Patents

Literature

96results about How to "Uniform hardness distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

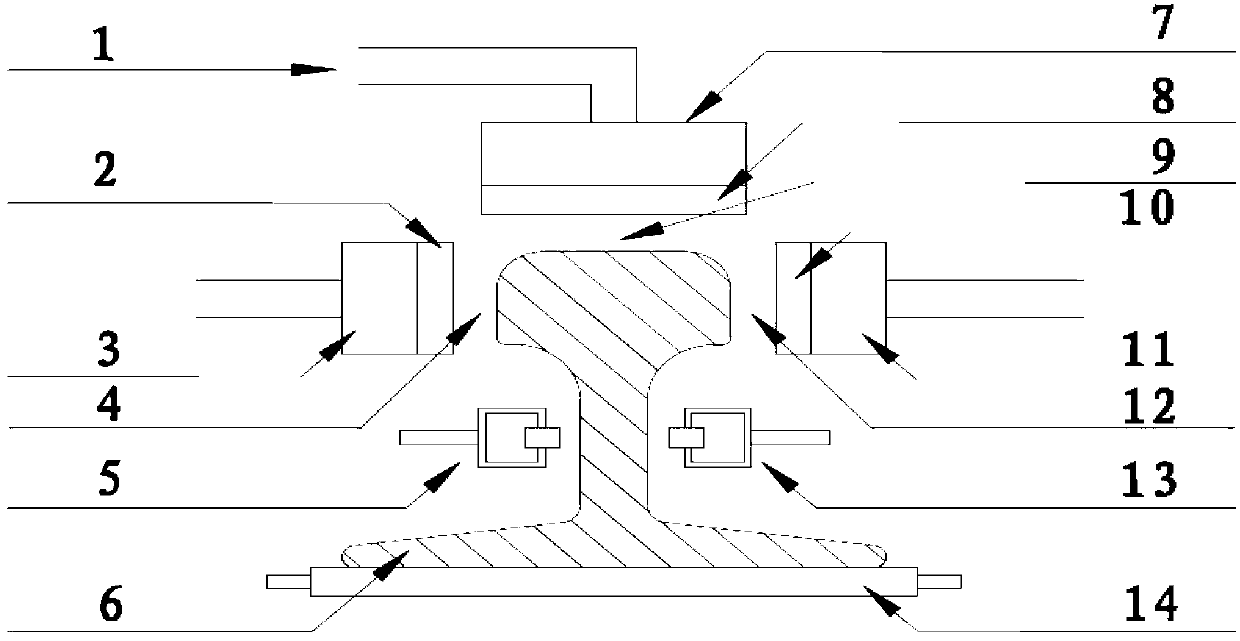

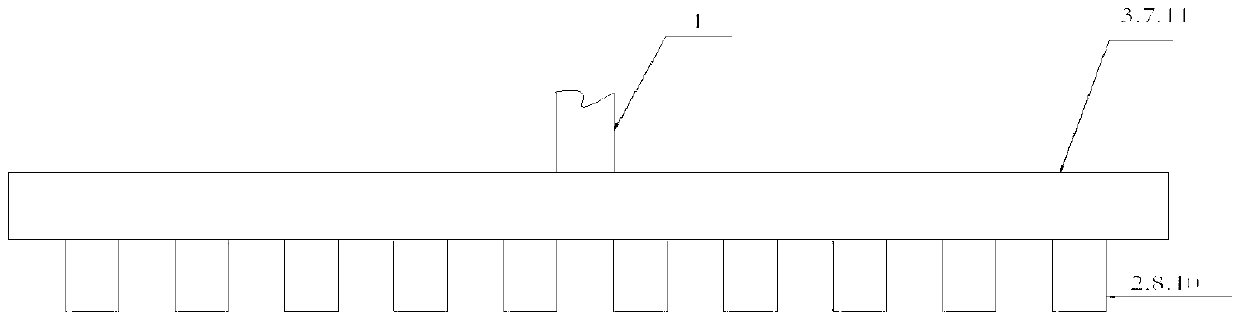

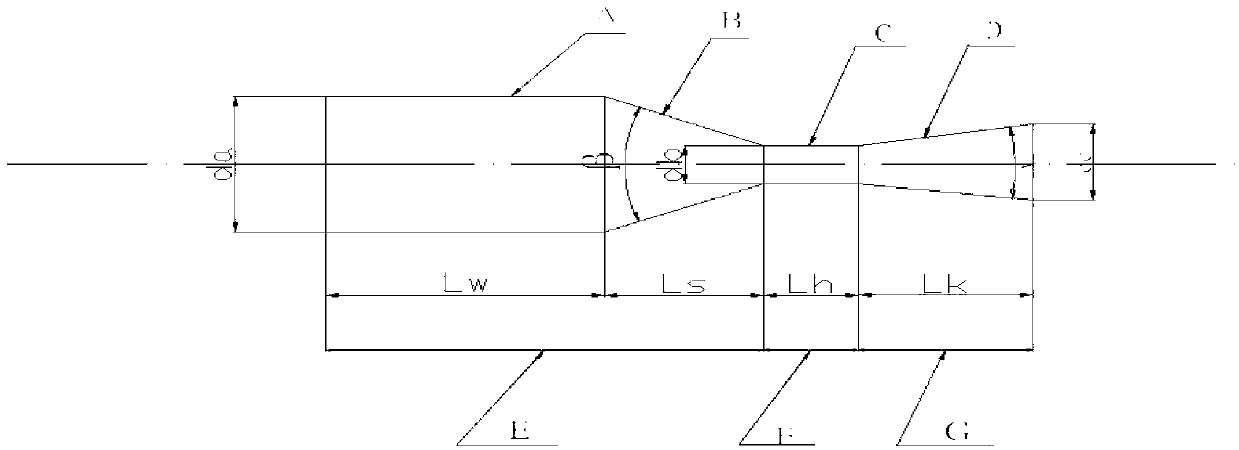

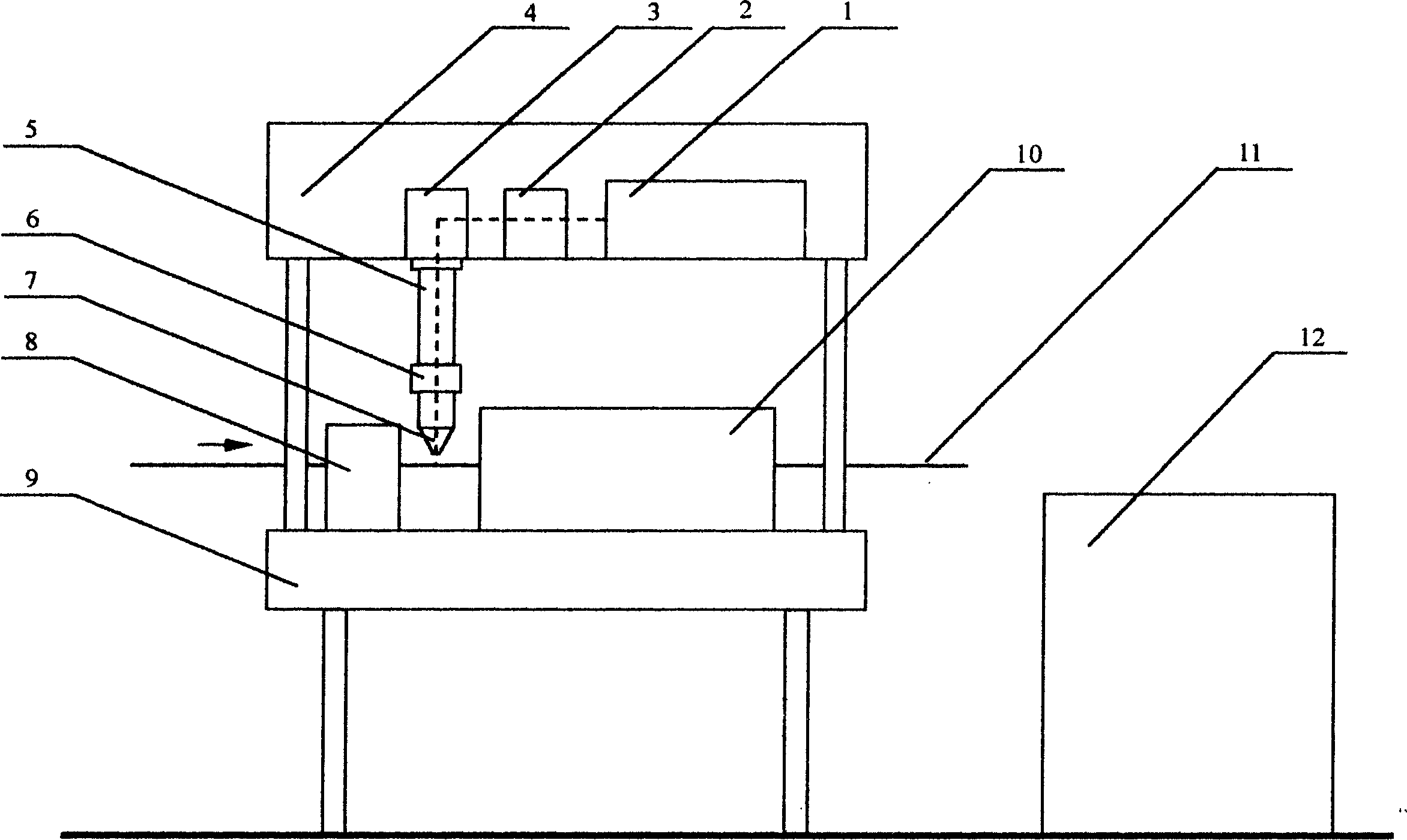

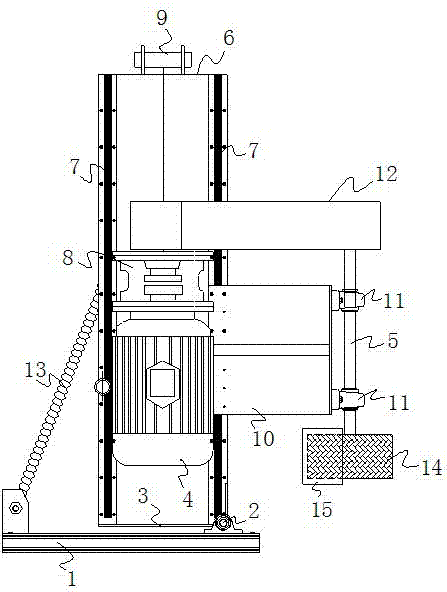

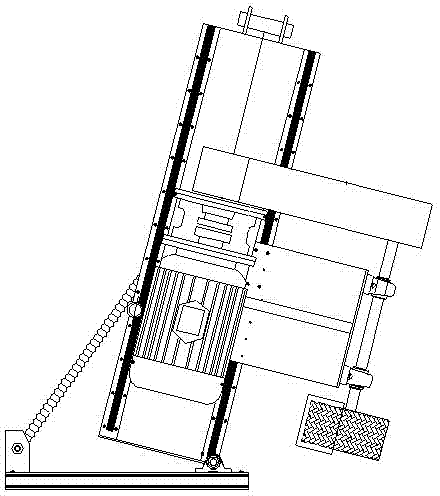

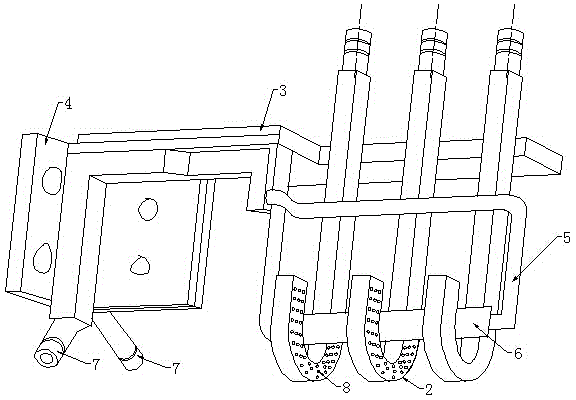

Steel rail on-line wind-jet quenching heat treatment simulation experiment device

InactiveCN103131826AEvenly distributedThe distribution is flat and stableFurnace typesQuenching agentsProduction lineExperimental research

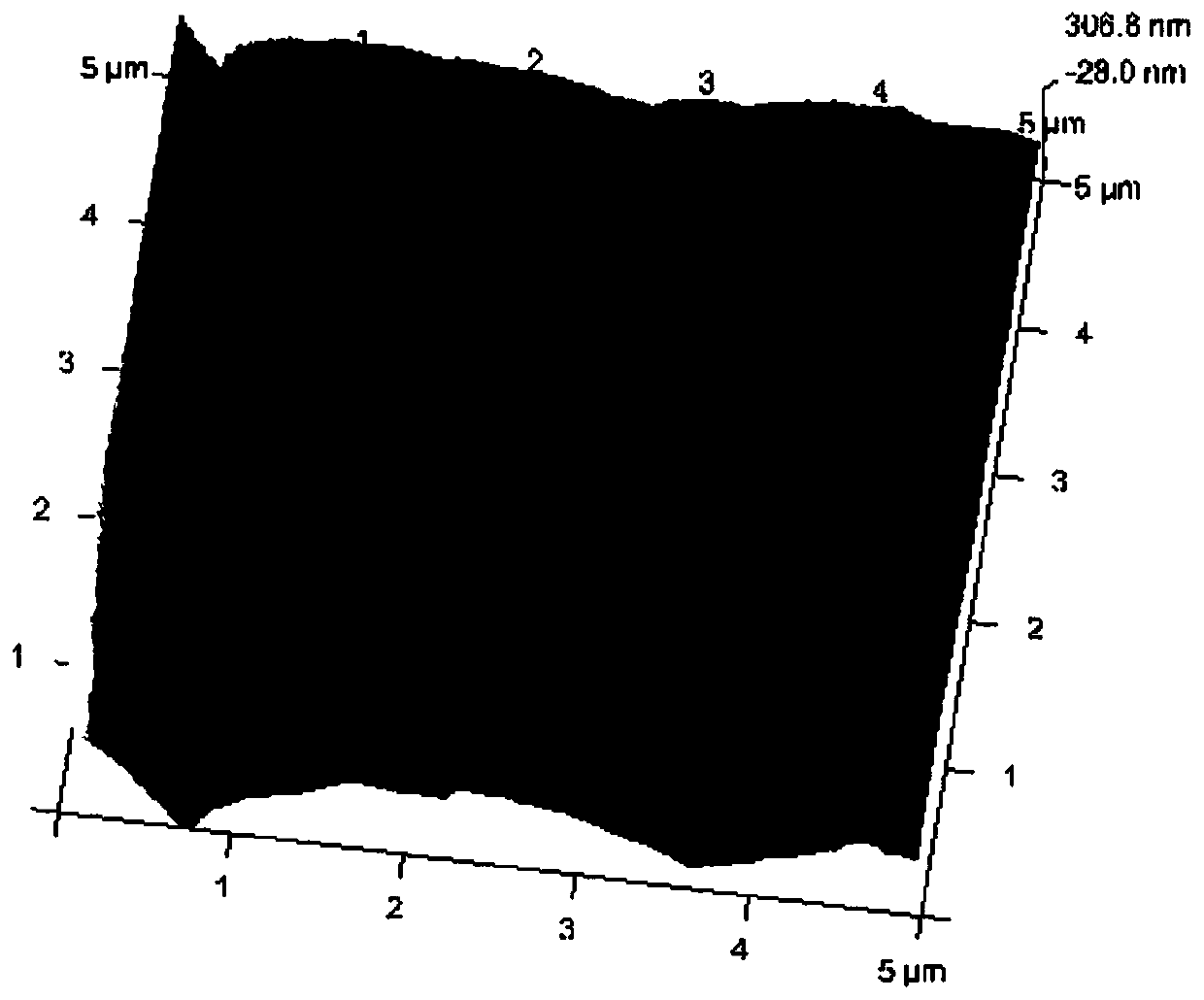

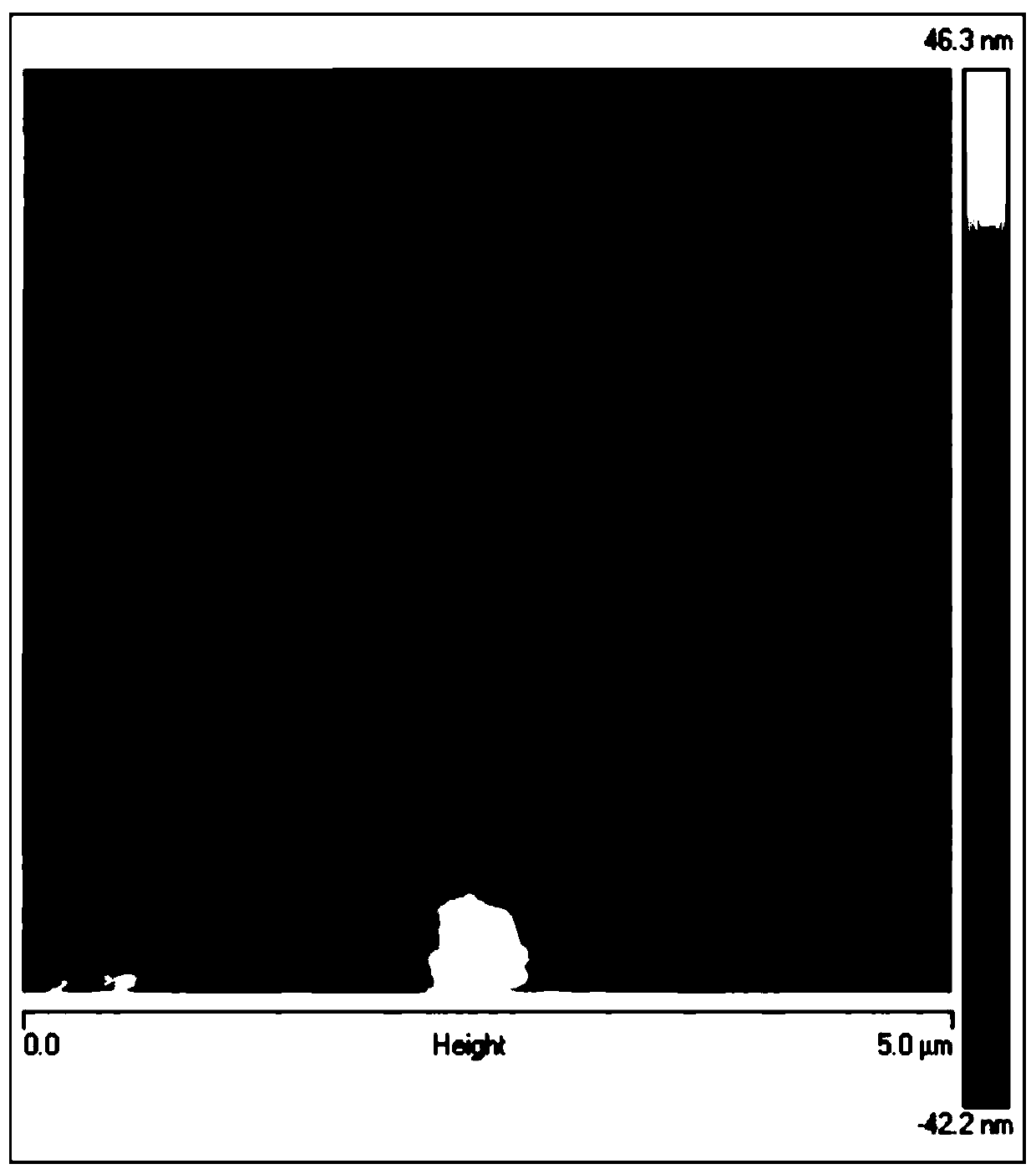

The invention relates to a steel rail on-line wind-jet quenching heat treatment simulation experiment device, and belongs to the technical field of steel metallurgy. The experiment device is composed of the structures of: a Laval-type flat-slot nozzle system, a steel rail guiding system, a frame system, a valve system, a compressed air pipe system, a roller way system, a detection instrument system, a steel rail heating furnace system, and the like. With wind, water, heating furnace, and roller way conditions in an experimental innovation platform in metallurgical rolling, a steel rail on-line wind-jet quenching heat treatment simulation experiment device is designed and manufactured, and a steel rail on-line wind-jet quenching heat treatment simulation experiment method is developed. The method and the device are used for carrying out heavy rail full-length on-line quenching simulation experimental researches. The experiment method is simple and reliable. With the method, heavy rail full-length on-line quenching process research period can be greatly shortened, and process research cost can be reduced. The method is a feasible method of laboratory simulation research currently. With the device and he method, technical support can be provided for a heavy rail full-length on-line quenching production line.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

High-grade wear-resistant steel plate and production method thereof

InactiveCN101748346AGuaranteed hardenabilitySolve the coarse and uneven grain sizeRoll mill control devicesElectric furnaceWear resistantQuenching

The invention discloses a high-grade wear-resistant steel plate. The steel plate comprises the following components in percentage by mass: less than or equal to 0.26 percent of C, less than or equal to 0.50 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.30 percent of Ni, less than or equal to 1.50 percent of Cr, less than or equal to 0.06 percent of Nb, 0.02 to 0.06 percent of Al, less than or equal to 0.03 percent of Ti, less than or equal to 0.50 percent of Mo, less than or equal to 0.08 percent of V, less than or equal to 0.004 percent of B, and the balance of Fe and inevitable impurities. A method for producing the steel plate comprises smelting, casting, heating, rolling, straightening, shot blasting, quenching, heat treatment, cutting and other process steps. The steel plate has the advantages of steel purity, high strength, high hardness, good low temperature toughness, good weldability, good processability, good cold bending property, large steel plate thickness, good plate cut, little noble metal added to the steel plate and low cost. The steel plate can be widely used in the industry of manufacturing mining, engineering, metallurgical and other machinery with broad application prospects.

Owner:WUYANG IRON & STEEL +1

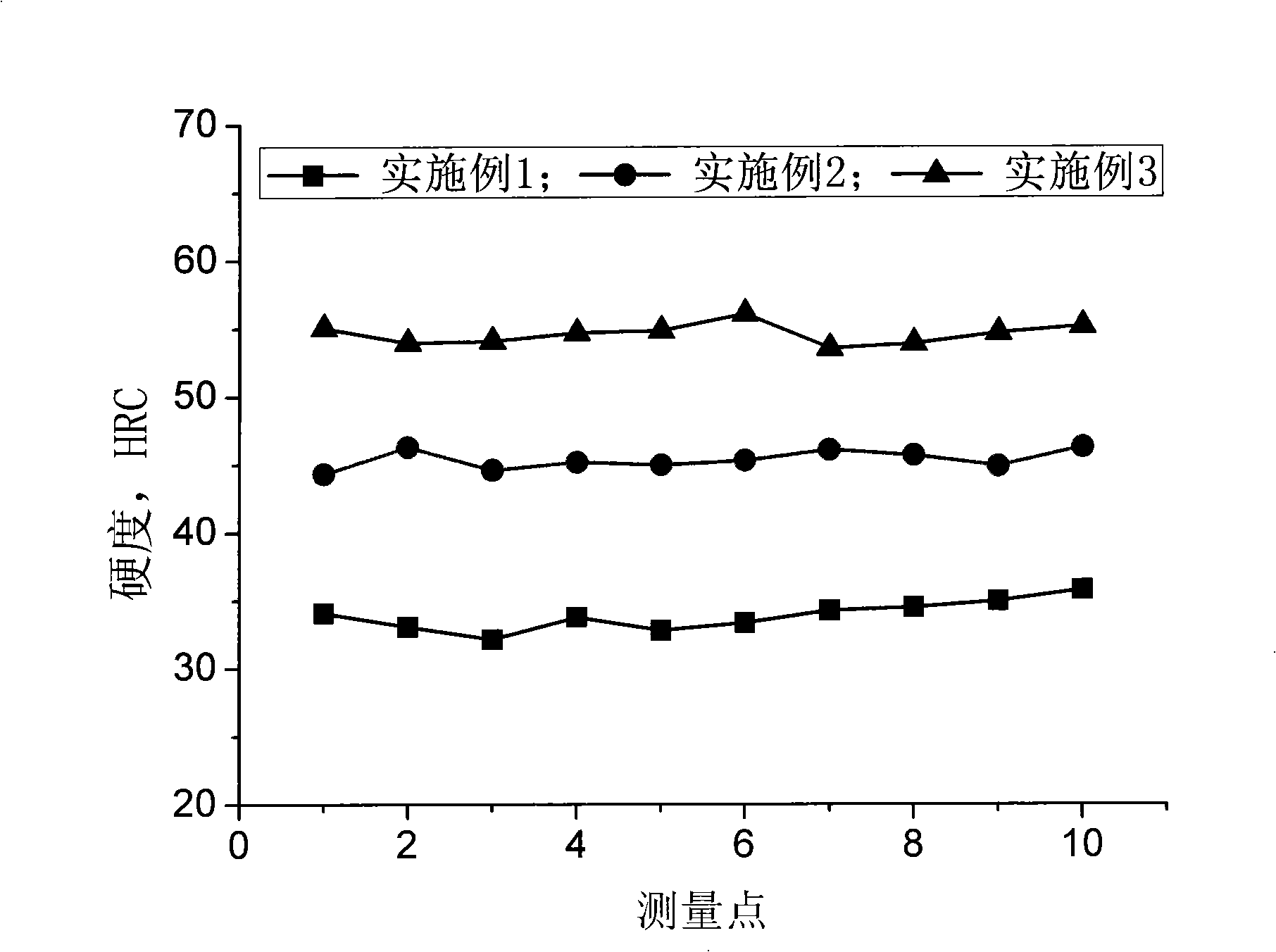

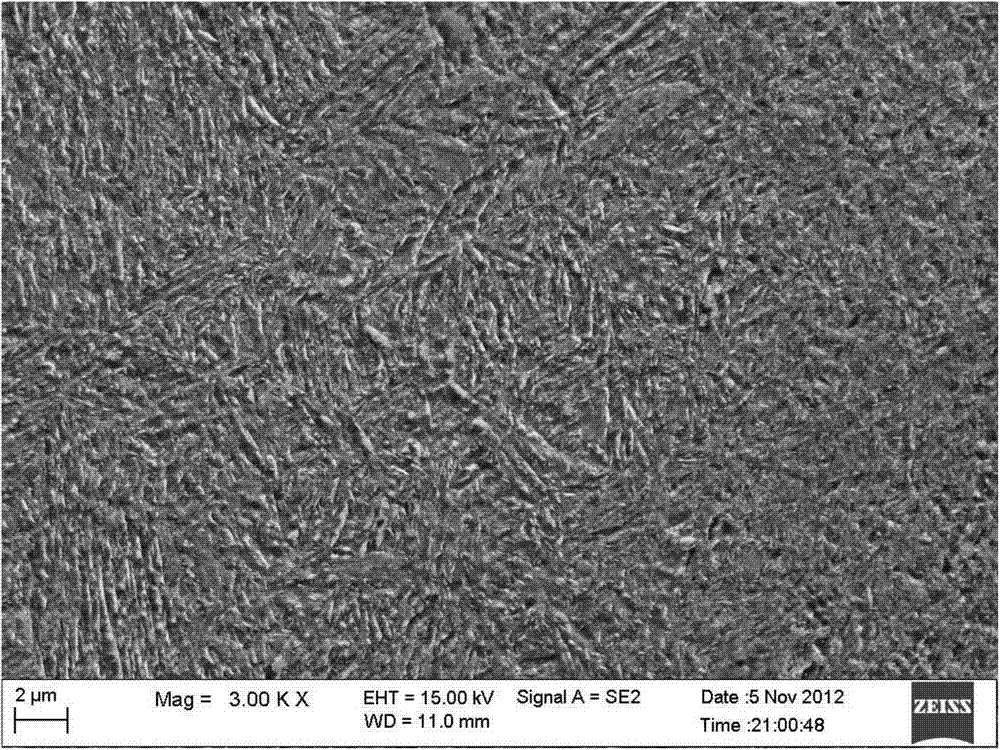

Cast iron series mould material thermal treatment method capable of acquiring controllable and uniform rigidity

The invention relates to a heat treatment method which can obtain the cast iron die material, the hardness of which is controllable and uniform. The heat treatment method has the steps as follows: in the first step, the cast iron die material is put in a vacuum firing furnace for prewarming until the temperature reach 900 to 950 DEG C, and is air-cooled after being taken out of the vacuum firing furnace after austenization; in the second step, a workpiece is put in the vacuum firing furnace, is heated until the temperature reaches 600 to 650 DEG C, is processed through heat preservation, is again heated until the temperature reaches 890 to 900 DEG C, then is taken out of the vacuum firing furnace after being processed through heat preservation, and is quenched in an oil cooling manner, so as to obtain a martensite structure; in the third step, the workpiece is put in the martensite structure for three temperature variations and tempers; wherein, in the first temper, the temperature ranges from 230 to 600 DEG C, and the heat preservation and the oil cooling are executed; in the second temper, the temperature ranges from 230 to 600 DEG C, and the heat preservation and the oil cooling are executed; in the third second temper, the temperature ranges from 250 to 600 DEG C, and the heat preservation and the oil cooling are executed. By the heat treatment method, the hardness of the obtained cast iron die can be controlled between 33HRC and 55HRC in a deterministic manner, the hardness fluctuation can be controlled within 10 percent, and the effect that the whole die is hardened is achieved.

Owner:SHANGHAI JIAO TONG UNIV

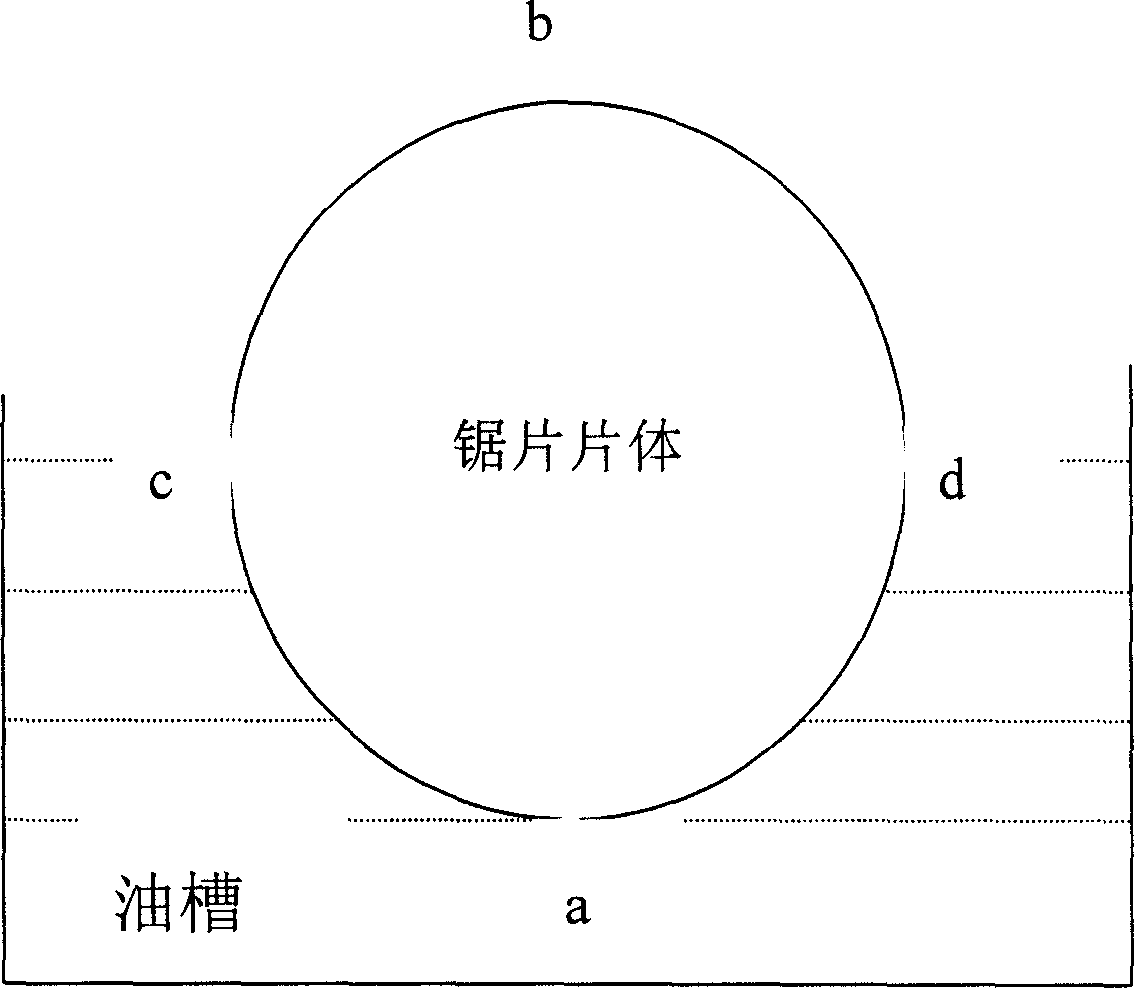

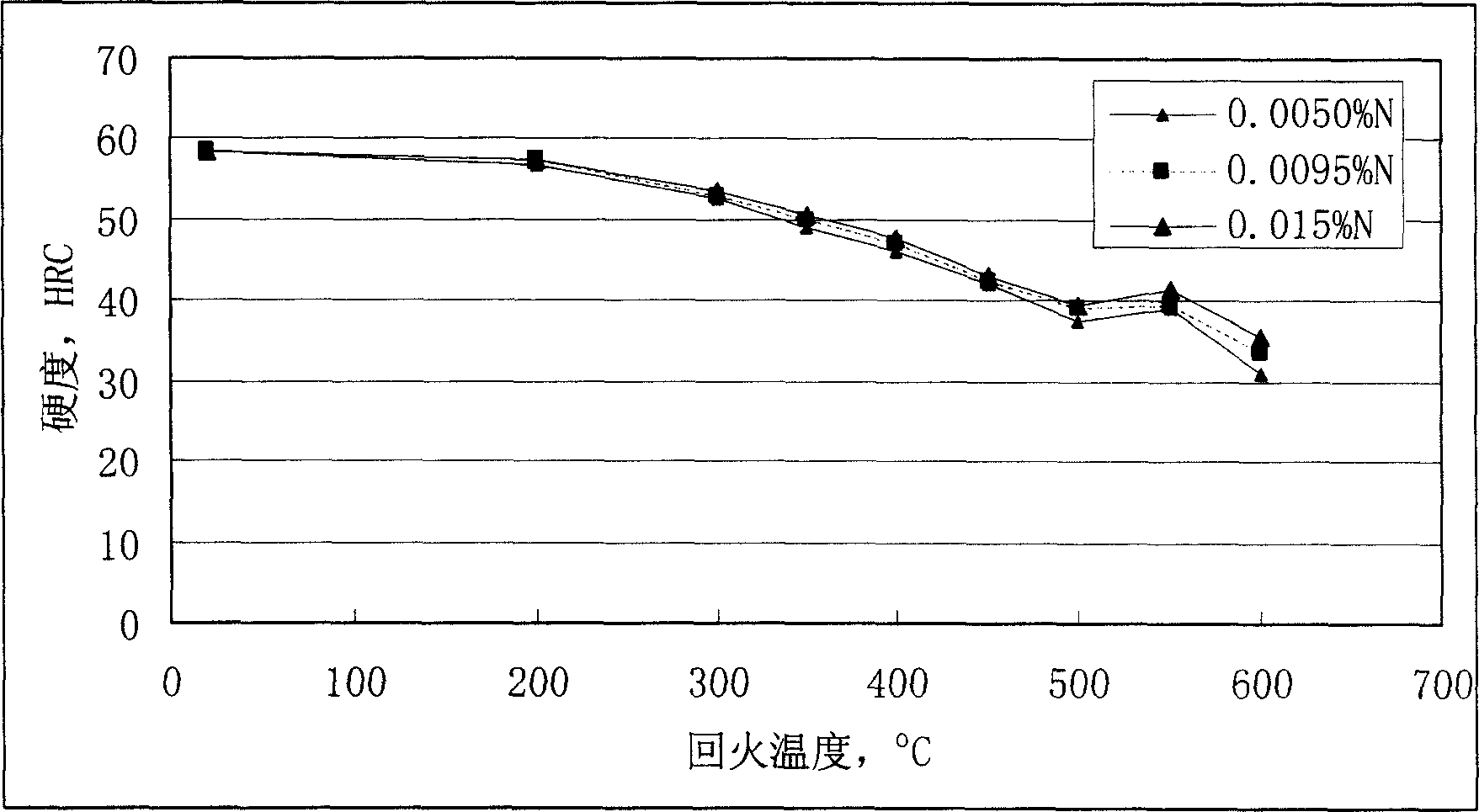

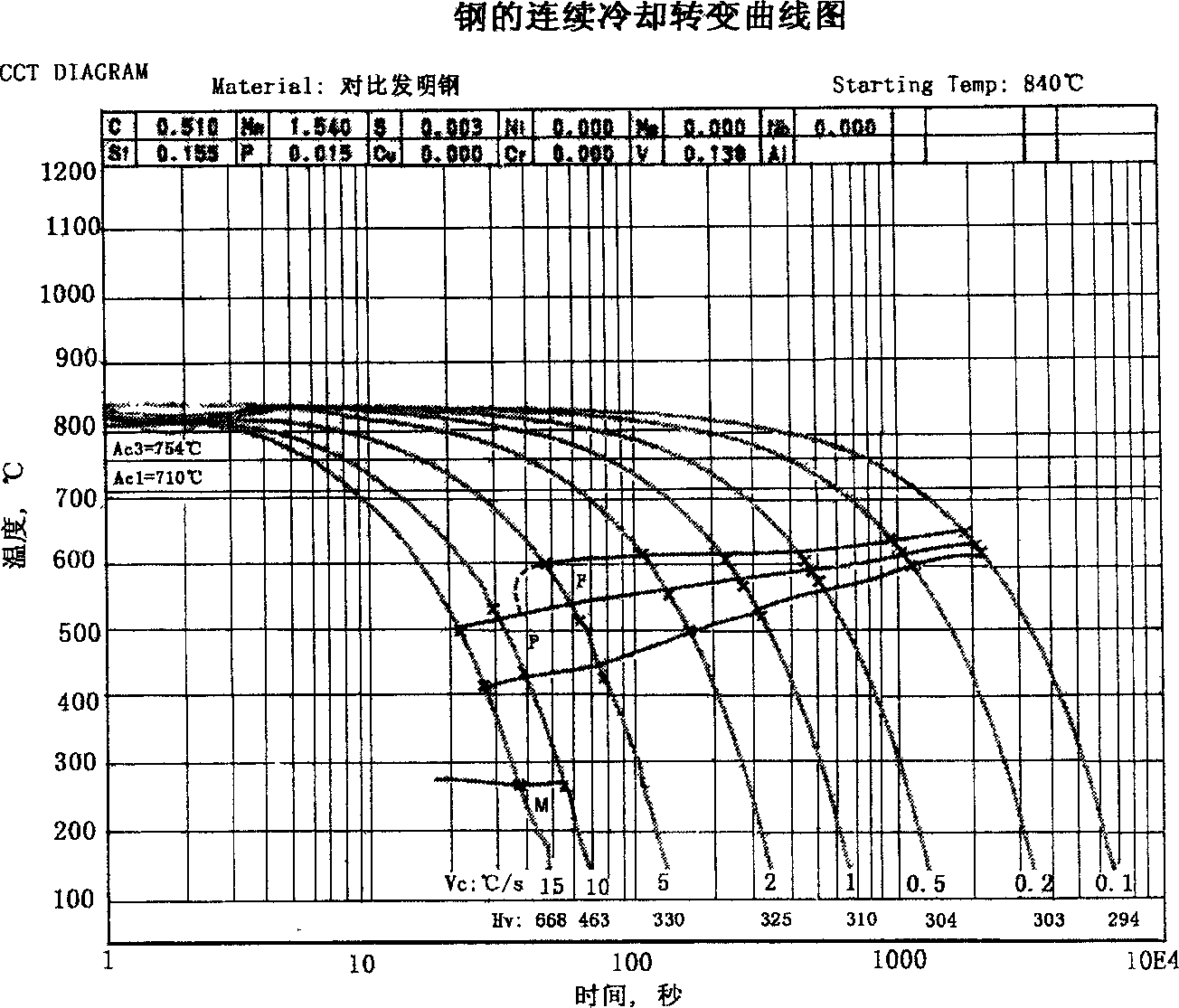

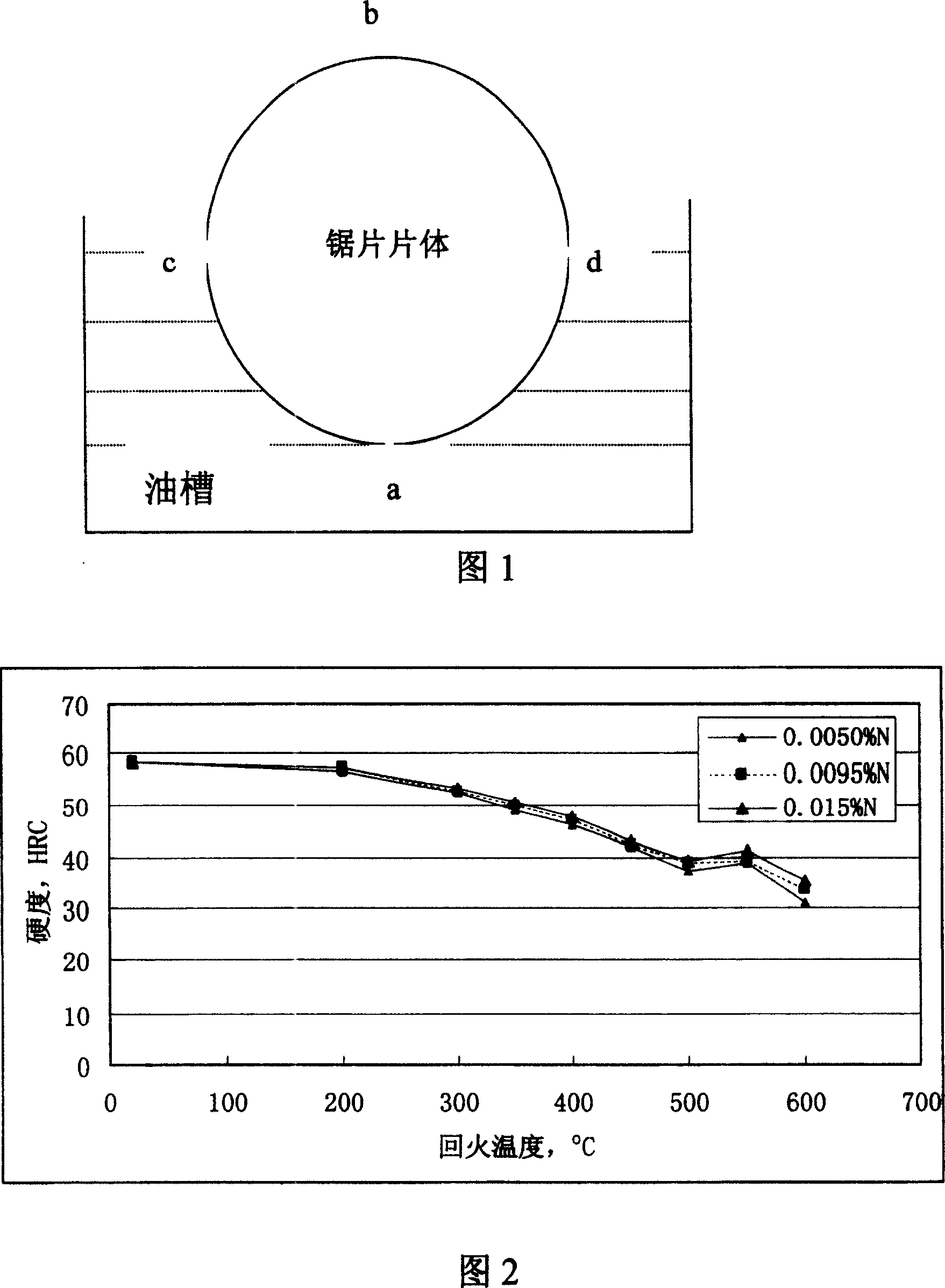

Stone material cutting saw blade steel and its manufacturing method

ActiveCN1904119AReduce the risk of continuous casting billet breakageReduce the technical problem of large deformation resistanceFurnace typesMetal rolling arrangementsChemical compositionImpurity

This invention relates to a type of steel used for saw blade for stone slotting. Account for weight the chemical composition is: C 0.45-0.60,Si 0.10- 0.60,Mn 1.30-1.80,P<=0.02,S<=0.01,V 0.05-0.20,Cr 0.15-0.30, N 0.005-0.020,Ca 0-0.0050,Al 0.005-0.040, and the rest is Fe and inevitable impurity. The process includes steps as follows: smelting, casting,; continuous casting billet use heat sending and heat packing , ensure the temperature keep above 300DEG C before it be send into plate body for heating; keep temperature for plate body heating above 1150DEG C,temperature for hot rolling above 900DEG C; cooling after rolling, then coiling, keep the coiling temperature above 700DEG C. This invention has higher hardenability then midst-carbon and low-alloy steel, especially refer to make large saw blade which diameter is above 1000mm.

Owner:BAOSHAN IRON & STEEL CO LTD

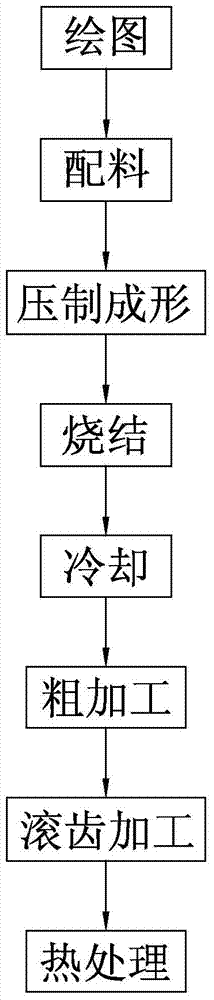

Mechanically actuated chain wheel material, and manufacturing method thereof

ActiveCN103757551AImproved mechanical properties and hardnessUniform hardness distributionAutomotive engineeringSprocket

The invention discloses a mechanically actuated chain wheel material, and a manufacturing method thereof. The mechanically actuated chain wheel material comprises following ingredients: 0.2 to 0.35 part of C, 0.35 to 0.55 part of Si, 0.6 to 0.9 part of Mn, Ni<=0.25 part, Cr<=0.20 part, S<=0.02 part, Al<=0.05 part, P<=0.03 part, Cu<=0.40 part, Mo<=0.05 part, V<=0.03 part, Nb<=0.01 part, Ti<=0.01 part, and the balance Fe. The manufacturing method comprises steps of (a) drawing; (b) material preparaing; (c) compacting and shaping; (d) sintering; (e) cooling; (f) rough machining; (g) gear hobbing processing; and (h) heat processing. According to the manufacturing method, the ingredients above are selected so as to obtain chain wheels with uniform strength. In preparation processes, the ingredients are delivered into a mould; a chain wheel blank material is obtained via upsetting extruding, and is subjected to sintering and cooling, so that the internal part of the mechanically actuated chain wheel material is compact, is high in strength, and is not easily fractured; gear hobbing processing is adopted, so that cost is reduced, and processing cycle is shortened; and phenolic aldehyde cloth base laminates are used, so that wear resistance and corrosion resistance of the chain wheels are increased.

Owner:中山舜人机械制造有限公司

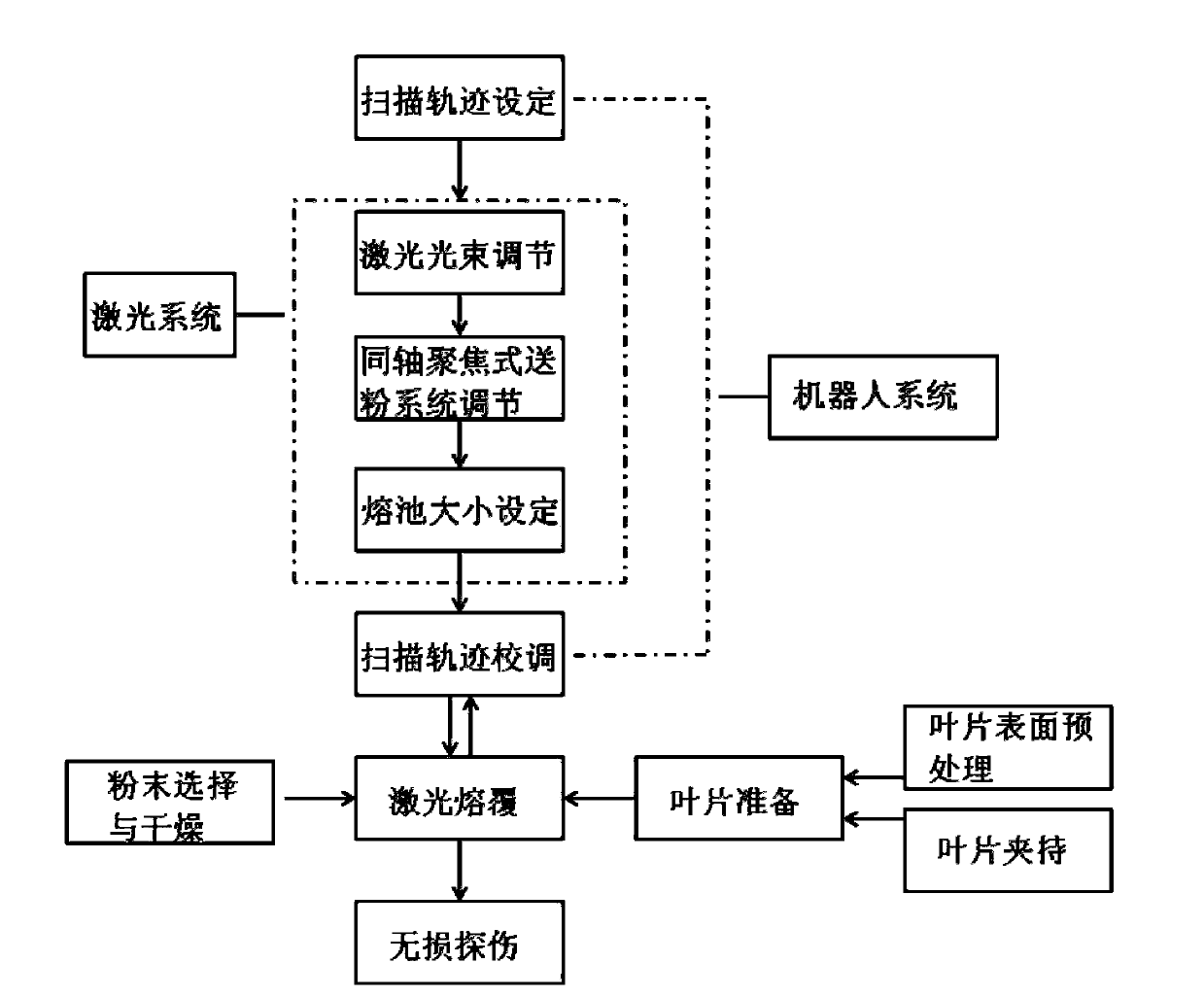

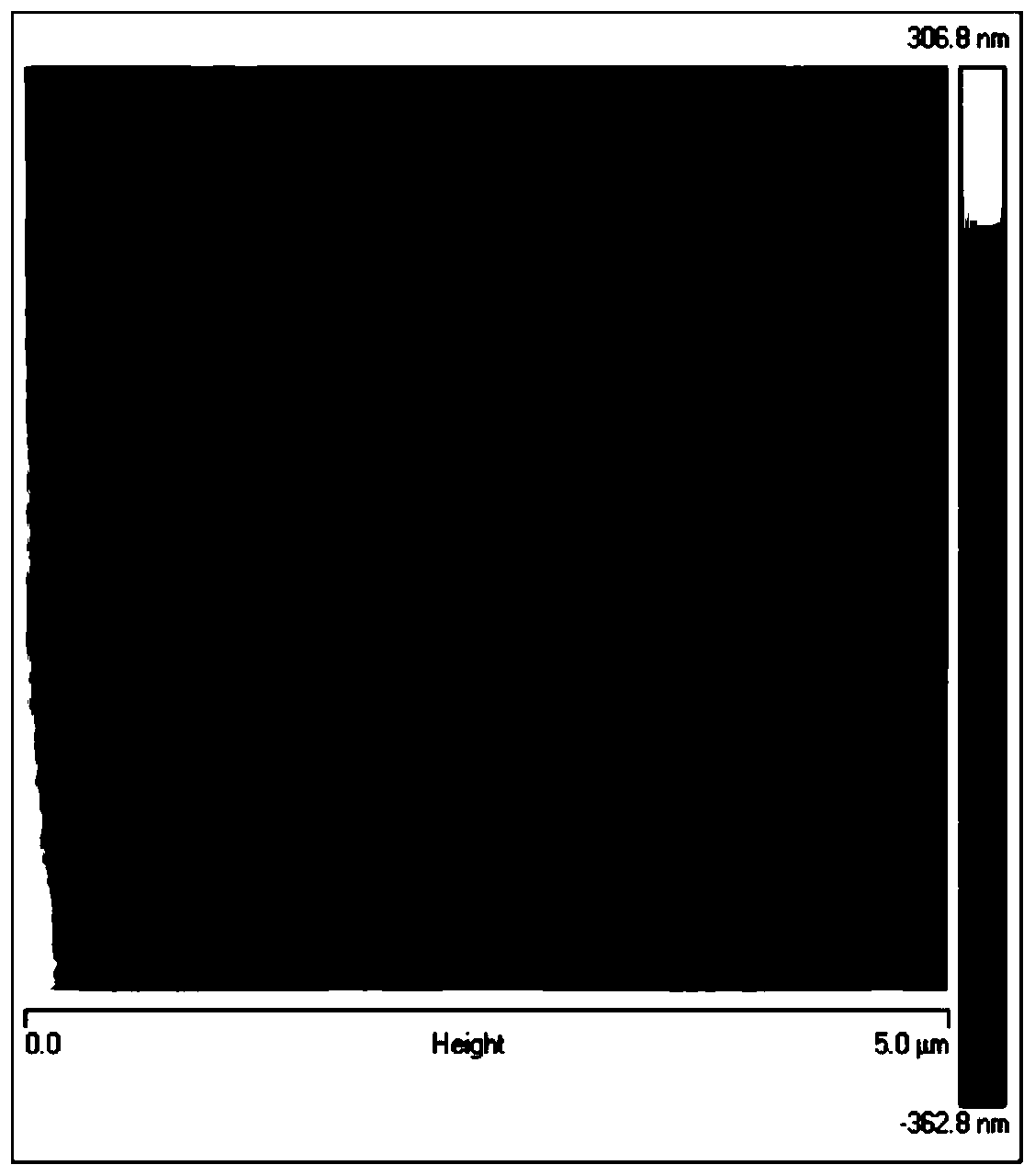

Preparation method for water erosion resistant coating of last-stage long blade

ActiveCN103276391AUniform compositionUniform tissueBlade accessoriesMachines/enginesManufacturing technologyThermal impact

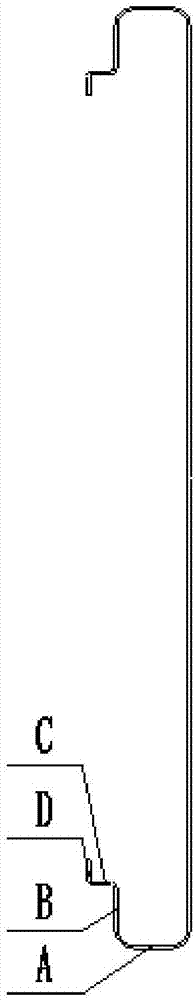

The invention belongs to the laser cladding field, relates to a preparation method for a water erosion resistant coating of a last-stage long blade, and particularly relates to a method for preparing a water erosion resistant coating of a last-stage long blade of a large nuclear turbine. The preparation method for the water erosion resistant coating of the last-stage long blade comprises the following steps of drying alloy powder, clamping a blade on a platform with the blade in a horizontal position; selecting a semiconductor laser; adjusting by a coaxially focused powder feeding system; setting the size of a molten pool; and cladding the water erosion resistant coating by the laser. The preparation method can be used in preparing the water erosion resistant coating of the last-stage long blade of the large nuclear turbine. The hardness distribution of a cladding layer is uniform with an up-down deviation within 10% and the hardness of 500 HV; the thermal impact performance and water erosion resistance of the cladding layer are excellent; the deformation of the last-stage long blade after the laser cladding is small; and profile tolerance meets the processing and manufacturing technological requirements of the long blades by nuclear power.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD +1

Biomass fuel forming mold surface powder metallurgy strengthening coating material and process

The invention belongs to the technology for improving biomass fuel forming mold surface hardness (namely improving abrasion resistance of the surface) and particularly relates to a biomass fuel forming mold surface powder metallurgy strengthening coating material and a process which aim at solving the problem of serious abrasion of the biomass fuel forming mold surface. The process includes: weighing appropriate mass of powder according to the area of the portion of a mold needing strengthening and the thickness of a pre-strengthening layer, wherein the powder is composite powder formed by mixing cobalt / nickel-based self-fluxing alloy powder and non-metallic ceramic powder in proportion; adding appropriate amount of bonding forming agents in the composite powder and sufficiently mixing through vacuum stirring to obtain plastic powder bodies; and evenly coating the powder bodies on the biomass fuel forming mold surface, drying and conducting powder metallurgy strengthening in a vacuum furnace according to corresponding temperature rising curves. Hardness of a powder metallurgy strengthening coating can reach rockwell hardness (HRC) 50-70, the thickness is above 2 mm, the coating is smooth, light and free of pore cracks, and a binding interface between the coating and a substrate is fused in metallurgy mode and is even in texture and free of obvious defects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

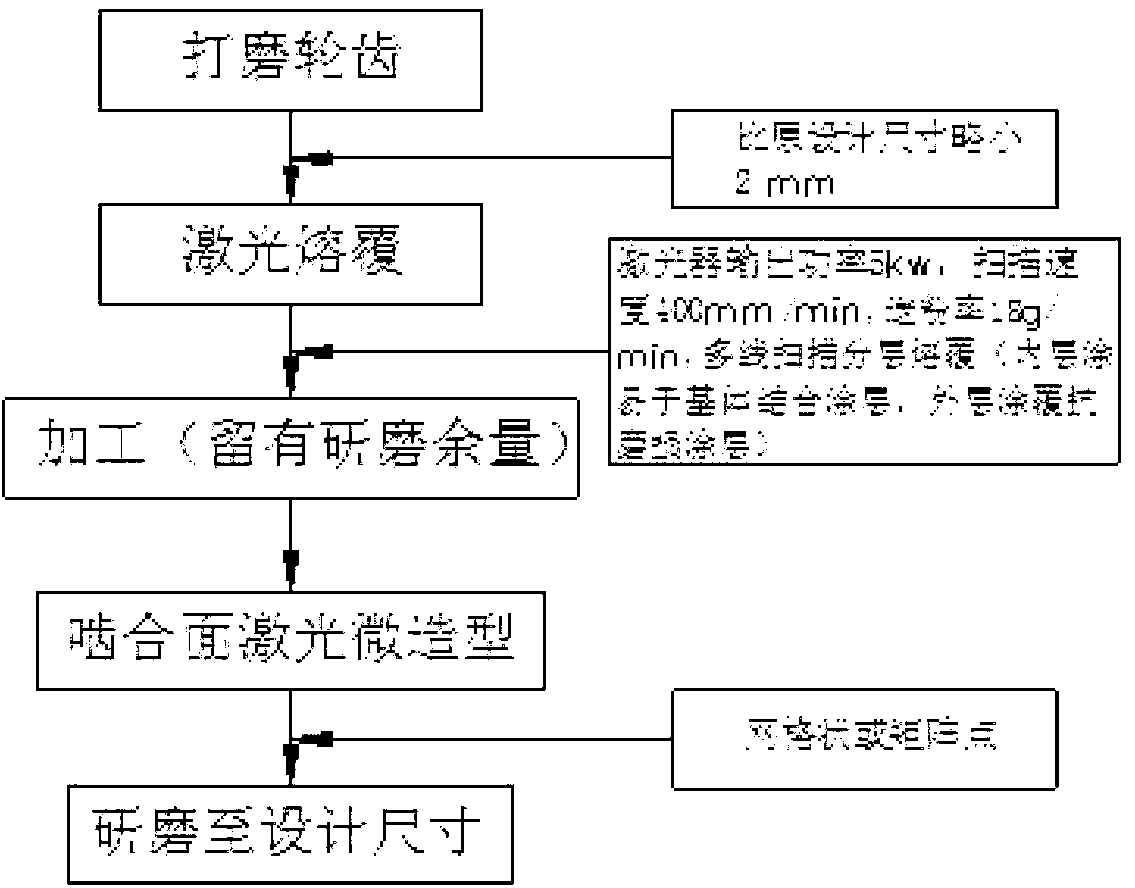

Method for repairing and strengthening gear through laser compound microtexture

InactiveCN103060796AHigh hardnessGood chemical stabilityMetallic material coating processesLaser coatingHardness

The invention provides a method for repairing and strengthening a gear through laser compound microtexture. The method comprises the following steps of (1) modeling through laser coating on a meshing surface of a gear; and (2) carrying out laser shock peening on a coating layer, so as to obtain the gear repaired and strengthened through compound microtexture. According to the method for repairing and strengthening the gear through laser compound microtexture, the gear is processed into the original size through a laser coating method, and the gear is strengthened through laser, so that the hardness and abrasion resistance of the gear are greatly improved. Through detection on the gear repaired and strengthened by the method, the wearing layer thickness is even, the distribution of hardness is uniform, the rockwell hardness of a strengthening layer is HRC65, and the abrasion resistance is three times more than that of a common gear.

Owner:WENZHOU UNIVERSITY +2

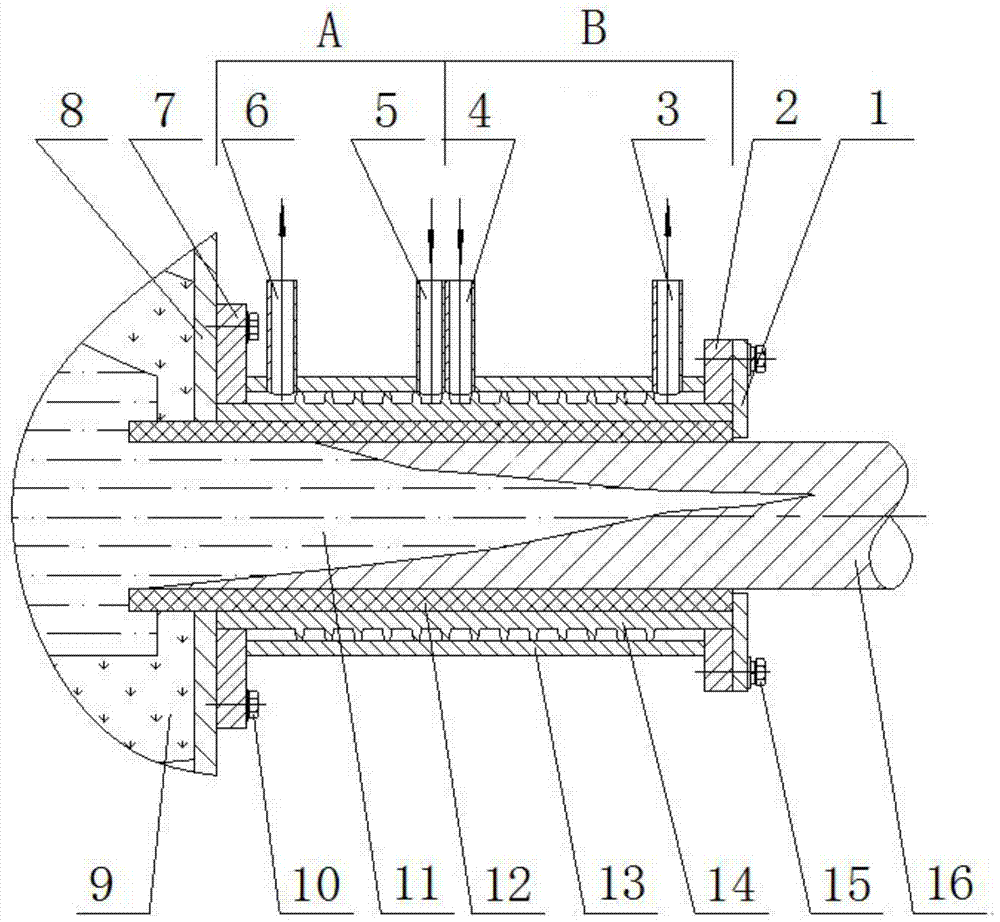

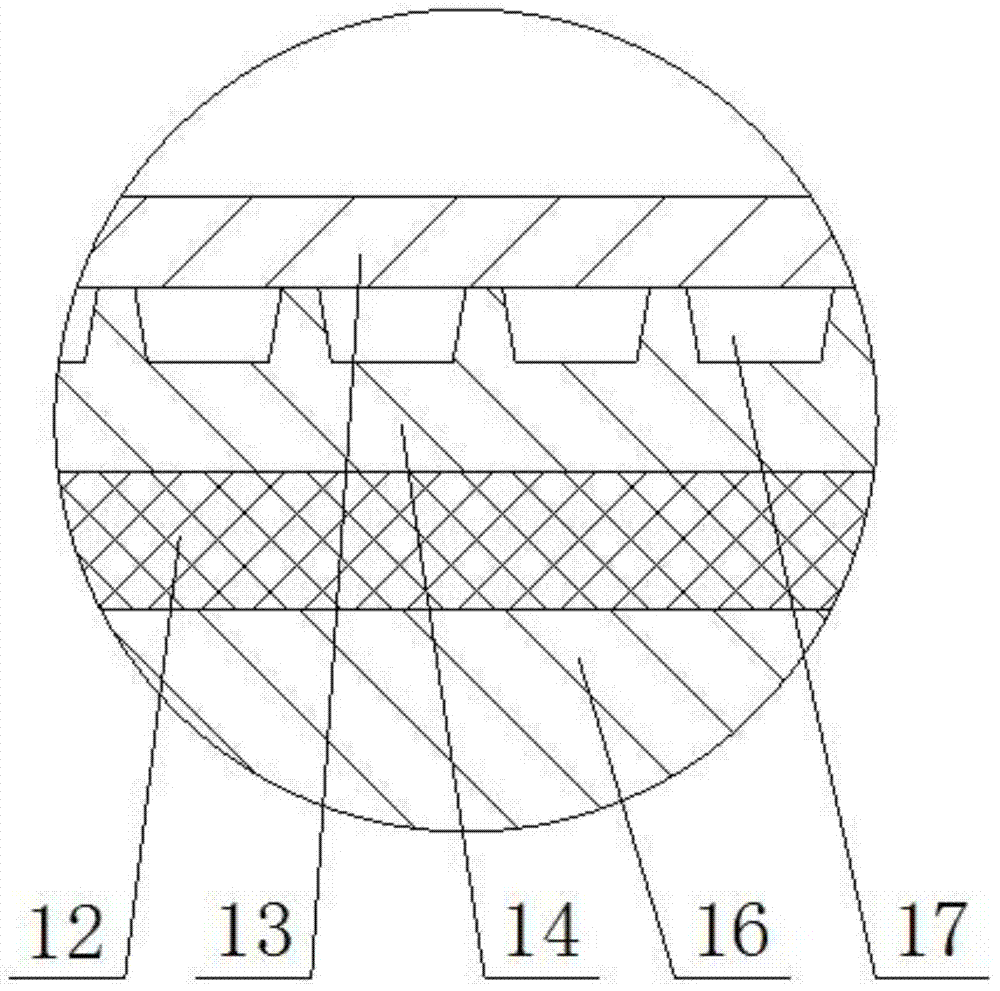

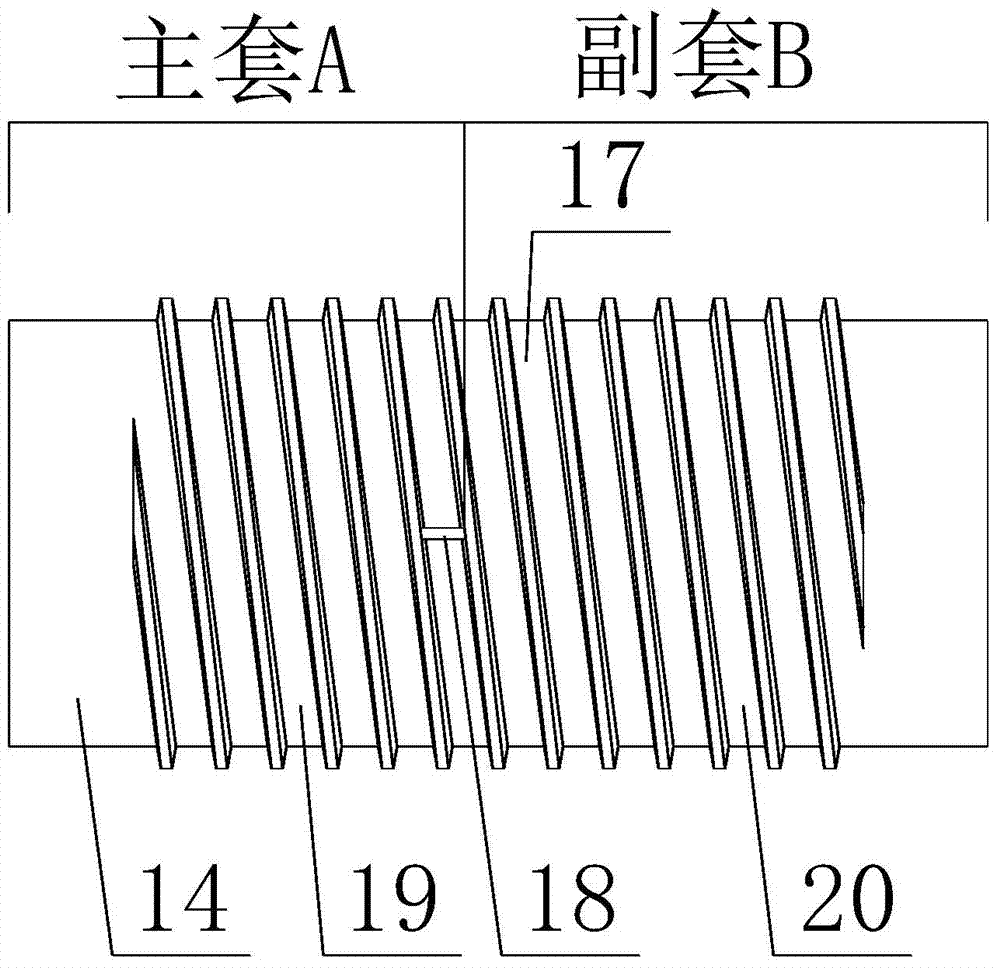

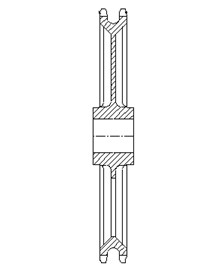

Cast iron horizontal continuous casting double-water jacket type crystallizer

The invention relates to a cast iron horizontal continuous casting double-water jacket type crystallizer, which comprises a double-water jacket type crystallizer steel sleeve and a high-purity graphite sleeve, wherein the high-purity graphite sleeve is embedded in the double-water jacket type crystallizer steel sleeve, the double-water jacket type crystallizer steel sleeve comprises a crystallizer steel sleeve inner sleeve and a crystallizer steel sleeve outer sleeve, the crystallizer steel sleeve outer sleeve is arranged at the exterior of the crystallizer steel sleeve outer sleeve, the crystallizer steel sleeve inner sleeve is provided with a spiral water passage with a trapezoidal cross section, a separating plate is arranged in the spiral water passage with the trapezoidal cross section, and is used for separating the spiral water passage with the trapezoidal cross section into a spiral water passage with a trapezoidal cross section I and a spiral water passage with a trapezoidal cross section II, the crystallizer steel sleeve outer sleeve is respectively welded with a water inlet pipe of a main sleeve A, a water outlet pipe of the main sleeve A, a water inlet pipe of an auxiliary sleeve A and a water outlet pipe of the auxiliary sleeve B, the water inlet pipe of the main sleeve A and the water outlet pipe of the main sleeve A are respectively communicated with the spiral water passage with the trapezoidal cross section I to form the main sleeve A, and the water inlet pipe of the auxiliary sleeve B and the water outlet pipe of the auxiliary sleeve B are respectively communicated with the spiral water passage with the trapezoidal cross section II to form the auxiliary sleeve B. The cast iron horizontal continuous casting double-water jacket type crystallizer has the advantages that the process advantages of horizontal continuous casting using separate control of the two water jackets are fully realized, the leakage of furnaces is avoided, the drawing speed is improved, and the cost is reduced.

Owner:陕西均安精工科技有限公司

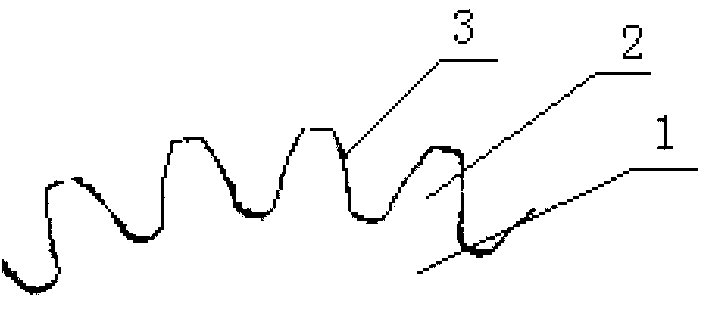

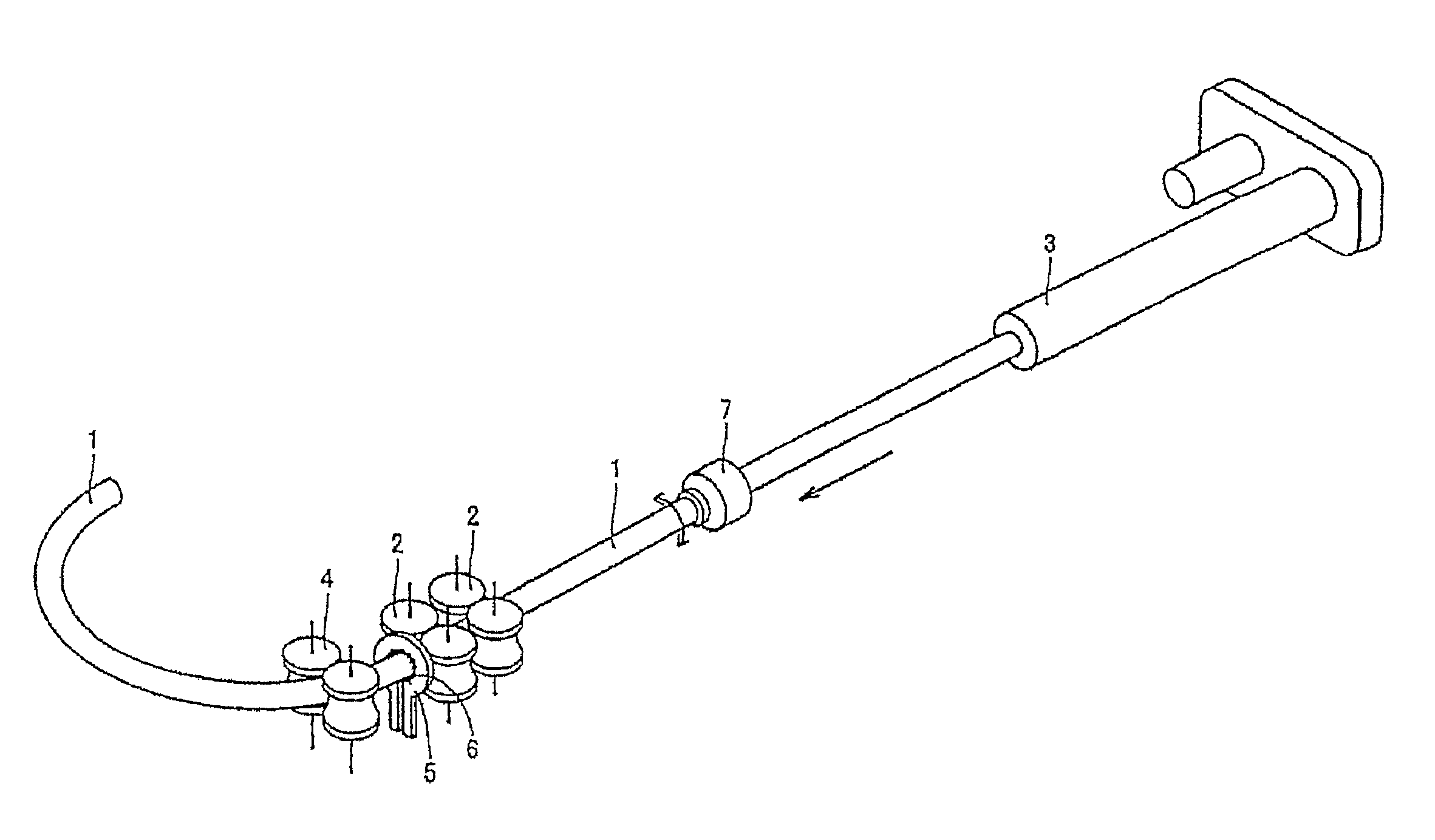

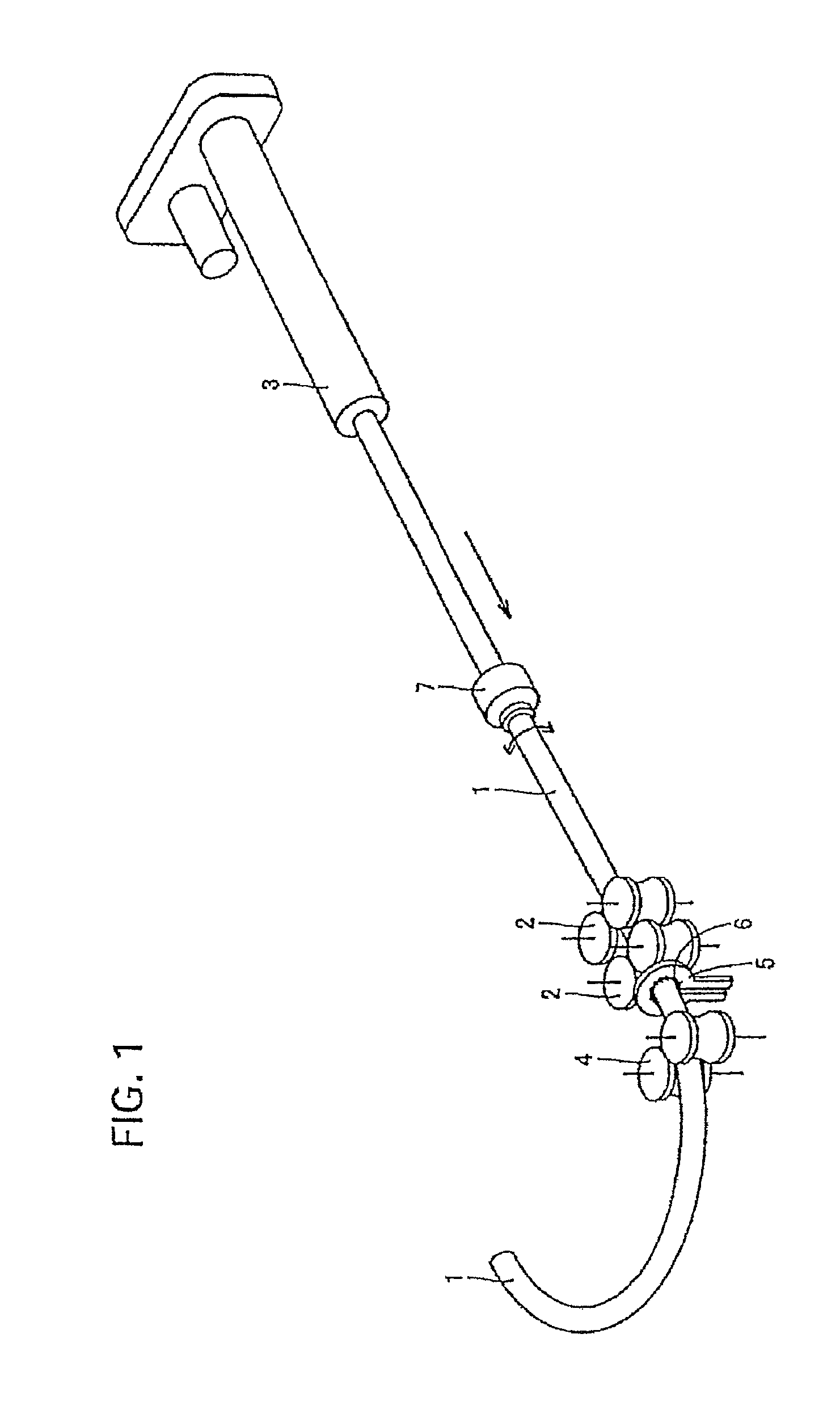

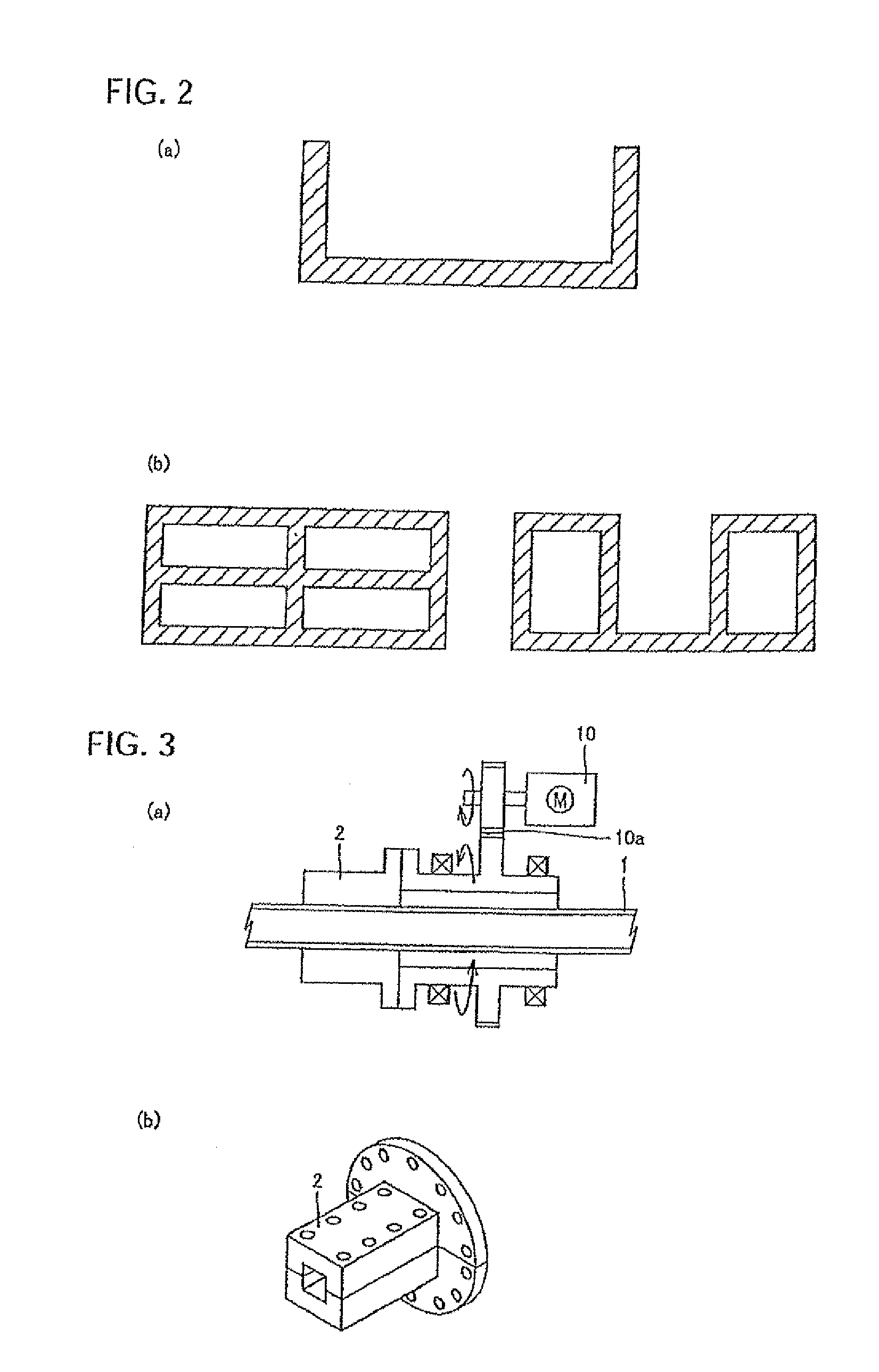

Three-dimensionally bending machine, bending-equipment line, and bent product

ActiveUS20100218577A1Excellent shape fixabilityUniform hardness distributionThin material handlingHeating/cooling devicesMetallic materialsEngineering

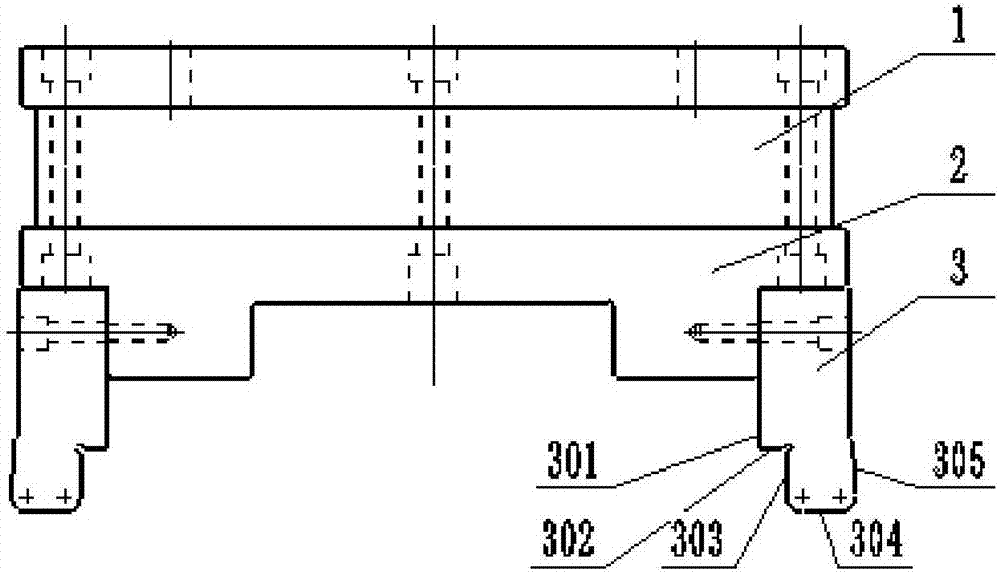

A three-dimensionally bending machine comprises a supporting unit to support a workpiece and a feeding unit to feed the workpiece from an upstream side of the workpiece. A heating and cooling unit, provided around the outer circumference of a portion of the workpiece downstream of said supporting unit heats the portion of workpiece in a temperature range for plastic deformation and quenches and rapidly cools the deformed workpiece. A three-dimensionally movable unit, provided downstream of said heating and cooling unit, supports the metal material and controls the supporting position and / or the moving speed of the metal material to apply the bending moment in association with a feed amount, a heating amount, and a cooling amount of the workpiece. Even when a high-strength workpiece is bent, a workpiece having excellent shape fixability and uniform hardness distribution can be made, especially for application to sophisticated automobile parts.

Owner:NIPPON STEEL CORP

Method of preparing wearable steel ball

InactiveCN101381848AReduce contentLow costFurnace typesHeat treatment furnacesHigh resistanceThermal insulation

The invention provides a method for manufacturing a wear-resistant steel ball, which comprises the following steps: 1) selecting round steel containing the following high carbon low alloy; 2) heating the round steel to between 1, 000 and 1, 100 DEG C and performing thermal insulation for a period of time; 3) diagonally rolling the round steel into a steel ball through a two-roll screw groove; and 4) adding the steel ball into a spiral quenching cylinder, and carrying out low-temperature tempering at a temperature of between 180 and 200 DEG C after the quenching. The method for manufacturing the wear-resistant steel ball selects the round steel with high carbon low alloy as a raw material, does not need to consume a large amount of alloy materials such as chromium, and reduces the cost; and the produced wear-resistant steel ball has the characteristics of high strength, high hardness, high wear resistance, shock resistance and so on.

Owner:CHANGSHU LONGTENG SPECIAL STEEL +1

High-hardenability big-diameter 65MnCr grinding ball and preparation method thereof

The invention provides a high-hardenability big-diameter 65MnCr grinding ball and a preparation method thereof, which belong to the field of wear-resistant materials. The grinding ball consists of the following components in percentage by weight: 0.55-0.75% of C, 0.1-0.5% of Si, 1.0-3.0% of Mn, 0.5-1.5% of Cr, 0.01-0.1% of Al, less than or equal to 0.1% of P, less than or equal to 0.01% of S, less than or equal to 0.01% of N and the balance of unavoidable impurities. The preparation technology comprises the following steps: heating a steel billet at temperature of 1050-1100 DEG C, preserving heat for 1 hour, soaking, milling the steel billet on a two-roll mill, placing the steel billet in water with temperature of 900-950 DEG C, quenching for 2.5-3 minutes in water, at grinding ball re-reddening temperature of 120-150 DEG C, then preserving heat for 6 hours in a furnace at temperature of 320-400 DEG C, and taking the steel billet out and cooling in heap. After tempering, internal stress is eliminated, impact toughness is enhanced and non-notched impact energy at normal temperature is over 25 J. The production technology is simple and feasible to operate, the produced 65MnCr grinding ball has very good hardenability as well as excellent matching of hardness and toughness, and the production can achieve practical industrial application.

Owner:UNIV OF SCI & TECH BEIJING

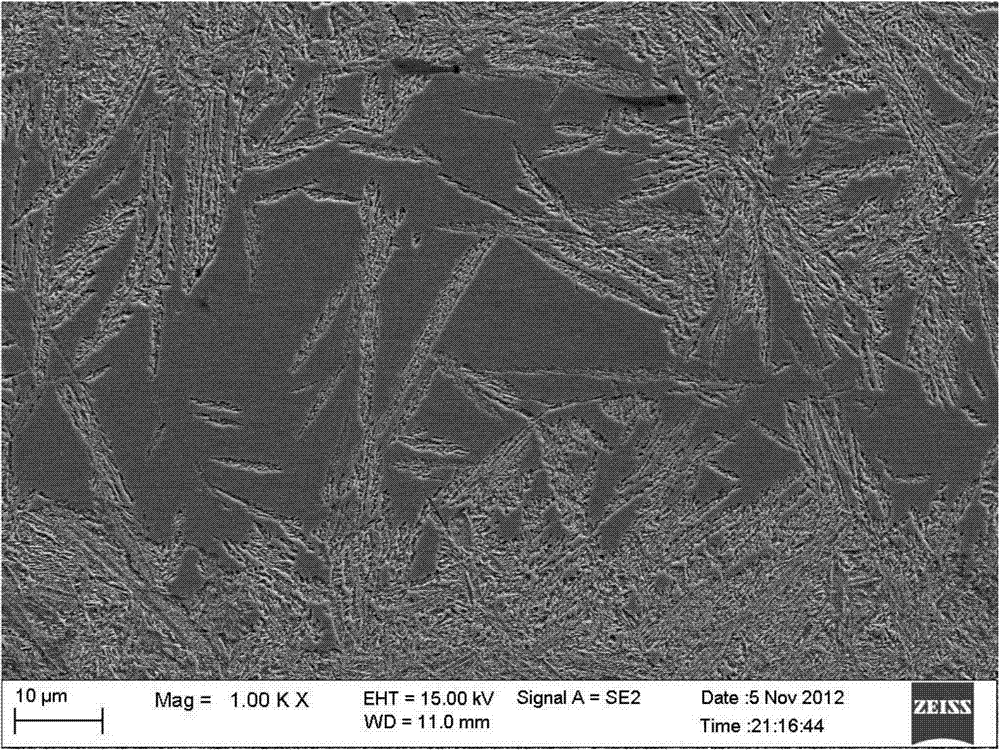

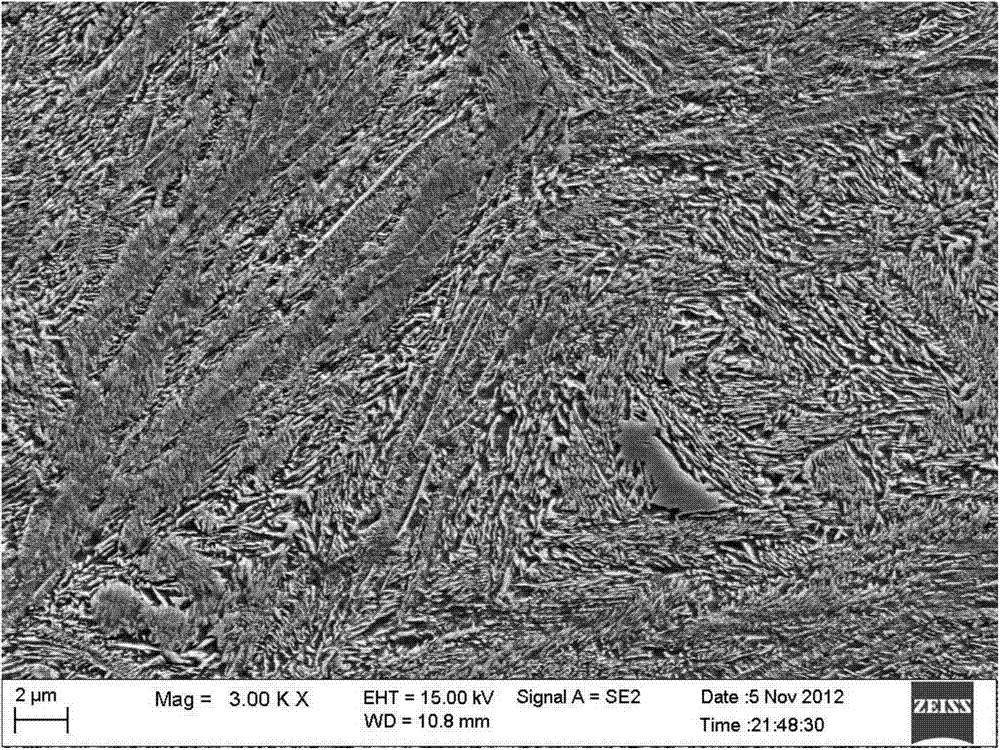

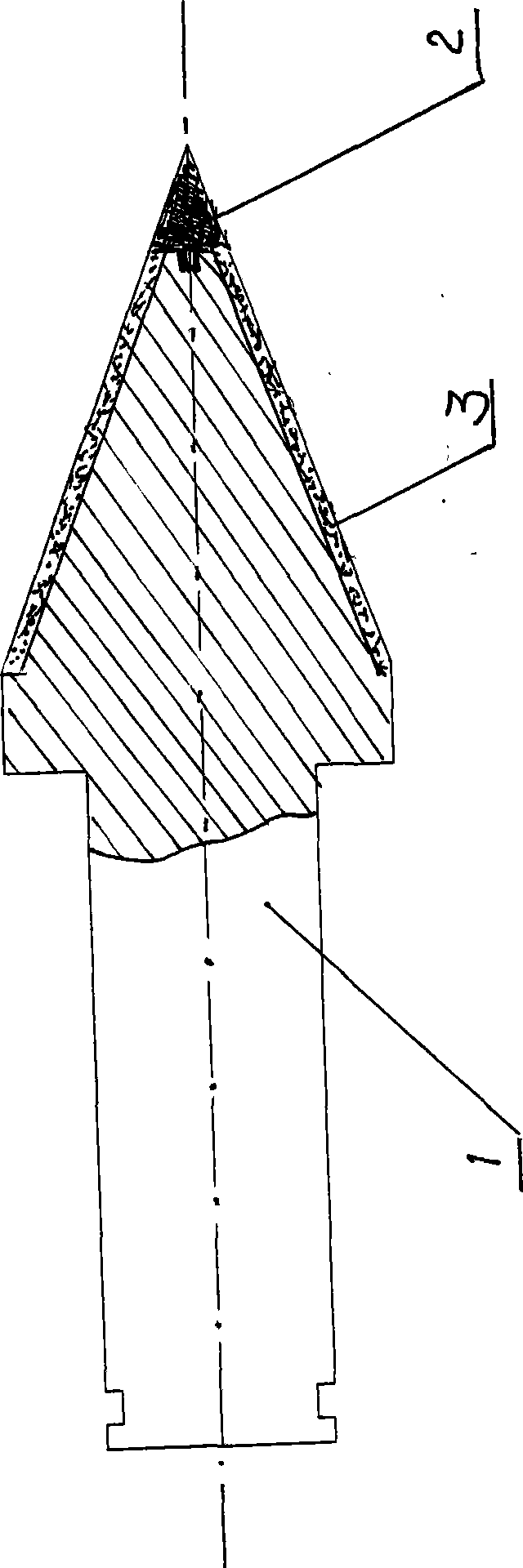

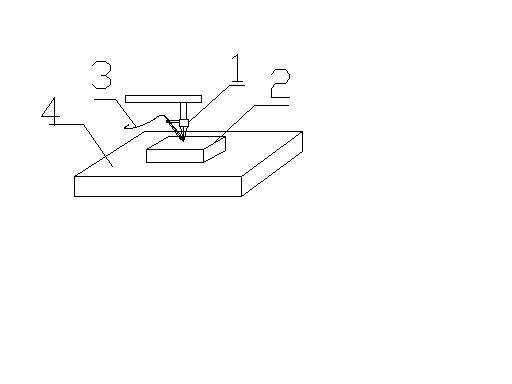

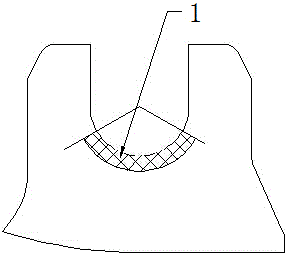

Antiwear laser strengthened pick and its processing method

InactiveCN101392649AUniform thicknessUniform hardness distributionFurnace typesMetallic material coating processesLaser quenchingHardness

The invention discloses an antiwear laser strengthening cutting pick for a coal mining unit and a processing method thereof. The conical surface of a body of the cutting pick is provided with a laser strengthening layer. The processing method for the antiwear laser strengthening layer comprises the following steps: a laser energy beam is utilized to perform laser cladding, surface alloying or laser quenching strengthening to the conical surface of the cutting pick, thereby improving the hardness and the wear resisting property of the conical position on the end part of the cutting pick, prolonging the wear rate, effectively protecting a hard alloy tool bit, and prolonging the service life of the cutting pick.

Owner:SHANDONG ENERGY HEAVY EQUIP MFG GRP CO LTD

Laser-cladding repairing method of mold with snakeskin grains

InactiveCN102465293AReduce distortionExtended service lifeMetallic material coating processesHardnessMachine tool

The invention relates to a laser-cladding repairing method of a mold with snakeskin grains. The laser-cladding repairing method comprises the following steps of: fixing the mold on a worktable, polishing an oxide layer on the surface of an abraded place of the mold, finishing the oxide layer to form regular geometric shapes and washing a region to be cladded with acetone; compiling a machine tool program according to the cladded position, setting process parameters, staring a laser and carrying out cladding by using a cladding material; cooling and then carrying out dyeing inspection to judge whether a crack defect exists and polishing the cladding layer after judging that the product is qualified; and regenerating snakeskin grains on the surface of the polished cladded layer. According to the laser-cladding repairing method disclosed by the invention, a wire material which is similar to a material of the mold is selected to be used as the cladding material to ensure that the hardness of the cladded region and the hardness of an uncladded region are uniformly distributed, and the generated snake effects of the cladded region and the uncladded region are the same. The mold has little deformation after being subjected to laser-cladding, no sputter generates in the cladding process, snake grains in other regions are not affected, and the thickness of the cladded layer can be well controlled by filling a damaged region with the laser-cladding wire material. The laser-cladding repairing method disclosed by the invention has the advantages of prolonging the service life of the mold and reducing the production cost.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

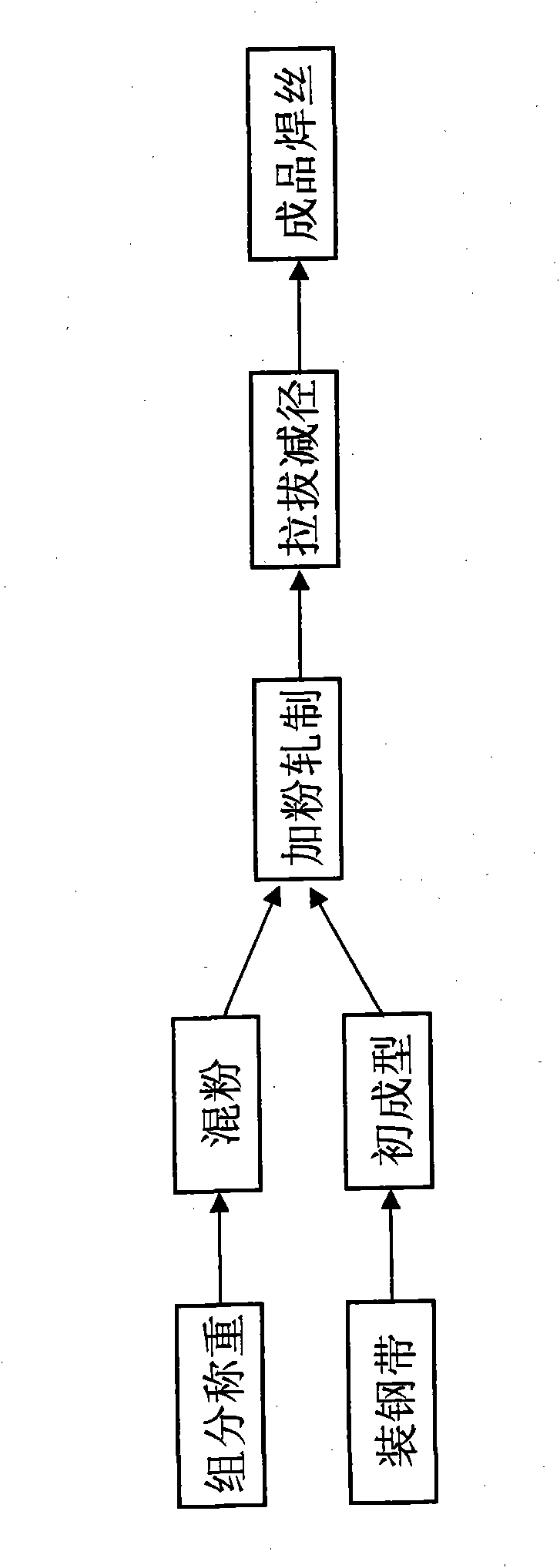

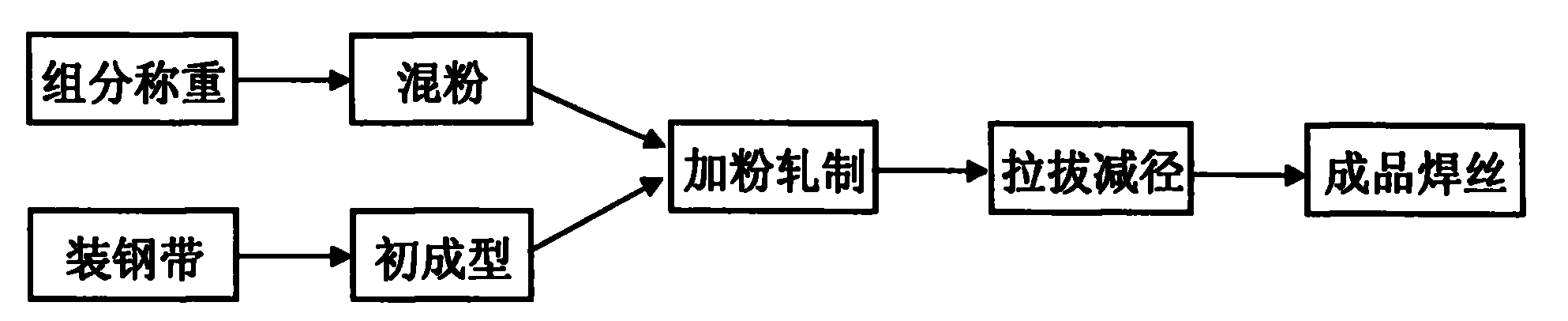

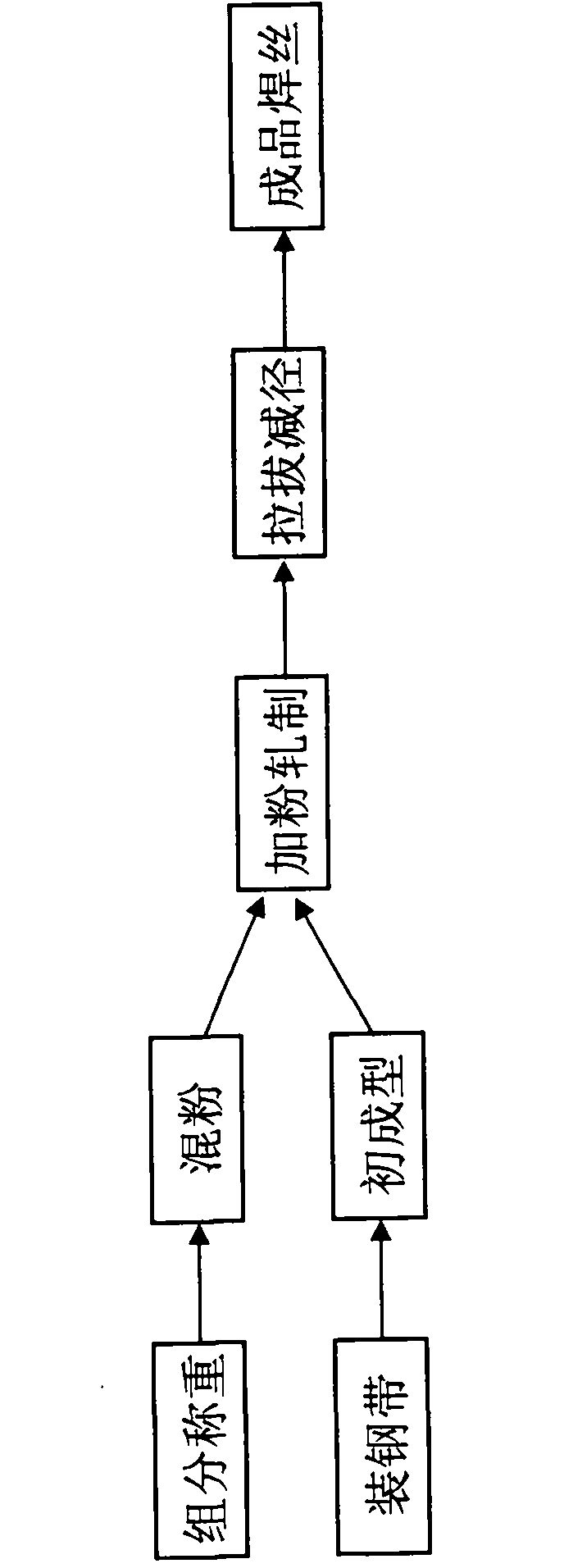

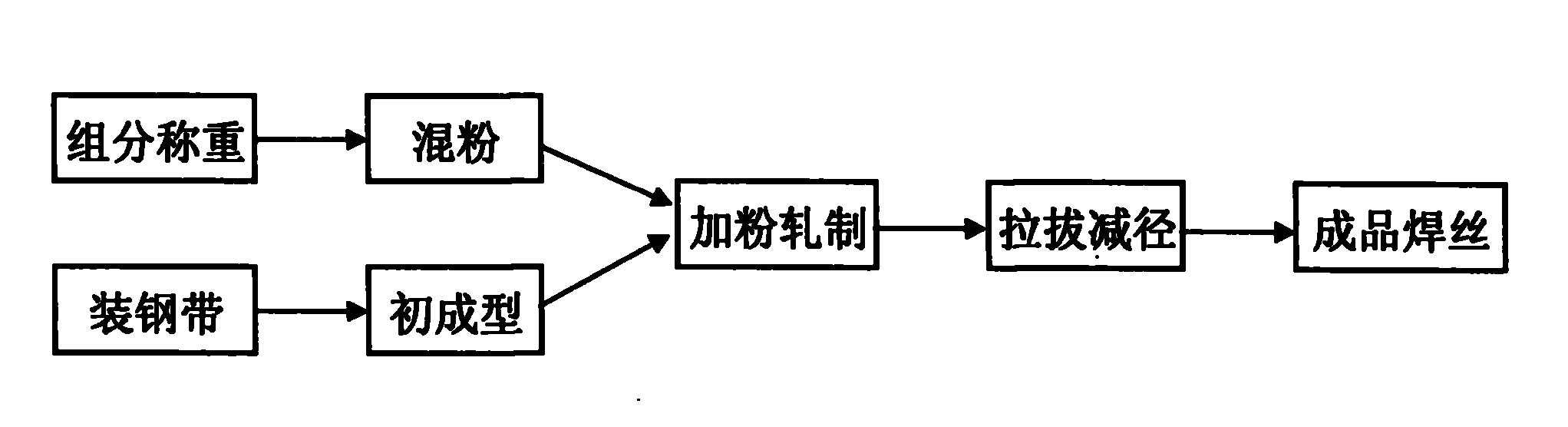

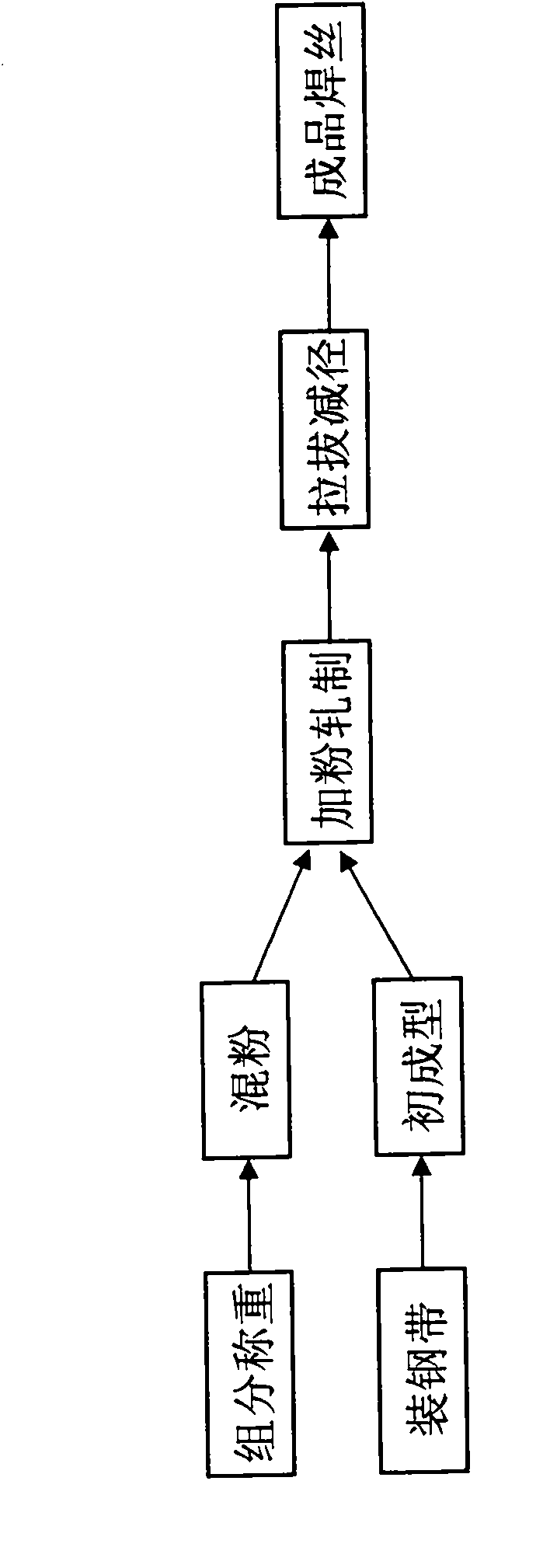

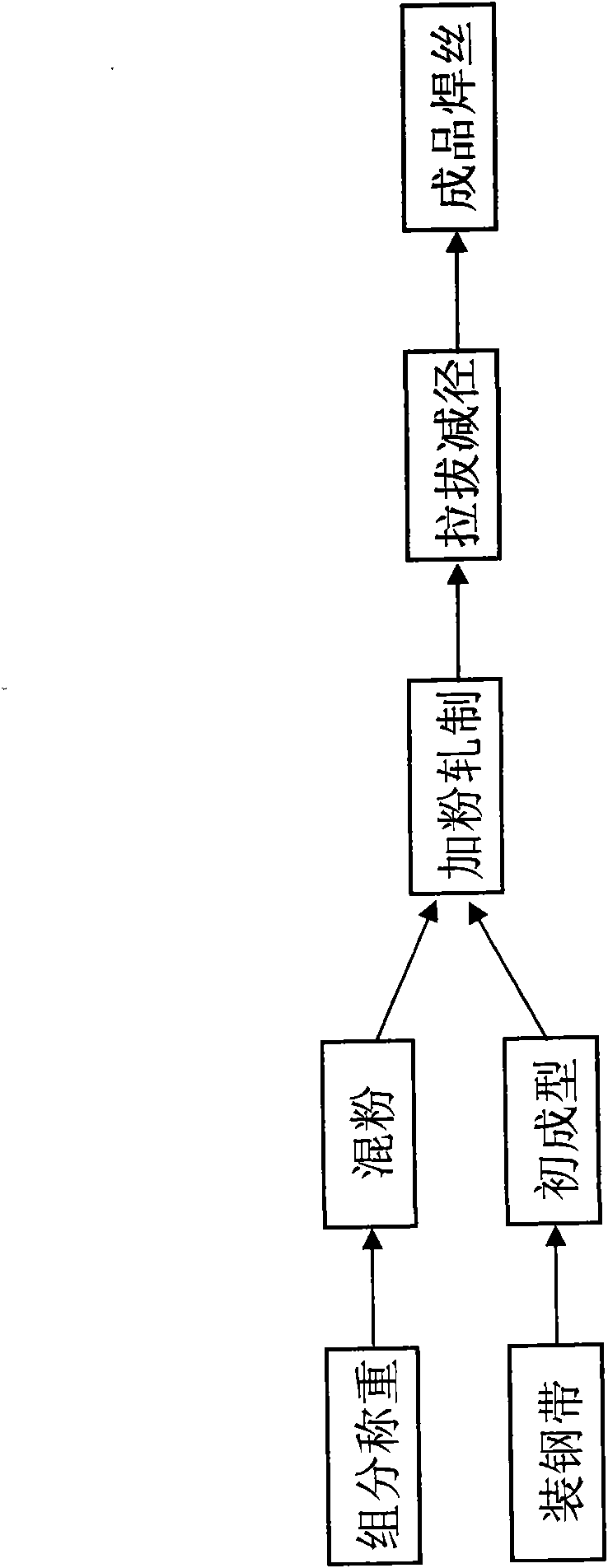

Niobium enhanced wear-resisting submerged arc bead weld flux-cored wire

InactiveCN101856776ASimple welding processUniform surface hardness distributionWelding/cutting media/materialsSoldering mediaIron powderHigh carbon

The invention discloses a niobium strengthening wear-resisting submerged arc bead weld flux-cored wire, which comprises a low-carbon steel cored solder wire and a power flux core arranged in the cored solder wire, and is mainly characterized in that the power flux core comprises the following components by weight percent: 30-55% of high-carbon ferrochrome, 4-16% of ferrocolumbium, 3-8% of deoxidant and 25-55% of iron powder. The bead weld layer of the invention has the advantages of evenly distributed hardness and high abrasive resistance; and the welding technological properties thereof are excellent.

Owner:HOHAI UNIV CHANGZHOU

Stone material cutting saw blade steel and its manufacturing method

ActiveCN100366779CReduce the risk of continuous casting billet breakageReduce the technical problem of large deformation resistanceFurnace typesMetal rolling arrangementsChemical compositionImpurity

This invention relates to a type of steel used for saw blade for stone slotting. Account for weight the chemical composition is: C 0.45-0.60,Si 0.10- 0.60,Mn 1.30-1.80,P<=0.02,S<=0.01,V 0.05-0.20,Cr 0.15-0.30, N 0.005-0.020,Ca 0-0.0050,Al 0.005-0.040, and the rest is Fe and inevitable impurity. The process includes steps as follows: smelting, casting,; continuous casting billet use heat sending and heat packing , ensure the temperature keep above 300DEG C before it be send into plate body for heating; keep temperature for plate body heating above 1150DEG C,temperature for hot rolling above 900DEG C; cooling after rolling, then coiling, keep the coiling temperature above 700DEG C. This invention has higher hardenability then midst-carbon and low-alloy steel, especially refer to make large saw blade which diameter is above 1000mm.

Owner:BAOSHAN IRON & STEEL CO LTD

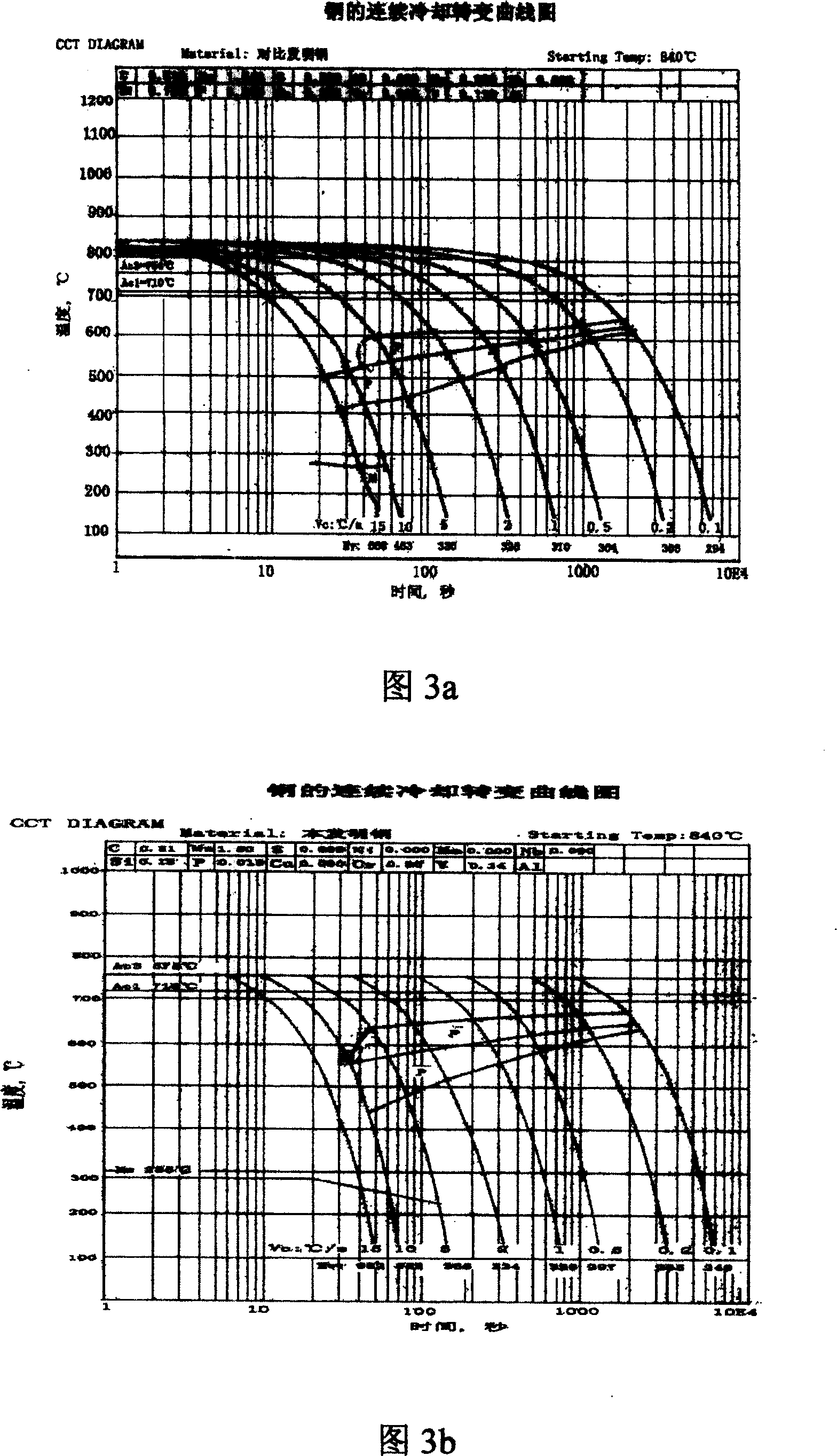

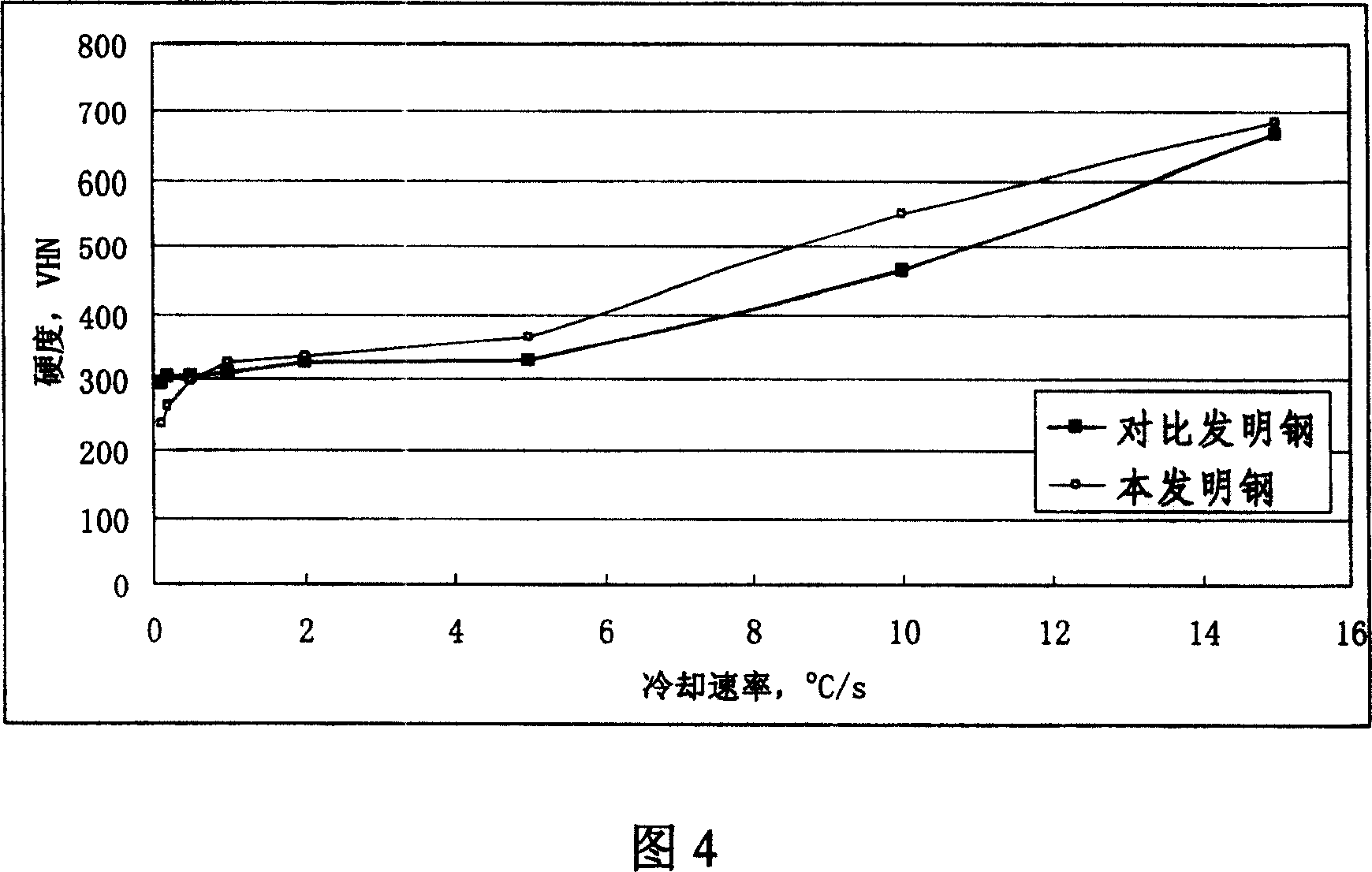

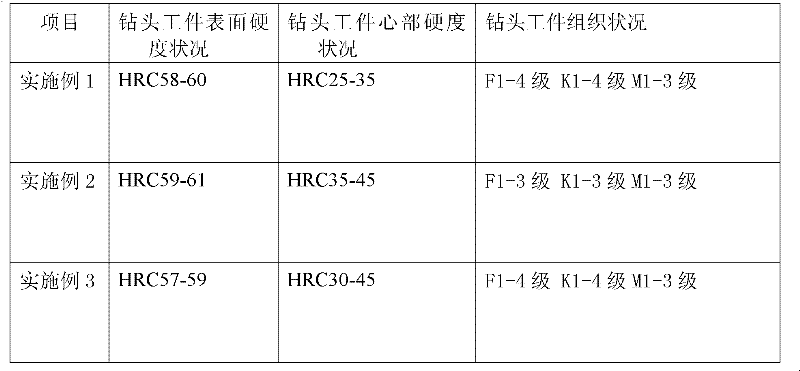

A kind of quenching method for 20crnimo material drill bit

InactiveCN102260779AExtended service lifeUniform hardness distributionFurnace typesHeat treatment furnacesQuenchingDrill bit

The invention relates to a quenching method for a 20CrNiMo material drill bit. The method comprises the following: a first quenching step, which comprises the steps of heating up a drill bit workpiece after being carburized, heat preserving, discharging from a furnace and oil cooling, washing with clear water, first tempering, heat preserving for at least three hours, naturally cooling, and discharging from the furnace and air cooling to the room temperature; and a second quenching step, which comprises the steps of second heating up the drill bit, heat preserving, discharging from the furnace and second oil cooling, extracting oil, washing with clear water, second tempering, and discharging from the furnace and air cooling to the room temperature. Due to the adoption of the two-time quenching process and a display of detected data from a test, the hardness of the workpiece of the 20CrNiMo material drill bit is uniformly distributed, the hardness value of the workpiece of the 20CrNiMomaterial drill bit reaches to Rockwell hardness 58-61, and the metallurgical structure of the workpiece of the 20CrNiMo material drill bit is further refined; moreover, the invention has the advantages of prolonging the service life of the 20CrNiMo material drill bit, increasing economic benefit, reducing replacement times and reducing production cost.

Owner:武汉钢铁重工集团冶金重工有限公司

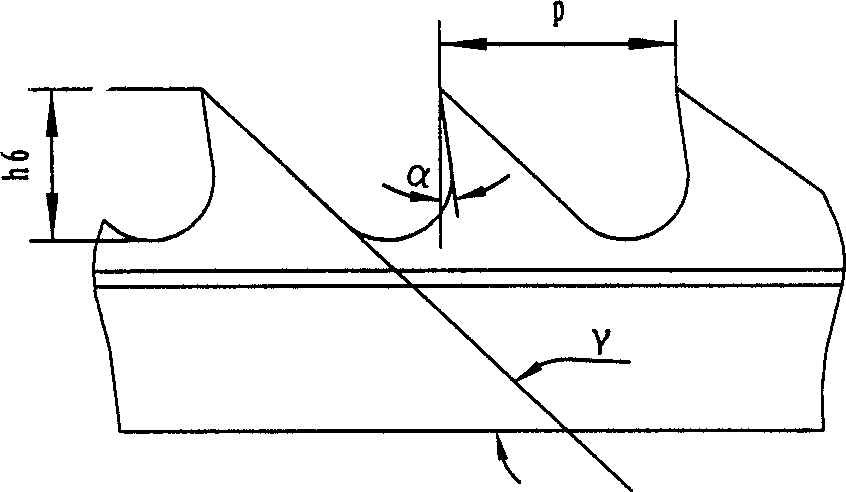

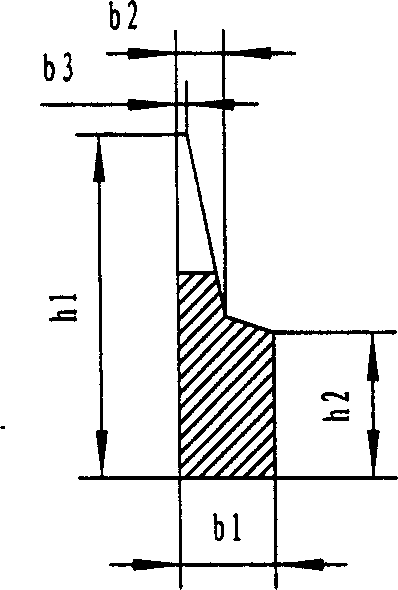

System and method for metal card clothing quenching treatment adopting YAG laser

InactiveCN1594606AUniform hardness distributionReasonable hardnessCarding machinesFurnace typesLight spotLight guide

The invention relates to a system and a method for rigid wire clothing quenching using YAG laser. The system includes: mounting beam enlarging lens, wholly reflective lens according to the YAG laser light path, reflective light entering into light guiding cartridge through light hole of work platform, other port of light guiding cartridge is connected with adjusting ring, adjusting ring is connected with focusing head, upper work platform is fixed on the low work platform, low work platform is fixed to ground, positioning device and cooling box is fixed to the low work platform, focusing head is in between, rigid wire clothing is fixing to movable mechanism of positioning device, the other end of rigid wire clothing pass through cooling box, controlling cabinet is mounted to ground, laser power resource and other bang-bang circuit is mounted in the controlling cabinet. Switching the laser power, YAG laser beam exported from laser is enlarged through beam enlarging lens, reflected by wholly reflective lens, focused by focusing lens in teeth of rigid wire clothing, form a high energy density light spot. That light spot energy is absorbed by teeth means thus the rigid wire clothing is quenched.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Titanium reinforced wear-resistance submerged overlaying flux-cored wire

InactiveCN101837523ASimple welding processUniform surface hardness distributionWelding/cutting media/materialsSoldering mediaIron powderHigh carbon

The invention discloses a titanium reinforced wear-resistance submerged overlaying flux-cored wire, comprising a mild steel cored solder wire and a powder flux core in the cored solder wire. The powder flux core is characterized by comprising the following components in percentage by weight: 30 to 55 percent of high-carbon ferrochrome, 10 to 25 percent of ferrotitanium, and 25 to 55 percent of iron powder. An overlaying welding layer using the flux-cored wire has the characteristics of uniform hardness distribution, high wear resistance and the like, and has excellent welding technical performance.

Owner:HOHAI UNIV CHANGZHOU

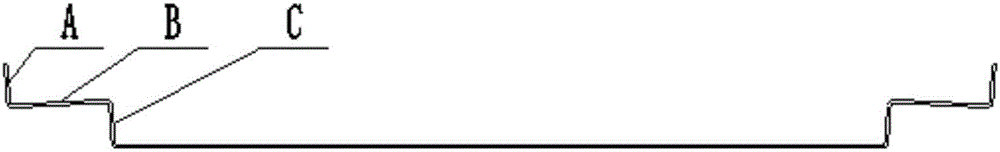

Bending die for safe case door frame plate and using and machining method thereof

The invention discloses a bending die for a safe case door frame plate and a using and machining method thereof and belongs to the field of die design. The die comprises an upper die assembly provided with an upper die body, and a lower die assembly provided with a lower die body. The stamping face of the upper die body is matched with the stamping groove face of the lower die body. The die can machine a safe case door frame plate workpiece required to be machined at a time, precision is high, secondary manual treatment is not needed, damage to the surface of the workpiece is avoided, operation is convenient, and cost is low. The using method of the die can machine the safe case door frame plate fast and efficiently and is high in bending efficiency and good in finished product quality. The machining method of the die is used in the upper die body or the lower die body, firstly, forging is carried out, then the shape of various parts is machined, then accurate grinding is carried out, finally, assembling is carried out, the special heat treatment technology is adopted, the hardness, the tenacity and the abrasion resistance of the die meet the technological requirement, and the die is still normal after being used for over ten thousand times and long in life.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

Repairing process and repairing tool for excircle crack conquassation of tires and carrier rollers of rotary kiln

The invention relates to a repairing process and a repairing tool for excircle crack conquassation of tires and carrier rollers of a rotary kiln. According to the invention, a flux-cored wire, of which the tensile strength is 585, is used for padding and isolating; padding, isolating and cladding are conducted twice on a circle of a plano-concave groove, wherein the current is 190, the voltage is 22, and the welding seam is required to be 10 mm higher than the upper part of a groove base metal; then a solid core wire, of which the yield strength is 580, is used for replacing the flux-cored wire to caulk and restore the size, wherein the integral appearance of a concave welding bead is required to be kept during the build-up welding process; segmental welding is adopted on the basis to restore the size; finally, a temper bead is additionally capped; when the size is restored through build-up welding, the internal stress can be lowered to the minimum value, and build-up welding is fulfilled; and on-site heat treatment is carried out immediately. Therefore, the repairing process and the repairing tool have the advantages that the integration of welding material and base metal can be better; the distribution of metallographic structures and hardness is uniform; impact of vertical welding is avoided; the construction is fast; the welding strength is high; the ductility and the toughness are good; wear-resistant, corrosion-resistant, heat-proof, shock-proof and crack-resistant capabilities are excellent; stop time in cement enterprises is reduced; and the production efficiency is improved.

Owner:水文文

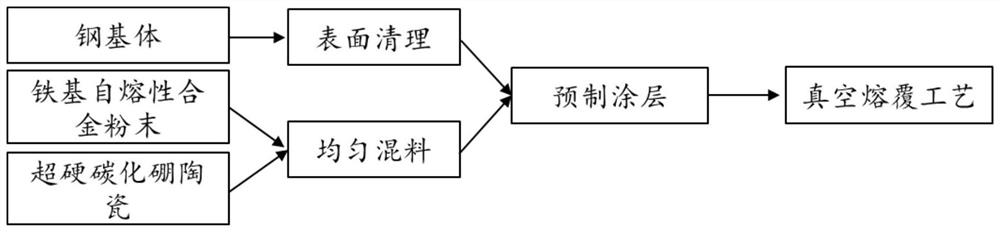

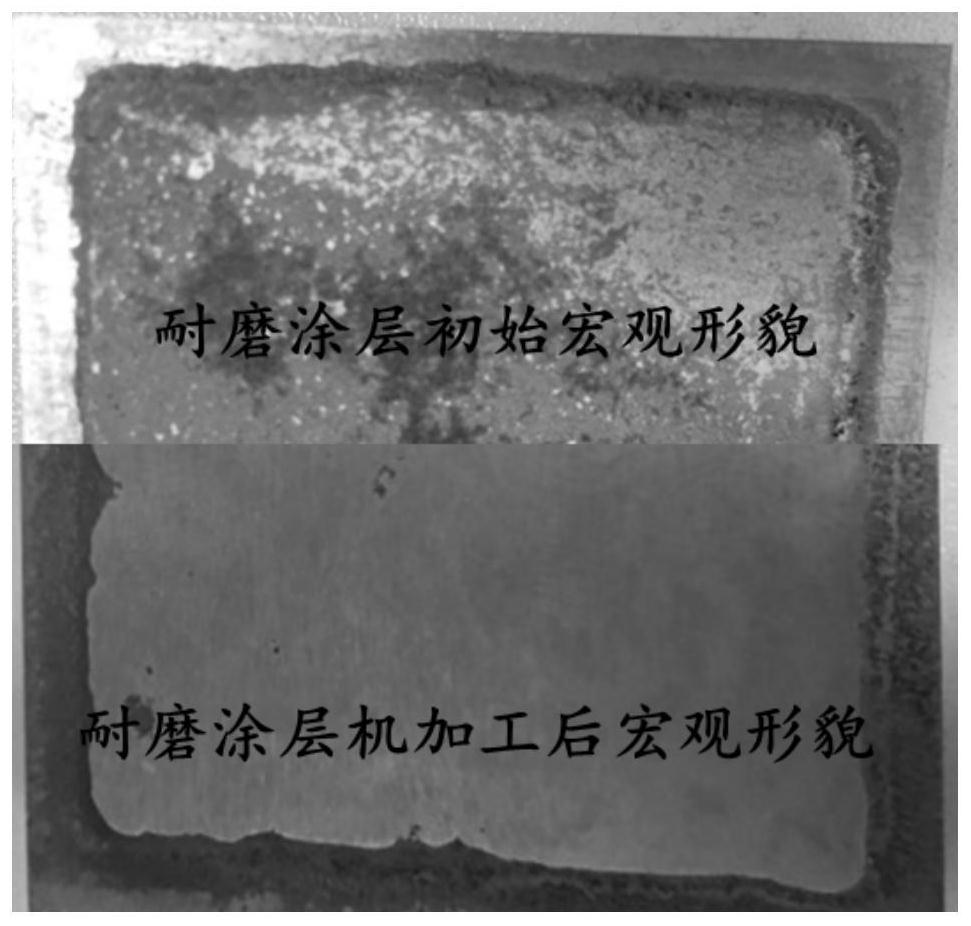

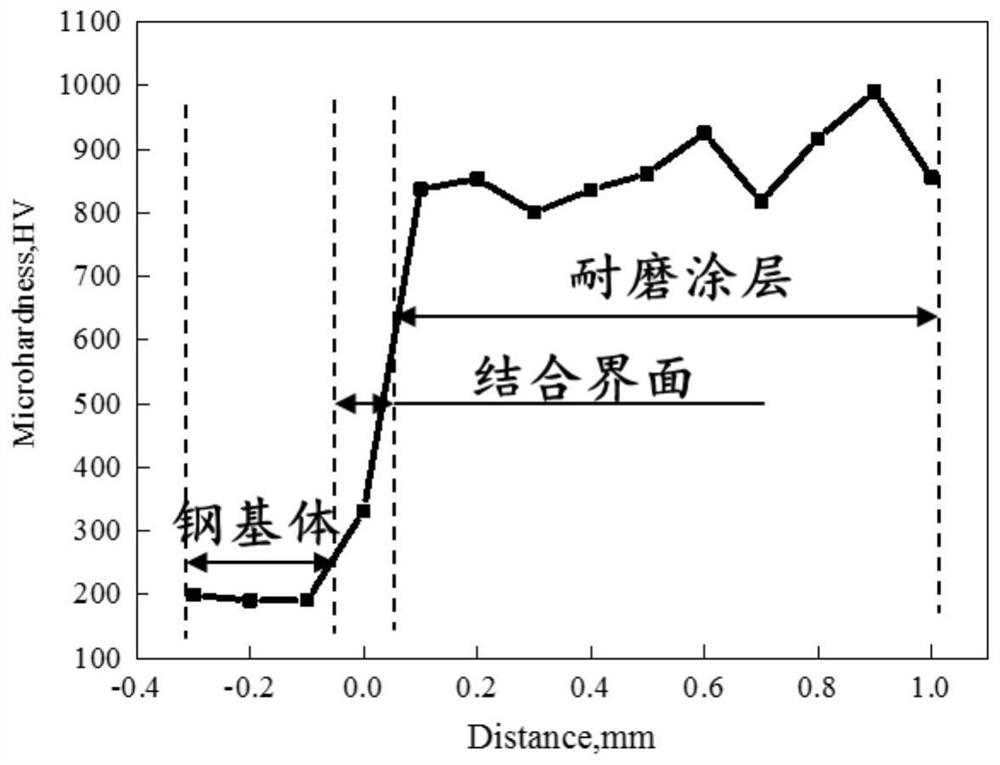

Preparation method of superhard boron carbide ceramic reinforced iron-based alloy composite wear-resistant coating

ActiveCN112708883AWide source of powderWide variety of sourcesMetallic material coating processesCrazingCeramic particle

The invention relates to a preparation method of a superhard boron carbide ceramic reinforced iron-based alloy composite wear-resistant coating. The preparation method comprises the following steps: (1) preparing boron carbide ceramic particles and iron-based self-fluxing alloy powder as raw materials; (2) preparing a steel substrate of which the surface is treated to form a surface to be cladded; (3) putting the boron carbide ceramic particles and the iron-based alloy powder into a ball mill for dry ball milling and mixing; (4) adding a binder into the mixed powder, uniformly stirring to form viscous paste, and coating the surface of the steel substrate with the viscous paste; (5) drying after air drying; and (6) carrying out vacuum cladding and then carrying out furnace cooling. The coating prepared by the method provided by the invention has no cracks and micropores penetrating through the whole thickness, is a continuous closed coating, and can significantly improve the wear resistance of mechanical parts, prolong the service life and improve the safety performance.

Owner:NORTHEASTERN UNIV

Tungsten-strengthened wear-resistant submerged-arc overlaying welding flux-cored wire

InactiveCN101870047ASimple welding processUniform surface hardness distributionWelding/cutting media/materialsSoldering mediaIron powderWear resistant

The invention discloses a tungsten-strengthened wear-resistant submerged-arc overlaying welding flux-cored wire which comprises a low-carbon steel cored solder wire and flux-cored powder arranged in the cored solder wire, wherein the flux-cored powder is mainly characterized by comprising the following components in percentage by weight (%): 30-55% of high carbon ferrochrome, 3-15% of tungsten powder, 3-8% of deoxidizer and 25-55% of iron powder. The overlaying welding layer of the invention has the characteristics of uniform hardness distribution, high wear resistance, excellent welding technological properties and the like.

Owner:HOHAI UNIV CHANGZHOU

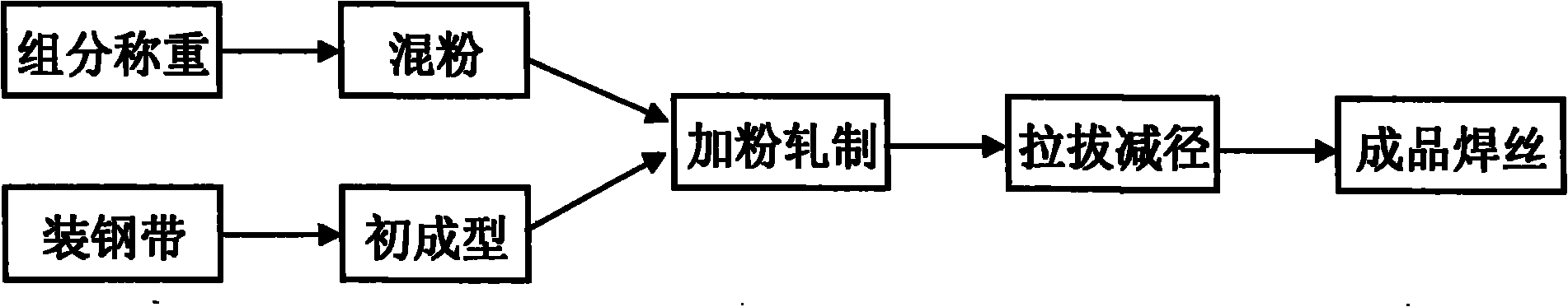

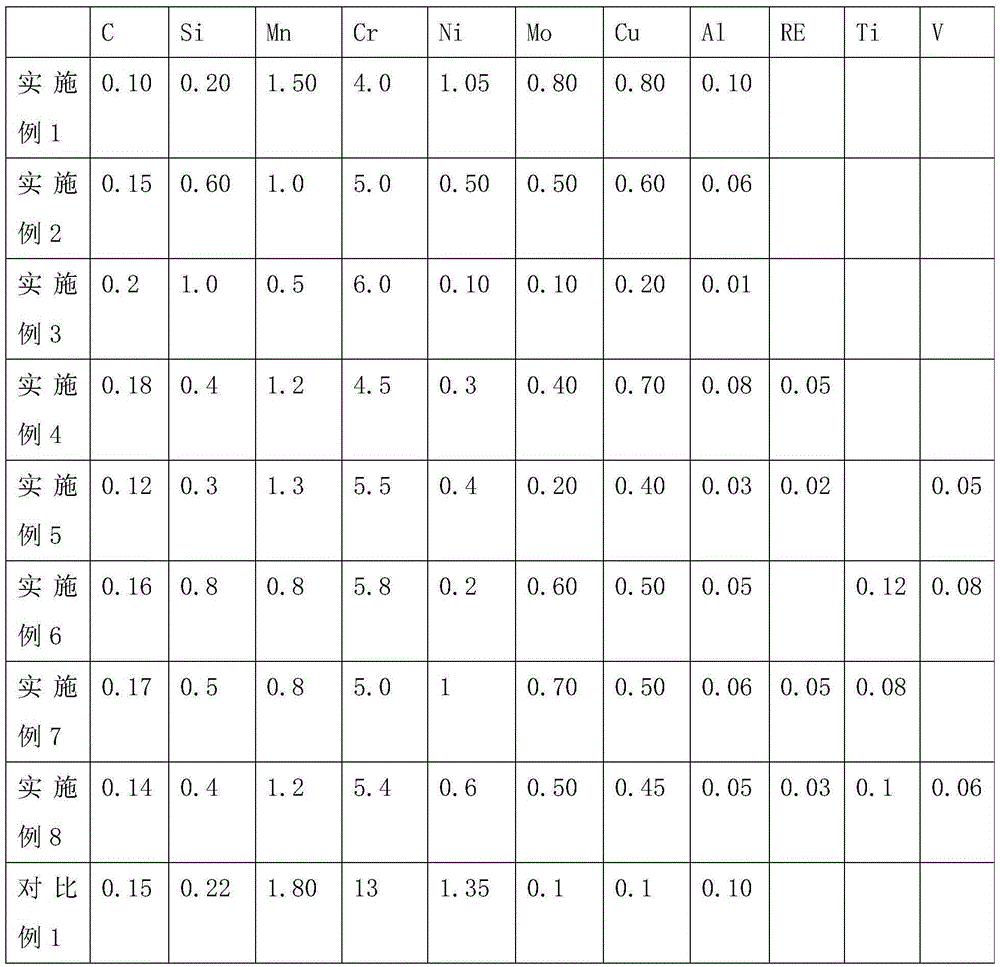

Corrosion-resistant steel for oil well and production method for corrosion-resistant steel

InactiveCN105256243AReduce manufacturing costStrong stress corrosion resistanceChemical compositionMechanical property

The invention provides corrosion-resistant steel for an oil well and relates to the technical field of steel. The corrosion-resistant steel is prepared from, by mass, 0.10%-0.20% of C, 0.20%-1% of Si, 0.05%-1.5% of Mn, 4.0%-6.0% of Cr, 0.10-1.0% of Ni, 0.10%-0.8% of Mo, 0.20%-0.80% of Cu, 0.01%-0.10% of Al and the balance Fe and inevitable impurity elements, wherein the total content of the inevitable impurity elements is not higher than 0.5%. The corrosion-resistant steel for the oil well achieves the mechanical properties that the yield strength ranges from 1,020 MPa to 1,150 MPa, the tensile strength ranges from 1,140 MPa to 1,300 MPa, the elongation is around 20%, and the Kv of a 140 ksi steel grade casting pipe product is around 30 J at 0 DEG C. In addition, the corrosion-resistant steel for the oil well belongs to the category of low-alloy steel, and the content of Cr and Ni is low; and the CO2 corrosion resisting performance and the H2S corrosion resisting performance of the steel are improved through the methods such as simultaneously adding a small quantity of elements retarding the anode process and elements promoting the cathode process and the surface activity. The corrosion-resistant steel for the oil well is low manufacturing cost and high in CO2 corrosion and H2S stress corrosion resistance.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

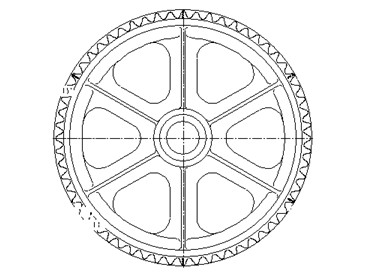

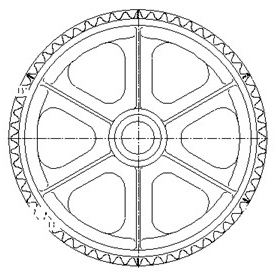

Cast steel material for chain wheel of marine diesel engine and casting method of chain wheel

ActiveCN102115851AHigh surface hardnessImprove mechanical propertiesPortable liftingGearing elementsChemical elementThermal treatment

The invention relates to a cast steel material for a chain wheel of a marine diesel engine. The cast steel material comprises the following chemical elements in percentage by mass: 0.18-0.21 percent of C, 0.85-1.00 percent of Mn, 0.35-0.55 percent of Si, less than or equal to 0.020 percent of S, less than or equal to 0.020 percent of P, less than or equal to 0.30 percent of Cr, less than or equal to 0.30 percent of Ni, less than or equal to 0.080 percent of Mo, less than or equal to 0.10 percent of V, less than or equal to 0.080 percent of Al, less than or equal to 0.060 percent of Nb, less than or equal to 0.40 percent of Cu and the balance of Fe element and other inevitable impurities. In the element proportion, the carbon equivalent that CEV is less than or equal to 0.39 percent is met, wherein CEV is calculated by a formula, namely CEV=C%+(Mn%) / 6+(Cr%+Mo%+V%) / 5+(Ni%+Cu%) / 15. In a manufacturing method, raw materials of the chain wheel are reasonably selected and unconventional normalizing thermal treatment is performed, so that the yield of the mechanical property of the chain wheel is increased, the technical problems of low tooth surface hardness and uniformity are solved, the running reliability of the marine diesel engine is enhanced, and production cost is lowered.

Owner:HUDONG HEAVY MACHINERY

Vanadium-reinforced wear-resistant submerged-arc surfacing flux-cored welding wire

InactiveCN101837522BSimple welding processUniform surface hardness distributionWelding/cutting media/materialsSoldering mediaHigh carbonWear resistant

The invention discloses a vanadium-reinforced wear-resistant submerged-arc surfacing flux-cored welding wire which comprises a low carbon steel hollow welding wire and a powder flux core arranged in the hollow welding wire, and is mainly characterized in that the powder flux core comprises the following components in percentage (%) by weight: 30-55 percent of high carbon ferro chrome, 8-20 percent of ferro vanadium, 3-8 percent of deoxidizing agent and 25-55 percent of ferrous powder. By using a surfacing welding layer of the invention, the vanadium-reinforced wear-resistant submerged-arc surfacing flux-cored welding wire has the characteristics of uniform rigidity distribution, high wearing resistance and the like, and has good welding process performance.

Owner:HOHAI UNIV CHANGZHOU

Organic-inorganic composite coating material, preparation method thereof, and method for preparing wear-resistant coating by using organic-inorganic composite coating material

The invention discloses an organic-inorganic composite coating material, a preparation method, and a method for preparing a wear-resistant coating by using the organic-inorganic composite coating material. The preparation method of the organic-inorganic composite coating material comprises the following steps: taking tetraethoxysilane as a precursor, and adding a silane coupling agent to prepare ahybrid silica sol; and reacting the hybrid silica sol with a titanium dioxide sol to obtain the organic-inorganic composite coating material. A matrix is pretreated, then is impregnated in the organic-inorganic composite coating material for 1-2 min, then is pulled out at a constant speed and stands for 2-4 h, and then the coating material is dried to form the wear-resistant coating on the matrix. The prepared organic-inorganic composite coating material can form the flat and compact coating on the surface of the matrix, so the wear resistance of the matrix is remarkably improved; the preparation method is simple, the production efficiency is high, and the organic-inorganic composite coating material has wide application prospects in the field of explosion-proof materials.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Methods for using and machining one-time forming die for safety box side plate

The invention discloses methods for using and machining a one-time forming die for a safety box side plate and belongs to the field of die design. The method for using the die comprises the steps thatan upper die assembly and a lower die assembly are assembled firstly; then the lower die assembly is fixed to a working table of a hydraulic machine; then the upper die assembly is hoisted to the lower die assembly, and the stamping groove faces of the upper die assembly and the lower die assembly are tightly matched; then the upper die assembly is fixed to a sliding block of the hydraulic machine; and finally, a workpiece on a lower die is subjected to bending forming through the upper die assembly. According to the method for using the die, the safety box side plate can be quickly and efficiently machined, the bending efficiency is high, and the quality of a finished product is good. The method for machining the die is used for machining an upper die and the lower die and comprises thesteps that forging is conducted firstly; the shapes of all parts are machined; then fine grinding is conducted; and finally assembling is conducted. A special heat treatment process is adopted, thus the hardness, toughness and abrasion resistance of the die meet the process requirements, the die is still normal after being machined and used for more than ten thousand times, and the life is long.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

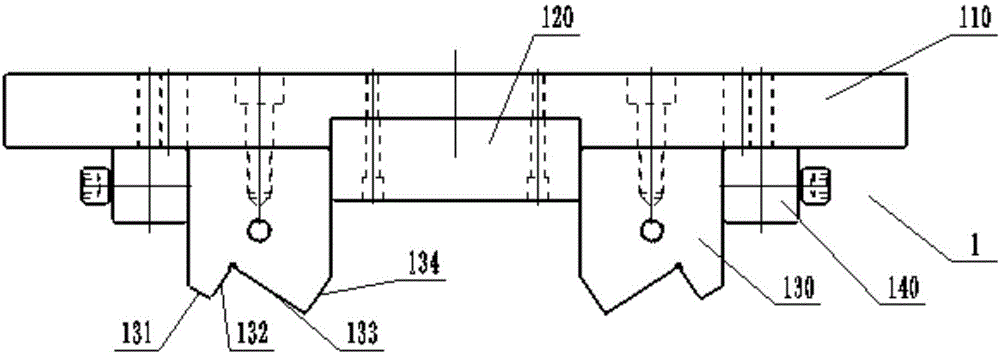

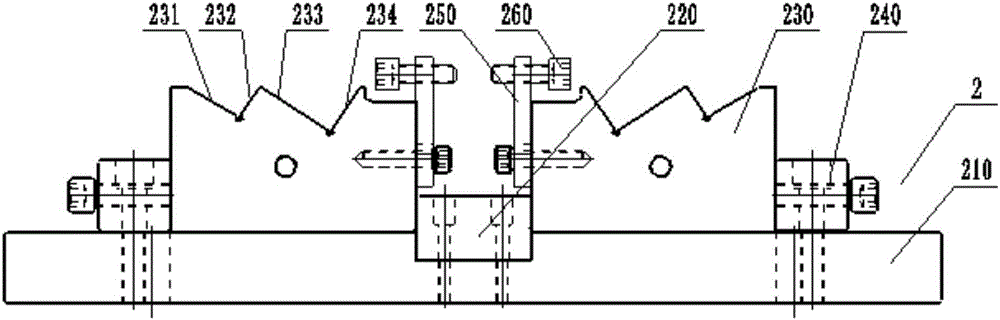

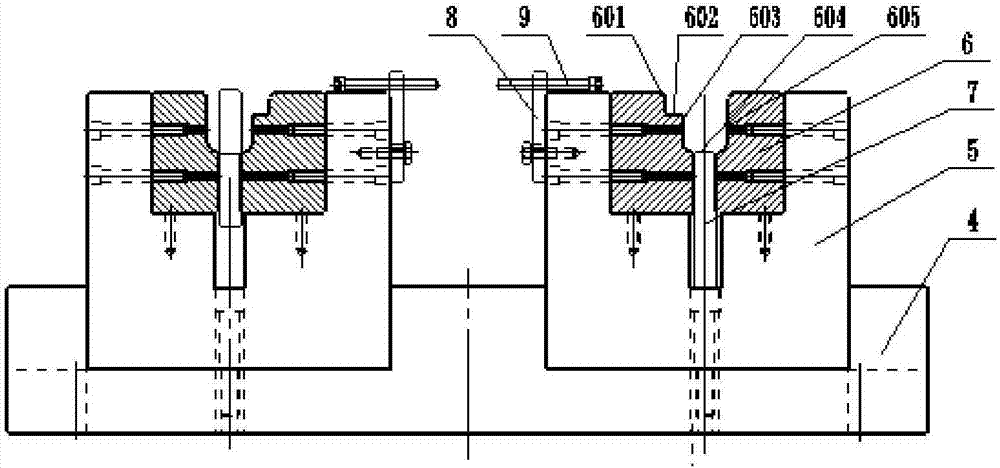

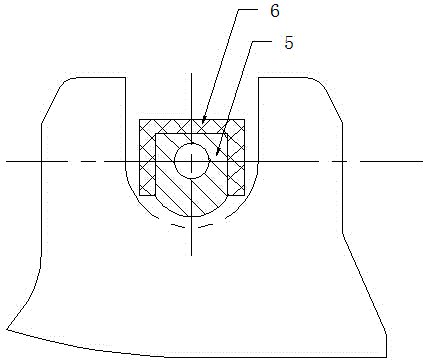

U-shaped groove surface quenching inductor

InactiveCN106319173AImprove quenching efficiencyUniform hardness distributionIncreasing energy efficiencyFurnace typesBusbarEngineering

A U-shaped groove surface quenching inductor comprises an induction heating part, a plurality of cooling parts and a supporting rack, the induction heating part and the plurality of cooling parts are fixedly arranged on the supporting rack, the induction heating part is formed by a busbar, an effective loop and a group of magnetizers, the effective loop is a variable cross section structure with the cross section gradually reducing along the length direction, and a cooling hole is arranged in the effective loop; and the group of magnetizers with U-shaped cross section is jointed to the effective loop, and the dimension of the U-shaped cavity of every magnetizer adapts to the dimension of the corresponding effective loop cross section. The variable cross section effective loop is adopted, and the magnetizers change with the effective ring and the part structure, so the U-shaped groove surface quenching inductor has the advantages of high quenching efficiency, uniform hardness distribution, simple structure and low production cost.

Owner:湖北华阳汽车制动器股份有限公司

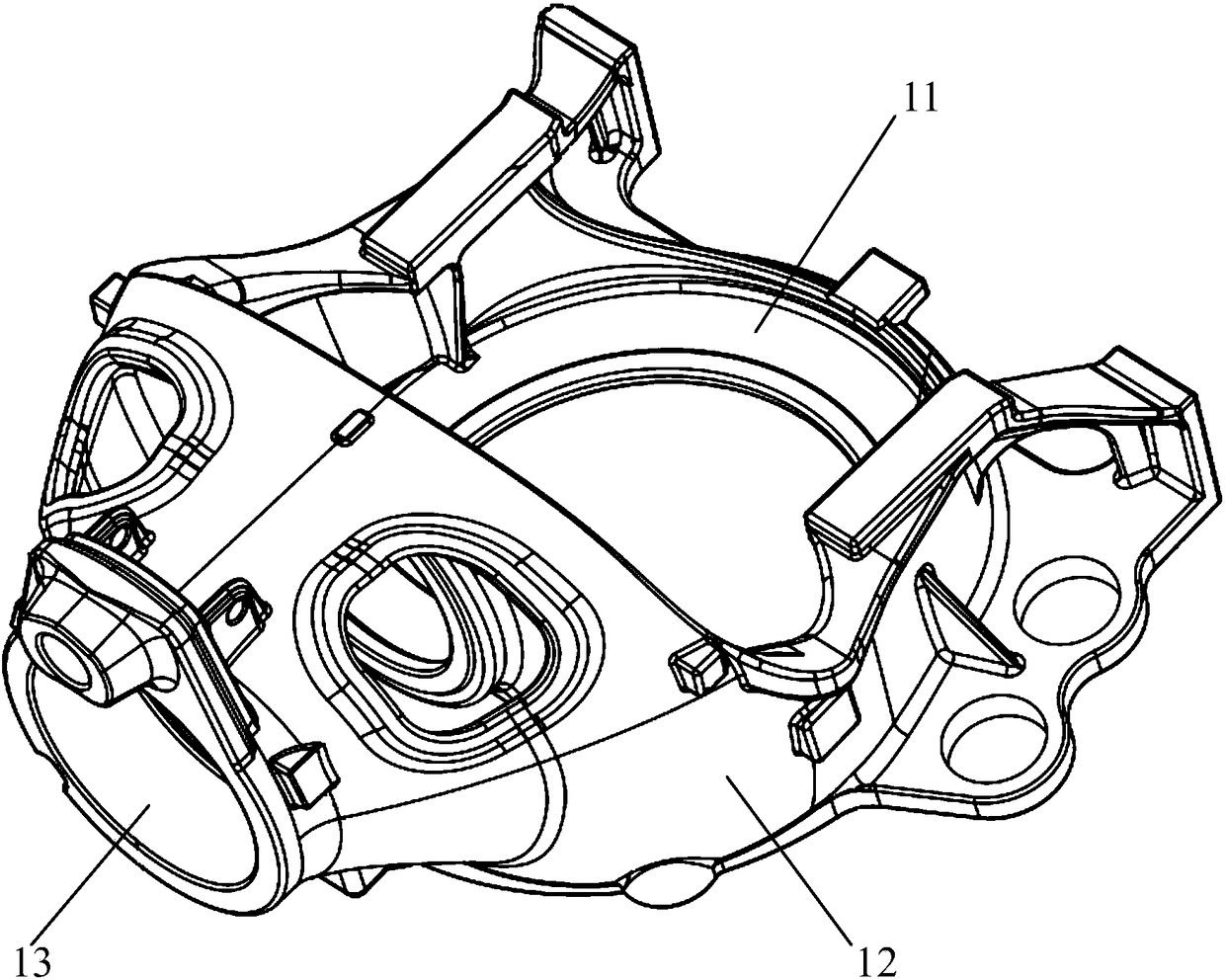

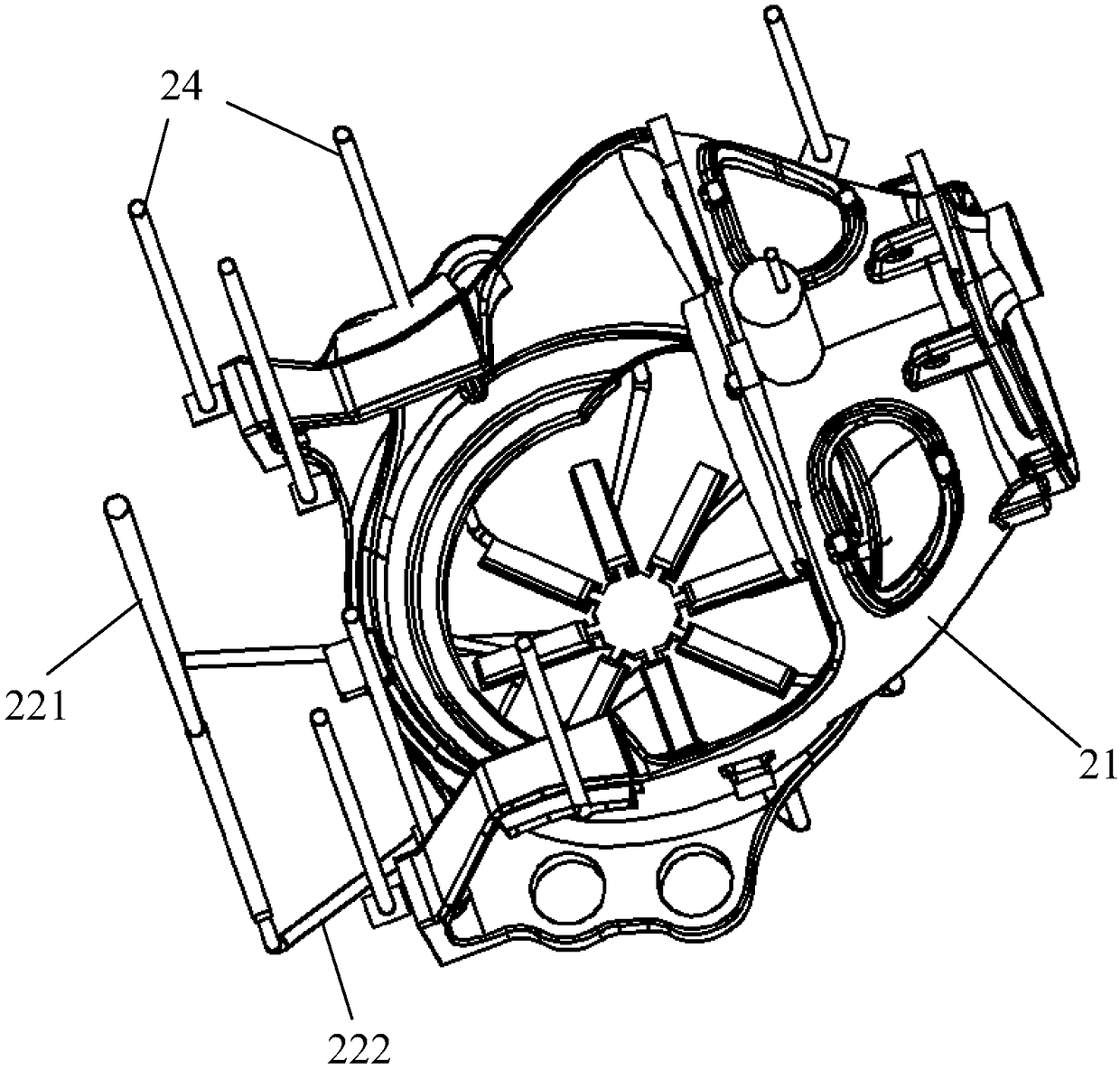

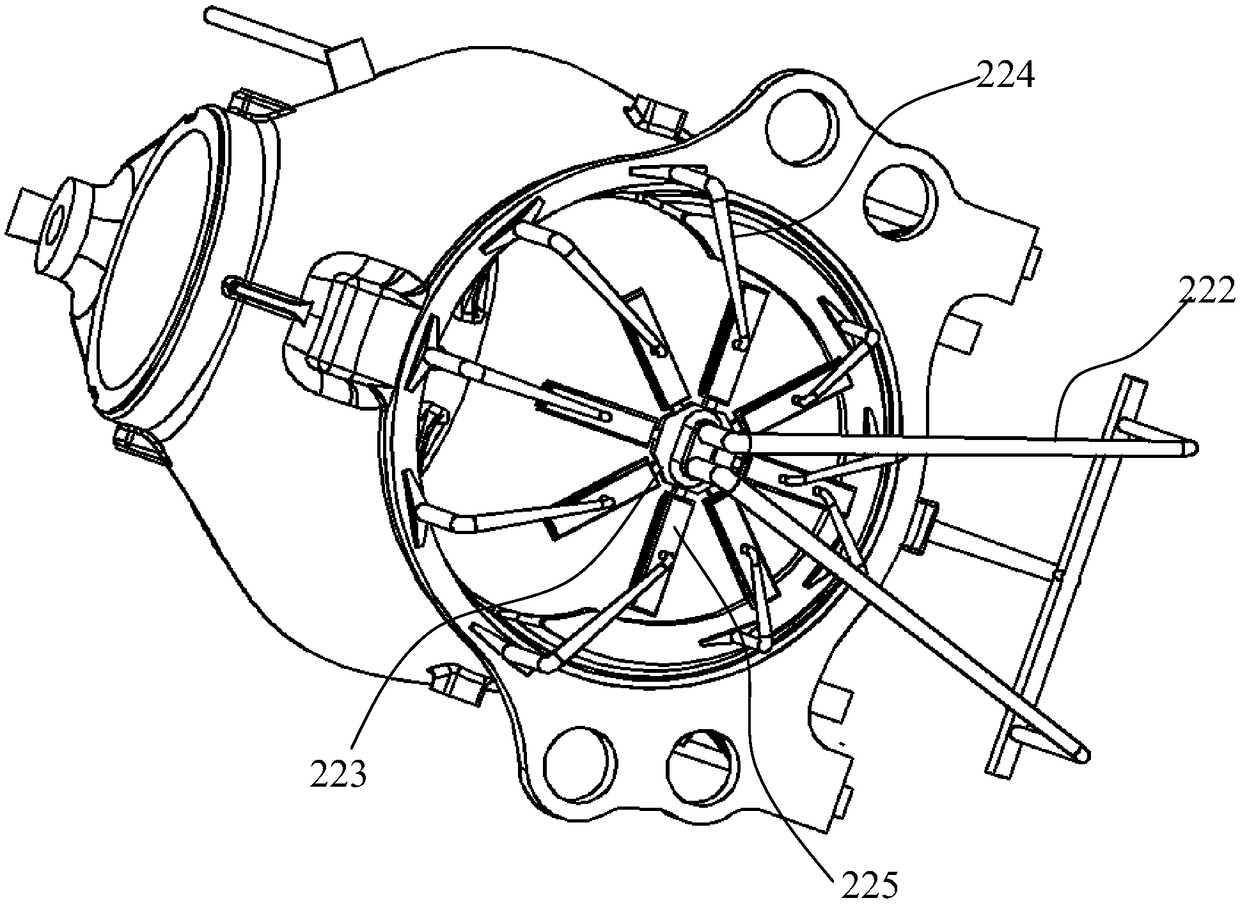

Mould and casting method of solid solution strengthened ferritic nodular cast iron wind power casting

PendingCN108311644AReasonable distributionGuaranteed feeder feedFoundry mouldsFoundry coresSlagDuctile iron

The invention discloses a mould and a casting method of a solid solution strengthened ferritic nodular cast iron wind power casting. The mould comprises a sandbox, a sand mold and a core. A cavity structure formed by combining the sand mold with the core comprises: a casting cavity arranged in the mould, wherein the shape of the casting cavity fits the profile of the wind power casting, and the casting cavity is provided with a plurality of risers; a casting system, wherein the casting system comprises at least one iron inlet, at least one molten iron main runner, a central shunting chamber, aplurality of molten iron sub-runners and a plurality of filters; and a warming system, wherein the warming system comprises a plurality of hot air channels, and the hot air channels are arranged above the casting cavity in a communicating manner. The casting system in the mould is reasonably distributed, the plurality of molten iron sub-runners greatly shortens the casting time and ensures stableiron feeding, and the filters are used to effectively avoid the defects of cold shut and slag inclusion of the casting. The arrangement of the risers ensures the riser feeding of the cavity.

Owner:JIANGSU JIXIN WIND ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com