Uniform load floating mechanism with regulable floating quantity for planetary gear

A technology of planetary gears and floating mechanisms, which is applied in the direction of belts/chains/gears, mechanical equipment, transmission parts, etc., can solve problems such as lack, and achieve the effects of small size, step-by-step adjustment, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

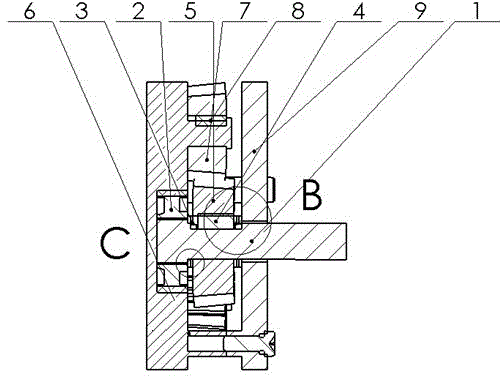

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

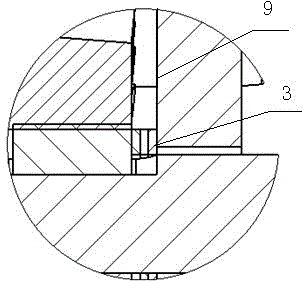

[0031] A planetary gear balance floating mechanism with adjustable floating amount, including a planetary carrier (6), a baffle (9), a gasket (3), a central shaft (1) and a planetary carrier (6) and a baffle (9) ) between the sun gear (5) and the planetary gear (7); the planet carrier (6) and the baffle (9) are connected by screws (10); one end of the central shaft (1) is connected to the planet carrier through a rolling bearing (6) connection, the other end passes through the center of the baffle (9); the sun gear (5) and the planetary gear (7) are bevel gears, the big end of the sun gear (5) and the planetary gear (7) The directions of the big ends are opposite and meshed with each other; the gasket (3) is sleeved on the central shaft (1) and located on both sides of the sun gear (5).

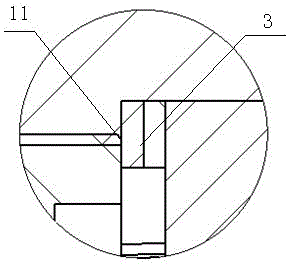

[0032] A shaft shoulder (11) is provided on the central shaft (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com