A Tundish for Electromagnetically Suppressing Submerged Nozzle Clogging

A tundish, immersion technology, applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

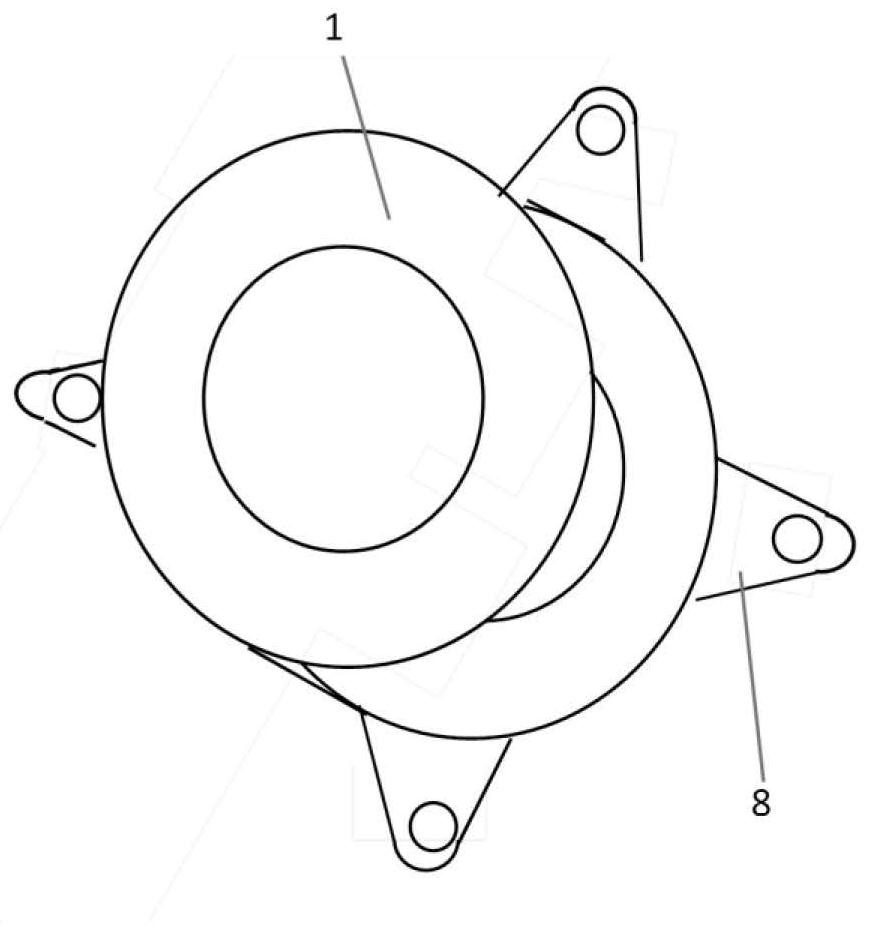

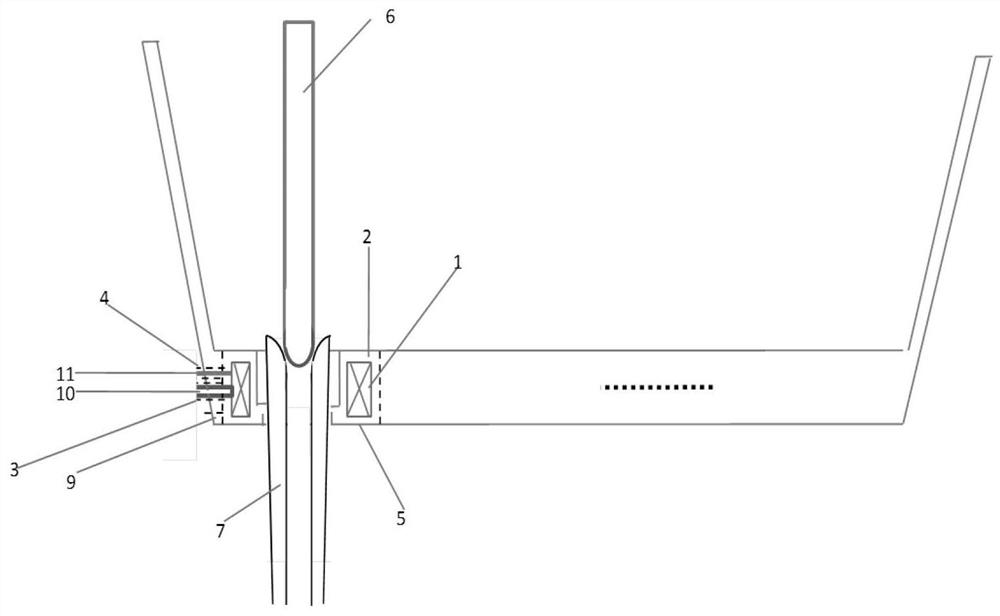

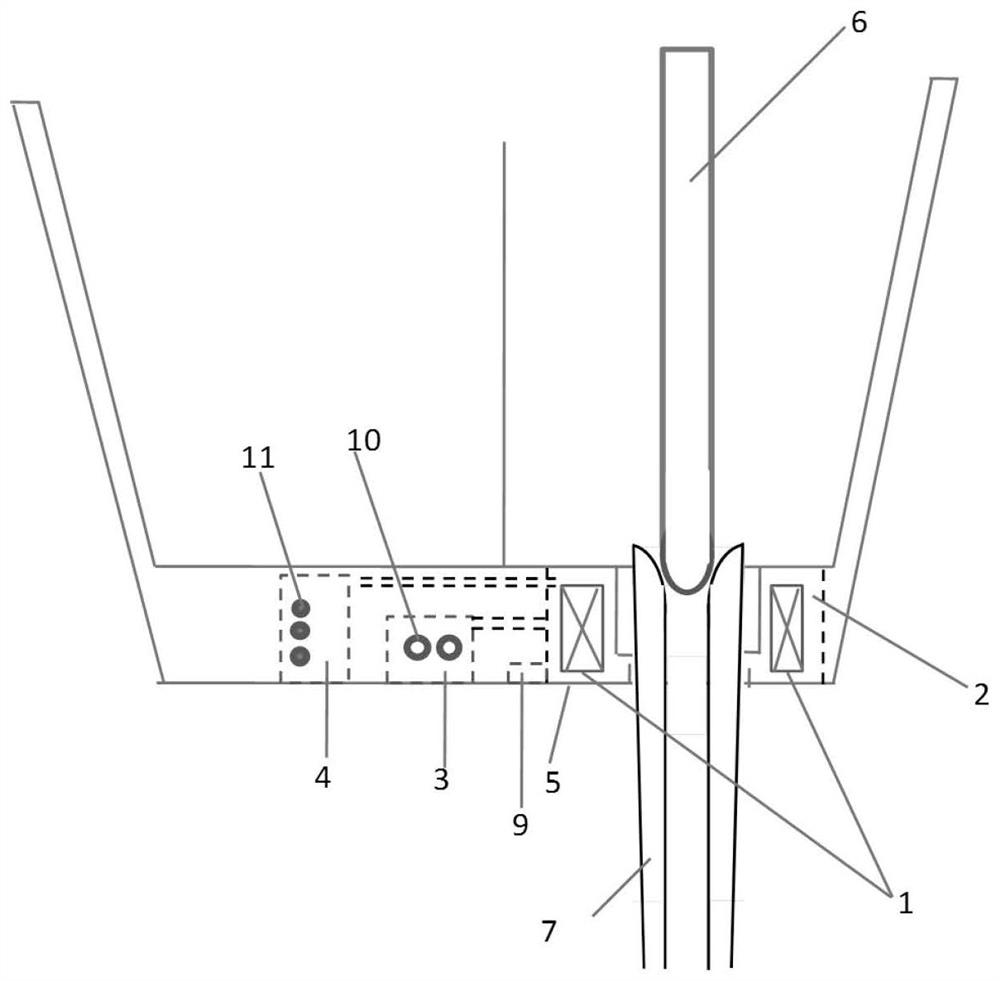

[0033] The utility model relates to a tundish for suppressing blockage of a submerged nozzle by electromagnetic means. The rotating magnetic field generating device is a ring-shaped device, which adopts cogging type concentrated winding, the frequency is 5Hz, the current is 1500A, and the magnetic induction intensity is 10 1 Tesla, the direction of rotation of the magnetic field is clockwise. The rotating magnetic field generating device uses a fixed supporting plate to be placed in the cavity of the rotating magnetic field generating device, and the fixing method may be screw connection. Both the waterway and the electric circuit need to be led out to the right end of the tundish for quick connection, and a single-flow slab tundish is used. There are installation holes for the submerged nozzle on the waterproof supporting plate, forming a closed space together with the cavity of the tundish, and there are leakage channels on both sides.

Embodiment 2

[0035] The utility model relates to a tundish for suppressing blockage of a submerged nozzle by electromagnetic means. The rotating magnetic field generating device is a circular device, using Clem winding, the frequency is 300Hz, the current is 10A, and the magnetic induction is 10 -4 Tesla, the direction of rotation of the magnetic field is counterclockwise. The rotating magnetic field generating device uses a fixed supporting plate to be placed in the cavity of the rotating magnetic field generating device, and the fixing method may be screw connection. Both the waterway and the electric circuit need to be led out to the left end of the tundish for quick connection, and a 6-strand billet tundish is used. There are installation holes for the submerged nozzle on the waterproof supporting plate, forming a closed space together with the cavity of the tundish, and there are leakage channels on both sides.

Embodiment 3

[0037] The utility model relates to a tundish for suppressing blockage of a submerged nozzle by electromagnetic means. The rotating magnetic field generating device is a ring-shaped device, which adopts cogging type concentrated winding, the frequency is 100Hz, the current is 800A, and the magnetic induction is 10 -2 Tesla, the direction of rotation of the magnetic field is counterclockwise. The rotating magnetic field generating device uses a fixed supporting plate to be placed in the cavity of the rotating magnetic field generating device, and the fixing method may be screw connection. Both the waterway and the electric circuit need to be led out to the left end of the tundish for quick connection, and a 3-strand large round billet tundish is used. There are installation holes for the submerged nozzle on the waterproof supporting plate, forming a closed space together with the cavity of the tundish, and there are leakage channels on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com