Purification device scanning leak detection system

A purification device and leak detection technology, which is applied in the field of online scanning leak detection system, can solve the problems of large space, complex mechanism, unevenness, etc., and achieve the effect of improving versatility and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

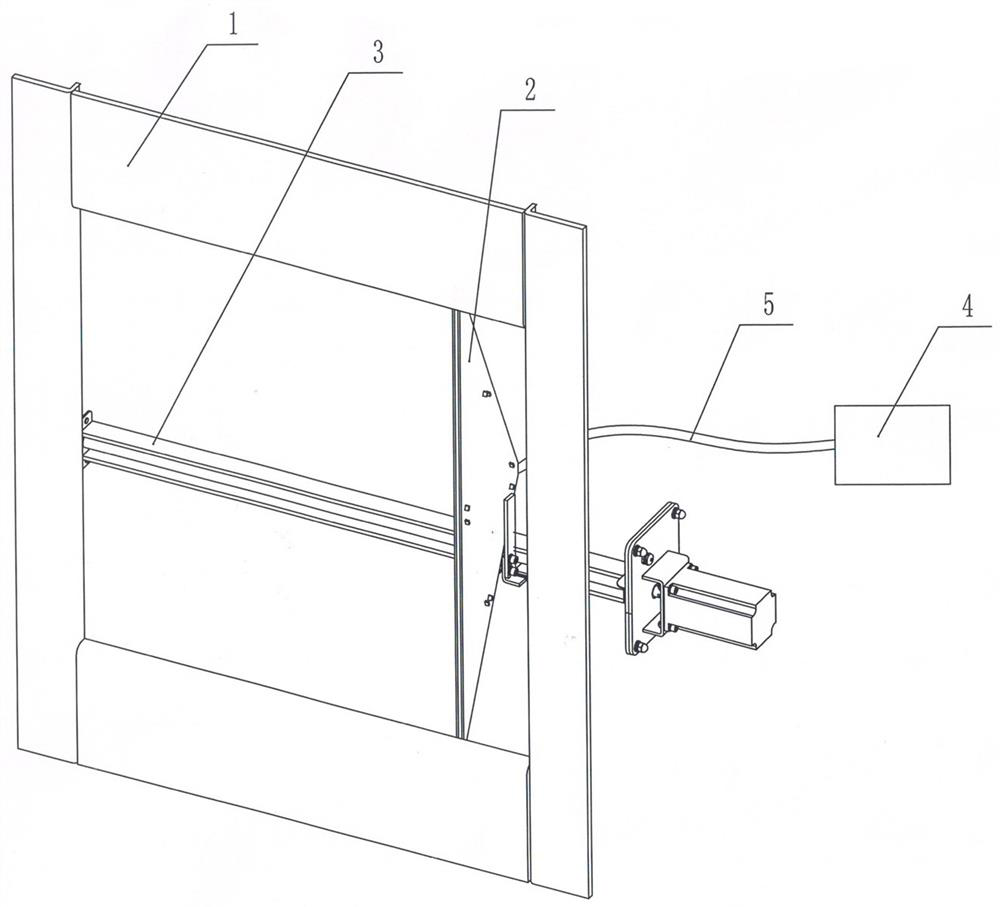

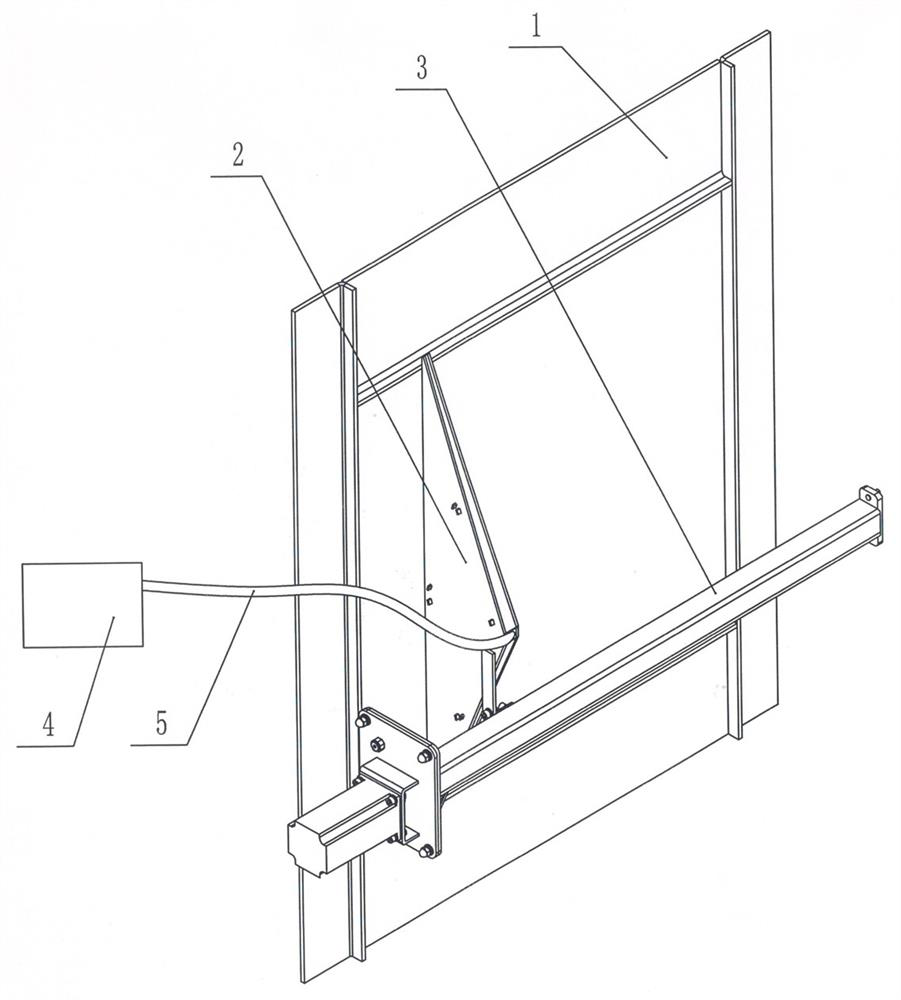

[0027] The present invention will be further described below in conjunction with the accompanying drawings:

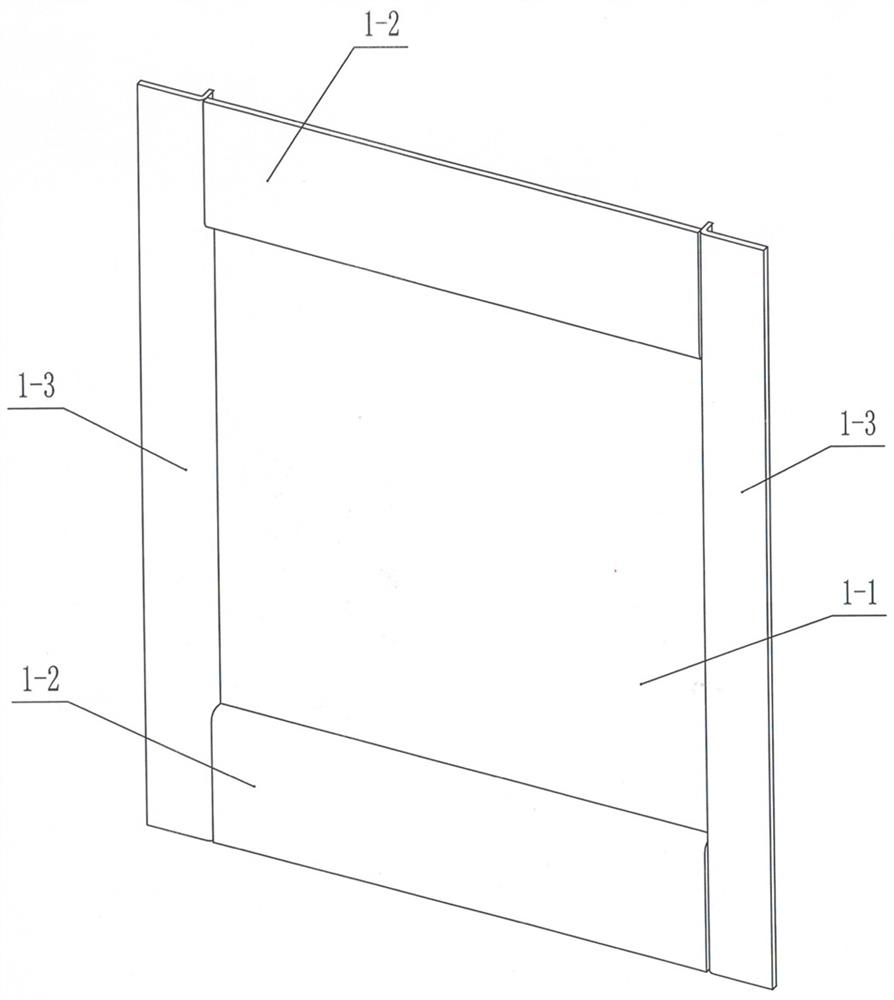

[0028] Such as Figure 1~Figure 8 As shown, a purifying device scanning leak detection system system of the present invention includes a bent frame 1 with a rectangular frame structure (the bent frame 1 is the installation basis of the present invention. As a connecting part of the present invention and the filter outlet, the present invention can be designed as a supporting system A number of racks 1 with different outer edge sizes and different purification device specifications are available for selection: just change the width of the cross beams 1-2 and vertical beams 1-3 used in the assembled frame 1, and the outer edges can be flexibly adjusted The size of the rack 1 used in conjunction with the specifications of the corresponding purification device expands the scope of application of the present invention; the rack outlet 1-1 of the optional rack has the same widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com