Heating body elastic supporting structure of mini electric cooker

An elastic support and electric rice cooker technology, which is applied to heating devices, cooking utensils, household utensils, etc., can solve the problems of easy shaking of electric heating devices, easy loss of heat around the inner tank, uneven heating, etc. Boiled, prevent heat loss easily, good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

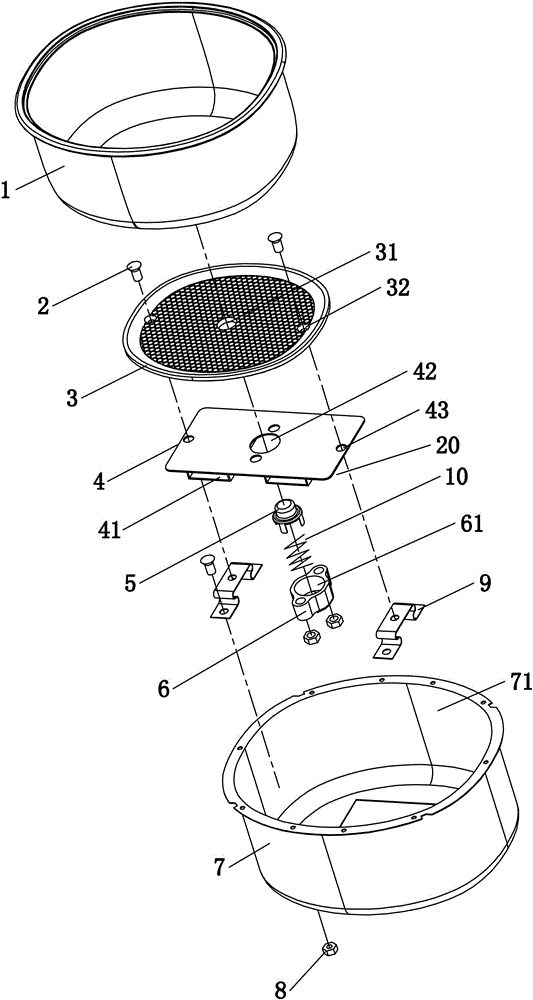

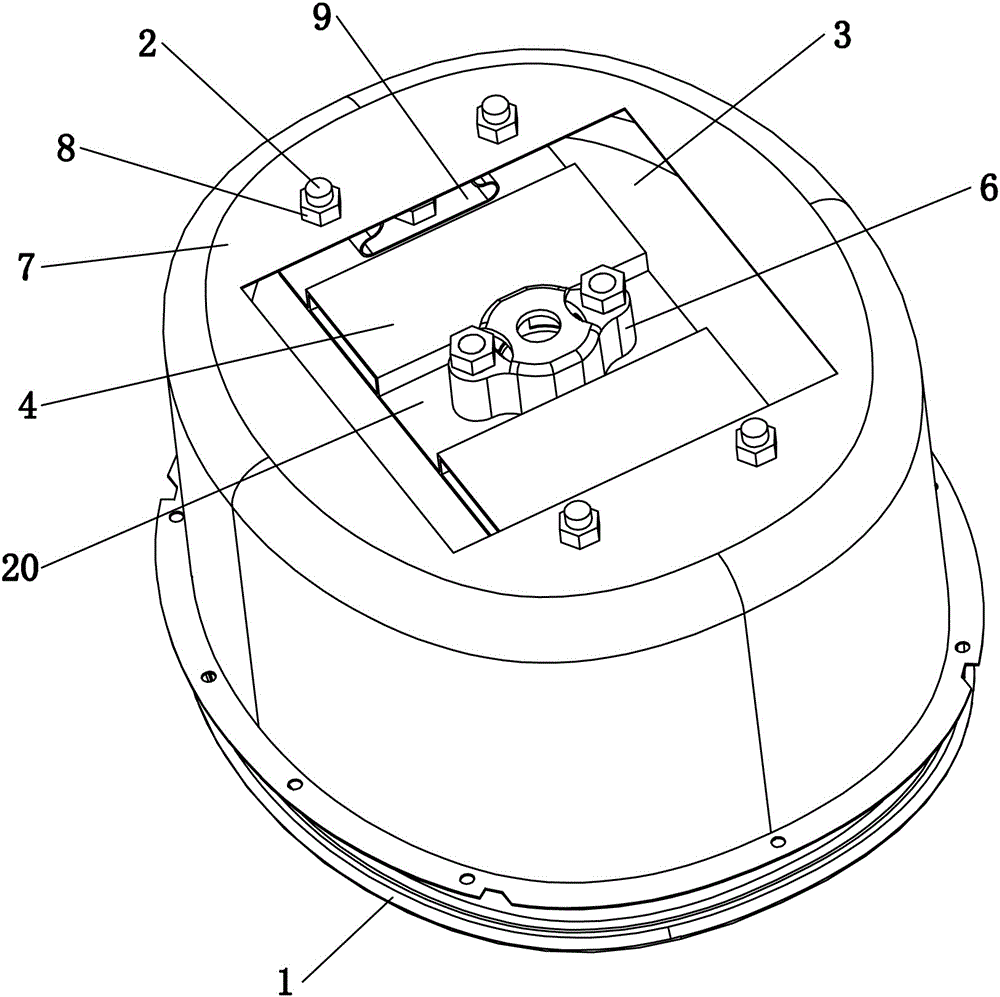

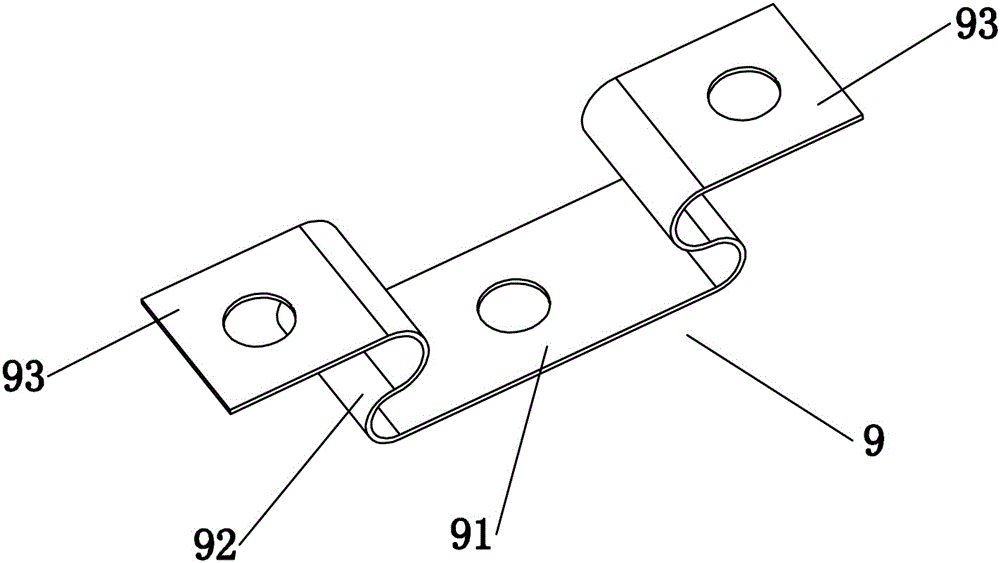

[0034] Embodiment one: if Figure 1 to Figure 3 As shown, the elastic support structure of the heating body of the miniature rice cooker includes an outer pot, an inner tank 1 and an electric heating device. The outer pot is provided with a middle layer 7, and the middle layer 7 is provided with an inner cavity 71. The electric heating device includes a heat conducting tray 3 and an electric heating device. The electric heating element 20, the electric heating element 20 is connected to the bottom of the heat conduction tray 3, and the electric heating device is arranged on the lower part of the inner chamber 71 of the middle layer 7 through the sheet elastic body 9, and the electric heating device is connected to the bottom wall of the inner chamber 71 of the middle layer 7 and There is a gap between the side walls. The sheet-shaped elastic body 9 is integrally formed by a supporting surface 91, a supporting surface 93 and an elastic surface 92. The supporting surface 91 and t...

Embodiment 2

[0040] The second embodiment differs from the first embodiment in that: Figure 8 As shown, the electric heating element 20 is a half-shell type PCT heating element, and the half-shell type PCT heating element includes a pressing plate 40 and a PTC heating element 30, and the pressing plate 40 is clamped between the supporting surface 91 of the sheet elastic body 9 and the heat conducting tray. 3 , the PTC heating element 30 is pressed against the bottom of the heat conduction tray 3 by the pressing plate 40 .

[0041] The top surface of the pressure plate 40 is provided with a concave surface 401 with an open top surface corresponding to the PTC heating element 30 , and the PTC heating element 30 is disposed in the concave surface 401 .

Embodiment 3

[0042] The third embodiment differs from the first embodiment in that: Figure 9 As shown, the electric heating element 20 is a shellless PCT heating element, and the shellless PCT heating element is a PTC heating element 30, and the PTC heating element 30 is clamped on the supporting surface 91 of the sheet elastic body 9 and the heat conducting tray between 3.

[0043] The support surface 91 is provided with a molded surface 94 corresponding to the PTC heating element 30 , and the PTC heating element 30 is pressed between the molded surface 94 and the heat conducting tray 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com