Rectification device and method for improving water distribution of diffusion type water inlet box culvert of urban water delivery pump station

A technology of rectification device and water inlet tank, which is applied in the direction of water supply device, water supply device, pump station, etc. It can solve the problems of partial flow in the sump of the pump station, poor water flow state, and uneven distribution of the flow velocity of the pump station, so as to achieve easy construction The production and rectification structure are simple, and the effect of improving the flow velocity distribution is

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

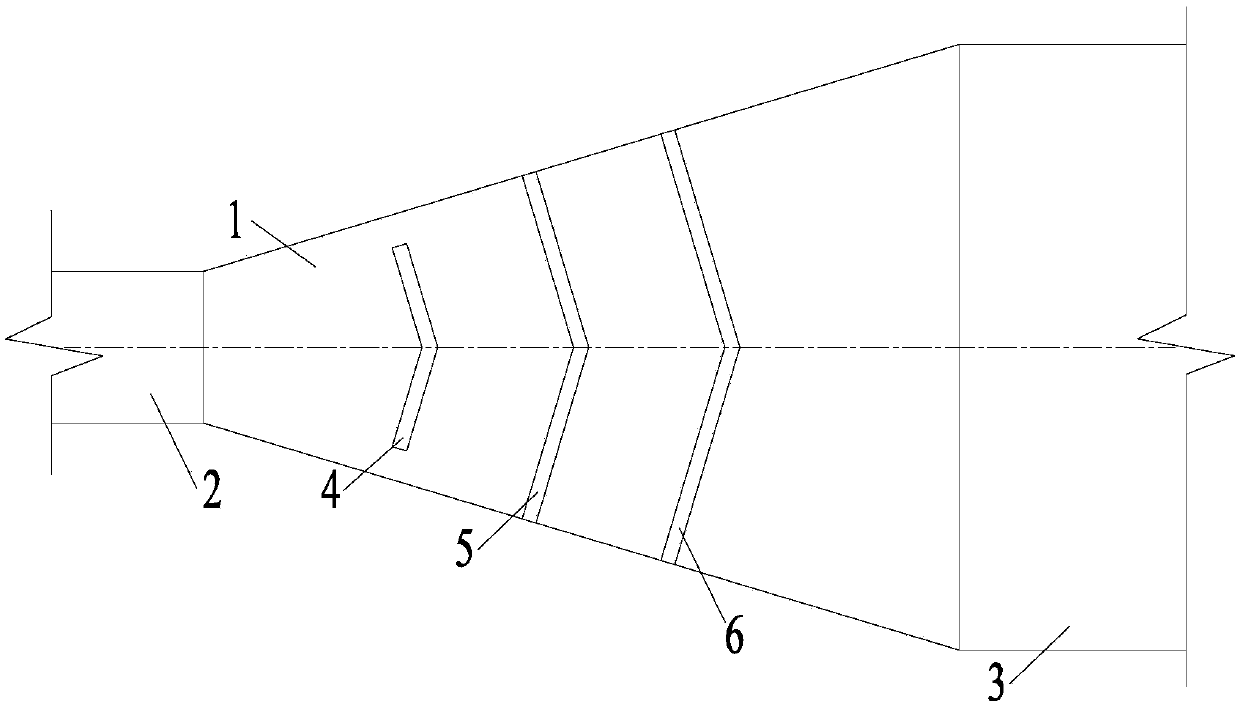

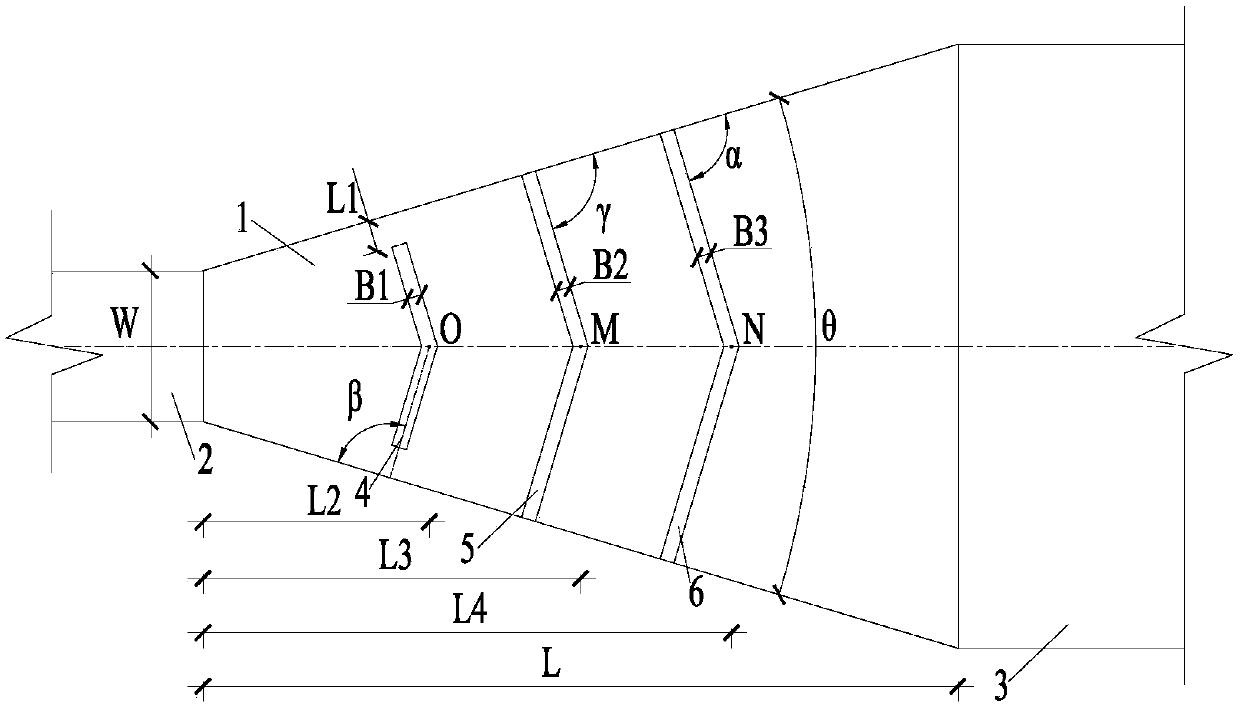

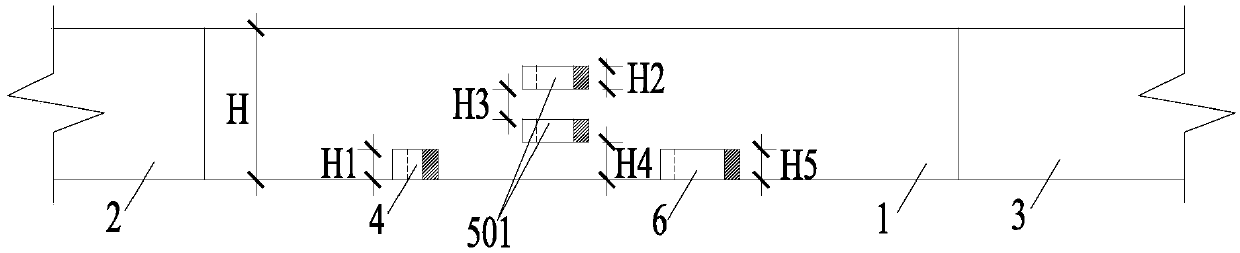

[0028] This embodiment improves the rectification device for the distribution of water in the diffusion type water inlet box culvert of the urban water pumping station, including the first bottom sill 4, the composite beam 5 and the second bottom sill 6 arranged in the diffusion type water inlet box culvert 1 along the water flow direction , wherein, the first bottom sill 4 and the second bottom sill 6 are folded, are located on the bottom surface of the diffusion-type water inlet box culvert and are arranged symmetrically along the center line of the diffusion-type water inlet box culvert; The composite beam 5 includes two beams 501 vertically arranged up and down, each beam is folded and arranged symmetrically along the center line of the diffused water inlet box culvert, and the two sides of each beam in the composite beam are aligned with the corresponding The side walls of the water tank culvert are connected, and the two ends of the second bottom sill are vertically conne...

Embodiment 2

[0031] This embodiment improves the rectification device for water distribution of diffused water inlet tank culverts in urban water delivery pumping stations. The difference from Embodiment 1 is that the extension lines of the two sides of the first bottom sill are connected with the clamping walls of the corresponding inlet tank culverts. Angle β=90°, distance L1=0.15W=0.6m between the end of the first bottom sill and adjacent culvert wall of the water inlet tank, height H1=0.3H=1.2m, width B1=0.15 of the first bottom sill W=0.6m, the distance between the center point O of the first sill and the inlet of the water inlet box culvert L2=0.15L=3m; the width of each beam of the composite beam B2=0.125W=0.5m, the height of a single beam H2=0.15H = 0.6m, the distance between two beams H3 = 0.2H = 0.8m, the height of the lowest beam from the bottom of the water inlet box culvert H4 = 0.25H = 1m, the center point M of each beam in the composite beam and the inlet of the water box cul...

Embodiment 3

[0033] This embodiment improves the rectification device for water distribution of diffused water inlet tank culverts in urban water delivery pumping stations. The difference from Embodiment 1 is that the extension lines of the two sides of the first bottom sill are connected with the clamping walls of the corresponding inlet tank culverts. Angle β=60°, distance L1=0.2W=0.8m between the end of the first bottom sill and the side wall of the corresponding inlet tank culvert, height H1=0.2H=0.8m, width B1=0.1W of the first bottom sill = 0.4m, the distance between the center point O of the first sill and the inlet of the water box culvert L2 = 0.2L = 4m; the width of each beam in the composite beam B2 = 0.15W = 0.6m, the height of a single beam H2 = 0.2H=0.8m, the distance between two beams H3=0.1H=0.4m, the height of the lowest beam from the bottom of the water inlet box culvert H4=0.3H=1.2m, the distance between the center point M of the composite beam and the inlet of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com