Mould and casting method of solid solution strengthened ferritic nodular cast iron wind power casting

A solid solution strengthening, ductile iron technology, applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of inability to mass-produce wind power castings, poor flow performance of molten iron, large shrinkage tendency, etc., to avoid cold The effect of separation and slag inclusion defects, stable iron feeding and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 The casting mold of the wind power base

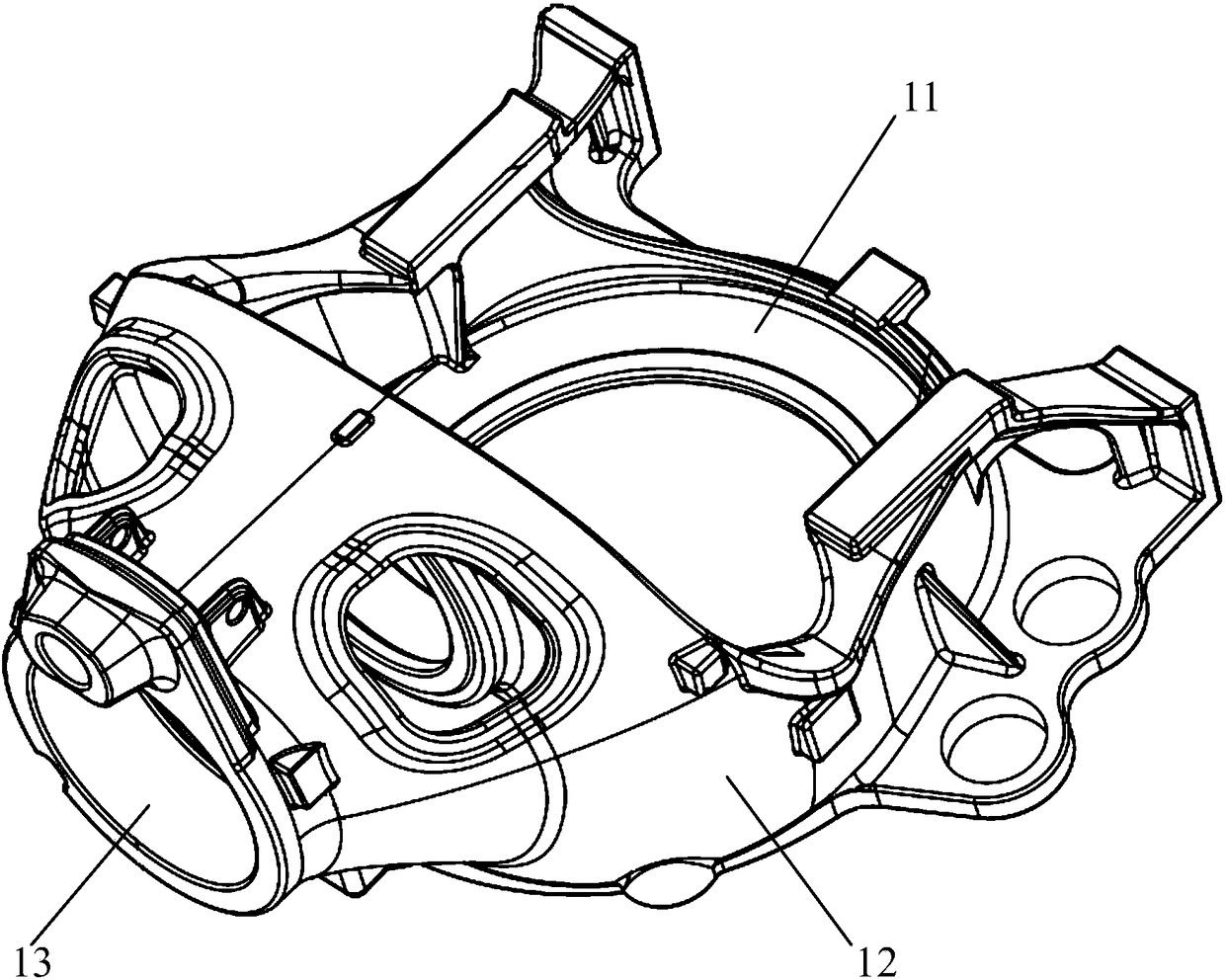

[0053] figure 1 Shown is a GE3.2MW-130 combined base, including a bottom flange 11, a special-shaped curved surface 12, and a hub installation ring 13. side. The weight of the wind power base is about 18.17T, the maximum size is 4042mm*3600mm*3010mm, the main wall thickness is 70-200mm, and the material is QT600-10.

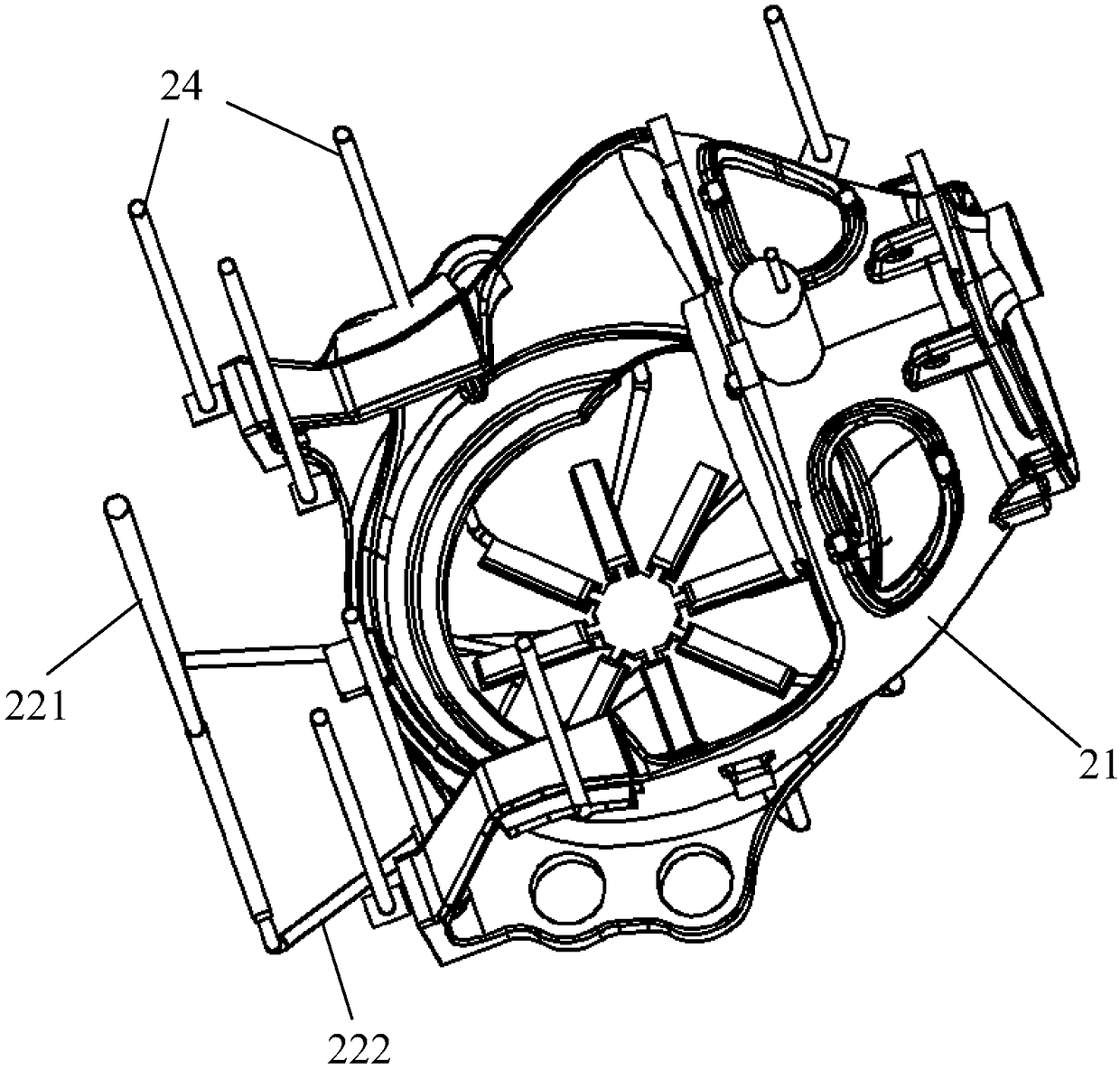

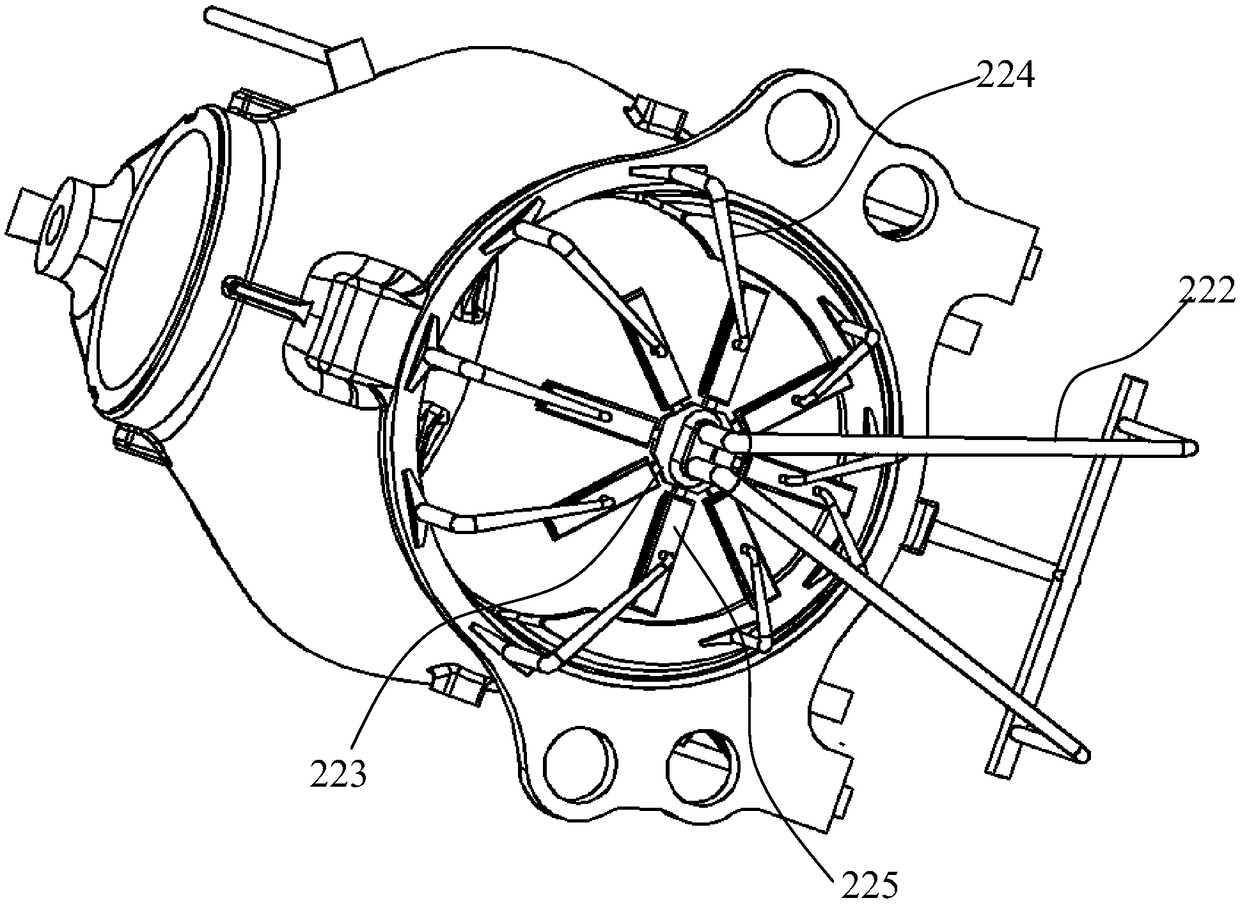

[0054] Taking the above-mentioned GE3.2MW-130 integrated base (QT600-10) as an example, the casting mold of solid solution strengthened ferritic ductile iron wind power castings designed by the present invention includes sand boxes, sand molds and cores. The sand mold is formed by falling sand into the sand box, then puts the core into the box, and forms the mold after closing the box. The casting mold is provided with: a casting cavity 21 , a pouring system 22 and a heating system 23 . Casting cavity 21, gating system 22 and heating system 23 are used as the internal structure, which is composed of s...

Embodiment 2

[0055] Embodiment 2 Use the mold of Embodiment 1 to cast GE3.2MW-130 fit base (QT600-10)

[0056] Casting steps:

[0057] (a) Smelting molten iron

[0058] Furnace charge: 40-50% new iron, 30-40% recycled charge, 10-20% steel scrap.

[0059] Further, the new iron is high-purity pig iron, wherein C: ≥ 4.0%, Mn: ≤ 0.10%, P: ≤ 0.025%, S: ≤ 0.015%, and the sum of harmful alloy elements due to anti-spheroidization ≤ 0.08%; The steel scrap mentioned above is thin flake carbon steel scrap, wherein C: ≤0.15%, Mn: ≤0.40%, P: ≤0.03%, S: ≤0.03%.

[0060] Smelting the burden into molten iron; adjusting the composition of the charge through spectral analysis to control the carbon equivalent in the molten iron: C: 3.4% to 3.5%, Si: 3.7% to 4.0%, Mn: 0.1% to 0.35%, P: <0.04%, S : ≤0.012%, Mg: 0.04% ~ 0.07%, Cr: <0.05%, Ti: <0.03%;

[0061] (b) Spheroidization treatment and inoculation treatment

[0062] Select a low-rare-earth ferrosilicon-magnesium alloy nodulizer (50% Elkem 5813+50% s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com