Novel environment-friendly anhydrous stemming for blast furnace iron notch and preparation method of stemming

An anhydrous taphole clay and taphole technology, applied in the field of refractory materials, can solve the problems of increasing the labor intensity of drill pipe workers, difficulty in drilling with strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

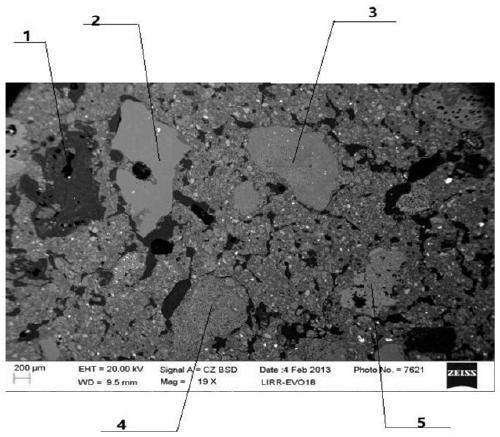

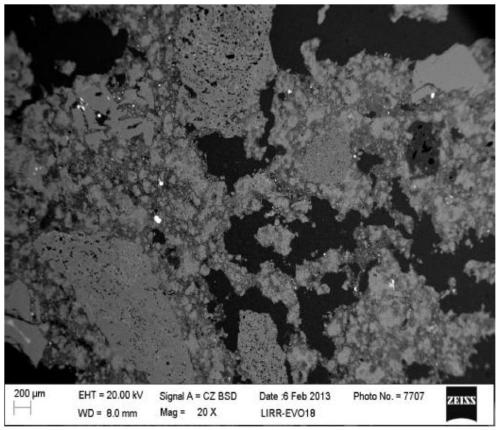

Image

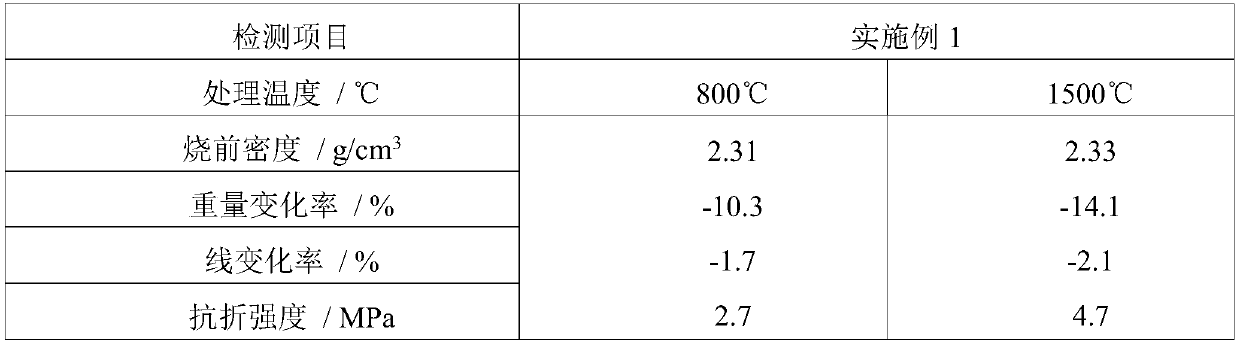

Examples

Embodiment 1

[0027] A kind of preparation method of the novel environment-friendly anhydrous taphole clay used in blast furnace taphole, comprises the following steps:

[0028] (1) Ingredients: weigh according to the formula ratio, and prepare materials for production. 12 parts of coke with a particle size of 1-3mm, 15 parts of calcined pyrophyllite particles of 1-3mm, 12 parts of brown corundum particles of 1-3mm, 12 parts of bauxite powder with a particle size of 100-200 mesh, and nitriding of 100-200 mesh 10 parts of ferrosilicon, 8 parts of silicon carbide powder of 100-200 mesh, 12 parts of clay of 100-200 mesh, and 5 parts of carbon-based composite material of 100-200 mesh are mixed ingredients to prepare raw materials;

[0029] (2) Premixing: Pour qualified raw materials into a strong mixer, mix for 5 minutes, and gradually add 8 parts of composite binders with a particle size of 100-200 mesh while stirring, to prepare a pretreatment material;

[0030] (3) Stirring and grinding: Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com