Corrosion-resistant steel for oil well and production method for corrosion-resistant steel

A technology for corrosion-resistant steel and production method, applied in the field of steel, can solve the problems of weak stress corrosion resistance and high cost of corrosion-resistant steel, and achieve the effects of strong CO2 corrosion resistance, low manufacturing cost, and strong H2S stress corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

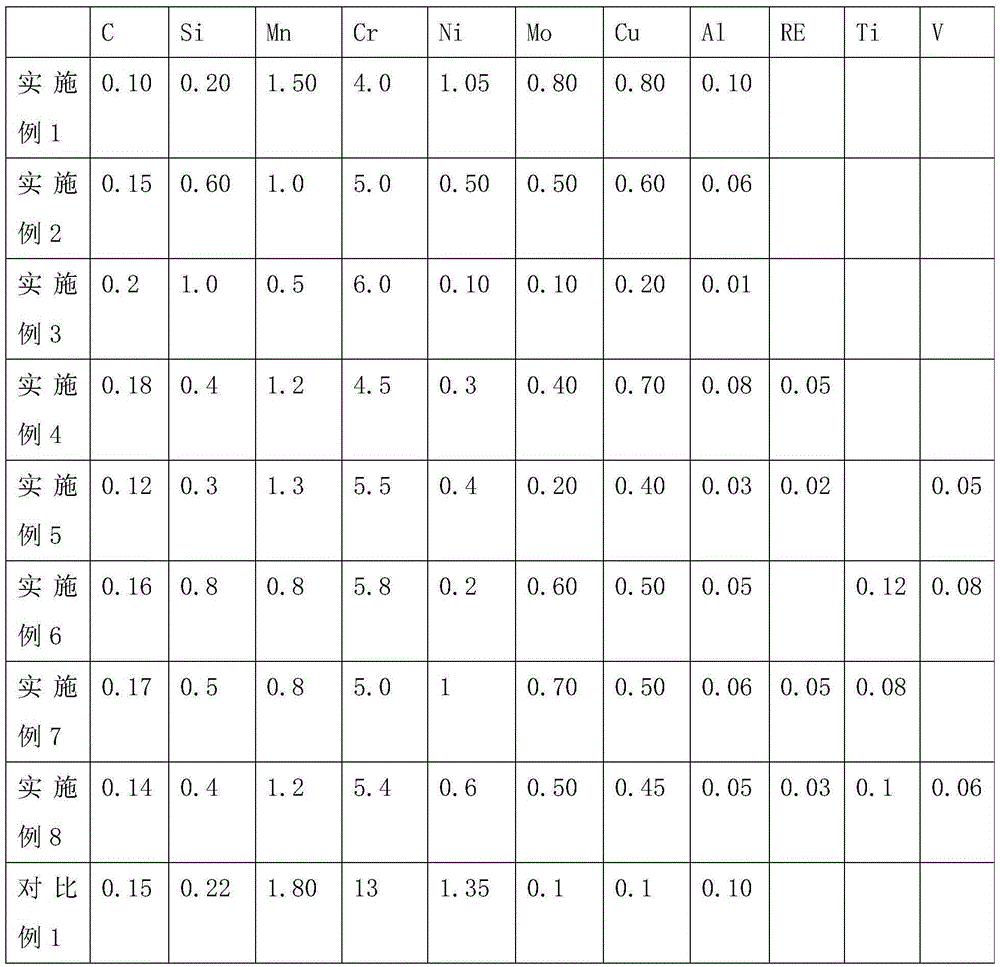

[0055] This embodiment provides a kind of corrosion-resistant steel for oil wells, which has the chemical composition as shown in Example 1 in Table 1 in terms of mass percentage:

[0056] Except for the chemical elements in Table 1, the rest are Fe and unavoidable impurity elements, and the total content of unavoidable impurity elements is not more than 0.5%, among unavoidable impurities: S: ≤0.01%, P ≤0.01%, N+O+H ≤80ppm.

[0057] The production method of corrosion-resistant steel for oil well in the present embodiment comprises the following steps:

[0058] S1: the step of electric furnace smelting, adding steel scrap and / or pig iron into the electric furnace for smelting, smelting until the carbon content is lower than 0.3%, and the phosphorus content is lower than 0.01%, and the steel is tapped;

[0059] S2: the step of tapping, adding Si and Mn alloy elements for deoxidation during tapping, and adding carbon powder and slagging agent;

[0060] S3: the step of refining ...

Embodiment 2

[0066] This embodiment provides a corrosion-resistant steel for oil wells, which has the chemical composition as shown in Example 2 in Table 1 in terms of mass percentage:

[0067] Except for the chemical elements in Table 1, the rest are Fe and unavoidable impurity elements, and the total content of unavoidable impurity elements is not more than 0.5%, among unavoidable impurities: S: ≤0.01%, P ≤0.01%, N+O+H ≤80ppm.

[0068] The production method of corrosion-resistant steel for oil wells of the present embodiment comprises the following steps:

[0069] S1: the step of electric furnace smelting, adding steel scrap and / or pig iron into the electric furnace for smelting, smelting until the carbon content is lower than 0.3%, and the phosphorus content is lower than 0.01%, and the steel is tapped;

[0070] S2: the step of tapping, adding Si and Mn alloy elements for deoxidation during tapping, and adding carbon powder and slagging agent;

[0071] S3: the step of refining outside...

Embodiment 3

[0077] This embodiment provides a kind of corrosion-resistant steel for oil wells, which has the chemical composition as shown in Example 3 in Table 1 in terms of mass percentage:

[0078] Except for the chemical elements in Table 1, the rest are Fe and unavoidable impurity elements, and the total content of unavoidable impurity elements is not more than 0.5%, among unavoidable impurities: S: ≤0.01%, P ≤0.01%, N+O+H ≤80ppm.

[0079] The production method of corrosion-resistant steel for oil wells of the present embodiment comprises the following steps:

[0080] S1: the step of electric furnace smelting, adding steel scrap and / or pig iron into the electric furnace for smelting, smelting until the carbon content is lower than 0.3%, and the phosphorus content is lower than 0.01%, and the steel is tapped;

[0081] S2: the step of tapping, adding Si and Mn alloy elements for deoxidation during tapping, and adding carbon powder and slagging agent;

[0082] S3: the step of refining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com