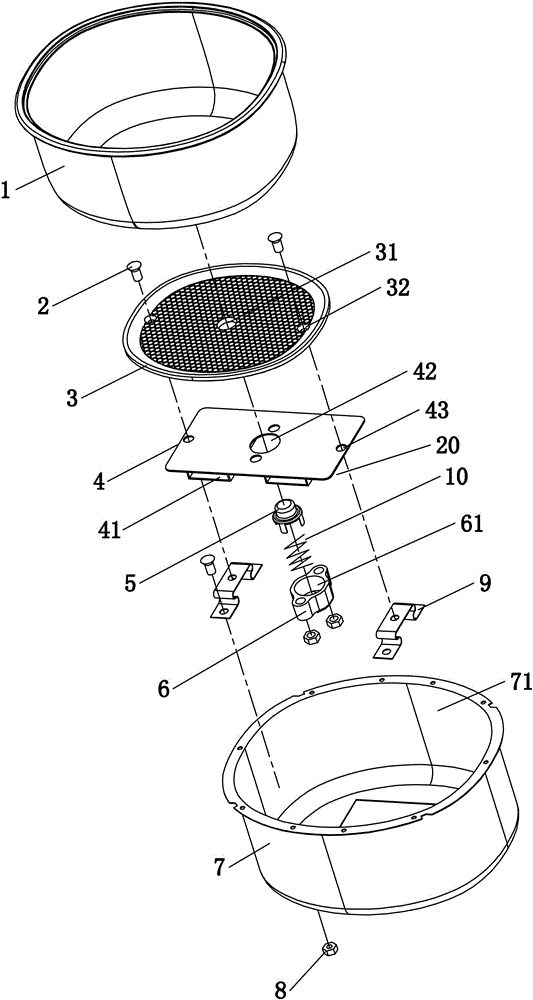

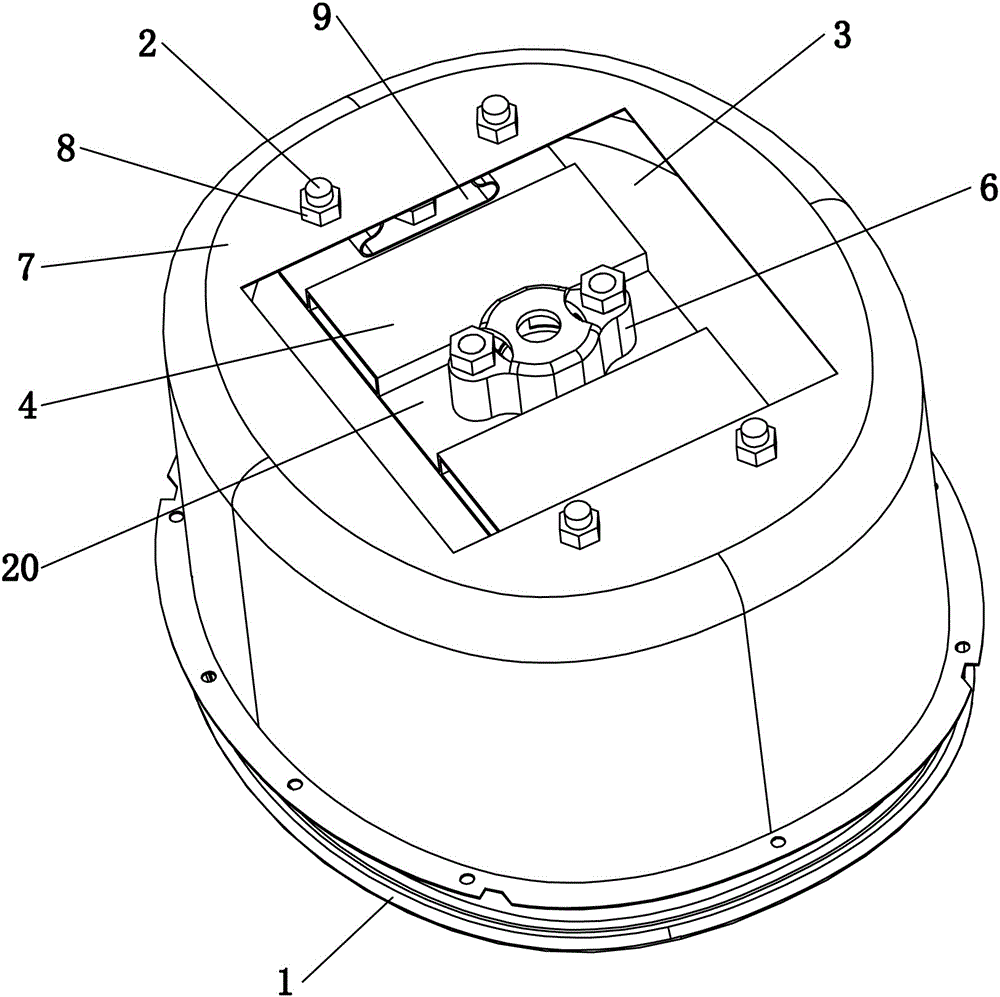

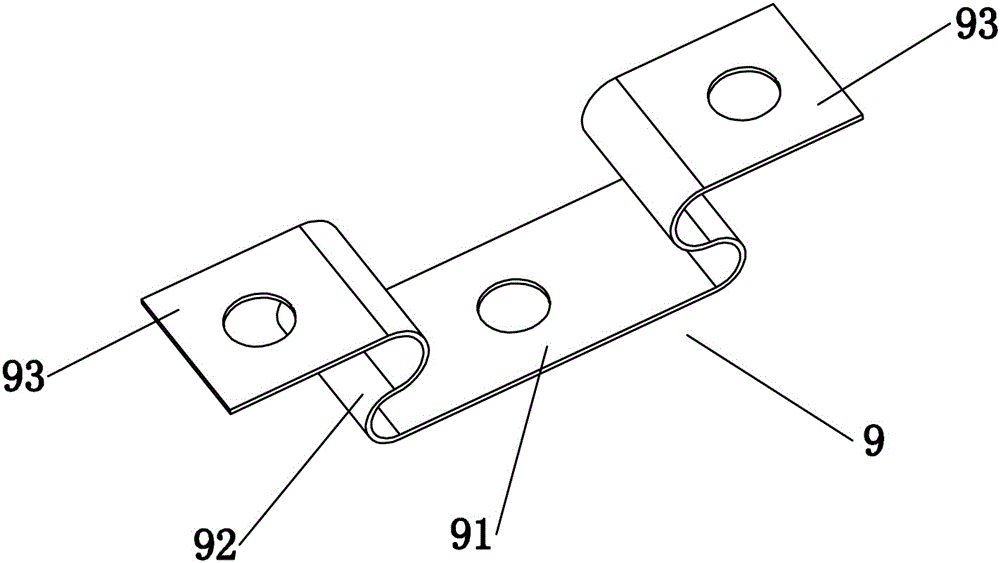

Heating body elastic supporting structure of mini electric cooker

InactiveCN105105619AChange horizontal positionPrevent easy lossWarming devicesElastomerHeat conducting

The invention relates to a heating body elastic supporting structure of a mini electric cooker. The heating body elastic supporting structure comprises an outer pot, an inner pot and an electric heating device. A middle layer is arranged in the outer pot and provided with an inner cavity. The electric heating device comprises a heat conducting tray and an electric heating body. The electric heating body is connected to the bottom of the heat conducting tray. The heating body elastic supporting structure is characterized in that the electric heating device is arranged at the lower portion of the inner cavity of the middle layer through a sheet elastic body, gaps are reserved between the electric heating device and the bottom wall of the inner cavity of the middle layer and between the electric heating device and the side wall of the inner cavity of the middle layer, the sheet elastic body is integrally formed by a bearing face, a supporting face and an elastic face, the bearing face and the supporting face are vertically staggered, the bearing face is connected with the electric heating body, the supporting face is connected with the middle layer, the elastic face is connected between the bearing face and the supporting face, and an inner container is arranged in the inner cavity of the middle layer and makes elastic contact with the heat conducting tray. The electric heating device of the mini electric cooker of the structure is supported by the sheet elastic body stably and reliably, so that it is guaranteed that the electric heating body makes contact with the inner container well, and the heat transfer effect is good.

Owner:何志雄

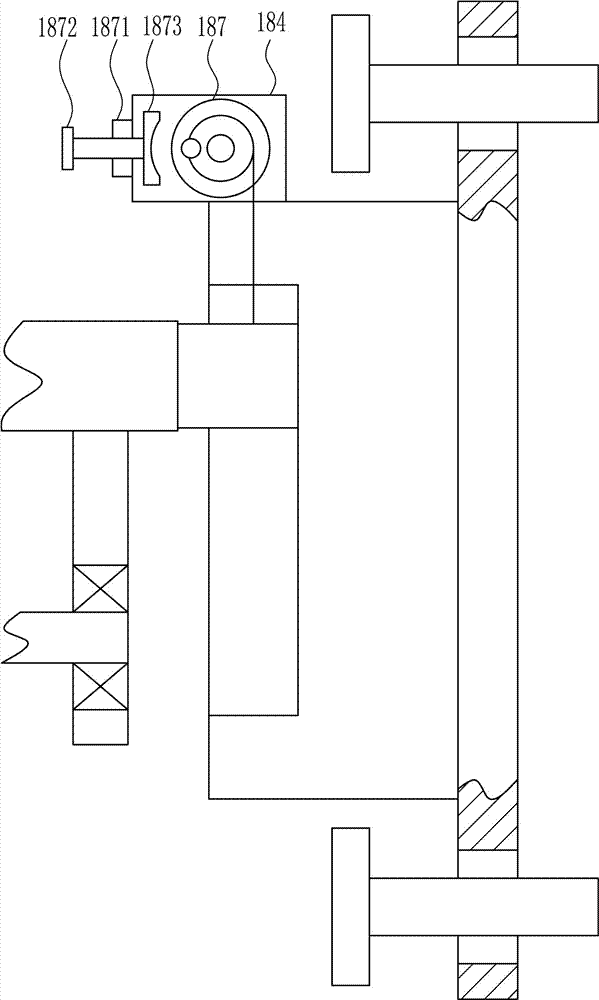

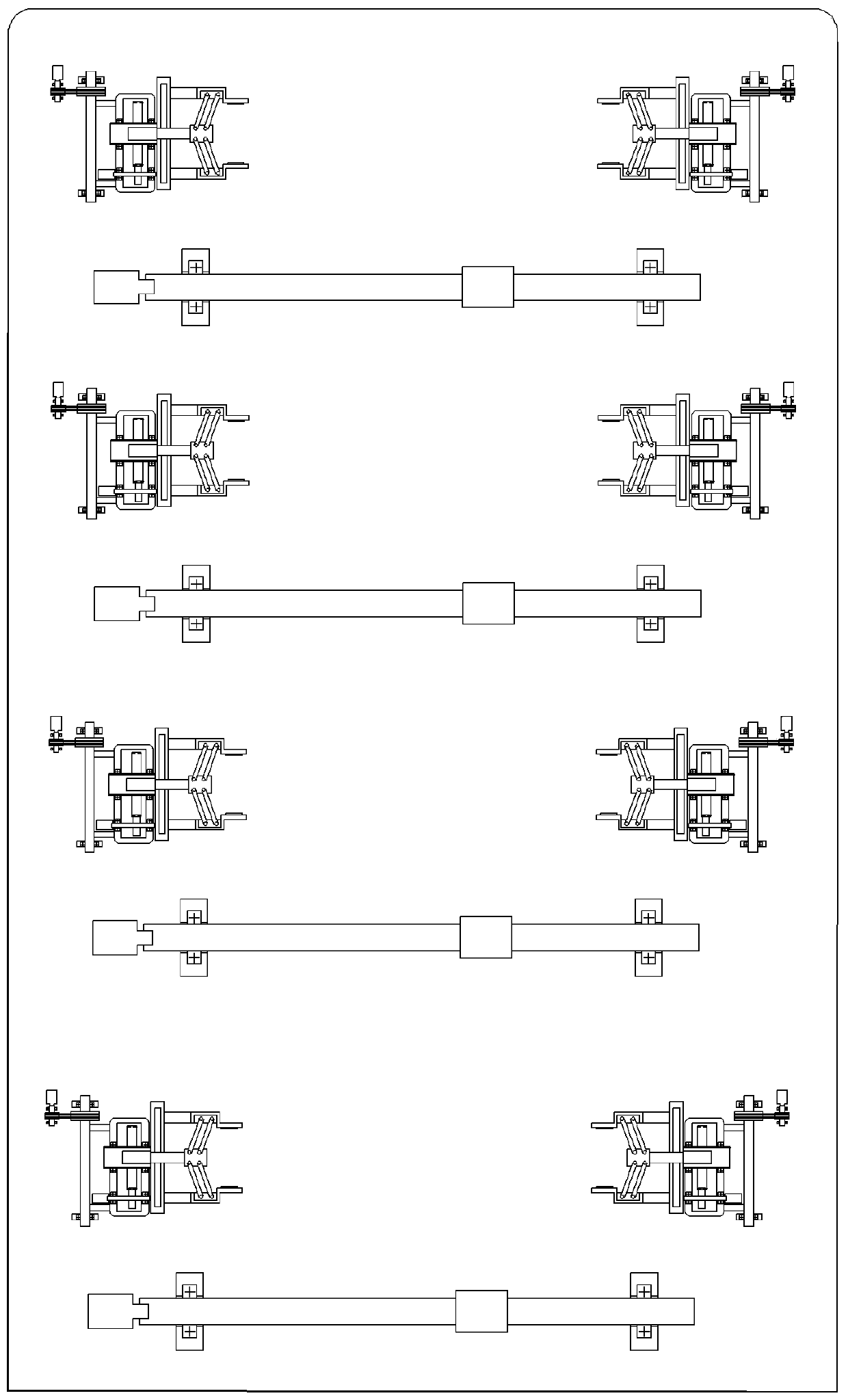

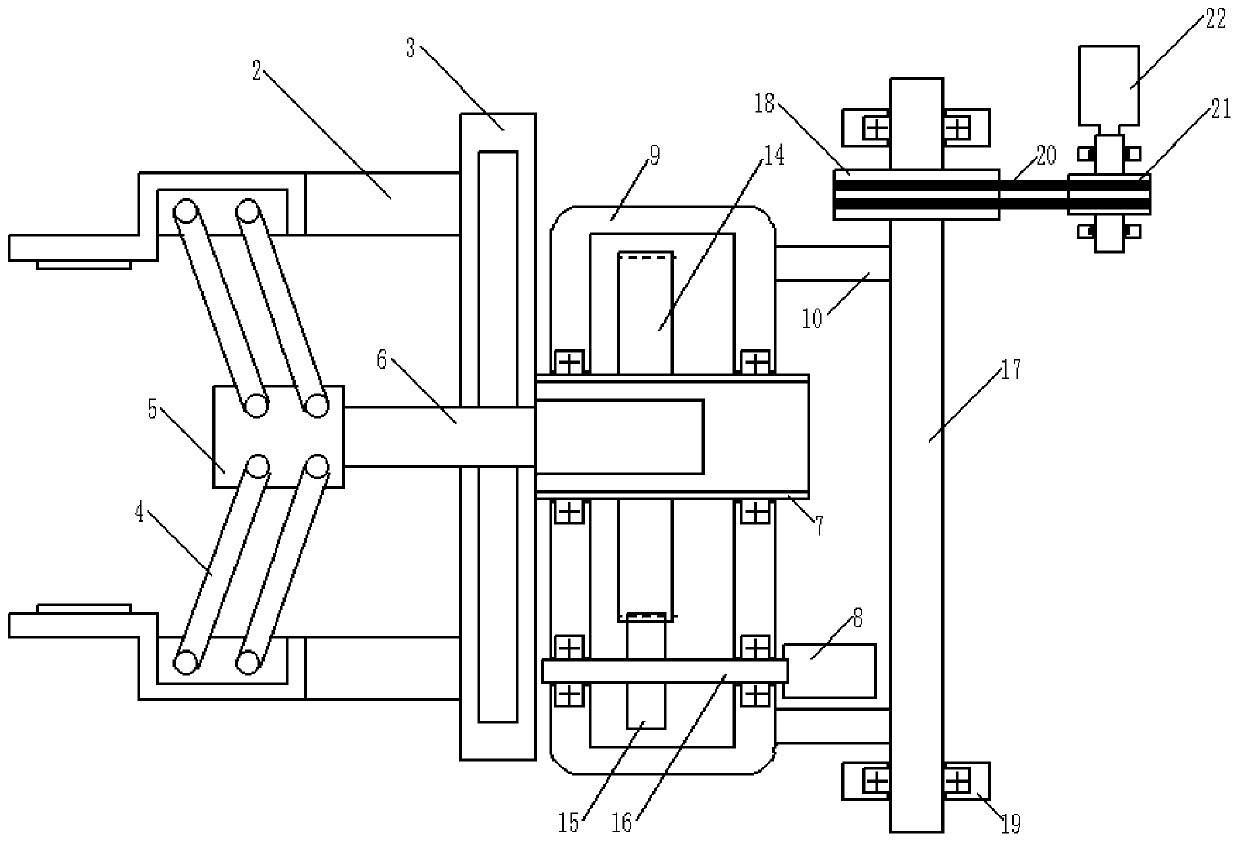

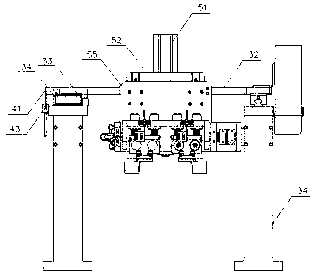

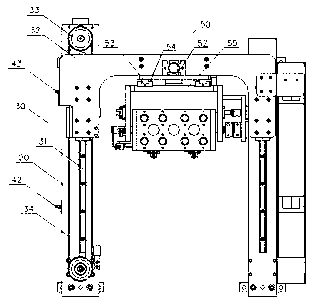

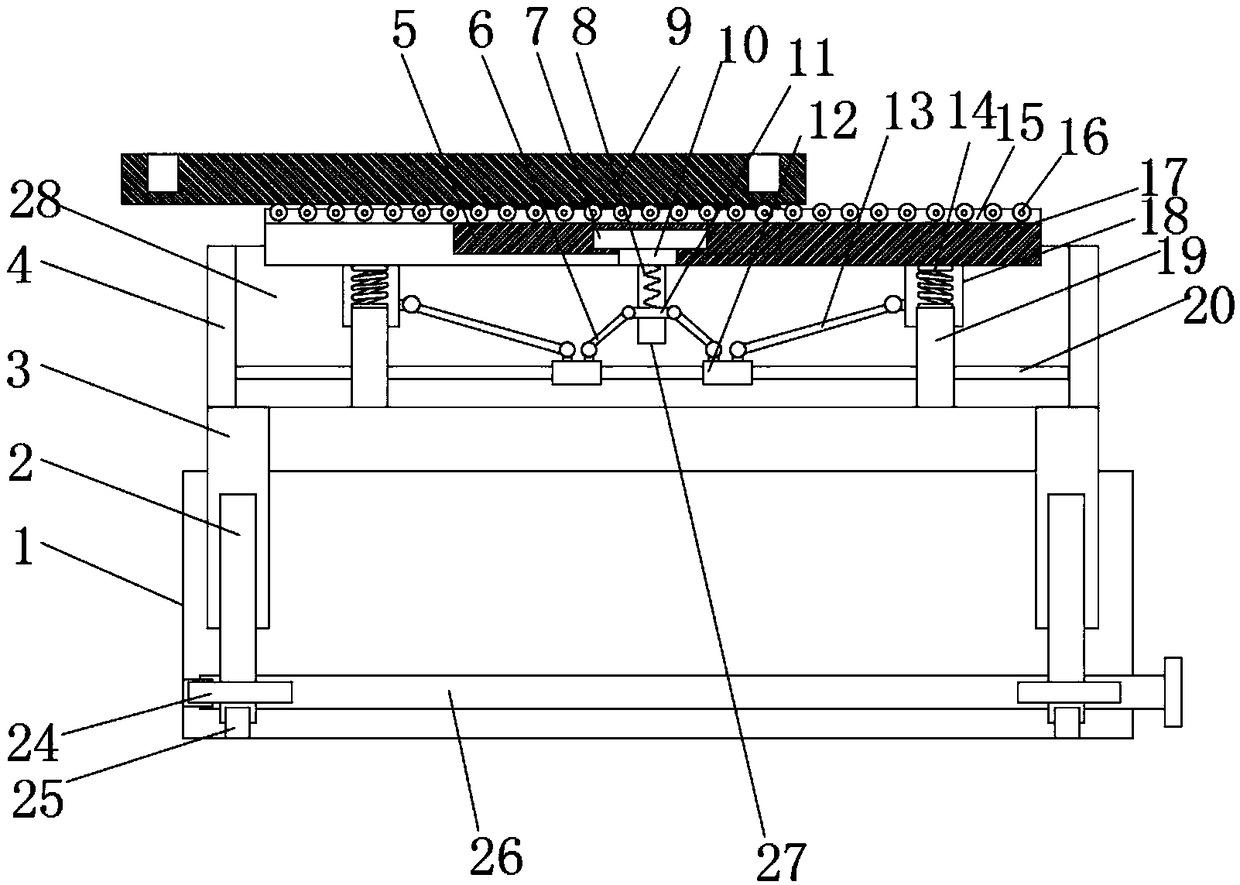

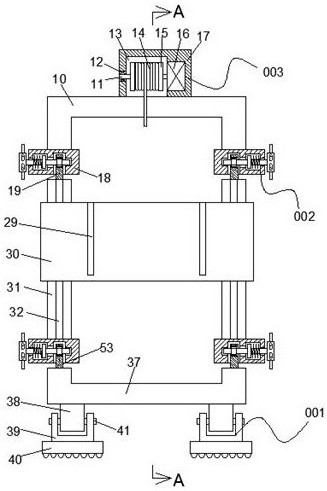

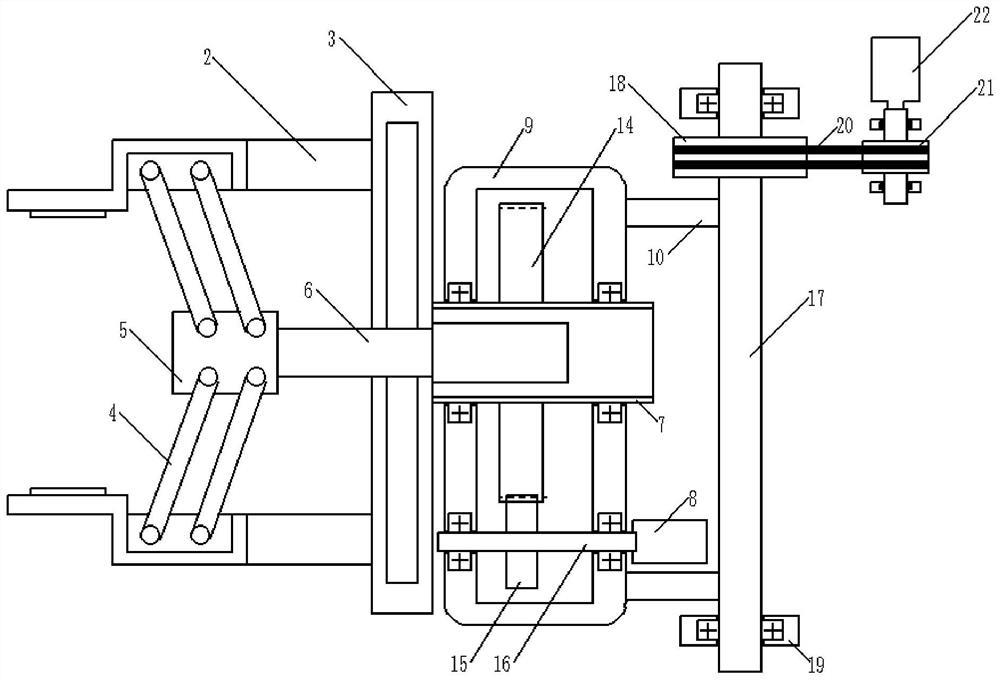

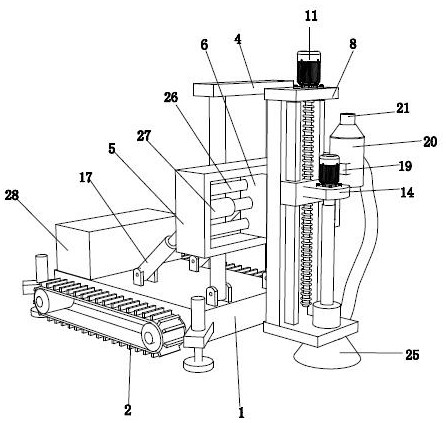

5G communication product turnover and floating clamping mechanism

The invention discloses a 5G communication product turnover and floating clamping mechanism and relates to the technical field of communication product processing. The 5G communication product turnover and floating clamping mechanism comprises two locating plates. Matched moving mechanisms are arranged on the two locating plates. Lifting structures are arranged on sliding table boards. Two parallel support plates are arranged on a supporting plate in each lifting structure. Each turnover mechanism comprises rotary plates rotatably arranged on the two corresponding support plates, wherein one support plate is provided with an L-shaped connecting plate and a limiting hole penetrating through the support plate, a stepping motor and a second cylinder are arranged on the connecting plate, an output shaft of the stepping motor is connected with one end of a coupling, the other end of the coupling is connected with a rotary shaft of one rotary plate, a plug pin aligned with the limiting holeis arranged on an output shaft of the second cylinder, and a second induction structure is arranged on the other support plate; the two rotary plates are connected with a base plate; and two matched clamping structures are arranged on the base plate. The 5G communication product turnover and floating clamping mechanism has the advantages of being simple in structure, high in stability and accuracydegree and the like.

Owner:HUAFENG COMM TECH CO LTD

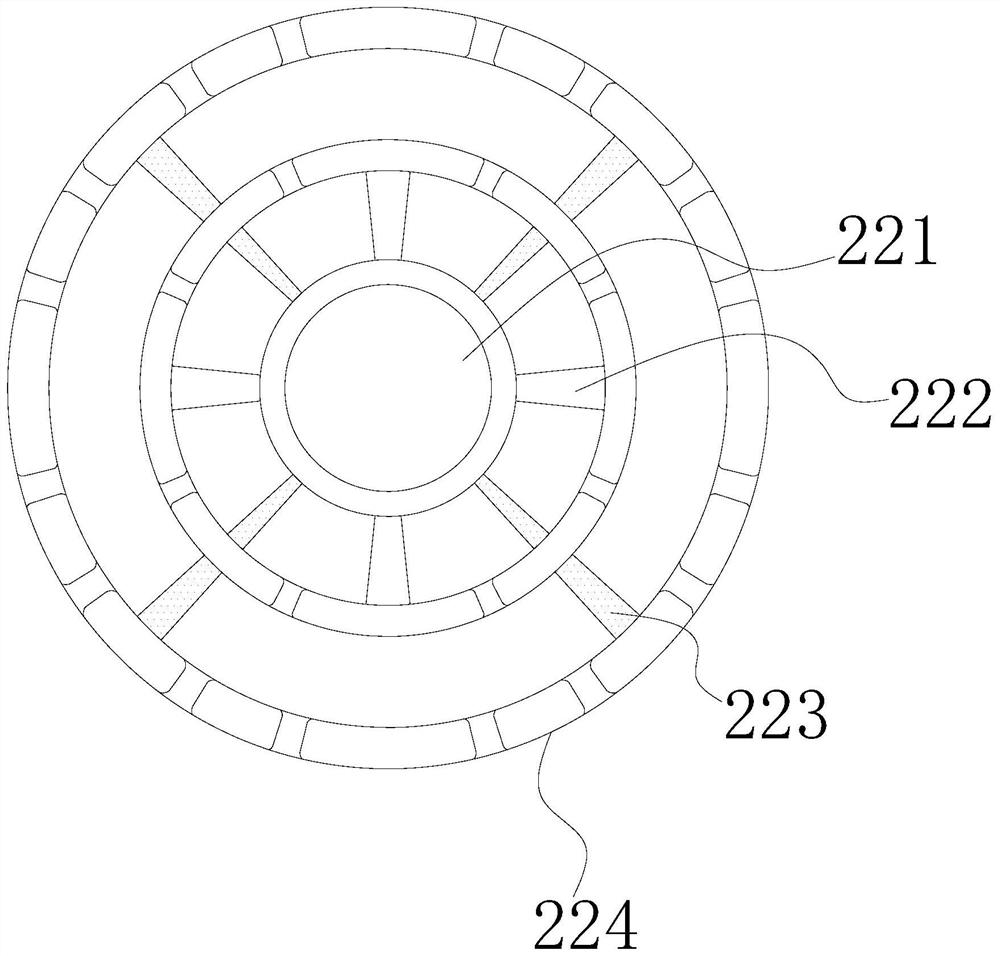

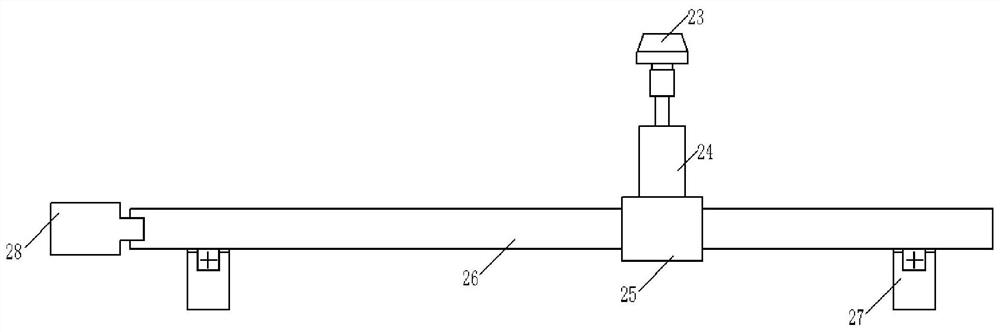

Uniform load floating mechanism with regulable floating quantity for planetary gear

ActiveCN104976335AChange gapTo achieve step-by-step regulationGearing detailsRolling-element bearingEngineering

The invention provides a uniform load floating mechanism with a regulable floating quantity for a planetary gear. The uniform load floating mechanism comprises a planetary frame, a baffle, spacers, a central shaft, a sun wheel and a planet wheel, wherein the sun wheel and the planet wheel are positioned between the planetary frame and the baffle; the planetary frame is connected with the baffle through screws; one end of the central shaft is connected with the planetary frame through a rolling bearing, and the other end of the central shaft penetrates through the center of the baffle; the sun wheel and the planet wheel are conical gears, and the large head end of the sun wheel and the large head end of the planet wheel are in opposite directions and mutually meshed; the spacers sleeve the central shaft and are positioned on two sides of the sun wheel. The uniform load floating mechanism disclosed by the invention is simple in structure, small in size and light in weight; the horizontal position of the center of the sun wheel is changed through changing the number of the spacers on the two sides of the sun wheel by the conical gears in the operation process of the floating mechanism, then a gap between the sun wheel and the planet wheel is changed, and staged regulation of the gap between the gears can be realized, so that the continuous regulation of the floating quantity of the sun wheel is realized.

Owner:WUHAN UNIV

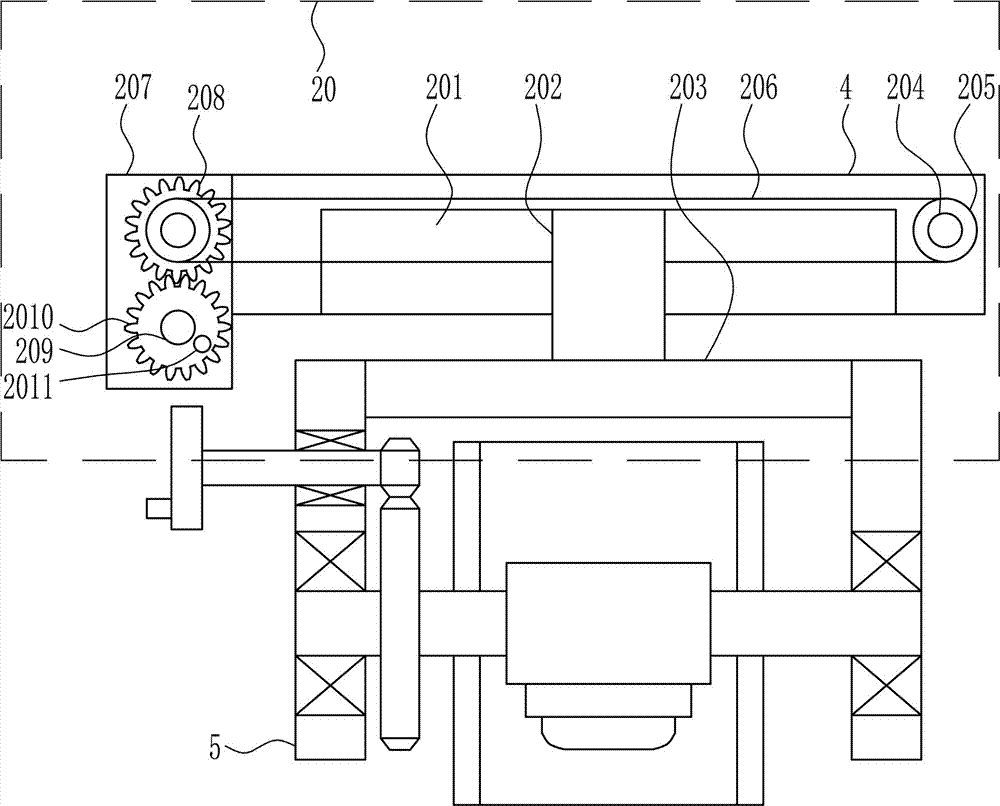

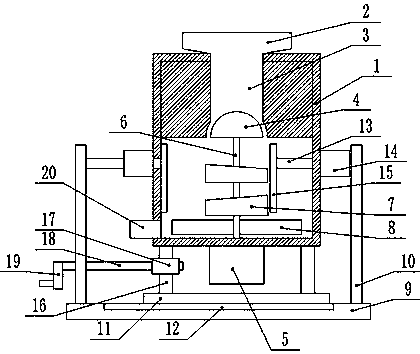

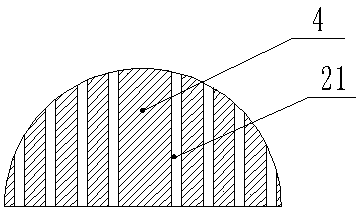

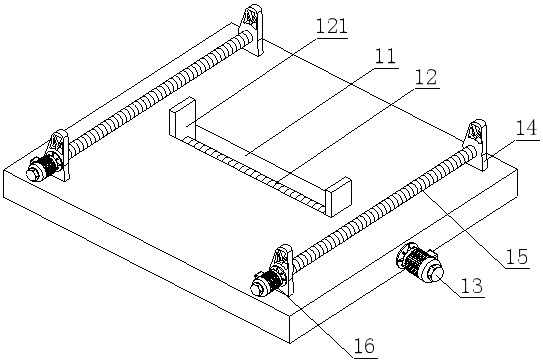

Coating dispersion machine capable of moving left and right

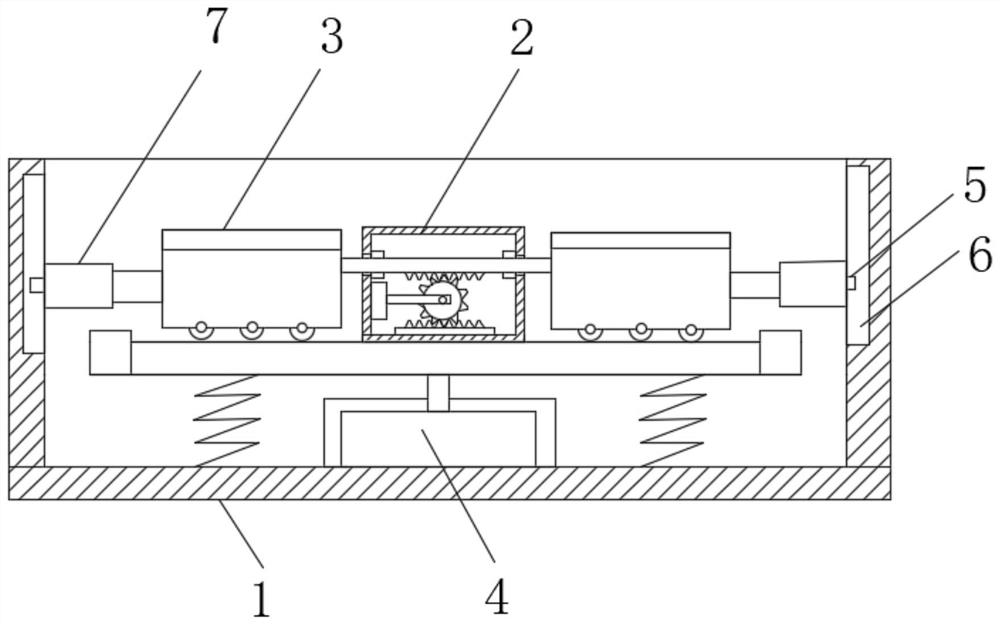

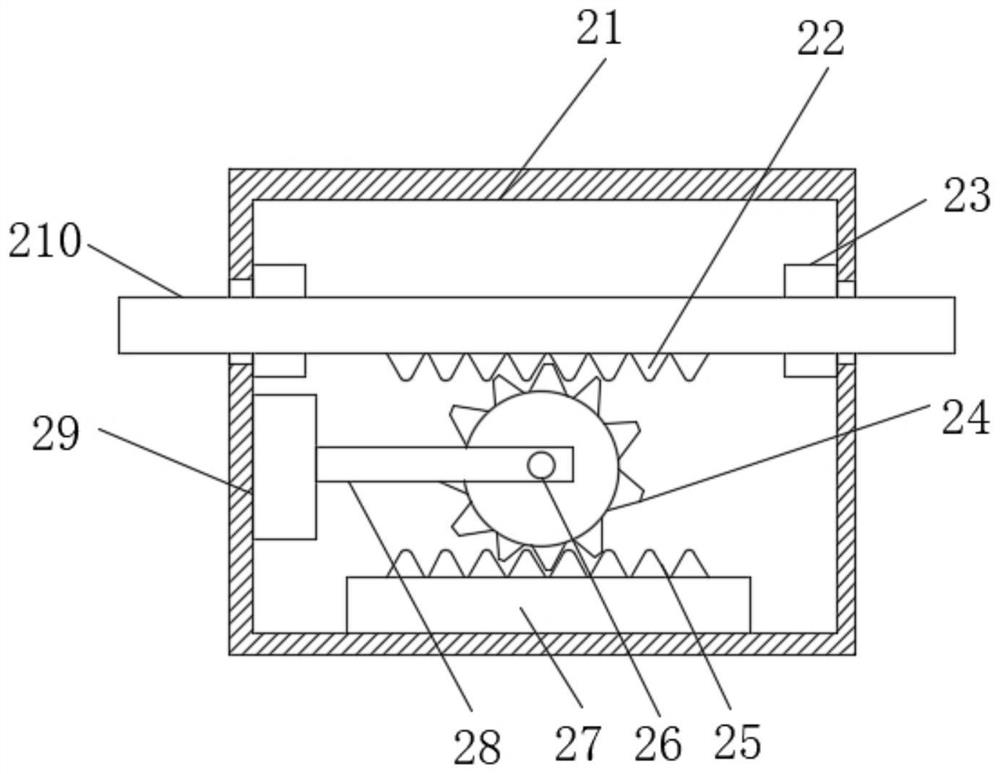

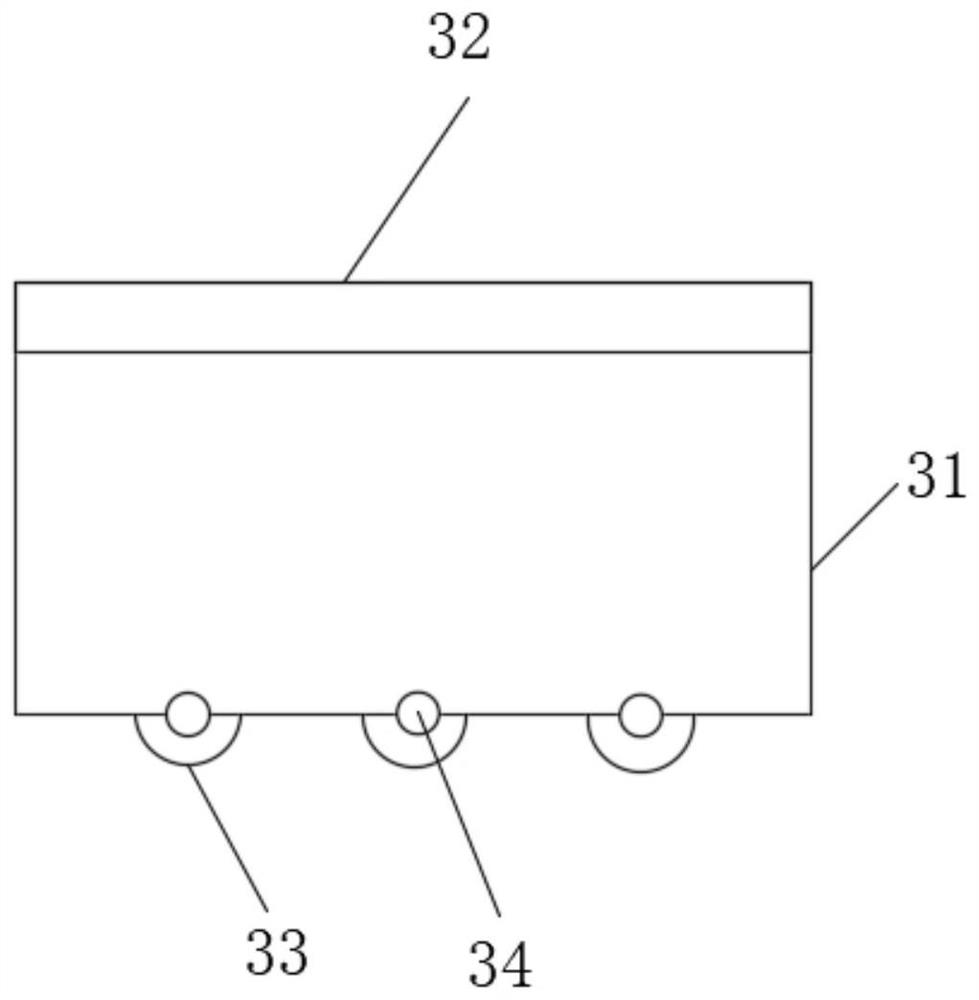

InactiveCN108273431AEvenly dispersedFully dispersedShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a coating dispersion machine capable of moving left and right. The coating dispersion machine comprises a shell, a feed hopper, a motor and a base; a horizontal sliding chute is formed in the base, a horizontal sliding seat is in sliding connection with the sliding chute, and the shell is located above the sliding seat; a vertical velocity-reducing chamber is communicated in the shell corresponding to the feed hopper; slab stirring blades, a bevel stirring disc and an end cap are orderly arranged on a rotating shaft from bottom to top; the end cap is a semi-sphere, a plurality of vertically downward unloading holes are further formed in the end cap, and a vertical push plate is fixed on the tail end of a connecting rod. The falling speed of a coating in the velocity-reducing chamber can be blocked by the end cap arranged at the lower end of the velocity-reducing chamber, thus a part of the coating can fall down from the unloading holes in the end cap, the end cap is rotated to drive the coating in the unloading holes to horizontally and centrifugally move, thereby outward flying; the coating is uniformly dispersed in the shell, the upper surface of the bevelstirring disc is bevel, and the stirring range can be increased in the stirring.

Owner:盐城元之元机械有限公司

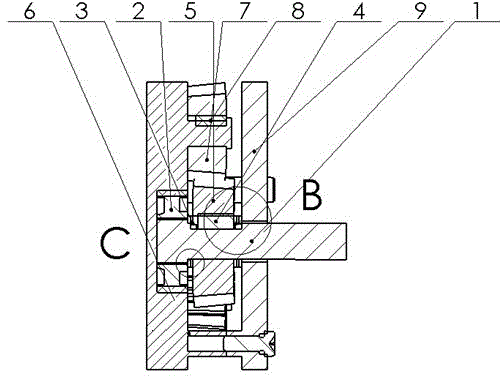

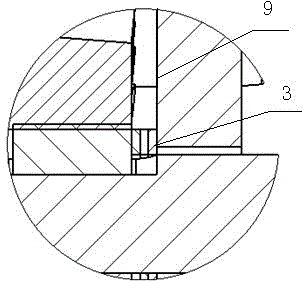

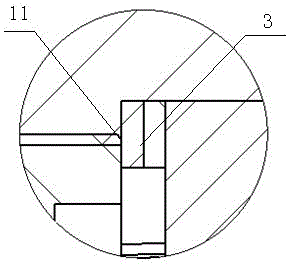

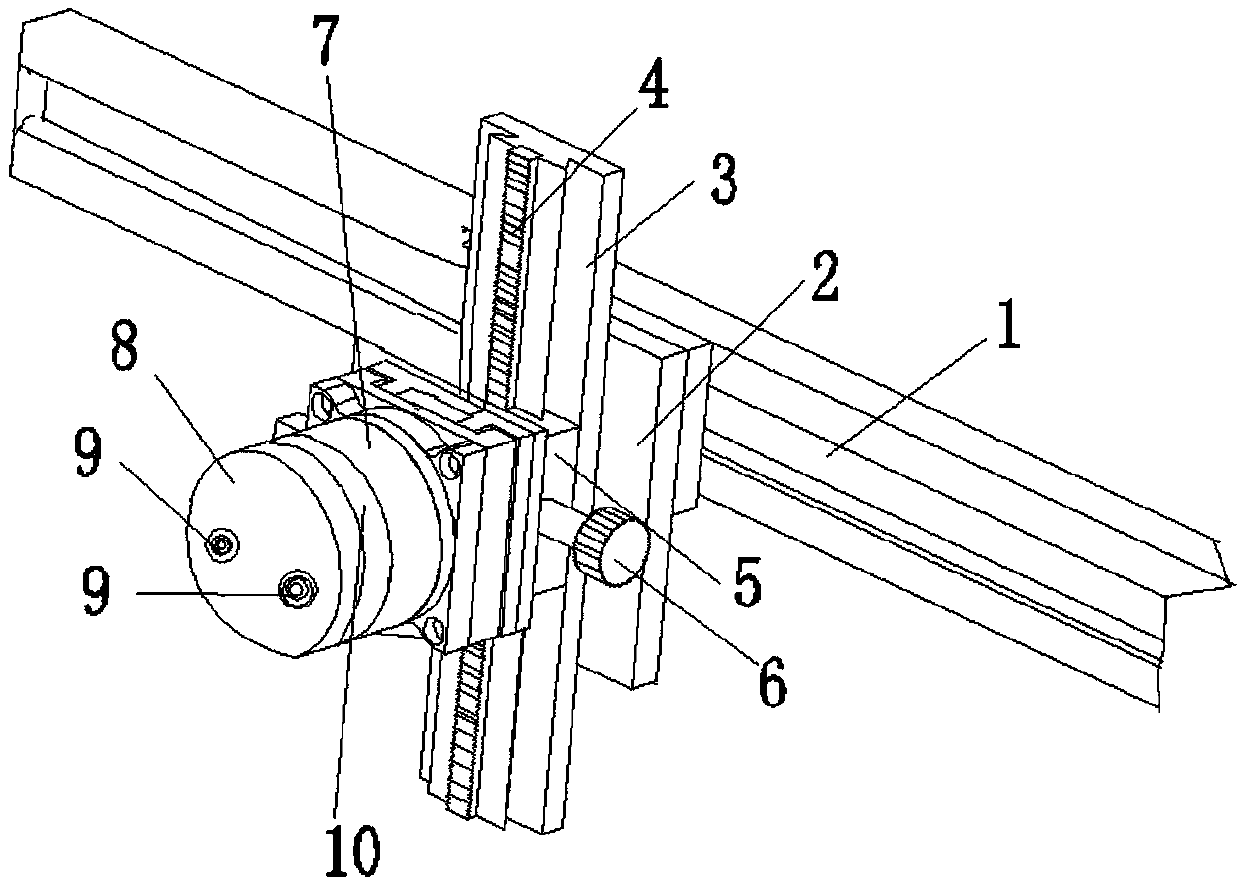

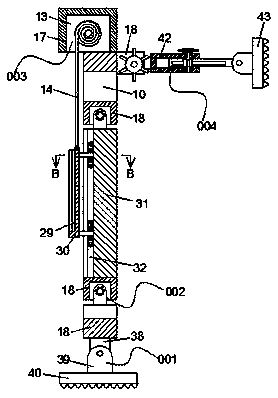

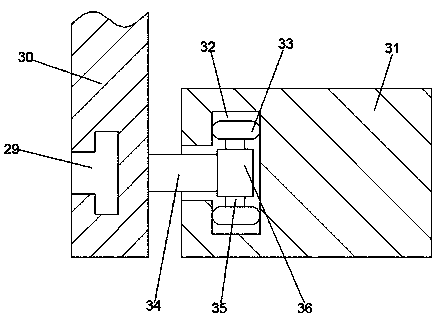

Lathe fixture

InactiveCN107932113AChange horizontal positionHeight adjustableLarge fixed membersPositioning apparatusGear wheel

The invention discloses a lathe fixture, which comprises a horizontal slide rail, a slider arranged on the horizontal slide rail, a fixed plate is arranged on the back of the slider, a rack is arranged on the fixed plate, and a moving block is cooperatingly arranged on the rack. A gear is arranged in the block, and the gear meshes with the rack. The front part of the moving block is provided with a first clamping part. At least one screw hole is provided in the first clamping part. The front part of the first clamping part is provided with a second Two clamping parts, the first clamping part and the second clamping part are non-contact connected together by screws. The present invention can change the horizontal position of the processing part through the movement of the slide block on the horizontal track, adjust the height of the processing part by adjusting the position of the rack and the gear, and adjust the screw on the second clamping part and the first clamping part The connection of the screw holes on the holding parts can adjust the spacing of the clamping space between the two clamping parts, so as to clamp processed parts with different thicknesses.

Owner:江门市坐标光电科技有限公司

Perpendicularity detection device for constructional engineering

InactiveCN113670260AEasy to useImprove work efficiencyIncline measurementLaser rangingStructural engineering

The invention relates to the field of constructional engineering detection, and discloses a perpendicularity detection device for constructional engineering, which comprises a bottom plate, a supporting plate is vertically and fixedly connected to the bottom plate, two guide plates are connected to the top end of the bottom plate, a moving plate is vertically and slidably connected between the two guide plates, and a laser range finder is connected to the moving plate. The support plate is provided with a first driving member that drives the moving plate to slide vertically reciprocatingly, the top end of the supporting plate is connected with a top plate, the top plate is connected with a connecting rope, the end, away from the top plate, of the connecting rope is fixedly connected with a gravity ball, the gravity ball is freely and vertically hung, the top end of the bottom plate is vertically and fixedly connected with a positioning column, and the top end of the positioning column is provided with a groove. When the bottom plate is in a horizontal state, the gravity ball is located in the groove, two sets of heightening units are arranged on the bottom plate, each heightening unit comprises an ejector rod and a power piece for driving the ejector rod to vertically slide in a reciprocating mode, and the ejector rods can stretch out of the bottom end of the bottom plate. The horizontal position of the detection device can be adjusted, and the accuracy of a building detection result is improved.

Owner:CHONGQING VOCATIONAL INST OF ENG

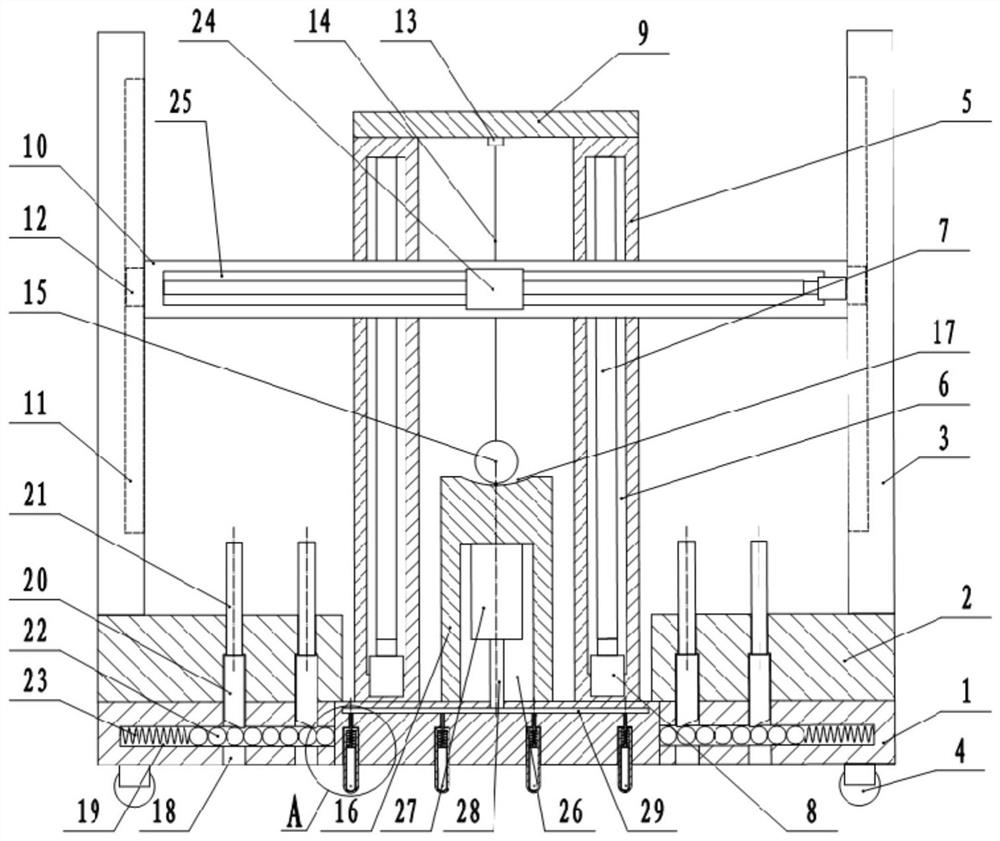

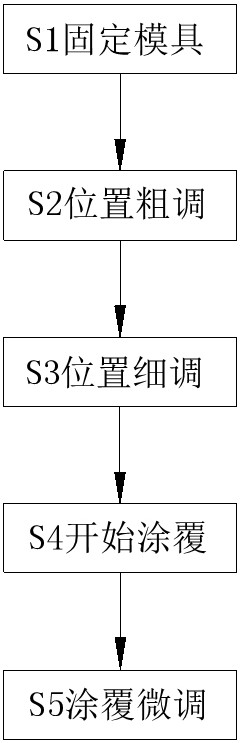

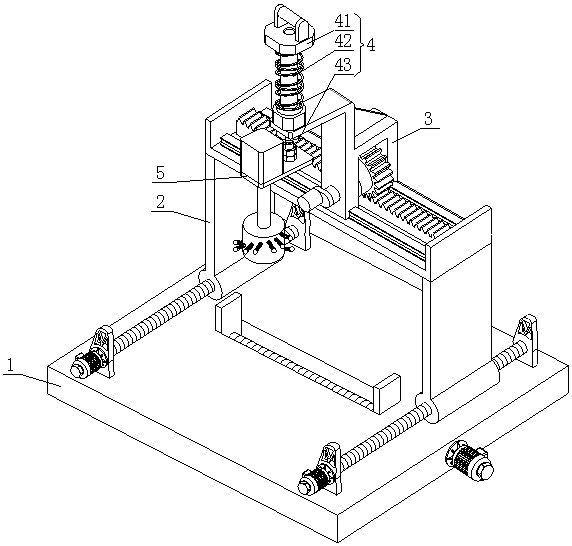

Easy-demolding treatment method for inner surface of casting mold

InactiveCN112371930AChange horizontal positionAutomatically adjust the lengthMoulding toolsElectric machineryEngineering

The invention discloses an easy-demolding treatment method for the inner surface of a casting mold. The easy- demolding treatment method comprises the following steps: S1, fixing the mold: placing themold needing to be coated with demolding liquid on the upper surface of a working table, starting a first motor, driving a first lead screw to rotate by the first motor, and oppositely moving positioning clamping plates to clamp and fix the mold; and S2, carrying out position coarse adjustment, specifically, driving a second lead screw to rotate through a second motor, and driving a movable support through a threaded sleeve to move on the second lead screw. According to the easy-demolding treatment method for the inner surface of the casting mold, the first lead screw and the positioning clamping plates are arranged to fix the mold, the second lead screw and an insection rail are used in cooperation, the horizontal position of a coating frame can be changed, position adjustment is accurate, a handle is held by hand, a guide column drives a coating device to integrally move downwards and rotate, control is convenient, the spraying position and angle can be manually adjusted according to the position of the inner wall of the mold, and use is flexible.

Owner:鲍业明

Spray pipe hanging device easy to disassemble and assemble for mixing machine

PendingCN112827422AIncrease contact areaReduce pressureTransportation and packagingSpraying apparatusWire ropePipe

The invention provides a spray pipe hanging device easy to disassemble and assemble for a mixing machine. The device comprises at least one spray pipe which is arranged below a steel wire rope, at least one adjusting part which is arranged on the outer side of the spray pipe and is provided with a plurality of positioning parts matched with nozzles, a connecting plate which is used for fixing the spray pipe and is provided with first kidney-shaped holes extending transversely and matched with the positioning parts so as to enable the transverse position and the water spraying angle of the spray pipe to be adjustably arranged, and a hanging plate which is arranged above the connecting plate. The hanging plate of the spray pipe hanging device easy to disassemble and assemble for a mixing machine can be directly hung on the steel wire rope or directly taken down, disassembly and assembly are convenient, and manpower, time and maintenance cost are effectively reduced. Meanwhile, by rotating or horizontally moving the relative positions of the adjusting part and the connecting plate, the spraying range of the nozzles can be accurately adjusted, and the percent of pass of the product is remarkably increased.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

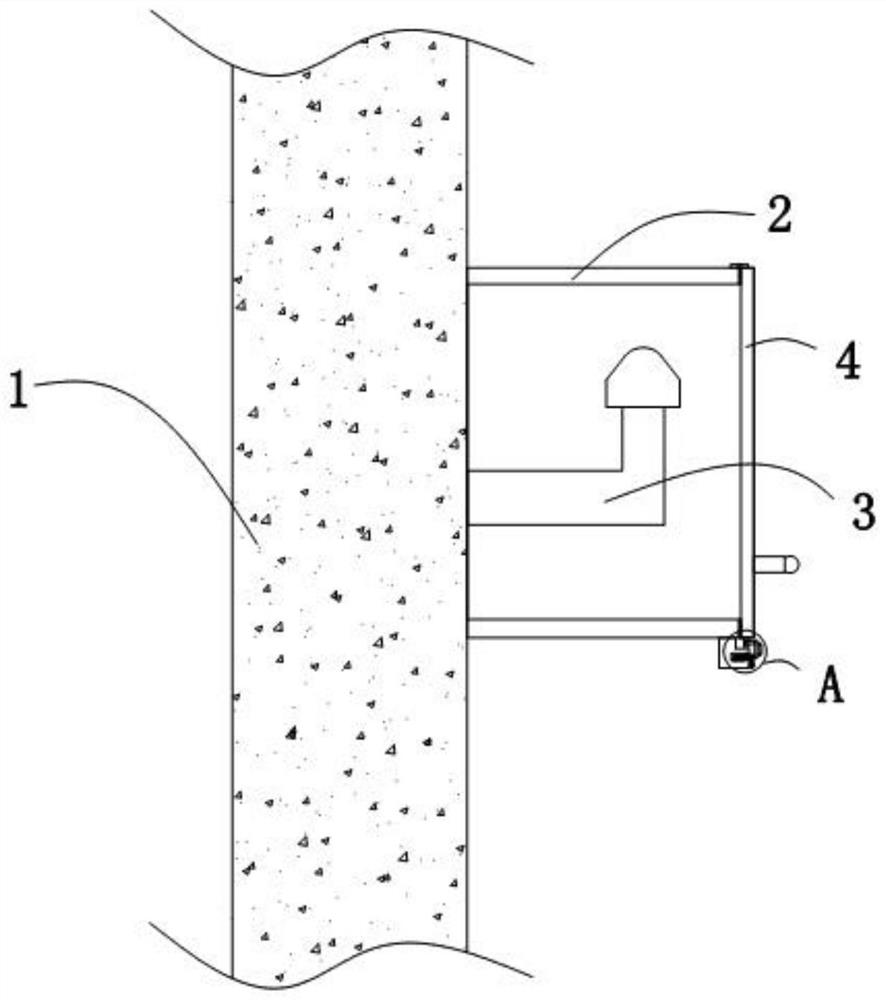

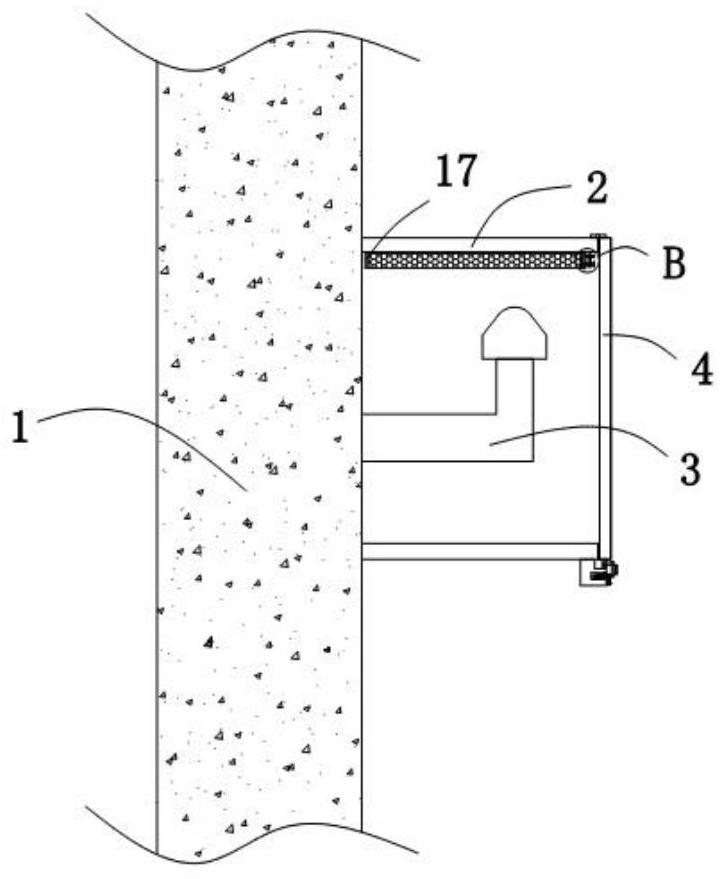

Building settlement observation point protection mechanism

InactiveCN112484694AEffective protectionAvoid damageMeasuring points markingHeight/levelling measurementObservation pointArchitectural engineering

The invention provides a building settlement observation point protection mechanism. The building settlement observation point protection mechanism comprises a wall body, a rectangular protection box,an embedded part, a connecting piece, a settlement observation point, an opening and closing door, a first rectangular block, an L-shaped fixing block, wherein the rectangular protection box is fixedly mounted on the outer wall of one side of the wall body; the embedded part is embedded in the wall body in advance; the connecting piece is in a horizontal state after being connected with the embedded part; the settlement observation point is in close fit and rotational connection with the connecting piece; the opening and closing door is arranged on one side of the rectangular protection box;the first rectangular block is fixedly mounted at the bottom part of the opening and closing door; and the L-shaped fixing block is fixedly mounted at the bottom part of the rectangular protection box. The rectangular protection box has the advantages that rectangular protection can be effectively conducted on the settlement observation point, corrosion or damage, caused by long-term exposure, ofthe settlement observation point is avoided, meanwhile, moisture in the rectangular protection box can be adsorbed, and the service life of the settlement observation point is prolonged.

Owner:陈烁

LED lamp illuminating system for poultry farm and construction method of LED lamp illuminating system

ActiveCN114097652AReduce the difficulty of operationEasy to installLighting support devicesLighting elementsEngineeringLighting system

The invention discloses an LED lamp lighting system for a poultry farm and a construction method thereof.The lighting system comprises an LED lighting lamp, a mounting column, a fixing bottom plate, a middle rod sleeve, a lamp pole and a supporting rod, the LED lighting lamp is arranged on the lamp pole, transverse extending rods are longitudinally distributed on the mounting column, a vertical through groove for the lamp pole to pass through is formed in the mounting column, and the middle rod sleeve is arranged in the middle rod sleeve; a transverse through groove for the lamp pole to pass through is formed in the transverse extension rod, and the transverse through groove is communicated with the vertical through groove; the construction method comprises the following steps: (a) determining a construction boundary; (b) arranging the supporting single bodies; (c) monomer forming; and (d) installing the lamp. The LED lamp illumination system is novel in structure, adjustable in illumination horizontal direction and illumination height, high in applicability, easy to operate and low in use cost, the construction method and process are simple, a single body is changed into an assembly body from small to large, gradual order is achieved, positioning is convenient, labor is saved, convenience is achieved, control is easy, and the construction quality is guaranteed.

Owner:嵊州市三九灯具有限公司

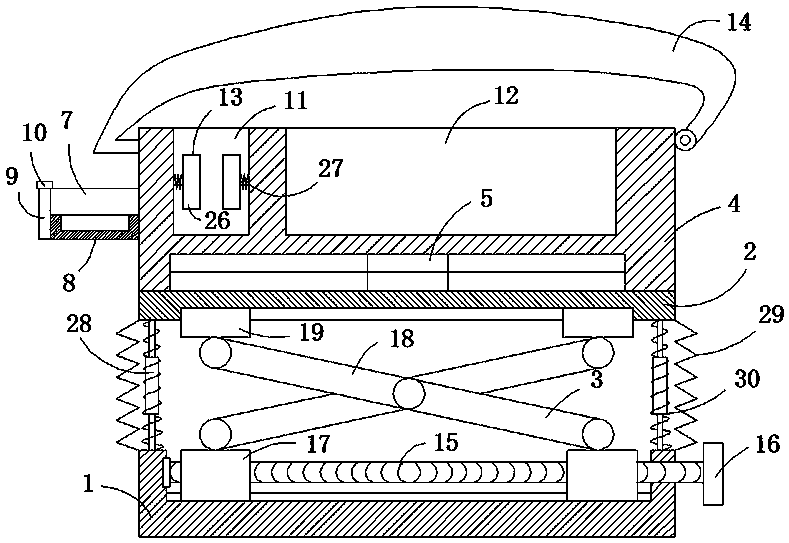

Adjustable water pump supporting device

InactiveCN109027118AChange heightChange horizontal positionMachine framesNon-rotating vibration suppressionEngineering

The invention discloses an adjustable water pump supporting device, including a base. A rotating rod is welded at the bottom of the inn wall of the base, a second worm wheel is arranged at the top ofthe rotating rod, a first screw rod is welded at the top central shaft of the second worm wheel, a first screw pipe is threadedly connected to the outside of the first screw rod, a first mating rod iswelded at one side of the inner wall of the base, one end of the first mating rod is provided with a second worm, and the second worm and the second worm wheel are arranged in the same plane. In summary, the device can change the installation position of the pump, facilitate the construction operation of the staff, alleviate the noise and vibration generated in the working process of the pump, and reduce the bodily injury of the staff caused by the pump work.

Owner:JIANGSU PROVINCE SINGE IRRIGATION & DRAINAGE EQUIP +1

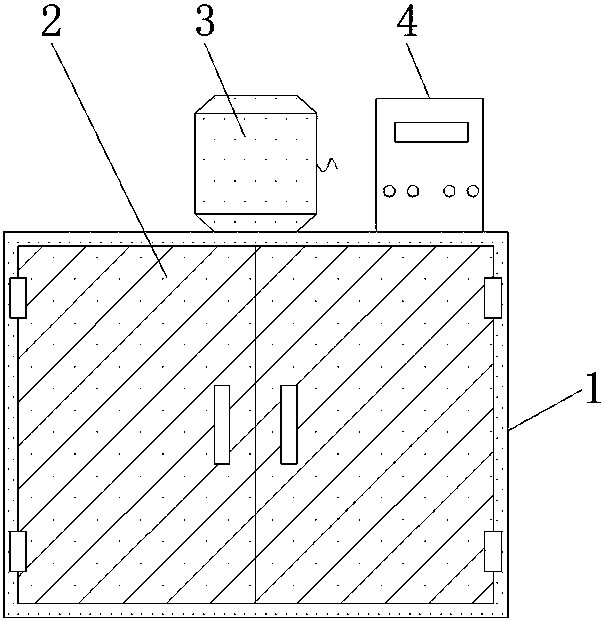

Touch screen frequency point calibration device and method

PendingCN108491111ALarge range of movementChange horizontal positionControl using feedbackInput/output processes for data processingHydraulic cylinderElectricity

The invention discloses a touch screen frequency point calibration device and method. The device comprises a shell and a control panel, wherein a switch door is mounted at the front end of the shell;a first hydraulic cylinder is mounted in the middle of the upper end of the switch door; the control panel is mounted on the right side of the first hydraulic cylinder; a driven wheel is mounted in the middle of a side surface of a rotating shaft; a second hydraulic cylinder is mounted on the left side of a second connecting plate; the right side of the second hydraulic cylinder is connected witha second telescopic rod; a tablet computer is mounted in the middle of the bottom end of the inside of the shell; inner threaded holes are uniformly and symmetrically formed along the vertical axis ofthe shell at the bottom end of the inside of the shell; a spring is mounted in the lower end of a mounting rod; a calibration pen is mounted at the lower end of the mounting rod; and the first hydraulic cylinder, a stepping motor and the second hydraulic cylinder are electrically connected with the control panel. The touch screen frequency point calibration device can calibrate a touch screen, awhole calibration process is automatic, and the calibration precision is high.

Owner:江苏中致显科技有限公司

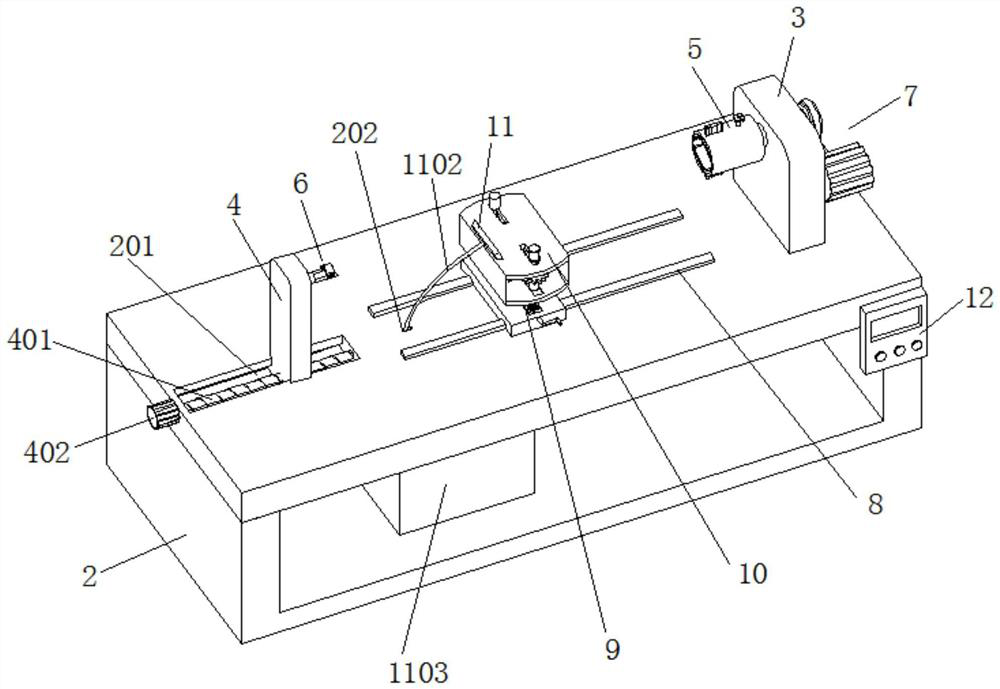

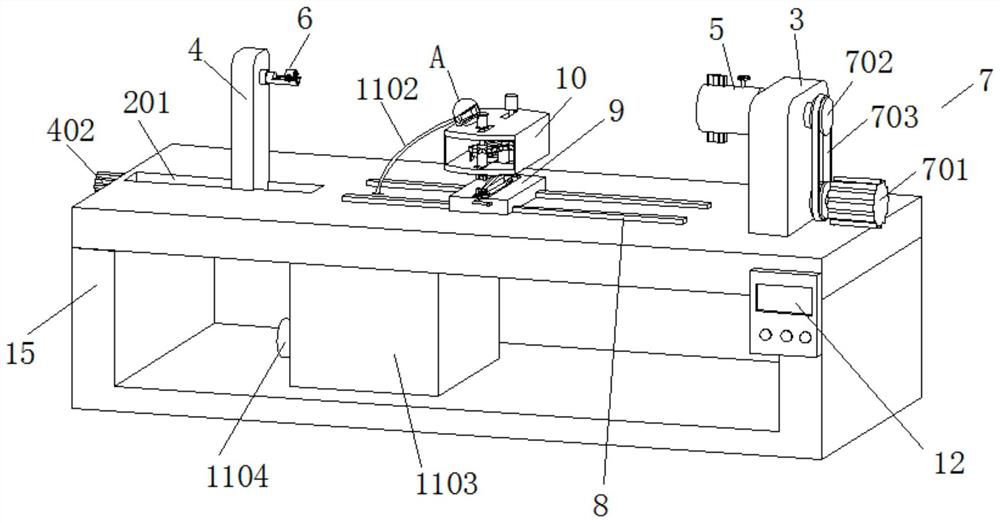

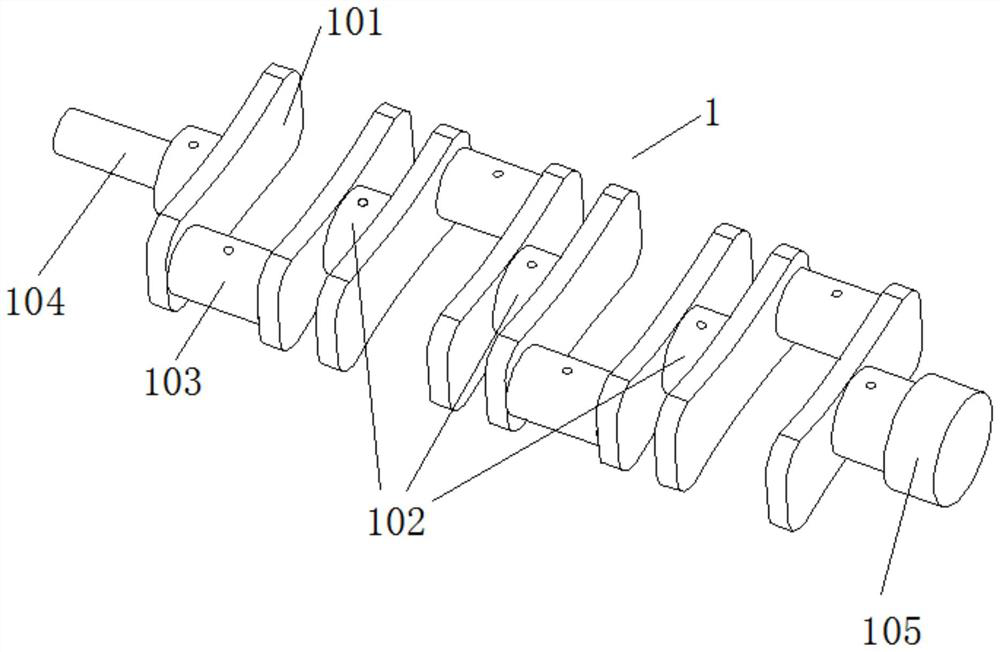

Crankshaft main journal polishing device

ActiveCN114367917AChange horizontal positionImprove polishing effectPolishing machinesRevolution surface grinding machinesEngineeringMotronic

The invention discloses a crankshaft main journal polishing device, and relates to the technical field of crankshaft machining, the crankshaft main journal polishing device comprises a machining table, the left end and the right end of the top of the machining table are provided with a flange end positioner and a shaft head end positioner through a vertical plate and a distance adjusting plate respectively, and a polishing assembly is further installed between the vertical plate and the distance adjusting plate through an electric sliding rail; a lifting assembly is arranged at the bottom of the polishing assembly, and an adsorption assembly is further arranged on one side of the top of the polishing assembly. The crankshaft main journal polishing device can be suitable for polishing crankshaft main journals of different models, adjustment is convenient, and the polishing effect can be effectively improved under dual polishing of oilstones and abrasive paper.

Owner:罡阳轴研科技(灌云)有限公司

A concrete pipe pile spreader

ActiveCN110054091BHorizontal spacing changesChange horizontal positionTrolley cranesTrolleysArchitectural engineeringChain link

The present invention relates to a spreader, more specifically, it relates to a concrete pipe pile spreader. The key points of its technical solution are: it includes a support and a transverse support rail which is slidably arranged on the top of the support along the horizontal direction, In the length direction, the two conveying vehicles set on the horizontal support rails are slid and correspondingly connected to the lifting mechanism at the bottom of the conveying vehicle. The lifting mechanism is connected to the spreader frame through the hanging ring and the chain, and the hook unit is installed on the spreader frame. The hook unit includes a mounting seat fixed on the spreader frame and a main shaft that rotates through the mounting seat. The main shaft is provided with a base along its length. Rotate and swing up and down in the long direction to hook the driving mechanism of the pipe pile. The spreader does not need to manually go to the side of the pipe piles, and the pipe piles are bundled and then hoisted. The operation is simple, and the hoisting process is stable, which saves human resources and improves the safety of the operation.

Owner:东莞市建安管桩有限公司

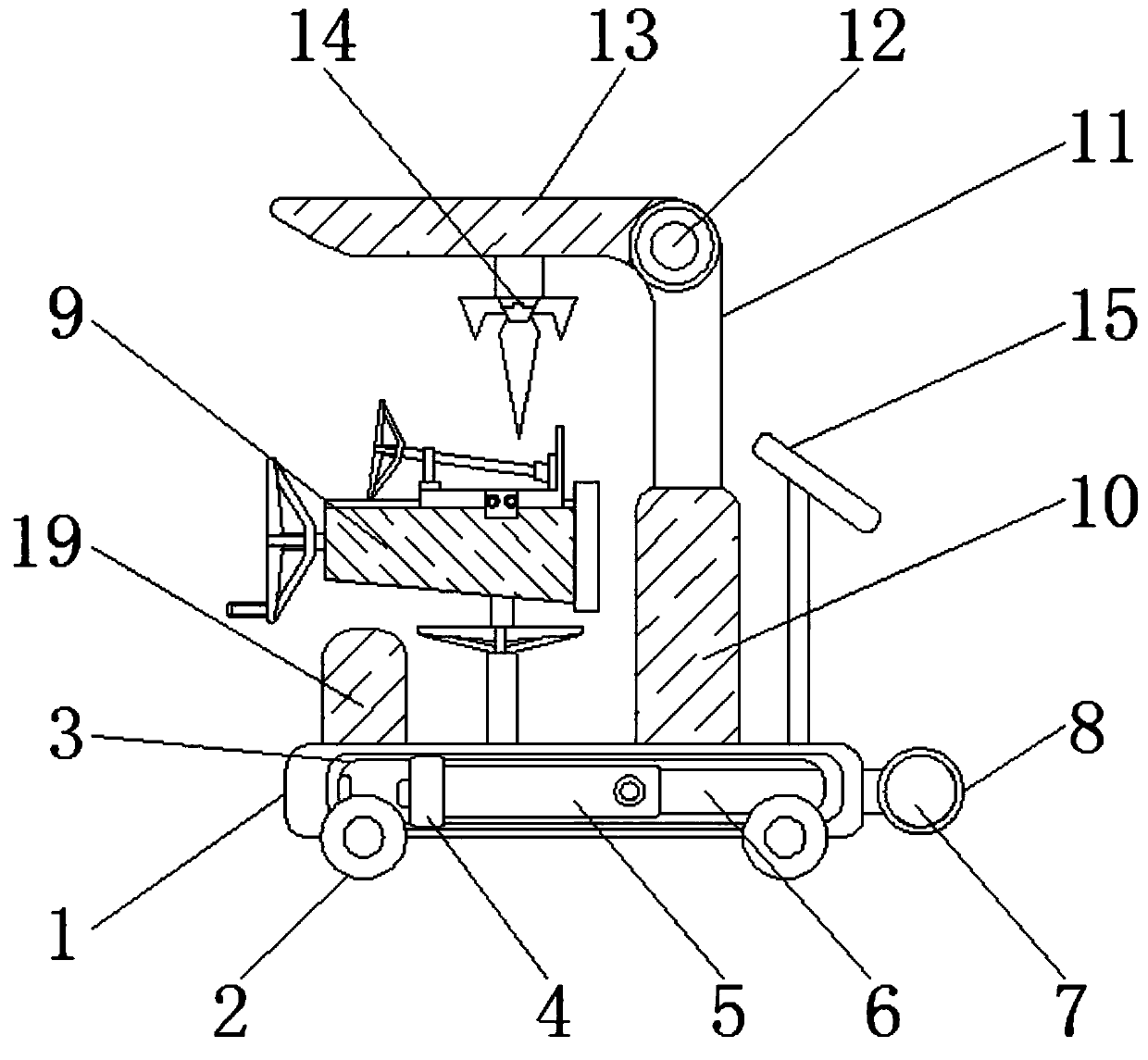

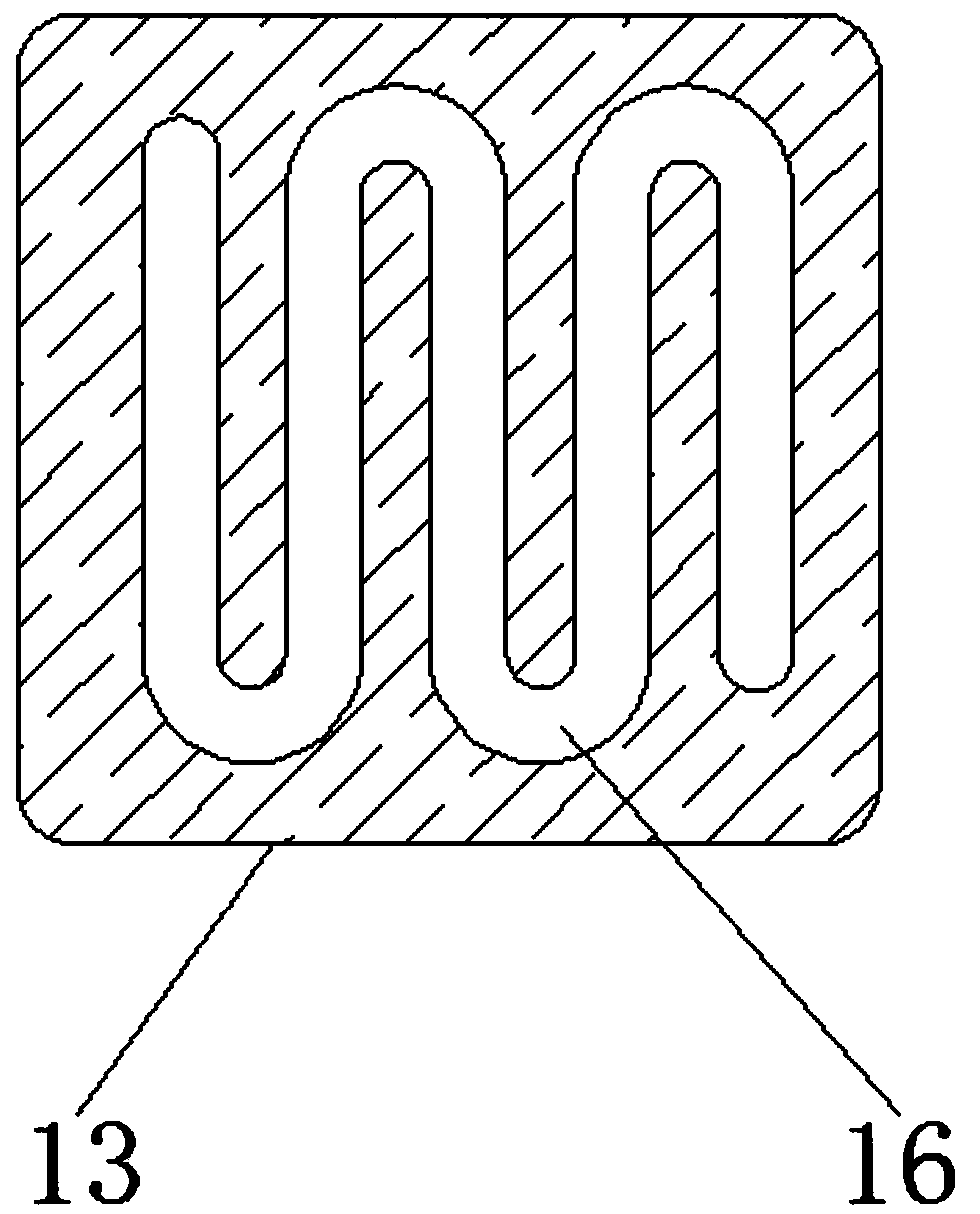

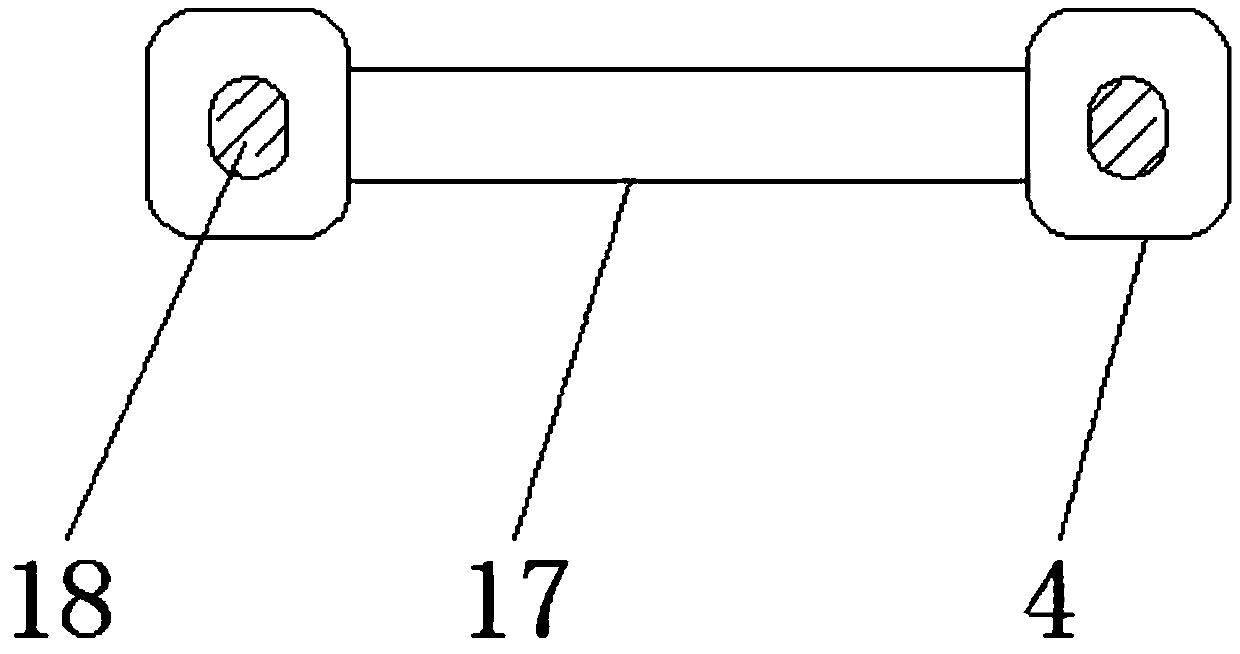

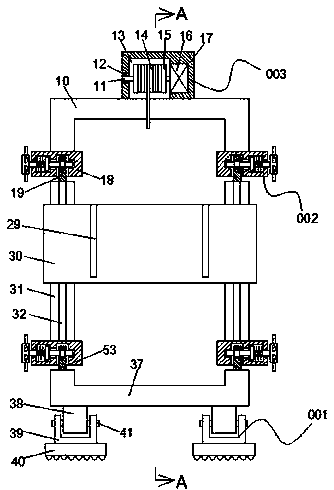

A fully automatic electric welding mechanical equipment suitable for large production workshops

ActiveCN107253005BEasy to moveEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical equipment

Owner:池州市勇攀智岩机电有限公司

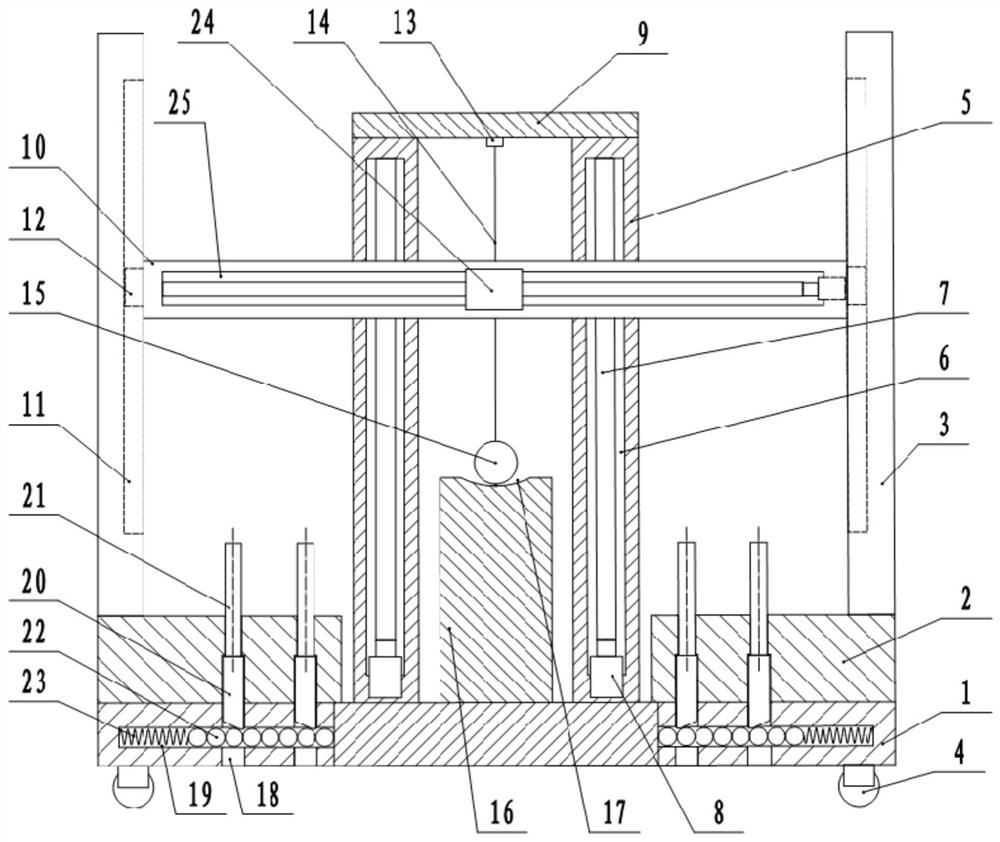

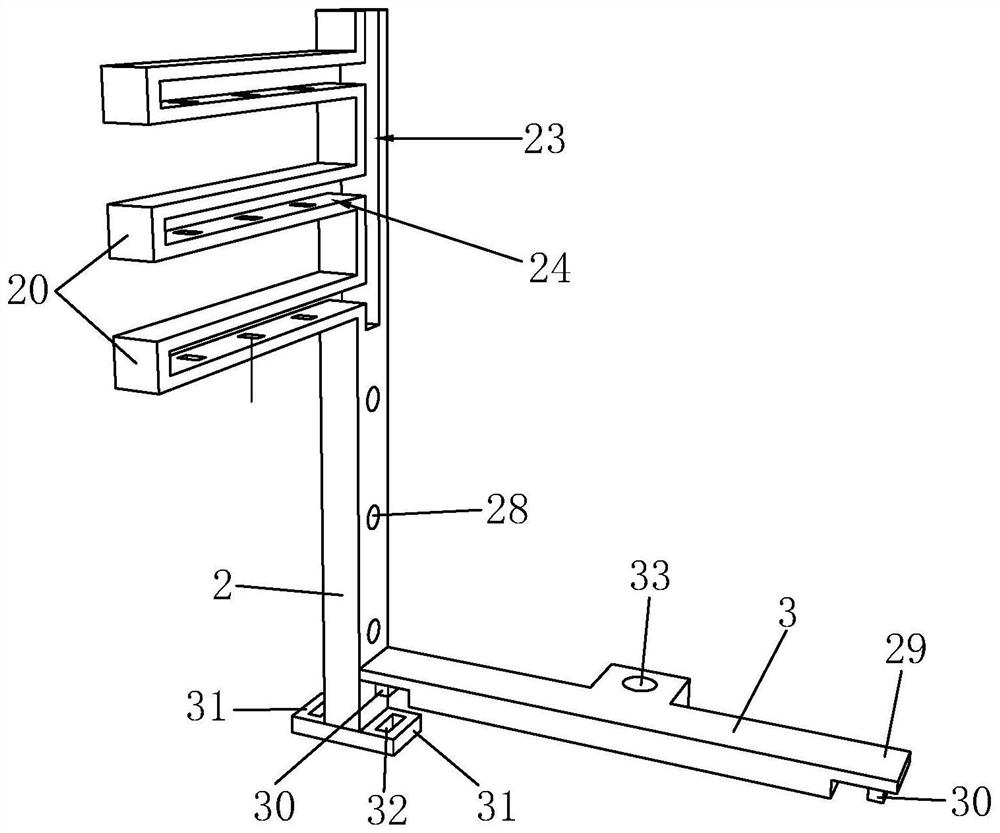

Assembled multi-angle heavy lifting machine

ActiveCN111470450AChange horizontal positionEasy to useLifting framesBuilding material handlingStructural engineeringIndustrial engineering

The invention discloses an assembled multi-angle heavy lifting machine. The machine comprises a lifting base, wherein a base fixing device which can be tightly fixed on the ground is arranged on the lower side end surface of the lifting base, a lifting top plate is arranged above the lifting base, and the left and right positions of the lower side end surface of the lifting top plate are correspondingly connected with the left and right positions of the upper side end surface of the lifting base through lifting rods capable of being accumulated up and down. According to the machine, by means of the lifting rods which can be assembled and disassembled, the height and the length of the lifting machine can be adjusted according to the requirements of a lifting place, and articles can be directly transported to the place requiring the articles; and meanwhile, the assembled lifting rods can be subjected to curve assembly with the cooperation of adjustable splines, and the horizontal position of the articles can be changed while the articles on the ground are lifted upwards through the lifting machine which is assembled in a curve shape.

Owner:浙江中路金属股份有限公司

A Planetary Gear Balanced Load Float Mechanism with Adjustable Float

ActiveCN104976335BChange gapTo achieve step-by-step regulationGearing detailsGear wheelRolling-element bearing

The invention provides a uniform load floating mechanism with a regulable floating quantity for a planetary gear. The uniform load floating mechanism comprises a planetary frame, a baffle, spacers, a central shaft, a sun wheel and a planet wheel, wherein the sun wheel and the planet wheel are positioned between the planetary frame and the baffle; the planetary frame is connected with the baffle through screws; one end of the central shaft is connected with the planetary frame through a rolling bearing, and the other end of the central shaft penetrates through the center of the baffle; the sun wheel and the planet wheel are conical gears, and the large head end of the sun wheel and the large head end of the planet wheel are in opposite directions and mutually meshed; the spacers sleeve the central shaft and are positioned on two sides of the sun wheel. The uniform load floating mechanism disclosed by the invention is simple in structure, small in size and light in weight; the horizontal position of the center of the sun wheel is changed through changing the number of the spacers on the two sides of the sun wheel by the conical gears in the operation process of the floating mechanism, then a gap between the sun wheel and the planet wheel is changed, and staged regulation of the gap between the gears can be realized, so that the continuous regulation of the floating quantity of the sun wheel is realized.

Owner:WUHAN UNIV

An assembled multi-angle heavy object hoist

ActiveCN111470450BChange horizontal positionEasy to useLifting framesBuilding material handlingClassical mechanicsStructural engineering

The invention discloses an assembled multi-angle heavy lifting machine. The machine comprises a lifting base, wherein a base fixing device which can be tightly fixed on the ground is arranged on the lower side end surface of the lifting base, a lifting top plate is arranged above the lifting base, and the left and right positions of the lower side end surface of the lifting top plate are correspondingly connected with the left and right positions of the upper side end surface of the lifting base through lifting rods capable of being accumulated up and down. According to the machine, by means of the lifting rods which can be assembled and disassembled, the height and the length of the lifting machine can be adjusted according to the requirements of a lifting place, and articles can be directly transported to the place requiring the articles; and meanwhile, the assembled lifting rods can be subjected to curve assembly with the cooperation of adjustable splines, and the horizontal position of the articles can be changed while the articles on the ground are lifted upwards through the lifting machine which is assembled in a curve shape.

Owner:浙江中路金属股份有限公司

Positioning pin mounting seat

InactiveCN112440220AChange horizontal positionTo achieve the purpose of precise positioningWork holdersComputer hardwareEngineering

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

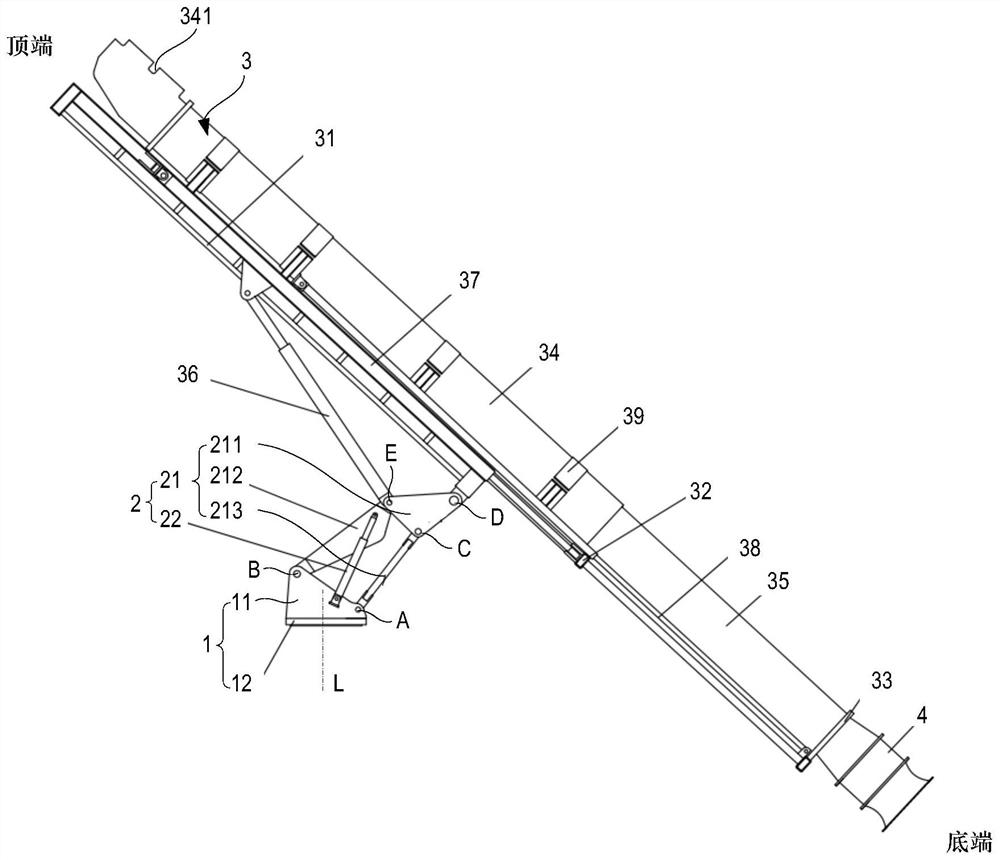

Cantilever crane and drainage vehicle

PendingCN114457738AMeet drainage needsChange horizontal positionSewerage structuresGeneral water supply conservationCantileverMarine engineering

The invention discloses a cantilever crane system and a drainage vehicle, relates to the field of flood disaster emergency rescue equipment, and aims to improve the structure of the cantilever crane system. The boom system comprises a rotary platform, a connecting frame assembly, a boom assembly and a water pump. The revolving platform is configured to provide support; the revolving platform is configured to revolve relative to its own rotation axis. The connecting frame assembly is rotatably installed on the rotary platform. The arm frame assembly is rotatably installed on the connecting frame assembly so as to change the inclination angle of the arm frame assembly. The water pump is installed at the tail end of the boom assembly. According to the cantilever crane system provided by the technical scheme, the overall rotation of the cantilever crane assembly is realized through the connecting frame assembly, so that the working position of the water pump mounted on the cantilever crane assembly is changed, and the drainage requirements of different places are met.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

A mechanical processing intelligent positioning device

ActiveCN111037323BEasy to operateGuaranteed stabilityWork clamping meansPositioning apparatusControl engineeringElectric machinery

The invention provides a machining intelligent positioning device, which includes a positioning plate. The upper surface of the positioning plate is provided with a plurality of clamping mechanisms for clamping thin-walled parts at different positions. The clamping mechanism includes two clamping arms. One clamping arm is slidingly connected with the plate body, the left ends of the two clamping arms are fixedly connected with the block body through the connecting rod, the block body is fixed at the telescopic end of the first telescopic element, the fixed end of the first telescopic element passes through the plate body and It is fixedly connected with the plate body; the side of the plate body is fixed with a first rotating shaft, the first rotating shaft is connected with the output shaft of the first motor through the rotating mechanism, the first rotating shaft is connected with the housing for supporting the rotating mechanism through the bearing, and the housing There is an ear plate fixed at the left and right ends, and the ear plate is connected with the pitch angle adjustment mechanism; the upper surface of the positioning plate is also provided with a plurality of supporting mechanisms; the invention provides a processing positioning suitable for thin-walled curved surface parts, which can It is a machined intelligent positioning device that can be clamped and supported by a support mechanism at the same time.

Owner:XINXIANG UNIV

Drilling machine for mining

InactiveCN113565437AAvoid the problem of poor selection accuracyChange horizontal positionDrilling rodsConstructionsElectric machineryMining engineering

The invention discloses a drilling machine for mining. The drilling machine comprises a rack and conveying crawler belts arranged on the two sides of the rack, wherein two mounting columns are rotatably arranged at the front end of the rack; connecting plates are connected to the ends of the two mounting columns; mounting frames are arranged at the front ends of the two mounting columns; sliding blocks are arranged in the mounting frames; mounting plates are arranged at the front ends of the sliding blocks; top plates and bottom plates are arranged at the upper ends and the lower ends of the mounting plates correspondingly; lead screws are rotatably arranged between the top plates and the bottom plates; two guiding blocks located on the two sides of the lead screws correspondingly are arranged on the front sides of the mounting plates; lifting plates slidably connected with the two guiding blocks are connected to the lead screws in a threaded mode; motor bases are arranged at the front ends of the lifting plates; second motors are arranged at the upper ends of the motor bases; and drilling rods located at the lower ends of the motor bases are arranged at the output ends of the second motors. Compared with the prior art, the drilling machine has the advantages that the drilling angle can be adjusted according to the requirements, and pollution of dust to the construction environment can be avoided.

Owner:XUZHOU HUAFENG MEASUREMENT & CONTROL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com