Submersed nozzle for plate blank electromagnetic rotational flow continuous casting

An immersion and electromagnetic technology, applied in the direction of casting equipment, casting melt containers, manufacturing tools, etc., can solve problems such as adverse effects, achieve the effects of preventing entanglement, reducing the impact of mold wide surface, and suppressing negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

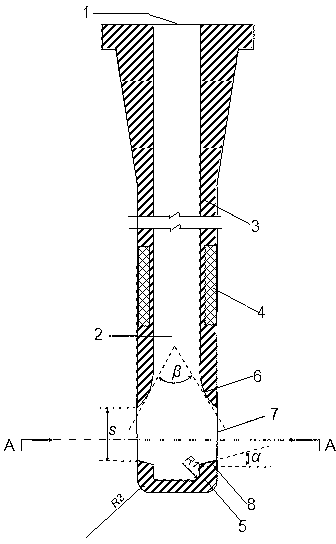

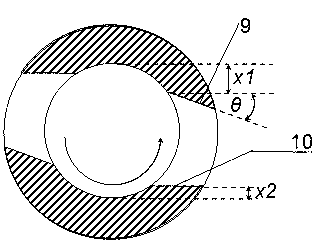

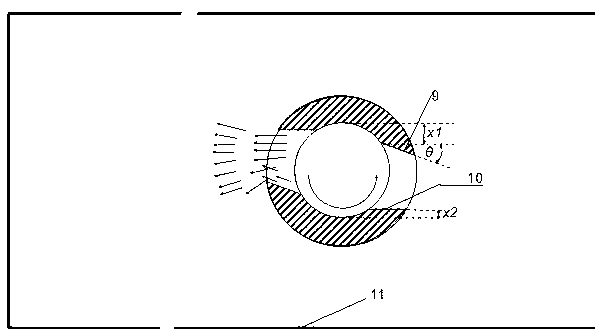

[0034] A submerged nozzle for slab electromagnetic swirl continuous casting, with a length of 700mm, an inner diameter of 50mm, and an outer diameter of 90mm. The cross-sectional shape of the hollow inner cavity 2 is flat with front and rear planes and left and right arc surfaces, and the hollow inner cavity is straight. , the depth of the slag line 4 is 10mm, the height of the slag line 4 is 100mm, the distance between the lower end of the slag line 4 and the lower surface of the nozzle bottom 5 is 100mm, and the inner curved surface 6 of the upper edge of the molten steel discharge hole on both sides is clamped by the tangent line horn β The value of 30°, the bottom structure of the nozzle is a convex bottom, chamfered R2 The value of is 0mm, the height s of the molten steel spout hole is 50mm, the shape is a rectangle with chamfers, and the inclination angle of the slope 8 at the lower edge of the molten steel spit hole α The value of +30°, the angle between the inwardly i...

Embodiment 2

[0036] A submerged nozzle for slab electromagnetic swirling continuous casting, with a length of 900mm, an inner diameter of 70mm, and an outer diameter of 120mm. The cross-sectional shape of the hollow inner cavity 2 is circular, and the hollow inner cavity adopts a tapered type. The depth of the slag line 4 is 15mm, the height of the slag line 4 is 130mm, the distance between the lower end of the slag line 4 and the lower surface of the nozzle bottom 5 is 150mm, and the angle between the tangent line of the inner curved surface 6 on the upper edge of the molten steel discharge hole on both sides β The value of 60°, the bottom structure of the nozzle is flat bottom, chamfered R2 The value of s is 10mm, the value of the height s of the molten steel spit hole is 60mm, the shape is circular, and the inclination angle of the slope 8 at the lower edge of the molten steel spit hole α The value of is 0°, the angle between the inwardly inclined side 9 of the molten steel spout hole a...

Embodiment 3

[0038] A submerged nozzle for slab electromagnetic swirl continuous casting, with a length of 1200mm, an inner diameter of 100mm, and an outer diameter of 150mm. The cross-sectional shape of the hollow inner cavity 2 is a square with chamfered corners. 300mm, the depth of the slag line 4 is 25mm, the height of the slag line 4 is 160mm, the distance between the lower end of the slag line 4 and the lower surface of the nozzle bottom 5 is 200mm, and the inner curved surface 6 of the upper edge of the molten steel spout hole on both sides is tangent angle of β The value of 120°, the bottom structure of the nozzle is a concave bottom, chamfered R1 The value of 20mm, chamfer R2 The value of s is 20mm, the value of the height s of the molten steel spit hole is 100mm, and the shape is a combination of semicircle and square in the middle. α The value of -30°, the angle between the inwardly inclined side 9 of the molten steel discharge hole and the wide surface of the crystallizer θ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com