Steel rail on-line wind-jet quenching heat treatment simulation experiment device

A technology for simulating experimental equipment and steel rails, applied in the field of iron and steel metallurgy, can solve the problems of unstable thermal conductivity, turbulent heat energy volatilization, high energy consumption, etc., and achieve the effects of uniform hardness distribution, uniform cooling, and scientific process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

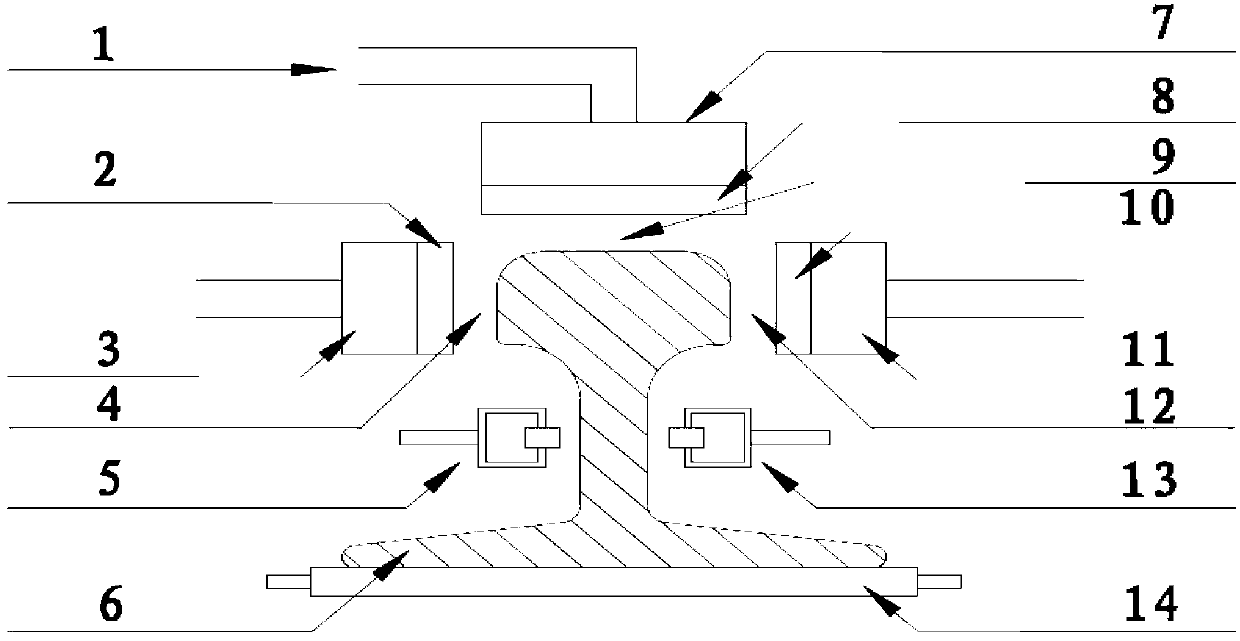

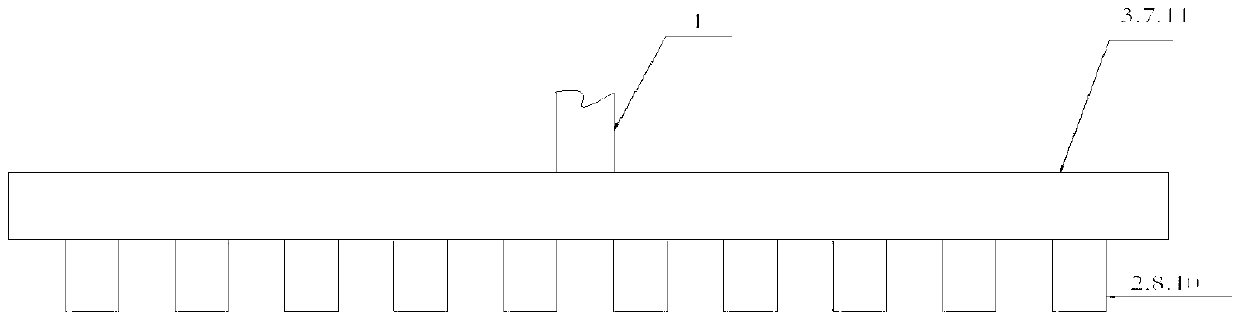

[0056] For adopting the jet cooling process, a novel cooling device has been designed, namely a kind of rail online jet quenching heat treatment simulation experiment device of the present invention (see figure 1 ), which consists of the following structures: nozzle system, rail guiding device, rack, valve, compressed air pipeline, testing instrument, heating furnace, etc.

[0057] The frame (not shown in the figure) is a steel structure welded by channel steel. The nozzle system (3 combined parts) and the rail guide (3 combined parts) are all fixed on the frame as independent combined parts. The compressed air is connected to the compressed air line of the 3 nozzle system through the laboratory compressed air line.

[0058] Air source: The air source of the rail online jet quenching heat treatment simulation experiment device adopts industrial compressed air pipeline or 3-5m 3 / min air compressor 3 sets.

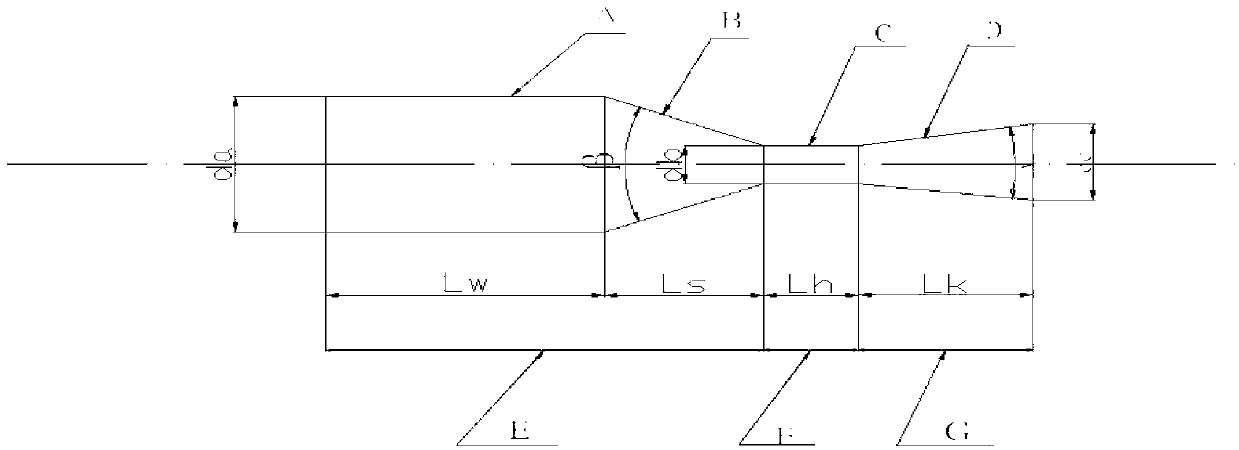

[0059] The nozzle system includes compressed air pipeline 1, rail he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com