A spring type piezoelectric pump with valve

A piezoelectric pump and spring-type technology, which is applied in the field of spring-type piezoelectric pumps with valves, can solve the problems of long reaction time of the passive valve body and achieve the effects of reduced possibility, improved performance and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. (but protection scope of the present invention is not limited to this.)

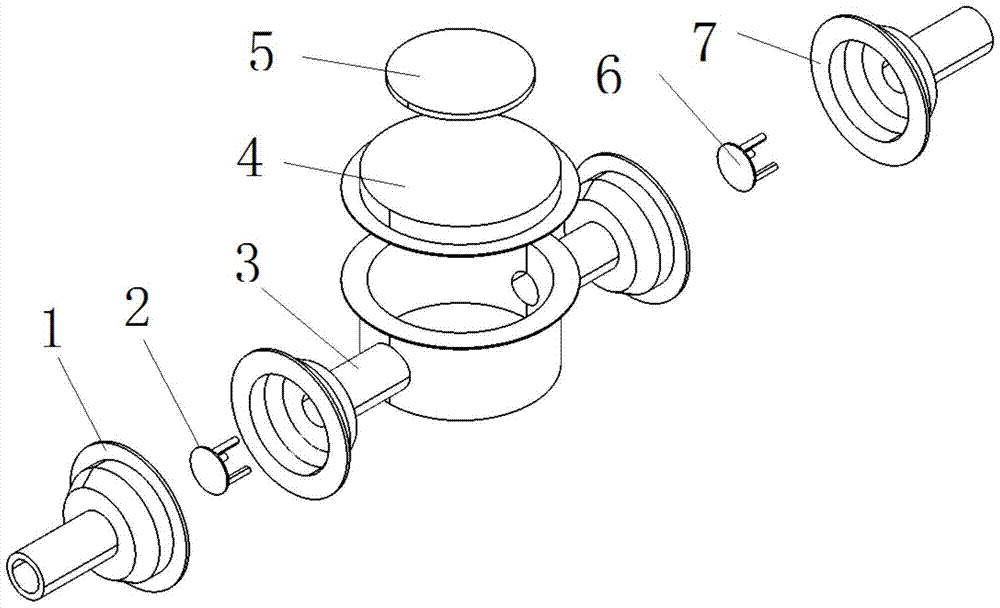

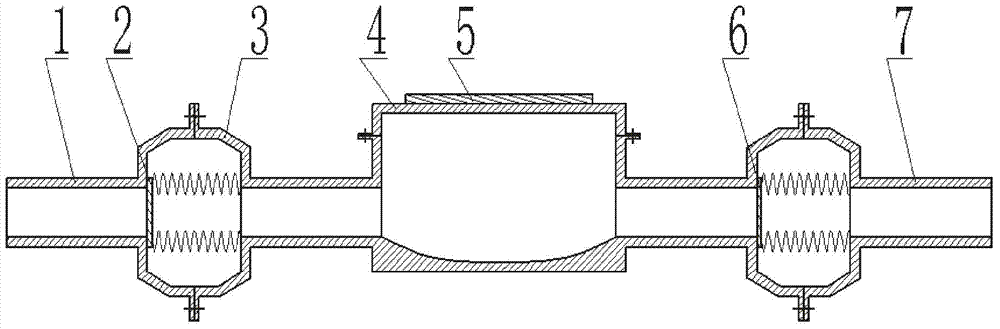

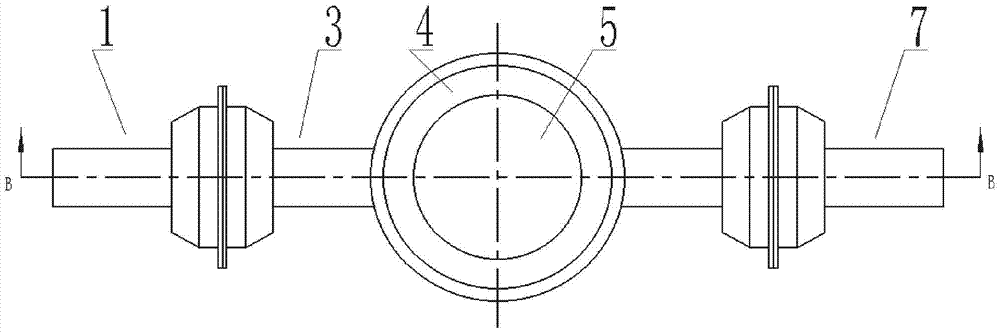

[0032] A piezoelectric pump with a spring valve body and a valve is mainly composed of a pump body, a piezoelectric chip, a rigid element, an elastic diaphragm, an elastic film, an inlet check valve, an outlet check valve and a controller. The left and right sides of the pump body are symmetrically arranged, and the inlet and outlet valve bodies are arranged in the same direction, so that when one of the valve bodies is open and working, the other is in a closed state, which can realize one-way transmission of liquid.

[0033] In the present invention, the pump body adopts 3D printing technology and uses plastic high molecular polymer, which has strong rigidity and high strength. Preferably, the one-way valve in the present invention is made of polymer rubber, which has good toughn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com