Foam prevention and control industrial dust method and evaluation device

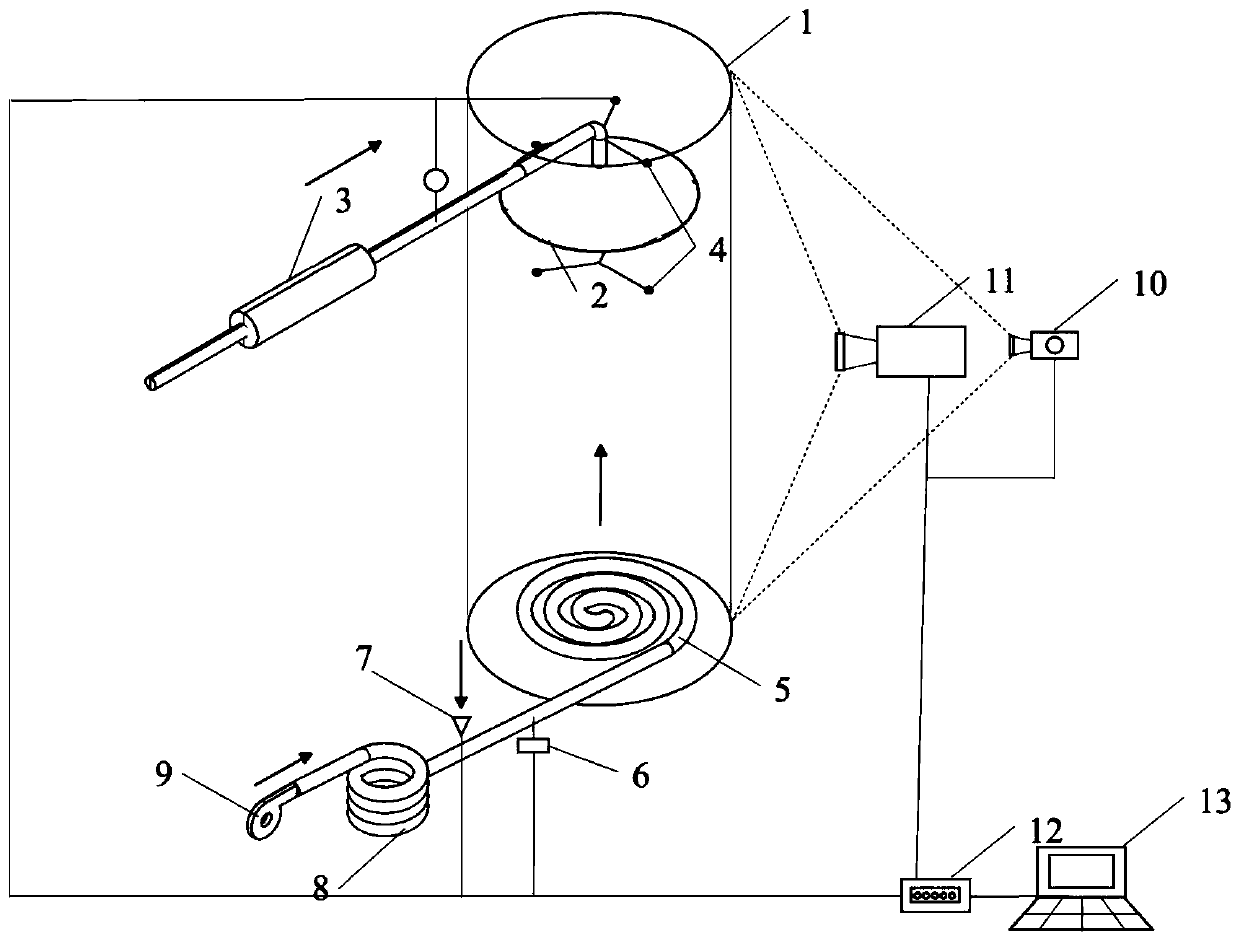

A technology of foam generating device and testing device, which is applied in the direction of measuring device, separation method, chemical instrument and method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

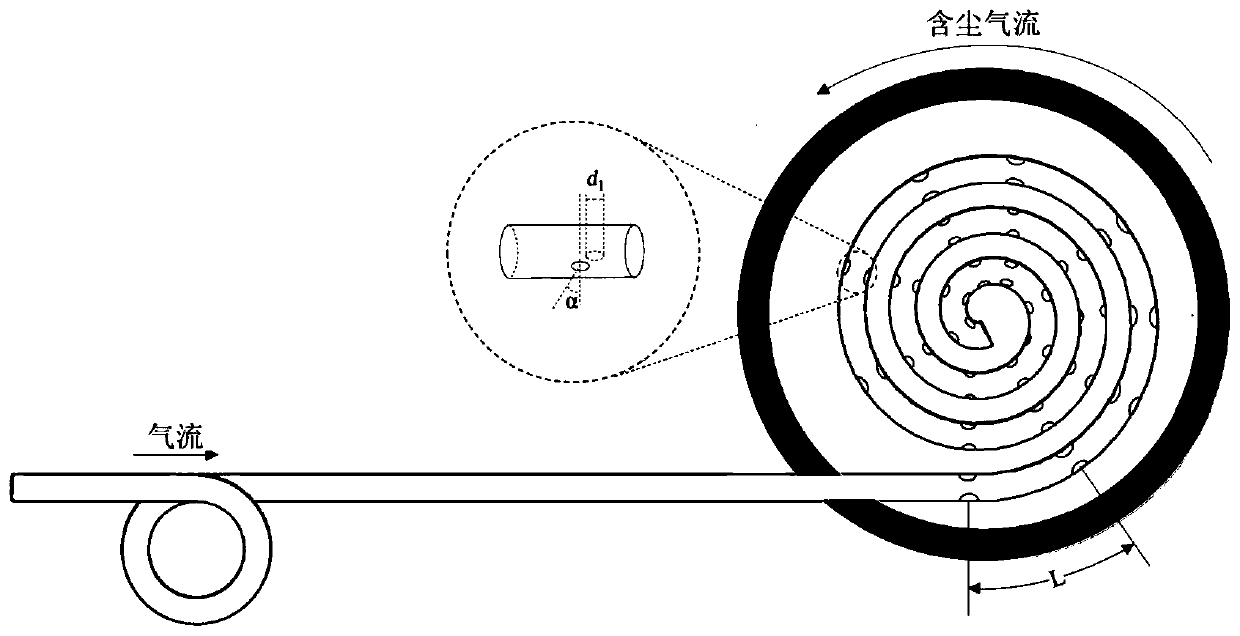

Method used

Image

Examples

Embodiment 2

[0076] An embodiment of the present invention is a foam performance evaluation method for preventing and controlling industrial high-temperature dust, which is used in the experimental platform described in any one of Embodiment 1, comprising the steps of:

[0077] Arrange the experimental platform, start the air supply device and the heating device, and add dust into the dust control device;

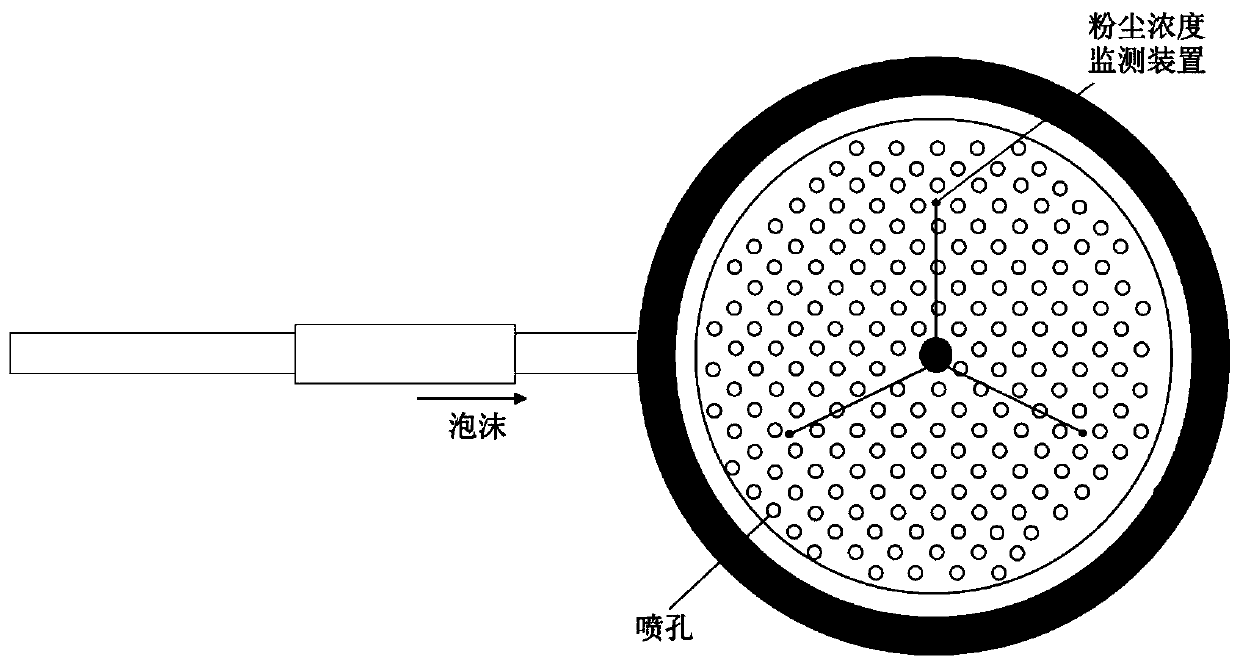

[0078] After the uniformly mixed dusty airflow is evenly distributed in the transparent shell, the dust concentration monitoring system is started to monitor the initial dust concentration under the condition of no foam dust removal, and the external foam generating device is started. The foam includes gel foam, magnetized foam, water Base foam, heterogeneous foam, etc.;

[0079] By controlling the heating device, changing the temperature of the dust-laden airflow, respectively monitoring the change of the dust concentration at different temperatures, so as to measure the dust removal e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com