Simple fold line scaling supersonic nozzle for numerical control laser cutting

A technology of supersonic nozzle and numerical control laser, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex curve of nozzle inner wall, increase of gas turbulence, and decrease of effective cutting area, etc. CNC cutting accuracy and cutting efficiency, easy processing and manufacturing, uniform and tidy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in detail below with reference to the drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following Mentioned examples.

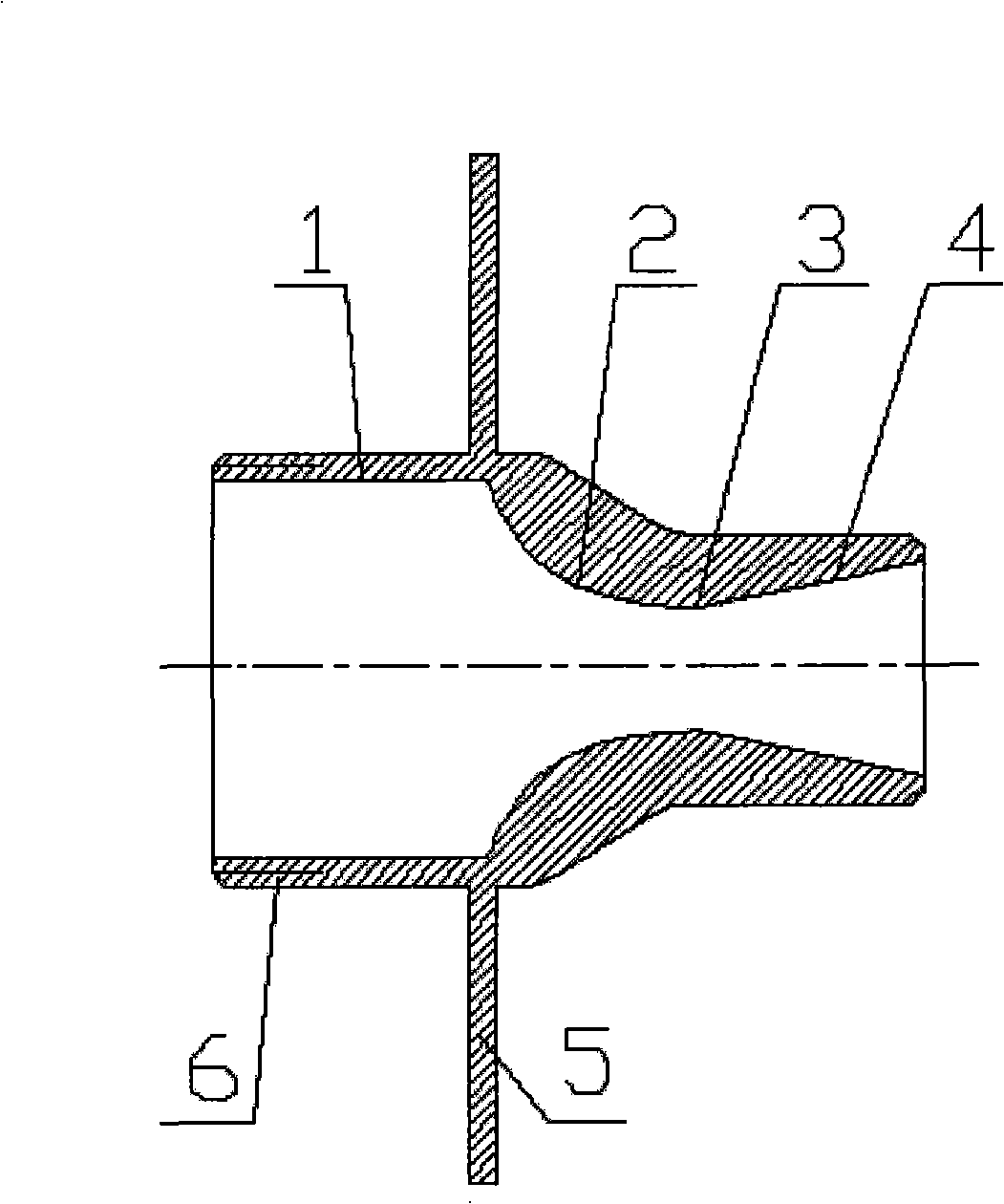

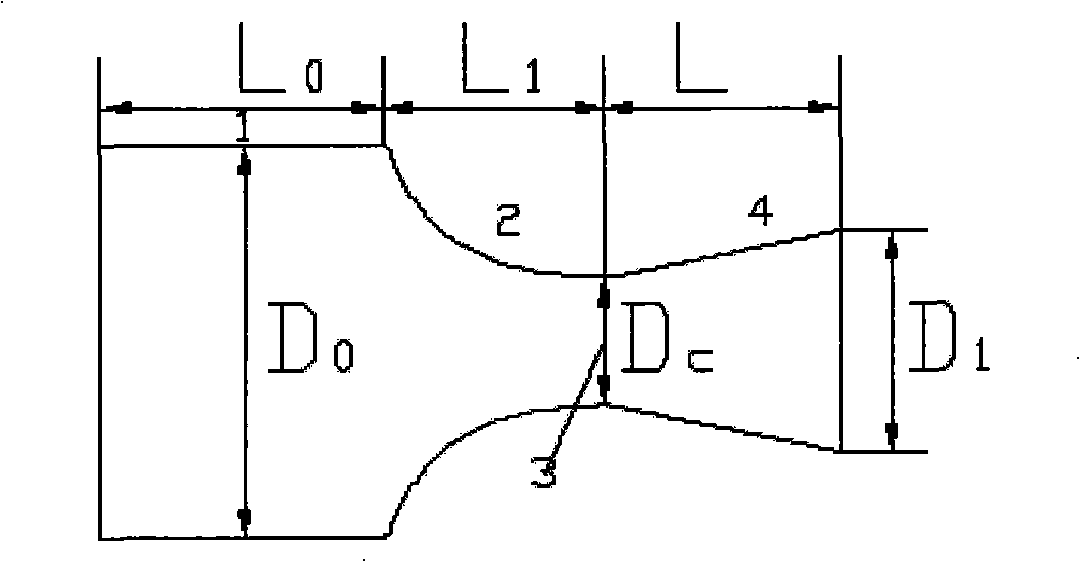

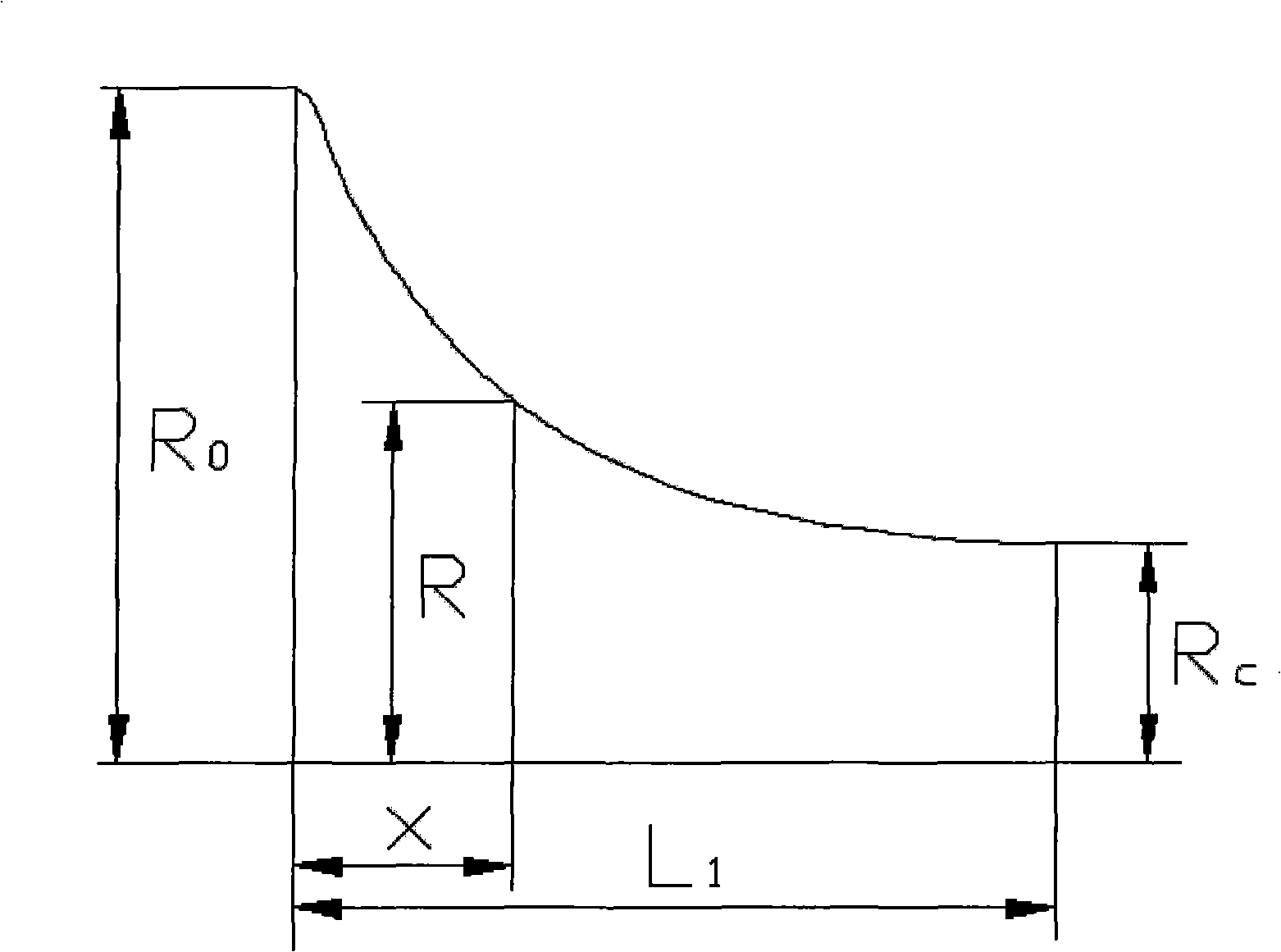

[0017] Such as figure 1 As shown, this embodiment includes: a parallel section 1, a contraction section 2, a throat 3, and an expansion section 4, which are constituted as a connected whole. The inlet of the parallel section 1 is connected to the laser gas cavity to store high-pressure auxiliary gas, the outlet of the parallel section 1 is connected to the inlet of the contraction section 2, the outlet of the contraction section 2 is connected to the left side of the throat 3, and the right side of the throat 3 is connected to the expansion section 4 and the throat 3 The design is used to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com