Crankshaft main journal polishing device

A technology of polishing device and main journal, applied in grinding/polishing safety device, grinding driving device, grinding/polishing equipment, etc., can solve the problems of limited polishing work efficiency, poor polishing efficiency, difficult to guarantee accuracy, etc. Improve polishing effect, good applicability, effect of changing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

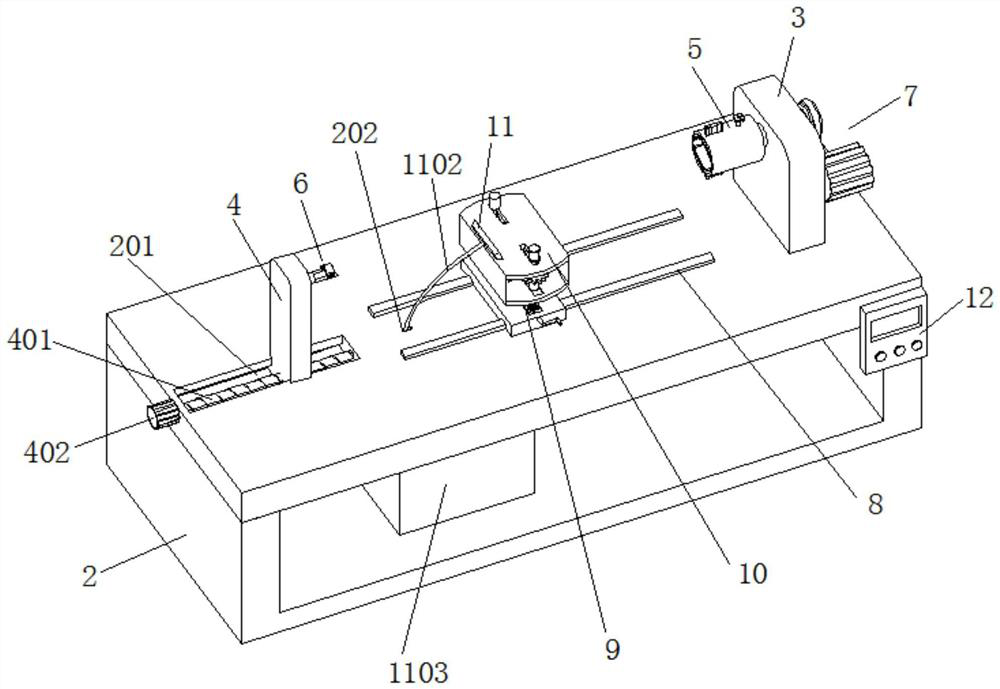

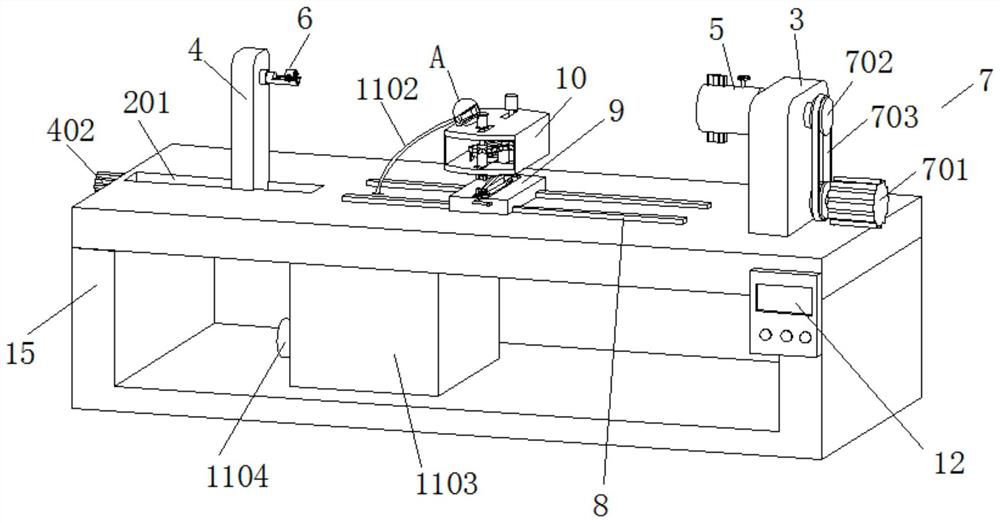

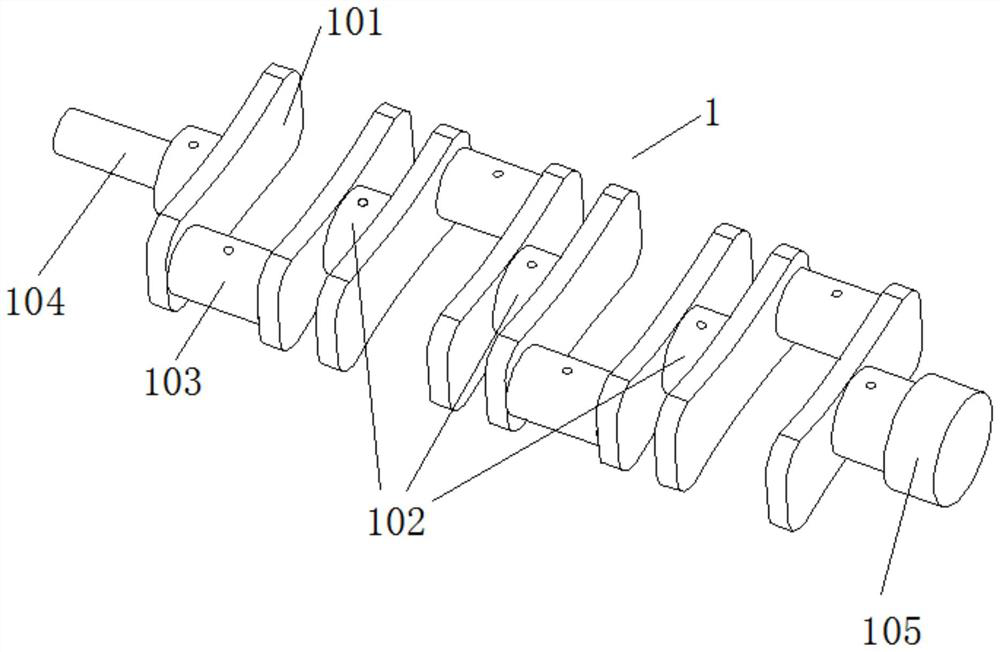

[0056] Embodiment 1 discloses a crankshaft main journal polishing device, refer to the attached figure 1 to attach image 3 , including a processing table 2 for placing the crankshaft 1. The crankshaft 1 is composed of a balance weight 101, a main journal 102, and a connecting rod journal 103 arranged in sequence. The flange end locator 5 and the shaft end locator 6 are installed on the left and right ends through the vertical plate 3 and the distance adjustment plate 4 respectively, and a polishing assembly is installed between the vertical plate 3 and the distance adjustment plate 4 through the electric slide rail 8 10. The bottom of the polishing component 10 is equipped with a lifting component 9, and a control panel 12 as a control center is installed on one side of the processing table 2;

[0057] Reference attached figure 2 And attached Figure 4 , the vertical plate 3 is fixedly installed on one end of the processing table 2 and the flange end locator 5 is movably ...

Embodiment 2

[0067] Reference attached figure 1 And attached Figure 10 At one side of the top of the polishing assembly 10, an adsorption assembly 11 is also provided. The adsorption assembly 11 includes a dust suction cover 1101 arranged on one side of the oilstone grinding wheel 1010 and the sandpaper grinding wheel 1011. The other end of the pipe 1102 passes downwards through the surface of the processing table 2 and is connected to a dust collection box 1103. A suction fan 1104 is arranged on one side of the dust collection box 1103, and an electromagnetic block 1105 is symmetrically arranged on the inner wall of the dust collection cover 1101.

[0068] The principle of the crankshaft main journal polishing device disclosed in embodiment 2 is as follows:

[0069] The debris produced by grinding is absorbed by the dust collection cover 1101, and then enters the dust collection box 1103 through the suction pipe 1102, and the electromagnetic block 1105 in the dust collection cover 1101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com