Intelligent positioning device for machining

A technology of processing intelligence and positioning device, which is applied in the field of mechanical processing, can solve the problems of complex surface structure of curved parts and difficult positioning of parts, and achieve the effect of increased cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

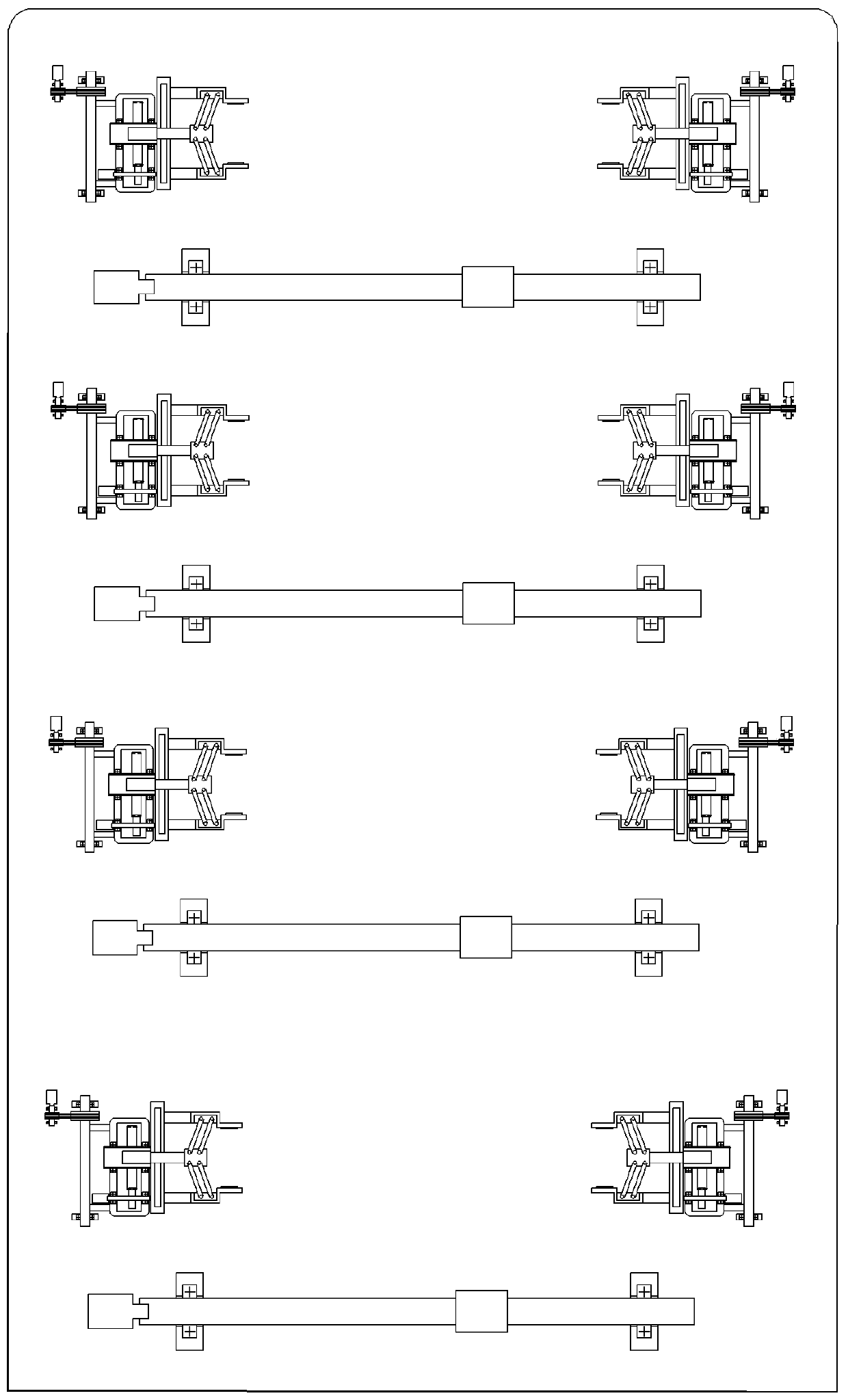

Image

Examples

Embodiment 1

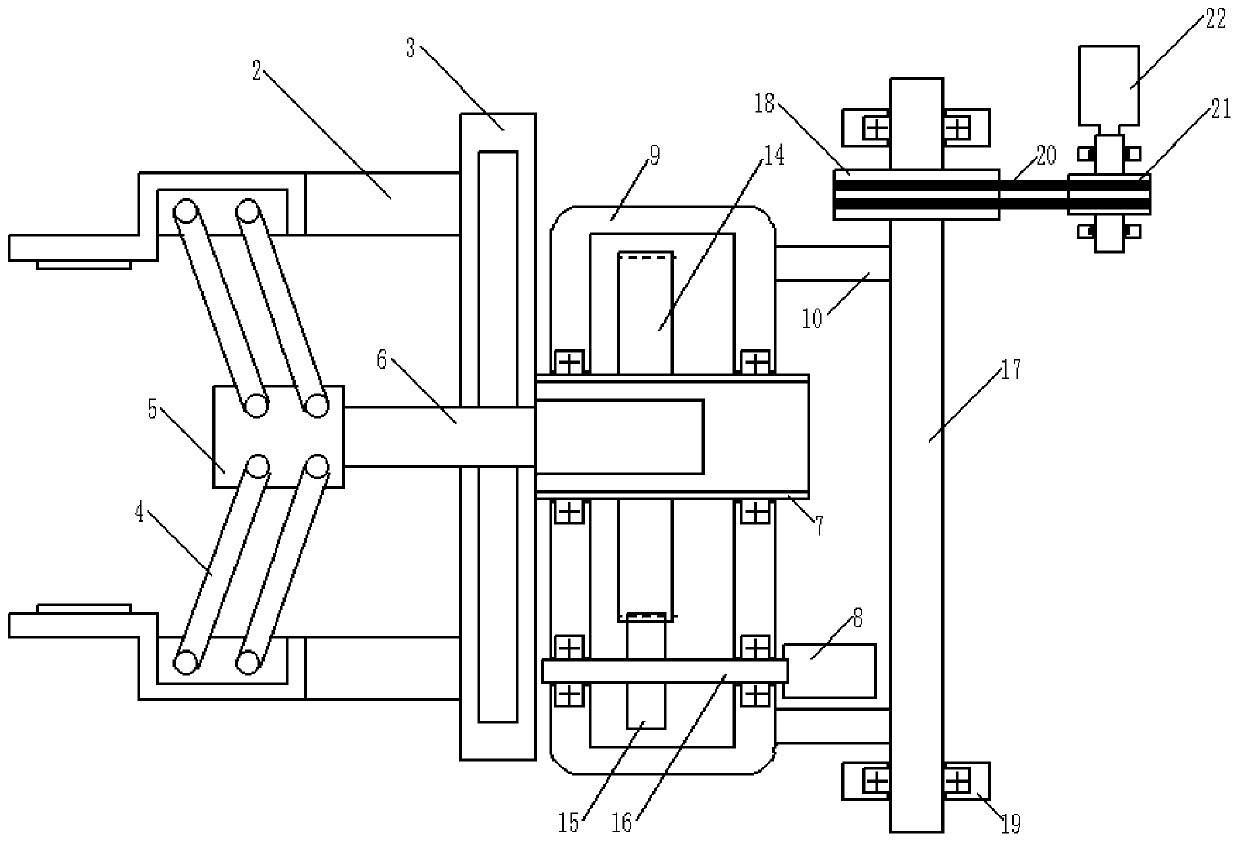

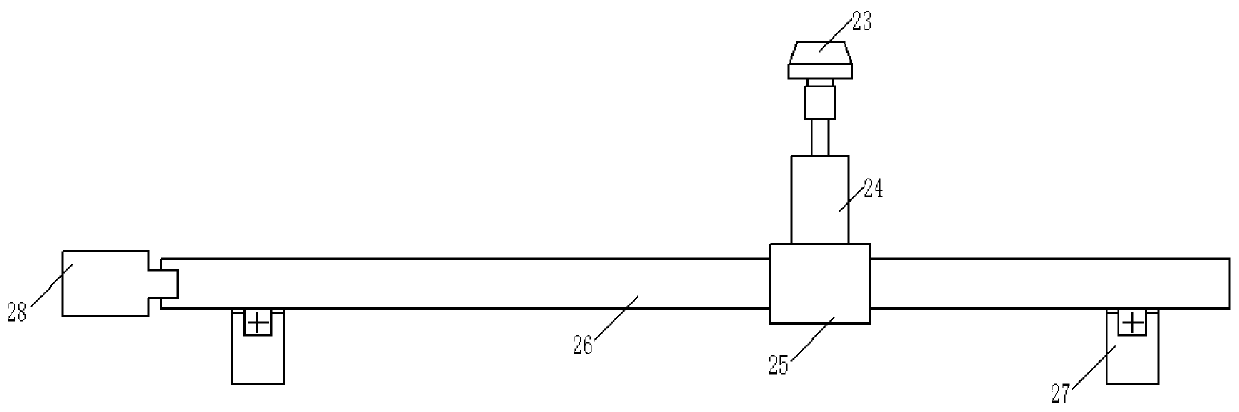

[0026] This embodiment provides a mechanical processing intelligent positioning device, which includes a positioning plate 1. The upper surface of the positioning plate 1 is provided with a plurality of clamping mechanisms for clamping thin-walled parts at different positions. The clamping mechanism includes two clamping mechanisms. Arm 2, the right ends of the two clamping arms 2 are slidably connected with the plate body 3 through a sliding assembly, the left ends of the two clamping arms 2 are fixedly connected with the block body 5 through the connecting rod 4, and the block body 5 is fixed on the first telescopic The telescopic end of the piece 6, the fixed end of the first telescopic piece 6 passes through the plate body 3 and is fixedly connected with the plate body 3; the side surface of the plate body 3 is fixed with a first rotating shaft 7, and the first rotating shaft 7 is connected to the first rotating shaft through a rotating mechanism. The output shaft of a moto...

Embodiment 2

[0031] This embodiment is based on Embodiment 1. The rotating mechanism includes a driven gear 14, the driven gear 14 is connected to the first rotating shaft 7 through a key, and both sides of the first rotating shaft 7 are connected to the housing 9 through bearings. The driving gear 14 meshes with the driving gear 15, and the driving gear 15 is connected with the second rotating shaft 16 through a key, and both sides of the second rotating shaft 16 are also connected with the housing 9 through bearings, and one end of the second rotating shaft 16 is connected with the first rotating shaft 16. The output shaft connection of the motor 8;

[0032] The rotary mechanism of the present application first starts the first motor 8 when in use, the first motor 8 drives the second rotating shaft 16 to rotate, the second rotating shaft 16 rotates to drive the driving gear 15 to rotate, the driving gear 15 rotates to drive the driven gear 14 to rotate, and the driven gear 14 rotates. Th...

Embodiment 3

[0034]This embodiment is based on Embodiment 1. The pitch angle adjustment mechanism includes a third rotating shaft 17, the side wall of the third rotating shaft 17 is fixedly connected to the ear plate 10, and one end of the third rotating shaft 17 is connected to the driven pulley 18 through a key. , both sides of the third rotating shaft 17 are connected with the first bearing seat 19 through bearings, the first bearing seat 19 is fixed on the upper surface of the positioning plate 1, the driven pulley 18 is connected with the driving pulley 21 through the timing belt 20, The central rotating shaft of driving pulley 21 is connected with second motor 22, and second motor 22 is the driver of pitch angle adjustment mechanism, and second motor 22 is connected with described microprocessor 11;

[0035] When the application needs to adjust the pitch angle, the control panel 29 sends a signal to the microprocessor 11, and the microprocessor 11 sends the signal to the second motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com