Novel fire extinguishing pipeline system

A fire extinguishing pipe, a new type of technology, applied in fire rescue and other directions, can solve the problems of pressure loss, small flow, uneven flow distribution and other problems along the way, and achieve the effect of reducing energy loss, reducing pressure loss, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

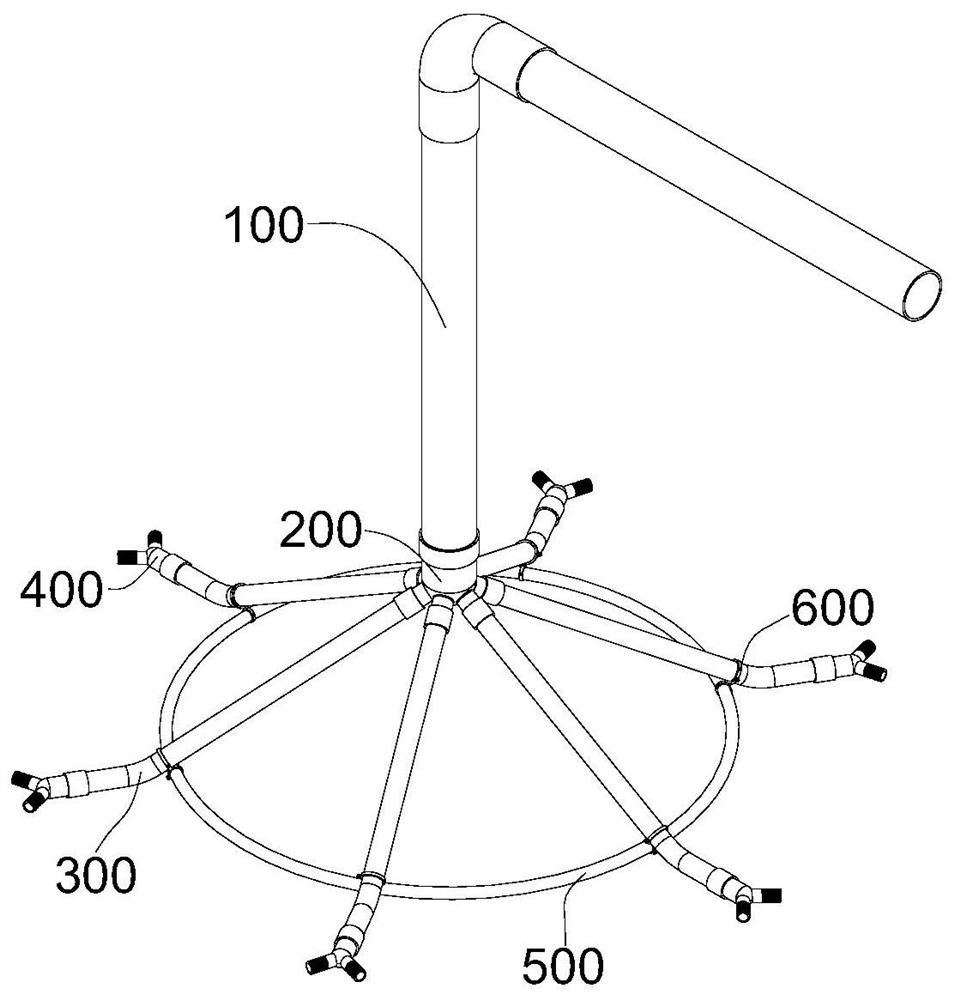

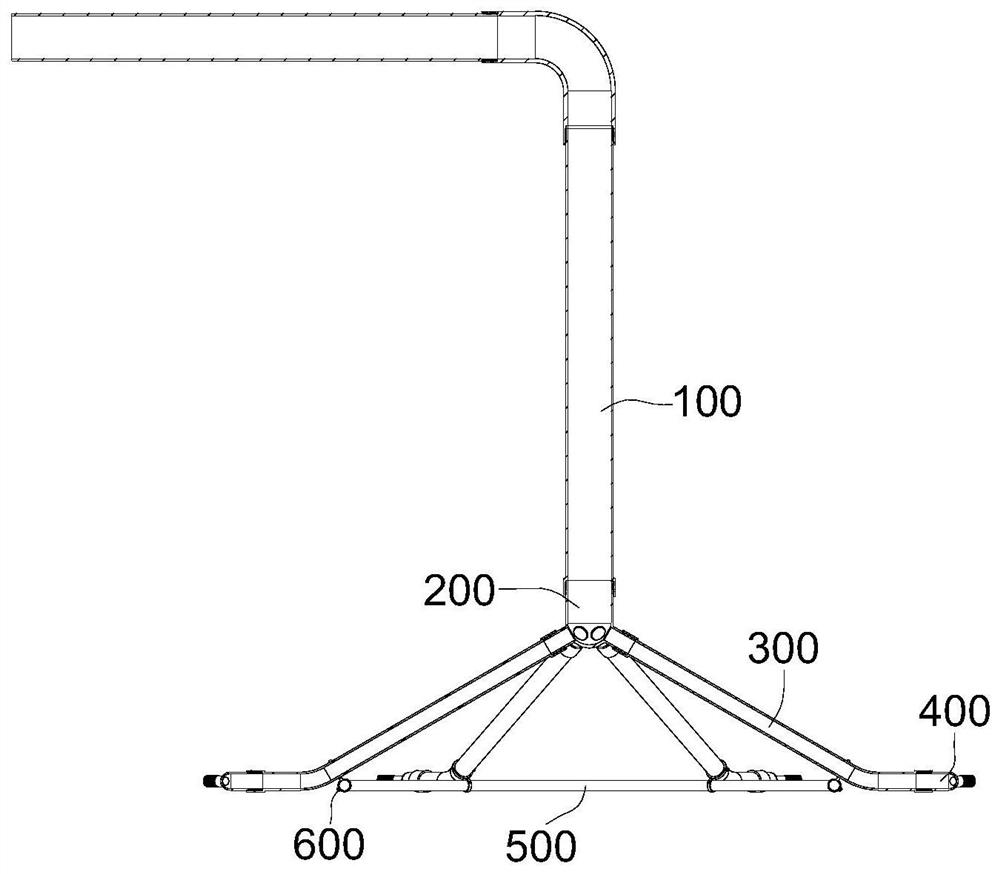

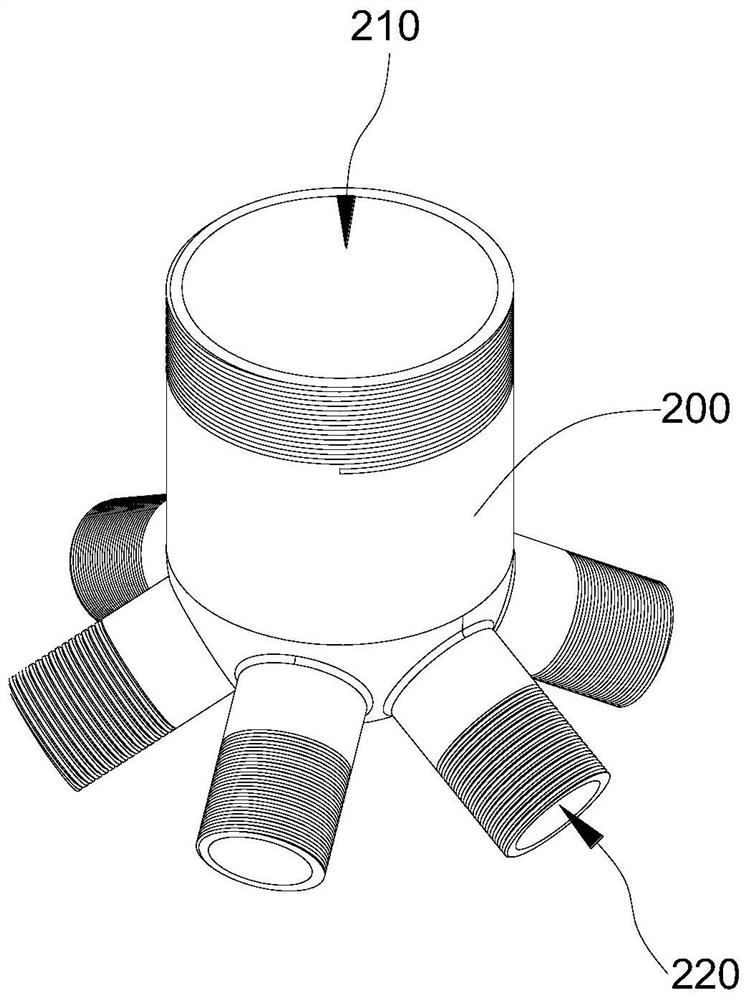

[0026] like Figure 1 to Figure 12 As shown, the embodiment of the present invention discloses a novel fire extinguishing pipeline system, which includes a main pipeline and at least two auxiliary pipelines. The main pipeline includes a main pipeline 100 and a spherical branch fluid 200, and the spherical branch fluid 200 includes a cavity A body 230, a first flow channel 210 and at least two second flow channels 220, the main flow pipe 100 communicates with the first flow channel 210, the first flow channel 210 and the at least two second flow channels 220 are both connected to The cavity 230 is in communication, at least two of the second flow channels 220 are evenly distributed along the circumferential direction of the spherical shunt 200, and the second flow channels 220 and the first flow channel 210 are arranged obliquely; the The auxiliary pipeline includes a connecting pipe 300 and a joint 400. One end of the connecting pipe 300 is connected to the spherical shunt 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com