A kind of quenching method for 20crnimo material drill bit

A technology for drill bits and workpieces, which is applied in the field of quenching for 20CrNiMo material drill bits, can solve problems affecting work efficiency, short service life, and increase production costs, and achieve the goals of reducing production costs, refining metallographic structure, and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

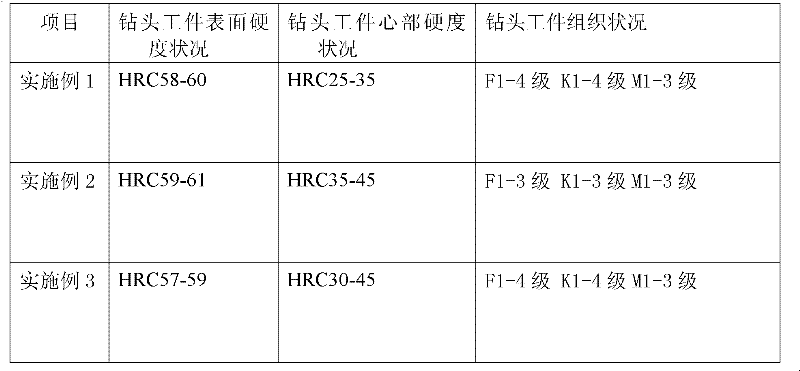

Examples

Embodiment 1

[0026] A kind of quenching method that is used for 20CrNiMo material drill bit, its step:

[0027] Do the first quench:

[0028] 1) The 20CrNiMo material drill bit workpiece is heated after carburizing, and the heating temperature is controlled at 868°C;

[0029] 2) heat preservation at 868°C for 1.5 hours;

[0030] 3) Take it out of the furnace and cool it with oil for the first time, and cool the surface temperature of the 20CrNiMo material drill bit workpiece to 100-110°C;

[0031] 4) Clean the 20CrNiMo material drill workpiece with 60°C water;

[0032] 5) Perform the first tempering, and the tempering temperature is controlled at 595°C;

[0033] 6) heat preservation at 595°C for 3 hours;

[0034] 7) Carry out natural temperature drop: 20CrNiMo material drill workpiece with natural temperature drop to 490 ~ 495 ℃ with the heating furnace;

[0035] 8) Take it out of the oven and air cool to room temperature;

[0036] Perform a second quench:

[0037] 9) The 20CrNiMo m...

Embodiment 2

[0044] A kind of quenching method that is used for 20CrNiMo material drill bit, its step:

[0045] Do the first quench:

[0046] 1) The 20CrNiMo material drill bit workpiece is heated after carburizing, and the heating temperature is controlled at 870°C;

[0047] 2) heat preservation at 870°C for 1.5 hours;

[0048] 3) Out of the furnace and oil-cooled for the first time, the surface temperature of the 20CrNiMo material drill bit workpiece is cooled to 150-165 °C;

[0049] 4) Clean the 20CrNiMo drill bit workpiece with 70°C water;

[0050] 5) Perform the first tempering, and the tempering temperature is controlled at 600°C;

[0051] 6) heat preservation at 600°C for 3.5 hours;

[0052] 7) Carry out natural temperature drop: 20CrNiMo material drill workpiece with natural temperature drop to 495 ~ 500 ℃ with the heating furnace;

[0053] 8) Take it out of the oven and air cool to room temperature;

[0054] Perform a second quench:

[0055] 9) The 20CrNiMo material drill b...

Embodiment 3

[0062] A kind of quenching method that is used for 20CrNiMo material drill bit, its step:

[0063] Do the first quench:

[0064] 1) The 20CrNiMo material drill bit workpiece is heated after carburizing, and the heating temperature is controlled at 872°C;

[0065] 2) heat preservation at 872°C for 1 hour and 45 minutes;

[0066] 3) Take it out of the furnace and cool it with oil for the first time, and cool the surface temperature of the 20CrNiMo material drill bit workpiece to 185-200°C;

[0067] 4) Clean the 20CrNiMo material drill workpiece with 75°C water;

[0068] 5) Perform the first tempering, and the tempering temperature is controlled at 605°C;

[0069] 6) heat preservation at 600°C for 4 hours;

[0070] 7) Carry out natural temperature drop: 20CrNiMo material drill workpiece with natural temperature drop to 505 ~ 510 ℃ with the heating furnace;

[0071] 8) Take it out of the oven and air cool to room temperature;

[0072] Perform a second quench:

[0073] 9) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com