Stirrer for plant cell culture device

A culture device and plant cell technology, applied in tissue cell/virus culture device, biochemical cleaning device, enzymology/microbiology device, etc., can solve problems such as low degree of liquid mixing, loss of plant cell activity, cell membrane rupture, etc. , to avoid cell rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

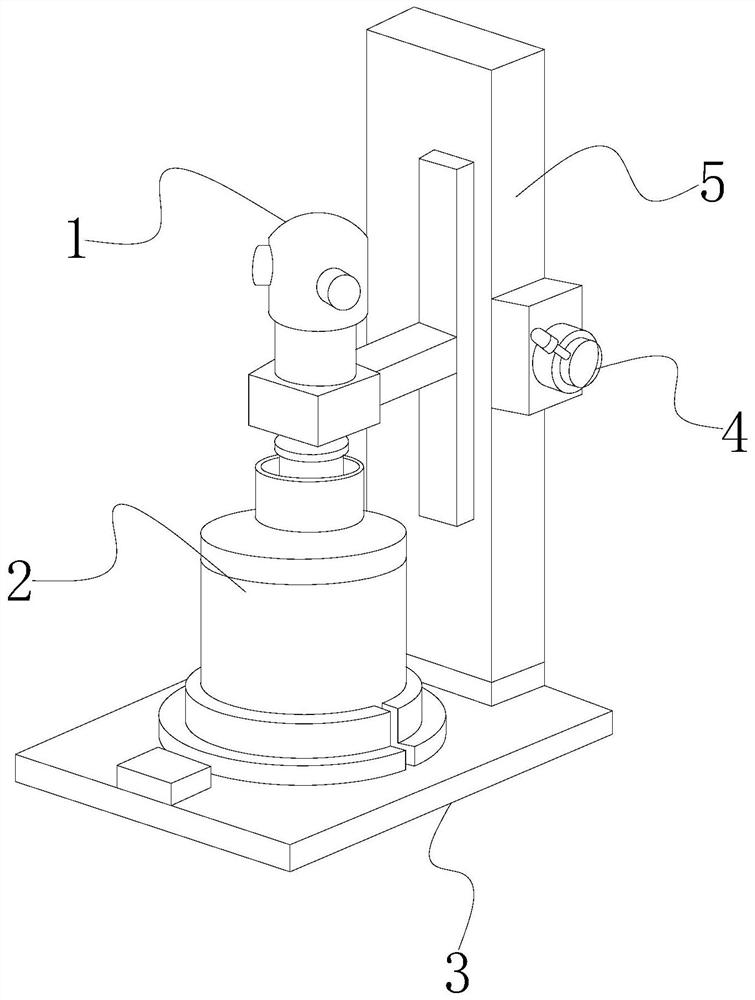

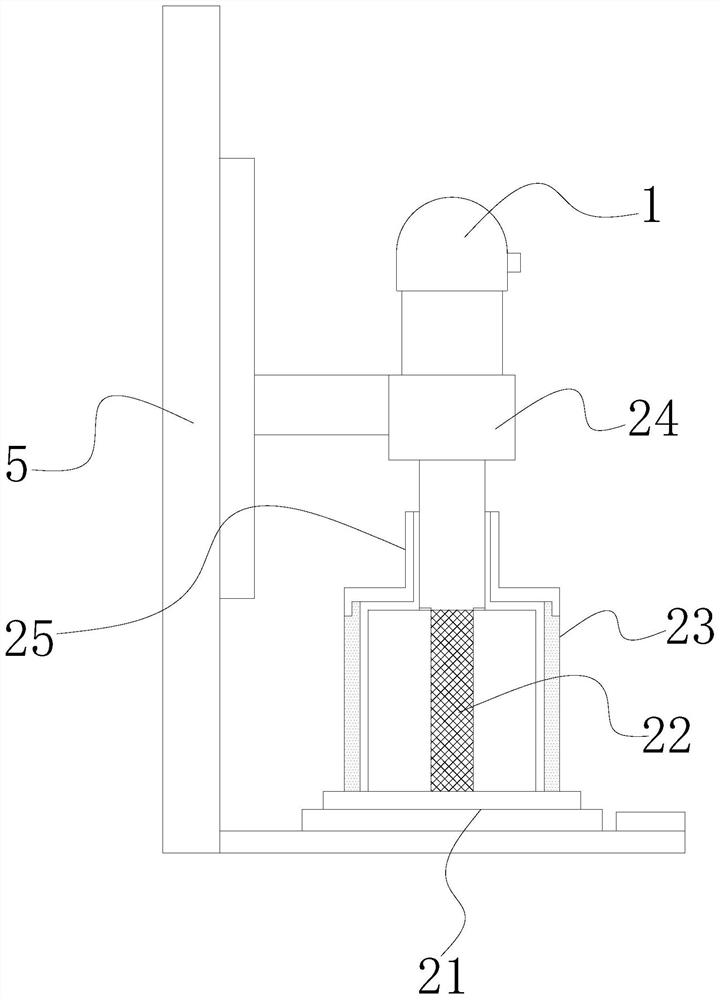

[0023] Such as Figure 1-Figure 5 Shown:

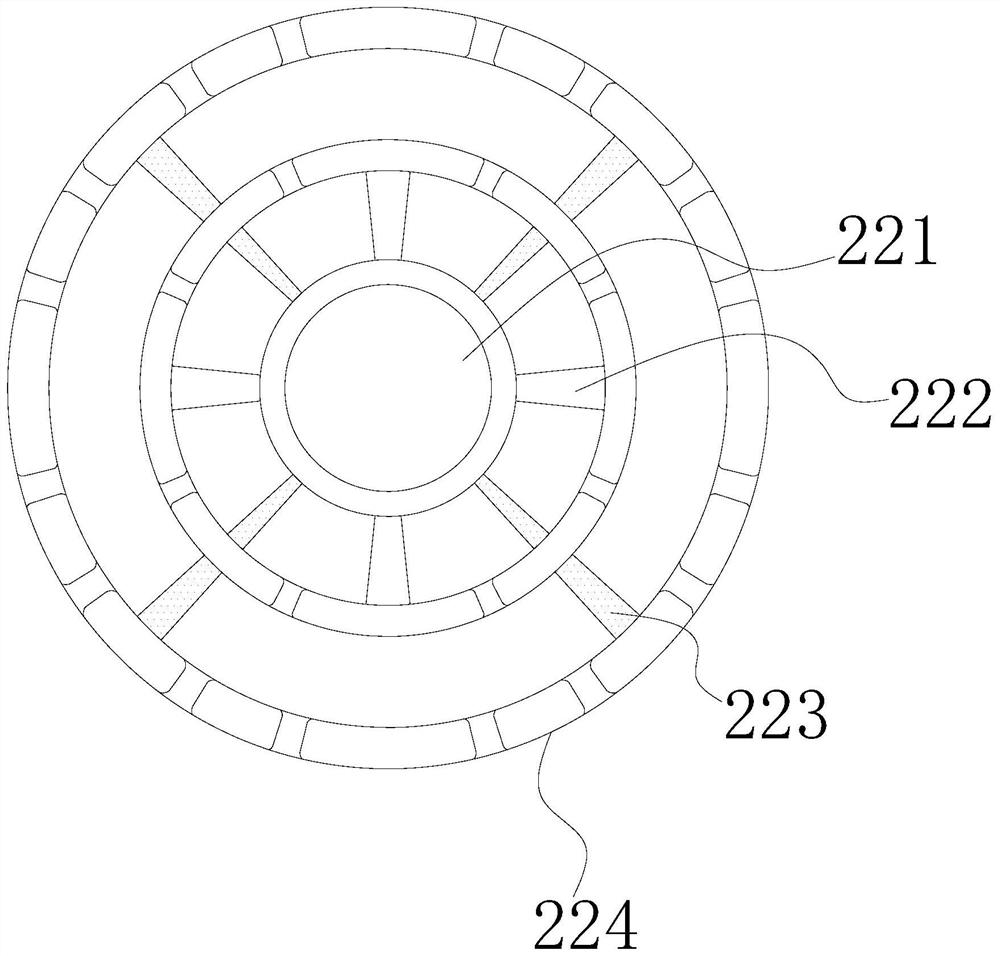

[0024] The present invention is an agitator for a plant cell culture device, its structure includes a motor 1, a stirring mechanism 2, a fixed plate 3, a controller 4, and a lifting plate 5, the motor 1 is embedded in the upper end of the agitating mechanism 2, and the The upper end of the stirring mechanism 2 is installed on the side of the lifting plate 5, the controller 4 is installed on the side of the lifting plate 5, the lower end of the stirring mechanism 2 is welded on the upper surface of the controller 4, and the lifting plate 5 is installed on the upper end of the fixed plate 3 , the stirring mechanism 2 is provided with a fixed tank 21, a stirring device 22, a placement tank 23, a fixer 24, and a blocking cover 25. , the blocking cover 25 is screwed with the placement tank 23, the lower end of the placement tank 23 is embedded in the fixing groove 21, the holder 24 is installed on the side of the lifting plate 5, and the ...

Embodiment 2

[0031] Such as Figure 6-Figure 7 Shown:

[0032] Wherein, the 233 is provided with a tilting mechanism w1, a sliding plate w2, and a drainage groove w3, the drainage groove w3 is attached to the inside of the sliding plate w2, the tilting mechanism w1 is located inside the sliding plate w2, and the sliding plate w2 is embedded Inside the fixing groove 21, the inclination angles between the drainage grooves w3 are the same, and the drainage groove w3 is a continuous curved structure, so that the liquid moves upwards following the drainage groove w3 under the action of the rotating force, thereby changing the horizontal position of the liquid.

[0033]Wherein, the tilting mechanism w1 is provided with a sealing groove w11, a force receiving block w12, a rubber plate w13, and a fixing frame w14, the sealing groove w11 is located on the right side of the rubber plate w13, and the force receiving block w12 is attached to the fixing frame w14 On the left side, the rubber plate w13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com